Professional Documents

Culture Documents

Ieee 11MS09 HR

Uploaded by

visaguyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ieee 11MS09 HR

Uploaded by

visaguyCopyright:

Available Formats

4th National conference on Integrated Engineering in Automobiles NCIEA 13,May 25 2013,PSG College of Technology, Coimbatore -641 004

Heartbeat Monitoring System using Driver Seat Belt

Velumurugan.M1, Ganesh Kumar.N2

1

M.E Automotive Engineering, Department of Automobile Engineering, PSG College of Technology 2 Assistant Professor, Department of Automobile Engineering, PSG College of Technology

Abstract Modern automobiles are integrated with medical systems in order to improve the drivers safety. Recent data depicts that there are many accidents occurred due to drivers health condition and fatigue. The Monitoring of drivers health conditions includes factors such as heart rate and respiration system which in turn determines vehicle handling, park assist, air bag deployment, location of occupants, etc. The research work implement sensor and control systems integrated with communication device by attaching an EPIC sensor to the driver seat belt which measures the heart signal even if the occupant wear clothes. The command signal of the heart pulse rate is analyzed in the controller and thereby if any irregularities of signal it will send the communication signal to GSM modem which in turn sends to emergency service. . Index TermsECG, EPIC, Capacitive, Heart rate, GSM

signal could be sent to a medical expert. In further scenarios, additional sensors could be added to gain a more complete information about the mental and health status of the driver. For example, a camera for the detection of eye blinking together with the ECG might allow to advice a rest period to the driver. An optical sensor integrated into the steering wheel would allow to acquire a pulse signal and thus, provides a more robust estimation of the heart rate by using redundancy. In future scenarios, the car might even perform a controlled and safe emergency brake in case of a heart attack.

II. METHODOLOGY Electrometer manages to combine robustness with sensitivity, enabling a range of medical and other applications. Traditionally the interaction of solid-state devices with the electromagnetic spectrum has concentrated on detecting perturbations in the magnetic field. Hall Effect sensors, for example, provide reliable detection in a variety of either analog or digital (Schmitt-triggered) applications. In our everyday lives we rely on information encoded into the magnetic flux density field (the B field) to carry data to our digital telephones and TV systems. While Maxwell's equations tell us that whenever a magnetic field induced then a corresponding electric field is present, detection and study of this component has been largely ignored. Electrometers measure the electric charge or electrical potential difference through voltmeters with extremely high input impedance such that the current flowing into the device can be considered to be zero [9]. Until recently, electrometers have been notoriously inaccurate and have often used delicate components that were sensitive to mechanical shock and thus easily damaged. The EPIC sensor described in this paper is an extremely robust solidstate electrometer with such a high input impedance that it is close to being a perfect voltmeter. A. Electric potential integrated circuit EPIC is a noncontact electrometer, meaning that there is no direct DC path from the outside world to the sensor input, a condition that is somewhat analogous to the gate electrode of an MOS transistor.

I. INTRODUCTION Demographic changes and the increasing number of elderly drivers medical-assistance systems in the automotive environment are inevitable. The German research projects INSITEX [1] and Smart Senior investigate autonomous medical assistance systems in the car [2]. An important feature of any medical-assistance system is the reliable measurement of vital signals. One method to detect one of the most important vital signs, i.e., the ECG and secondary parameters, such as heart rate, heart-rate variability, and arrhythmias, is capacitive ECG [3]. This technology allows unobtrusive measurement of the ECG through the clothing without prior preparation and has been implemented into an automotive environment by several groups [4]. However, during driving, the relative movements occurring between the seat and the driver cause a change in the capacitive coupling and introduce severe artifacts [5]. These artifacts are associated with the turboelectric effects between electrode and body surface and are difficult to compensate due to their random nature [6]. However, during normal driving, there are many periods in which no motion occurs. Moreover, because the driver is probably not severely ill, there is no need for a perfect signal at every second as is needed, e.g., during intensive care. On the other hand, if intervals of QRS complexes are detected, this signal needs to be highly reliable to provide relevant health status information. As a first step, the ECG could be used for stress monitoring, or in the case of abnormal patterns, as during arrhythmias, the

4th National conference on Integrated Engineering in Automobiles NCIEA 13,May 25 2013,PSG College of Technology, Coimbatore -641 004

layout or substrate issues. The capacitor Cext models the capacitive coupling to the measurement target. For close coupling (Cext>> Cin) this is usually defined by

For loose coupling (Cext<< Cin) we have the limiting case (self-capacitance) defined by

The corner frequency(Fc1) can be expressed by Fig 1. Block diagram of EPIC sensor By applying the bootstrapping techniques mentioned earlier, we can control the values for Cin and Rin to give effective values, allowing us to control both the gain plateau and the corner frequency (Fc1 moves to Fc2). The response of the sensor can be further controlled by the design of subsequent stages and positive feedback loops. B. Driven right leg system Signals measured on the human body always include a large amount of noise, the major component of this being 50 or 60 Hz power line noise capacitively-coupled to the body from the surrounding electricity supply. Measurements such as ECG depend on being able to extract the small electrophysiological signals from the much larger noise signals. EPIC sensors can be used in contact mode for ECG measurement, where the subject touches both the capacitive electrode surface and metal at the system ground directly with the skin.

The device is AC coupled with a lower corner frequency (dB) of a few tens of MHz and an upper corner frequency above 200 MHz. This response is adjustable and can be tailored to suit a particular application. Such an electrometer cannot be DC coupled because the Earth's electric field close to the surface is ~100150 V/m. In single-ended mode the device can be used to read electric potential; used in differential mode it can measure the local electric field; or it can be deployed in arrays to provide spatial potential mapping (locating a conducting or dielectric material placed within free space). The input resistance to the device can be boosted by using bootstrapping techniques while the input capacitance can be reduced using guarding techniques. The input capacitance can be driven as low as 1017 F with the input resistance being boosted to values up to around 1015 , thus keeping the interaction with the target field to an absolute minimum and ensuring that all currents are small displacement currents only.

Fig.2. The Input stage of EPIC Sensor A better understanding of the feedback mechanisms can be obtained by considering the input buffer of the amplifier and its associated impedances as shown in Fig 2. The resistors RG1 and RG2 are used to set the gain of the first stage, which is nominally unity. Cin and Rin represent the input capacitance and resistance native to the amplifier, respectively, and include any parasitic components due to

Fig 3. Driven right leg circuit This ground reference allows filtering and differential amplification of signals from two sensors to be effective in removing the mains frequency noise, leaving a high quality

4th National conference on Integrated Engineering in Automobiles NCIEA 13,May 25 2013,PSG College of Technology, Coimbatore -641 004

ECG signal. In non-contact ECG measurement there is by definition no skin contact, and thus no direct connection can be made between the subjects body and the system ground. Some other method of reducing the power line noise is therefore required to enable the ECG signal to be extracted reliably and accurately. One such method utilizes an approach very similar to the Driven Right Leg (DRL) system that is used for the same purpose in conventional ECG measurement techniques. In conventional ECG the DRL signal is coupled directly to the patients skin. The DRL signal reduces power line noise on the sensor signals by feeding back an inverted average of the signals from two sensors on to the patients body. In noncontact ECG, the generated DRL signal can be capacitivelycoupled to the body through clothing, via a piece of conductive material placed at seat bottom. The DRL circuit improves the sensor signal/noise ratio enormously. The generated DRL signal is connected to a piece of conductive material placed either on the seat or at the bottom of the seat back, contacting the subjects clothing in the normal sitting position. Copper-coated nylon fabric is one possible material suitable for the DRL coupling material, but other conductive materials may be equally successful. A thin, non-conductive material such as a cotton fabric may be used to cover both the sensors and the DRL coupling fabric if required, for instance when building the sensors into a seat. Consideration must be give as to how material will reduce the coupling capacitance between the sensor and the subject, or add additional noise to the signals through static charging effects. A DRL requires feeding back the noise signal to the subjects body in antiphase, which works as a noise cancellation technique. This system uses a conductive fabric around the steering wheel and on the driver seat, with the feedback signal connected to it and thus capacitively coupled back to the driver. This results in an increased dynamic range, which helps both in reduction of the movement artifact and stops the sensors from saturating. It is a standard summing amplifier, generating an amplified and inverted signal that is the average of the individual signals A and B. The operational amplifier output is expressed by

Fig 4. Block diagram of heart beat monitoring system.

III. EXPERIMENTAL SETUP In this methodology, two ultrahigh input impedance epic sensors are used to measure the heart rate. This epic sensors are placed in the seat belt separated by 6-10 inches. The signal retrieved from the electrode are weak and noisy. To eliminate this drawbacks, an differential amplifier and DRL circuit is implemented. The desired ECG signal is analyzed using pic16f877a microcontroller were it measures the interval between an R wave and the next R wave. If there is any irregular heart rate is detected, the pic16f877a send AT command to GSM modem to send message to the appropriate emergency service.

The optimum value for Rf will be dependent on the type of sensors being used, as well as the clothing being worn by the subject being measured, as well as the background noise levels. Rf should be set to achieve maximum noise reduction, while ensuring circuit stability and is thus best implemented as a potentiometer. Rp, the protection resistor, is included to limit the current that can be fed back to the human body. Fig 5. Experimental setup with seat belt sensors

4th National conference on Integrated Engineering in Automobiles NCIEA 13,May 25 2013,PSG College of Technology, Coimbatore -641 004

A .Coding for heart rate Coding is developed based on ecg signal amplitude and R-R interval time. The analog signal of ecg signal is converted into digital pulse. The interrupt time between two pulses is calculated in ms. Based on timer count, interrupt is enabled for every 10ms. The main coding for heart rate is mentioned below. void main() { OPTION_REG = 0x84; ADCON0=0X81; // Pins AN1 is configured as analog TRISA = 0xFF; // All port A pins are configured as inputs ADCON1=0X00; TRISD = 0; // All port D pins are configured as outputs PORTD = 0x00; // Reset port D UART1_Init(9600); delay_ms(100); while(1) { inputsignal = ADC_Read(1); if (inputsignal>=64) { delay_ms(50); if (firstRun==1) { firstRun = 0; cnt = 0; // Variable cnt is assigned a 0 TMR0 = 194; // Timer T0 counts from 194 to 255 INTCON = 0xA0; // Enable interrupt TMR0 } else { HR=60000/cnt; outlcd=HR/1000 ; outlcd=(HR/1000)%10;//tens digit in HR outlcd=(HR)%10 ;//ones digit in HR Lcd_out(2,5,"puls/min.") cnt = 0; TMR0 = 194; // Timer T0 counts from 194 to 255 INTCON = 0xA0; // Enable interrupt TMR0 } } } The above coding is developed using MPLAB software and burned into PIC16F877a using pickit 2 device. C. Validation for measured heart rate The measured HR values is validated using heart rate device. The values taken from normal heart rate device are compared with measured values of epic sensor. measurements 1 2 Normal heart rate 71 65 Epic sensor heart rate 70 64

IV. RESULTS AND DISCUSSIONS A. Voltage sensitivity of cloth thickness For various cloth thickness the voltage level of sensor is measured and graph is plotted. Thickness (mm) 0.18 0.244 0.25 0.27 0.37 0.455 0.62 Voltage (v) 2.68 2.68 2.68 2.67 2.66 2.66 2.66

Table 1. Thickness vs Voltage Sensitivity

Fig 6. Voltage sensitivity of Cloth Thickness Voltage sensitivity readings are taken with different cloth thickness at nominal room temperature. Using multimeter device, the voltage values are taken and graph is plotted between voltage and cloth thickness which shown above fig 6. B. Heart rate variability analysis High and low pass filter frequencies of 8 and 25Hz remove breathing artifacts and are ideal for showing the R-R cardiac cycle interval. Good results can be obtained with one or two layers of cotton material between the sensors and the skin. Other materials, including a wool-mix sweater and a polyester fleece in addition to two layers of cotton material have been successful. If the key greatest interest is in the R-R interval, adjusting filter settings to reduce or re-center the signal bandwidth can give improved signal quality. ECG waveform R-R interval are shown in fig 7. R wave Maximum voltage = 0.05*2.5 = 0.12V R-R time interval = 10ms

4th National conference on Integrated Engineering in Automobiles NCIEA 13,May 25 2013,PSG College of Technology, Coimbatore -641 004

ECG signals measured from a subject wearing a polyester cotton shirt. Sensors attached to the belt were covered with an additional layer of cotton material. Filter settings limit the bandwidth to 16-40Hz. The heart rate can be easily extracted.

Fig 7. ECG waveform R-R interval

Fig 10. Bandwidth limit between 16-40Hz

Fig 8. Non-contact ECG signals measured through a single layer of cotton clothing (0.25mm), with a capacitive coupled DRL circuit. Software filters limit the bandwidth to 8-25Hz.

Fig11.Heart Rate Histogram for bandwidth 16-40Hz For various high pass and low pass filter frequency heart rate Histogram is plotted shown above fig .9. and fig .11.using bandpass filter and rectification noisy is greatly reduced in ECG signal. V. CONCLUSION Heart rate value is attained using heartbeat monitoring system without touching the skin surface of driver. The measured heart rate is transmitted through GSM modem incase of cardiac arrest. The following analysis has been tested in different cloth thickness with altered cutoff frequency of high pass and low pass filters. Using heart

Fig 9. Heart rate Histogram for bandwidth 8-25Hz.

4th National conference on Integrated Engineering in Automobiles NCIEA 13,May 25 2013,PSG College of Technology, Coimbatore -641 004

rate variability analysis the ecg signal is generated by values of R-R waveform and the noise signal present in the waveform is eliminated by bandpass filter and rectification. Still this system can be improved by implementing wireless technology to measure the heart rate of driver which is efficient interms of motion artifacts and noise.

REFERENCES [1] B. Chamadiya, S. Heuer, U. G. Hofmann, and M. Wagner. (2009). Towards a capacitively coupled electrocardiography system for car seat integration, in 4th European Conference of the International Federation for Medical and Biological Engineering, pp. 12171221. [2] M. Zens, M. Govercin, and E. Steinhagen-Thiessen, Gesundheitstechnikfur die alternde Bevolkerung, Bundesgesundheitsblatt Gesundheitsforschung Gesundheitsschutz, vol. 53, no. 5, pp. 474478, 2010. [3] S. Heuer, D. Martinez, S. Fuhrhop, and J. Ottenbacher. (2009). Motion artifact correction for capacitive ECG measurement, in Proc. IEEE Biomed. Circuits Syst. Conf., pp. 113116. [4] Y.M. Chi, T.-P. Jung, and G. Cauwenberghs, Drycontact and noncontact biopotential electrodes: Methodological review, IEEE Rev. Biomed. Eng., vol. 3, pp. 106119, Oct. 2010. [5] T. Matsuda and M. Makikawa. (2008). ECG monitoring of a car driver using capacitively-coupled electrodes, in Proc. IEEE 30th Ann. Int. Conf. Eng. Med. Biol. Soc., pp. 13151318. [6] J. Ottenbacher and S. Heuer, Motion artefact s in capacitively coupled ECG electrodes, in IFMBE Proceedings World Congress on Medical Physics and Biomedical Engineering, vol. 25/4, 2010, pp. 10591062. [7] Tobias Wartzek, Benjamin Eilebrecht, Jeroen Lem, Hans-Joachim Lindner, Steffen Leonhardt,ECG on tpositionhe Road: Robust and Unobtrusive Estimation of Heart Rate IEEE Transactions On Biomedical Engineering, Vol. 58, No. 11, November 2011 [8] Akinori Uneo, Yasunao Akabane, Tsuyoshi Kato, Hiroshi Hoshino, Sachiyo Kataoka, And Yoji Ishiyaam, Capactive sensing of electrocardiographic potential through cloth from the Dorsal surface of the body in a suspine position: A preliminary study IEEE Transactions On Biomedical Engineering, Vol. 54, No. 4, April 2007. [9] http://en.wikipedia.org/wiki/Electrometer.

You might also like

- Non Operative MachinesDocument1 pageNon Operative MachinesvisaguyNo ratings yet

- Personal Budgeting Trend For A PersonDocument2 pagesPersonal Budgeting Trend For A PersonNufita Twandita DewiNo ratings yet

- Holiday Budget PlannerDocument2 pagesHoliday Budget PlannervisaguyNo ratings yet

- Instruction Book FXe1-5 enDocument32 pagesInstruction Book FXe1-5 envisaguyNo ratings yet

- Daily Self-Evaluation - Monthly Data: P H Y S I C A LDocument1 pageDaily Self-Evaluation - Monthly Data: P H Y S I C A LSead ZejnilovicNo ratings yet

- Control SystemsDocument1 pageControl SystemsvisaguyNo ratings yet

- Simple Gantt Chart1Document3 pagesSimple Gantt Chart1misszomby100% (1)

- Personal Budgeting Trend For A PersonDocument2 pagesPersonal Budgeting Trend For A PersonNufita Twandita DewiNo ratings yet

- Holiday Budget PlannerDocument2 pagesHoliday Budget PlannervisaguyNo ratings yet

- Process Map ExampleDocument3 pagesProcess Map ExamplevisaguyNo ratings yet

- Simple Gantt Chart1Document3 pagesSimple Gantt Chart1misszomby100% (1)

- Personal Budgeting Trend For A PersonDocument2 pagesPersonal Budgeting Trend For A PersonNufita Twandita DewiNo ratings yet

- Introduction To Programming of Embedded SystemsDocument35 pagesIntroduction To Programming of Embedded SystemsvisaguyNo ratings yet

- Intelligent Security System PDFDocument62 pagesIntelligent Security System PDFluiz augusto vieiraNo ratings yet

- Power Electronics LectureDocument84 pagesPower Electronics LecturevisaguyNo ratings yet

- ps25251 DatasheetDocument6 pagesps25251 DatasheetvisaguyNo ratings yet

- Velocity of Sound On Kundts TubeDocument7 pagesVelocity of Sound On Kundts Tubevisaguy100% (1)

- Automotive Embedded Systems PDFDocument46 pagesAutomotive Embedded Systems PDFYellaturi Siva Kishore ReddyNo ratings yet

- Power Spectral Density CodeDocument4 pagesPower Spectral Density CodevisaguyNo ratings yet

- Making Sentences - EnglishDocument10 pagesMaking Sentences - Englishrjumaat100% (2)

- Acoustic ImpedanceDocument4 pagesAcoustic ImpedancevisaguyNo ratings yet

- AVR194 Brushless DC Motor Control Using ATMega32M1Document16 pagesAVR194 Brushless DC Motor Control Using ATMega32M1u776287No ratings yet

- At CommandDocument9 pagesAt CommandvisaguyNo ratings yet

- IBPS Clerk Vacancies by State: SC, ST, OBC, UR, Others - Total 39690Document1 pageIBPS Clerk Vacancies by State: SC, ST, OBC, UR, Others - Total 39690visaguyNo ratings yet

- Term Paper Bachelor IT 16s.unlockedDocument11 pagesTerm Paper Bachelor IT 16s.unlockedvisaguyNo ratings yet

- Finite Element Analysis of Deep DrawingDocument4 pagesFinite Element Analysis of Deep DrawingTamer HagasNo ratings yet

- Payment Instruments in India: Currency, Cheques, DraftsDocument5 pagesPayment Instruments in India: Currency, Cheques, DraftssciencenokiaNo ratings yet

- DC MotorDocument47 pagesDC MotorArun SaraswathyNo ratings yet

- Alernate FuelsDocument4 pagesAlernate FuelsvisaguyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Electric Machines ELCT 708 Assignment: 1Document19 pagesElectric Machines ELCT 708 Assignment: 1AhmedYehiaZakariaNo ratings yet

- Electro-Pneumatic Regulator Electronic Vacuum RegulatorDocument52 pagesElectro-Pneumatic Regulator Electronic Vacuum RegulatorRaquel AlexandreNo ratings yet

- Lectures 16 To 18 - Op-AmpDocument19 pagesLectures 16 To 18 - Op-AmpAniketsingh MundlothNo ratings yet

- EC-6401 2 mark questionsDocument20 pagesEC-6401 2 mark questionsseenusoftNo ratings yet

- Assignment TX LineDocument3 pagesAssignment TX LineMynam Meghana0% (1)

- Design and Experiments of A High Conversion Efficiency Recgenna at 5.8 GHZDocument8 pagesDesign and Experiments of A High Conversion Efficiency Recgenna at 5.8 GHZaqib qayyumNo ratings yet

- HMC 960Document20 pagesHMC 960Kenan TiroNo ratings yet

- Kamran J16Document12 pagesKamran J16Nithya VelamNo ratings yet

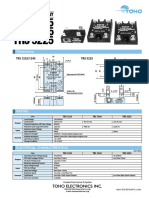

- Solid State Relay Guide with Technical Specs and Load Current DataDocument2 pagesSolid State Relay Guide with Technical Specs and Load Current DataserpilNo ratings yet

- Expt1 CE AmplifierDocument5 pagesExpt1 CE AmplifierkeshavNo ratings yet

- Cat4-1 enDocument256 pagesCat4-1 enalltheloveintheworldNo ratings yet

- Electronics Devices and CircuitsDocument38 pagesElectronics Devices and Circuitsvaishnavi khilari100% (1)

- EM Waves and Guide Structure Chapter 3 & 4 worksheet solutionsDocument5 pagesEM Waves and Guide Structure Chapter 3 & 4 worksheet solutionsAbrham GojjamNo ratings yet

- Delta Wye ReportDocument5 pagesDelta Wye ReportAhmad Hariez FuzeinNo ratings yet

- Honeywell UDC 2000Document12 pagesHoneywell UDC 2000Emil Ghiorghiu50% (2)

- Stub MatchingDocument10 pagesStub MatchingEnos Marcos BastosNo ratings yet

- POWER LAB Manual PDFDocument82 pagesPOWER LAB Manual PDFHamda KhalilNo ratings yet

- TDA7449 Datasheet PDFDocument17 pagesTDA7449 Datasheet PDFlaurentina52No ratings yet

- Test Bench for Differential CircuitsDocument6 pagesTest Bench for Differential CircuitsHoang NguyenNo ratings yet

- CN-6000 SERIES: Isolated Converter Part Descriptions Input Type Selection SwitchDocument2 pagesCN-6000 SERIES: Isolated Converter Part Descriptions Input Type Selection Switchlogr1992No ratings yet

- Zen ManualDocument33 pagesZen Manualsingulares2199No ratings yet

- Amplificador 1 THD stk4432Document7 pagesAmplificador 1 THD stk4432Juan Moya BlasNo ratings yet

- DS - TQ902 - TQ912 - EA902 - IQS900-en 01.2022Document21 pagesDS - TQ902 - TQ912 - EA902 - IQS900-en 01.2022Lãng DuNo ratings yet

- ML50 Spec TechDocument29 pagesML50 Spec TechmfresiaNo ratings yet

- AnalogDocument33 pagesAnalogAmit UpadhyayNo ratings yet

- GS Ys1500Document20 pagesGS Ys1500Esen HawerNo ratings yet

- A Tuned Rectifier For RF Energy Harvesting From Ambient RadiationsDocument6 pagesA Tuned Rectifier For RF Energy Harvesting From Ambient RadiationsAppu ManiNo ratings yet

- AN11062 - Broadband DVB-T UHF Power Amplifier With The BLF888ADocument20 pagesAN11062 - Broadband DVB-T UHF Power Amplifier With The BLF888AerdemsecenNo ratings yet

- RF Power AmplifiersDocument18 pagesRF Power Amplifiersghfj08100% (1)

- Bai Tap Chuong 1 - Tieng Anh - 89 BaiDocument7 pagesBai Tap Chuong 1 - Tieng Anh - 89 BaiNgọcÁnhĐặngNo ratings yet