Professional Documents

Culture Documents

SKF Bearing System Design

Uploaded by

saiemCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SKF Bearing System Design

Uploaded by

saiemCopyright:

Available Formats

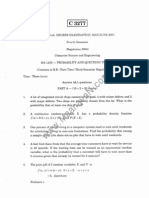

Design Engineering OEM301 Bearing System Design

Recommended for Course description

Bearing System Design uses a combination of hands-on training, directed exercises, audio visuals, lectures and discussion opportunities. Specific topics include:

Friction and speeds

Design engineers directly responsible for machine design incorporating rolling element bearings at OEM facilities or users interested in optimizing performance in existing machinery. Those interested in optimizing rolling element bearing performance in rotating equipment.

Friction model within rolling element bearings Speed rating methodologies

Bearing system design

Bearing theory

Purpose of bearings Rolling element bearing history Rolling element contact behavior

Bearing components and functions

Course objective

Students will gain an understanding of rolling element bearing, seal and lubrication technologies and theories used in selection processes for typical industrial applications, with the ultimate objective of improving the life, functionality, and operational reliability of rotating equipment.

2013 course schedule

May 79 Edmonton, AB

Rolling elements, rings and cages Component materials

Associated component design Locating and non-locating Shaft and housing fits Selection of internal clearance or preload Bearing material selection Mounting and dismounting considerations Sealing requirements Mechatronics

Selection of bearing type

Advantages and disadvantages of various bearing types Bearing features and functionality Determining loads and duty cycles Bearing life determination using: --Basic L 10 method --Adjusted life method --Optimizing bearing life with the latest life methodologies Computer-based tools (SKF.com, IEC and Bearing Select)

Bearing arrangements Lubrication

Bearing types and integration Overview of lubricants Selection of appropriate lubricant Lubricant life estimation Lubrication methods

Selection of bearing size

Machine system health

Vibration analysis Temperature monitoring Lubrication analysis

2013 tuition

Public classes On-site per class # people 6+ people $8,995 5 $395 per person $1,195

Bearing damage and causes

Bearing dimensional tolerances

Dimensional tolerance classes Internal clearances and preload classes

Analysis of common failure modes Mounting and operating conditions

Storage, shipping and handling

Prerequisites

Reading material*

EVOL01_n01_p25 The SKF Formula for Rolling Bearing Life EVOL02_n01_p21 Simulation of Dynamic Behavior of Rolling Bearings GSO4010 New Life to Machines GSO3013 (Re-)Design of Bearing Units

* On-line learning material at aptitudexchange.com

3 days

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Organization and Administration of Maintenance FunctionsDocument4 pagesOrganization and Administration of Maintenance Functionssaiem100% (1)

- Analysis of Excessive Hydrogen Generation in TransformersDocument8 pagesAnalysis of Excessive Hydrogen Generation in TransformersandikaubhNo ratings yet

- Driving BeginnersDocument40 pagesDriving BeginnerssaiemNo ratings yet

- CAM Systems & CNC Machine Overview - Lecture 3Document54 pagesCAM Systems & CNC Machine Overview - Lecture 3Rithesh Baliga BNo ratings yet

- SKF Advanced LubricationDocument1 pageSKF Advanced LubricationsaiemNo ratings yet

- Masterflow 928T PDFDocument5 pagesMasterflow 928T PDFChristian D. OrbeNo ratings yet

- Lubrication of SKF Rolling BearingDocument1 pageLubrication of SKF Rolling BearingsaiemNo ratings yet

- Product Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?Document3 pagesProduct Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?saiemNo ratings yet

- SKF Bearing Damage AnalysisDocument1 pageSKF Bearing Damage AnalysissaiemNo ratings yet

- Technical DecisionsDocument1 pageTechnical DecisionssaiemNo ratings yet

- SKF Advanced LubricationDocument1 pageSKF Advanced LubricationsaiemNo ratings yet

- SKF Reliability MainatenenceDocument1 pageSKF Reliability MainatenencesaiemNo ratings yet

- Product Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?Document3 pagesProduct Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?saiemNo ratings yet

- Automation Summer Training ReportDocument45 pagesAutomation Summer Training ReportLaxman GautamNo ratings yet

- Ch-5 Cost BehaviourDocument5 pagesCh-5 Cost BehavioursaiemNo ratings yet

- Masterflow 928T PDFDocument5 pagesMasterflow 928T PDFChristian D. OrbeNo ratings yet

- Unit 2: Vehicle Engine Principles, Operation, Service and RepairDocument12 pagesUnit 2: Vehicle Engine Principles, Operation, Service and RepairsaiemNo ratings yet

- FitsDocument1 pageFitssaiemNo ratings yet

- DSHCJDocument3 pagesDSHCJsaiem50% (2)

- Shaft TorqueDocument9 pagesShaft Torquesaiem100% (1)

- Solar Water HeaterDocument4 pagesSolar Water HeatersaiemNo ratings yet

- Micro Stepping Technical NoteDocument3 pagesMicro Stepping Technical NotesaiemNo ratings yet

- Shaft TorqueDocument9 pagesShaft Torquesaiem100% (1)

- Single SourcingDocument6 pagesSingle SourcingsaiemNo ratings yet

- PumpDocument4 pagesPumpsaiemNo ratings yet

- Basic Chemistry Review (Students)Document16 pagesBasic Chemistry Review (Students)AnilovRozovaNo ratings yet

- Recurrent Neural Network-Based Robust NonsingularDocument13 pagesRecurrent Neural Network-Based Robust NonsingularDong HoangNo ratings yet

- Eb 20 11Document408 pagesEb 20 11henryNo ratings yet

- PQT MJ07Document6 pagesPQT MJ07Raguraman BalajiNo ratings yet

- LC 72322Document13 pagesLC 72322thecanislupusNo ratings yet

- Tomescu PDFDocument353 pagesTomescu PDFLuís Farias100% (3)

- Tool Geometry and Tool LifeDocument29 pagesTool Geometry and Tool LifeSudeepHandikherkarNo ratings yet

- Welding robot aviation plug terminal definitionDocument4 pagesWelding robot aviation plug terminal definitionPhươngNguyễnNo ratings yet

- ThesisDocument32 pagesThesis783255No ratings yet

- Physico-Chemical Properties of DrugsDocument64 pagesPhysico-Chemical Properties of DrugsYap Jacky33% (6)

- Signal and Telecommunication - 1Document83 pagesSignal and Telecommunication - 1srinathNo ratings yet

- TheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Document60 pagesTheAndTecOfRocExcForCivEng Páginas 283 285,294 302,319 329,449 485Omar George Cayllahua SaicoNo ratings yet

- Training Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Document51 pagesTraining Seminar ON GSM Held at BSNL: Presented By: Charli Bagga Kriti Rastogi (AEI-08)Ankita BharadwajNo ratings yet

- Microsoft Office Tips and TricksDocument12 pagesMicrosoft Office Tips and TricksJayr BVNo ratings yet

- V Single Vane Pumps: 1 - "F3" 2 - Pump TypeDocument14 pagesV Single Vane Pumps: 1 - "F3" 2 - Pump TypeJose Leandro Neves FerreiraNo ratings yet

- Measuring Propeller Drop With The Help of Poker GaugeDocument2 pagesMeasuring Propeller Drop With The Help of Poker Gaugeas100% (1)

- LCD Interfacing PDFDocument37 pagesLCD Interfacing PDFPeeyush Kp100% (1)

- Operation Manual Zoomlion QY40Document133 pagesOperation Manual Zoomlion QY40Hải Tiến100% (1)

- Bayesian Network Approach To Root Cause DiagnosisDocument17 pagesBayesian Network Approach To Root Cause DiagnosisDhinesh GanesanNo ratings yet

- Operations Management 1St Edition Cachon Test Bank Full Chapter PDFDocument36 pagesOperations Management 1St Edition Cachon Test Bank Full Chapter PDFwayne.martin885100% (11)

- Power-Electronics-News December-2022 HIGHDocument37 pagesPower-Electronics-News December-2022 HIGHtrival001No ratings yet

- Women Security Assistance System With GPS Tracking and Messaging SystemDocument4 pagesWomen Security Assistance System With GPS Tracking and Messaging Systemhamed razaNo ratings yet

- Uncontrolled: Direct Shear Test of Soils Under Consolidated Drained ConditionsDocument9 pagesUncontrolled: Direct Shear Test of Soils Under Consolidated Drained ConditionsMohannad QutubNo ratings yet

- Using LD - PreloadDocument4 pagesUsing LD - Preloadmr z3iyaNo ratings yet

- Hysys For Aspen Plus Users PDFDocument11 pagesHysys For Aspen Plus Users PDFKarim KholeifNo ratings yet

- LSE MA100 Background CheckDocument5 pagesLSE MA100 Background CheckAlternative EgoNo ratings yet

- Scalable Analog/Addressable Fire Alarm Control System: IFP-2100ECS / IFP-2100ECSBDocument2 pagesScalable Analog/Addressable Fire Alarm Control System: IFP-2100ECS / IFP-2100ECSBMurali DaranNo ratings yet

- Vesda Arrange Fire Alarm SystemDocument1 pageVesda Arrange Fire Alarm SystemGaurav Kumar SharmaNo ratings yet

- Excel ShortcutsDocument21 pagesExcel Shortcutsrushishinde9797No ratings yet