Professional Documents

Culture Documents

Wet Area Panelling

Uploaded by

Kc TanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wet Area Panelling

Uploaded by

Kc TanCopyright:

Available Formats

(

t

Linear Series

Linear Series

GUNNERSEN

Ll

GUNNERSEN PTY LTD ABN35004051

ooo

ADELAIDE (08) 8359 1660 BRISBANE (07) 3722 3500 CAIRNS (07) 4035 3955 M ELBOURNE (03) 9647 9911 PERTH (08) 9356 9911 SYDNEY (02) 9757 6999 TOWNSVILLE (07) 4779 0877

www.gunnersens.com.au

RONGNN01 73

LINEAR SERIES WET AREA PANELLING

Add a touch of class to your home or workplace with the Linear Series, WallArt's line of wet area panelling. With a striking range of colours and patterns to choose from, you're sure to create a space that's not only functional, but stylish, too.

WATER RESISTANT The Linear Series is perfect for any indoor space that collects mo isture , including the bathroom, ki tchen . laundry and showe r recess. DURABLE Made from

Thickness: 3 .0mm !tolerance 0.2mml Finis h: Gloss Density: 1450 kg/m 3 We ight: 4.35 kg/m 2 Product tested and approved to international s tandard

IS O 4586 for highVersuvio ITile) 2400m m x 1200mm Travertina llile) 2400mm x 1200mm Latte 2400mm x 1200mm

Rossano Sand

SHEET COLOURS

Snow White 2400m m x 1200mm 1800mm x 900mm

Milano IT ilel 2400mm x 1200mm

Carrara Ice

2400mm x 1200mm

Designer White (Tile I 2400m m x 1200mm

Silver Haze (Tile I 2400mm x 1200mm

2400m m x 1200mm

Silve r Oak 2400 mm x 1200mm

high-pressure laminate it can w ith sta nd impact far greater than ce ramic tiles. and will not di scolo ur or fade. Being non-poro_u s allows it to perform even in humid condition s l ike shower recesses . HYGIENIC The Lin ear Se ries wi ll not attract mou ld beca use it is grout-free. Th is also makes cleaning a breeze- simply wipe w ith a damp cloth and non-abrasive cleanse r. STYLISH Th e Linear Series offers you a range of attractive styles. from classic monochromes to contempo rary pattern s. Its strea m l ined fini sh makes it a versa tile alternative to co nventi onal tiles. SIMPLE TO INSTALL Our easy-to-follow in stallation guide enables you to give your space a professional look at just a fract ion of the cost, without the need for backing materials. JOINERS

Snow White

Copp er Glaze ITile) 2400mm x 1200mm

Zebra Wood 24 00mm x 1200mm

Roman Marble ITilel 2400 mm x 1200mm

JOINER COLOURS

Carra ra Ice

Travertina

Brushed Aluminium (PVC I

pressure laminate.

The Linear Series. Streamlined style.

~~~e::~

lnl c rnal Corner

Sheet Joiner

External Corne r

Top/End Cap

Bath Mould

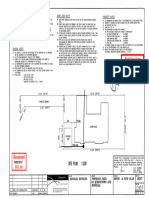

INSTALLATION GUIDE

INSTALLATION GUIDE

Safety First When working in areas that generate dust it is advisable that you wear protective goggles. a dust mask and wor k gloves. Storage and work areas should be well ventilated. Conditioning It is importa nt t hat you condit ion your panels by placing them in the room where they w ill be installed. Leave a space between sheets to allow for air circulation. For rooms above ground level, allow panels to condition for 24 hours. For rooms below ground level, allow for 48 hours. Handling To avoid scratch ing the surface of you r pa nels, ensure that t he work area remains clean. avoid contact between the panel and abrasive surfaces and take care when moving the pa nel to avoid chi pping any edges. Planning and Preparation Calculate the number of panels req uired to complete your project and gather the necessary toots and mater ials from the following list: Tape measure Spirit level Pencil Carpenter's square Fine tooth handsaw or fine tipped tu ngsten machine saw Fine tooth hacksaw Hand plane Sandpaper Timber battens Electric dri ll & hole cutt ing bit Nails Hammer Staple gun Caulking gun Adhesive (we recommend a synthetic rubber based adhesive like Bostik Wallboard Adhesive or Selleys Pro Series Adhesive. Rigid or semi-rigid adhesive is not recommended] Sealant (we recommend Selley's All Clear or Selley's Bat hroom & Kitchen Sealant ) Caulking compound (we recommend Selley's Bath room & Kitchen Silicone) Wood block I cloth Mineral spirits Colour- matched joiners to join panels and fin ish off installation

Silicone Joins WallART Linear can be installed using a butt join system rather t han the matching joining st rips. If you choose to do this, apply bond breaker tape to t he timber frame at the centre of the join before fixing the sheet to the wall. Leave a 3mm gap between the sheets using an off cut as a spacer. Run masking tape down the sides of each j oin and fill w ith a matching bathroom silicone. Trowel off any surplus and remove masking tape. Wipe off any excess silicone on the su r faces using a damp clot h or mineral turpentine. Installation on Plaste rboard and Cement Sheets WallART Li near can be fi tted to walls that are already lined with a flat sheet. such as plasterboard and cement sheeting. Plasterboard sheeting can only be used in tow humidity applicat ions. In wet areas, cement sheeting such as Hardie's Vi llaboard is required. Watts subj ect to possi ble dampness or high m oisture pick- up should not have WallART Linear fi xed direct. but installed to dressed t imber frame, or the wa ll surface must be waterproofed with an impermeable coating. Installation requi res the followin g: All su r faces must be clean and free of grease, oil, dust and paint. Walls must be completely dry. Walls must be flat and square. Use profiles in t hese applications. Use a 5mm bead of ad hesive around t he edge of t he sheet. Use a zig zag pattern of 5mm bead of ad hesive making sure that the bead is w ithin 15- 20mm of t he sheet edge. Press the sheet against the wall to transfer t he ad hesive to the watt. Remove t he sheet and hold away from the wall to allow ad hesive to become tacky. This witt take approximately 5- 15 minu tes depending on climat ic conditions. Once tacky, press t he sheet back against the watt and continue as before. Care and Maintena nce To maintain i ts original luster, your panels should be cleaned with a mi ld liquid non- abrasive cleanser. Avoid using abrasive powder cleansers.

f

f.

1 We recommend that panels be fixed to a framework of timber battens 50mm x 25mm in size with a maximum spacing of 450mm between the vertical and horizontal battens. Panels should not be fi xed directly to plasterboard walls. Ensure t he lowest point of the frame is at least 25mm above the floor or shower base. Where two panels are joined together, place a timber batten behind the join and ensu re the timber framework provides a flat surface.

2 When cutting straight lines use a fine tooth handsaw and always cut with the panel face up. If using a fine tipped tungsten machine saw ensure the panel is face down. Sand or hand plane cut edges to achieve a smooth finish. Use a fine toothed hacksaw to cut your colour matched joiners to size.

} )

3 When cutting holes for taps, shower

fi tting and pipes measure and mark the outline of the area on the face of the panel, then drill and cut with the face up. For holes 20m m or larger in diameter, a 2mm allowance for expansion should be made. These expansion gaps should later be sealed with silicone. Do not cut square corners in your panel. Drill holes on the inside of each corner you have marked and cut along your outlined area up to each drill hole. Lightly sand the inside edges of your cutout area to remove any burrs.

4 Begin in one corner by nailing or

stapling an internal corner joiner to the timber frame.

INSTALLATION GUIDE

INSTALLATION GUIDE

5 Apply a 5mm bead of adhesive to the

face of each timber batten that the first panel will be applied to.

6 Rub the back of each panel with coar se sandpaper in the areas that will make contact with the adhesive. Work w ith one sheet at a time, applying adhesive and installing . Position the panel carefully and press firmly to make contact with adhesive. Remove the panel until the adhesive becomes touch dry !approximately 5 to 10 minutes! and fo l low the adhesive manufacturer's instructions.

9 Use a wood block wrapped in a soft cloth to work acro ss the surface of each panel , tapping the block gently with a hammer to ensure the adhesive on all battens makes contact w ith the panel, particularly around the edges.

10 Allow for a 3mm expansion ga p on each side of the next joi ner a nd nail or

staple the JOiner to the frame .

7 Place a bead of silicone sealant along the inside of each joiner !internal corner , sheet joiner, etc. I to create a 3mm expansion gap.

8 Slide the panel into the joiner and position the panel carefully. Fix the next joiner to the free edge of the panel and press the sheet into its final position .

11 Continue this process to fix panels around each wall and seal gaps at the base of each panel using silicone sea lant.

12 Upper and lower edges may also be fin ished using end caps. Should this joiner be used, ensure all lengths of verti cal sheet joiner finish 11 mm short of edges. A bath mould is recommended for the lower edge of panels butting against a bath rim.

*Impor tant : Some sheets have a protective film on both sides. Th is must be removed before installa tion

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Vessel Generated WavesDocument92 pagesVessel Generated WavesKc TanNo ratings yet

- 7.000 X 2.875 HD RETRIEVABLE PACKER (17-26) (26-32) 613-7000-004 Rev DDocument5 pages7.000 X 2.875 HD RETRIEVABLE PACKER (17-26) (26-32) 613-7000-004 Rev DAlejandroMoscosoNo ratings yet

- PIANC Guidelines For The Design of Fender Systems PDFDocument71 pagesPIANC Guidelines For The Design of Fender Systems PDFKc Tan100% (1)

- Osborn Roller CatalogueDocument48 pagesOsborn Roller CatalogueOsborn RollermanNo ratings yet

- 01-Catalyst FundamentalsDocument12 pages01-Catalyst FundamentalsPrateek SoniNo ratings yet

- Typical Grade of Cellulose EthersDocument25 pagesTypical Grade of Cellulose EthersDang Chi Cong0% (1)

- RFI 004 - Extension of Lane ClosureDocument2 pagesRFI 004 - Extension of Lane ClosureKc TanNo ratings yet

- RFI 002 - Drainage Specific Drawings and SpecificationDocument5 pagesRFI 002 - Drainage Specific Drawings and SpecificationKc TanNo ratings yet

- Approved PlansDocument2 pagesApproved PlansKc TanNo ratings yet

- RFI 005 - Lane Closure RelaxationDocument2 pagesRFI 005 - Lane Closure RelaxationKc TanNo ratings yet

- Eco 88 PDFDocument2 pagesEco 88 PDFKc TanNo ratings yet

- CTIQ Book 1 Defintions and Descriptions Sept2013Document71 pagesCTIQ Book 1 Defintions and Descriptions Sept2013Kc TanNo ratings yet

- ROC124 WinchesProductCatalogueWGD ProofDocument8 pagesROC124 WinchesProductCatalogueWGD ProofKc TanNo ratings yet

- ROBCO CatalogueDocument18 pagesROBCO CatalogueKc TanNo ratings yet

- Staticki Odredjeni Nosaci Zadaci Dio1Document25 pagesStaticki Odredjeni Nosaci Zadaci Dio1Kc TanNo ratings yet

- A Beginners Guide To Consent ConditionsDocument29 pagesA Beginners Guide To Consent ConditionsKc TanNo ratings yet

- BREMBOLT Load-Controlled AnchorDocument5 pagesBREMBOLT Load-Controlled AnchorKc TanNo ratings yet

- HumeSlab Tech ManualDocument60 pagesHumeSlab Tech ManualKc TanNo ratings yet

- Jetties Approval GuidelinesDocument13 pagesJetties Approval GuidelinesKc TanNo ratings yet

- Material Testing Manual Amdt32 Dec2010Document1,356 pagesMaterial Testing Manual Amdt32 Dec2010Kc TanNo ratings yet

- Filter ElementDocument3 pagesFilter Elementmauroman78No ratings yet

- Ciclo Di VerniciaturaDocument2 pagesCiclo Di VerniciaturaMaffone NumerounoNo ratings yet

- PWHTDocument75 pagesPWHTAhmed shabanNo ratings yet

- Fit-Up Weld MaterialsDocument42 pagesFit-Up Weld MaterialsEvan Jared L. GalvezNo ratings yet

- Lesson 1 Prepare Construction Materials and ToolsDocument38 pagesLesson 1 Prepare Construction Materials and ToolsJenneth Bondoc RapistaNo ratings yet

- DFM 2021Document42 pagesDFM 2021Damian DariusNo ratings yet

- Methacrylate Structural Adhesives: Plexus MA422 Plexus MA832Document1 pageMethacrylate Structural Adhesives: Plexus MA422 Plexus MA832johnNo ratings yet

- Filtration and Separation Technology: Lenzing AKF / KKF - Automatic Backwash FilterDocument6 pagesFiltration and Separation Technology: Lenzing AKF / KKF - Automatic Backwash FilterseinthaiserNo ratings yet

- Application Methodology - ShaliEnamelDocument5 pagesApplication Methodology - ShaliEnamelPradeep SinghNo ratings yet

- Swedish LadderDocument11 pagesSwedish Ladderrauljrz146No ratings yet

- Unit 1: Introduction:: Basic Mechanical Engineering Syllabus (ME 102)Document2 pagesUnit 1: Introduction:: Basic Mechanical Engineering Syllabus (ME 102)kargoNo ratings yet

- Daily Weld Fit-Up and Production Report (Field Weld) - Pipeline SATR-W-2007 WeldDocument87 pagesDaily Weld Fit-Up and Production Report (Field Weld) - Pipeline SATR-W-2007 WeldmmmNo ratings yet

- Additive Manufacturing Notes Unit II Solid Based RPSDocument10 pagesAdditive Manufacturing Notes Unit II Solid Based RPSVenkata Naveen MaddaliNo ratings yet

- Inch Dia Inch MeterDocument6 pagesInch Dia Inch MeterRadhakrishnan SreerekhaNo ratings yet

- Air Release ValveDocument24 pagesAir Release ValveDawet Kemayu RawalumbuNo ratings yet

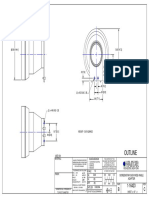

- Outline: Screenstar 0.65X Wide Angle AdapterDocument1 pageOutline: Screenstar 0.65X Wide Angle AdapterdnyaneshwaNo ratings yet

- Astm A 960 - 03 - QTK2MC0WMWDocument9 pagesAstm A 960 - 03 - QTK2MC0WMWEjat ISNo ratings yet

- Corrosion Company BrochureDocument12 pagesCorrosion Company BrochureMythri Metallizing Pvt Ltd ProjectsNo ratings yet

- Rolling Bearings in Vertical Mills Built by Gebr. Pfeiffer AG, GermanyDocument2 pagesRolling Bearings in Vertical Mills Built by Gebr. Pfeiffer AG, GermanyAnonymous H9Mu3yQNo ratings yet

- 067 735 Cylinder 1st Compression StageDocument8 pages067 735 Cylinder 1st Compression StageNitesh MakwanaNo ratings yet

- Welding Summary by Test PackageDocument11 pagesWelding Summary by Test PackageSANUNo ratings yet

- Microsoft PowerPoint - WeldingDocument42 pagesMicrosoft PowerPoint - WeldingGOBLIN XXXNo ratings yet

- 03 23814 MvolaDocument13 pages03 23814 MvolaDanem HalasNo ratings yet

- BM Full CatalogueDocument109 pagesBM Full CatalogueMiguelNo ratings yet

- EKA DLP 3D Printer BrochureDocument15 pagesEKA DLP 3D Printer BrochureRam Mohan ChalamalasettyNo ratings yet

- ElectropolishingDocument5 pagesElectropolishingCharles HangNo ratings yet