Professional Documents

Culture Documents

Graco Husky 716 Diaphragm Pump Data Sheet

Uploaded by

MROstop.com0 ratings0% found this document useful (0 votes)

270 views8 pagesGraco's air-operated double diaphragm pumps are ideal for a wide range of applications, including corrosive and abrasive fluid transfer. Our Husky double diaphragm pumps feature a patented air valve design with a three-way pilot valve for true non-sticking operation

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGraco's air-operated double diaphragm pumps are ideal for a wide range of applications, including corrosive and abrasive fluid transfer. Our Husky double diaphragm pumps feature a patented air valve design with a three-way pilot valve for true non-sticking operation

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

270 views8 pagesGraco Husky 716 Diaphragm Pump Data Sheet

Uploaded by

MROstop.comGraco's air-operated double diaphragm pumps are ideal for a wide range of applications, including corrosive and abrasive fluid transfer. Our Husky double diaphragm pumps feature a patented air valve design with a three-way pilot valve for true non-sticking operation

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

22

Husky 716 Metal Pumps

Air-Operated Double-Diaphragm

PROCESS EQUI PMENT CATALOG

Features

8/4 in (19.O5 mmj center- and end-porting

ho seals to leak or fail

0uiet running - less than 85 dBa with eas]-to-use remote muffer

capability for even lower noise levels

High fow rates in a small, portaole package

External controller for optional remote operation

Patented, high-reliaoilit] closed center air valve is

externally serviceable

Typical Applications

Nachine luorication servicing

Cleaning fuids and detergents

Plating and dip tanks

water treatment

Typical Fluids Handled

0il

water

Nost solvents

Husky 716 Aluminum

D53XXX or D43XXX

Husky 716 Stainless Steel

D54XXX or D44XXX

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

23

PROCESS EQUI PMENT CATALOG

Husky 716

Metal Pumps

Maximum uid working pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 psi (7 bar, 0.7 MPa)

Maximum free ow delivery* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 gpm (61 lpm)

Maximum pump speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 400 cpm

Displacement per cycle** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 gallon (0.15 liter)

Maximum suction lift (D53331) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 ft (3.4 m) dry

Maximum size pumpable solids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.09 in (2.5 mm)

Maximum diaphragm operating temperature***

PTFE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220F (104.4C)

Santoprene. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180F (82.2C)

Buna-N. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180F (82.2C)

TPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150F (65.5C)

Fluoroelastomer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250F (121.1C)

Typical sound level at 70 psi air

(4.9 bar, 0.49 MPa) air @ 200 cpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 dBa

Maximum air consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 scfm (0.672 m3/min)

Air pressure operating range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 to 100 psi

(1.8 to 7 bar, 0.18 to 0.7 MPa)

Air inlet size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 npt(f)

Air exhaust port size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8 npt(f)

Fluid inlet & outlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4 npt(f) or bspt(f)

Weight

Aluminum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 lb (3.9 kg)

Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 lb (8.2 kg)

Wetted parts (in addition to ball, seat and diaphragm materialswhich may vary by pump)

Aluminum pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum, Stainless Steel, PTFE, Buna-N,

Santroprene, Zinc-Plated Steel

Stainless Steel pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Acetal, Polypropylene, Stainless Steel, Polyester, Santoprene,

Fluoroelastomer, Nickel-Plated Brass, Epoxy-Coated Steel

Instruction manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308981

* Flow rates are with mufer and do not vary based on diaphragm material

** Displacement per cycle may vary based on suction condition, discharge head, air pressure and uid type

*** Actual pump performance may be affected by prolonged usage at temperature

Typical System Drawings

Technical Specications

Husky 716 Wall-Mount with Drum Feed Husky 716 Drum-Mount with Siphon Feed

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

24

PROCESS EQUI PMENT CATALOG

PUMP SIZE (AIR MOTOR TYPE AND MATERIAL) WETTED PARTS SEATS BALLS DIAPHRAGM

5 = 3/4 (19.05 mm) Standard: polypropylene center section 3 = Aluminum (npt) 2 = Acetal 1 = PTFE 1 = PTFE

4 = 3/4 (19.05 mm) Remote: polypropylene center section 4 = Stainless Steel (npt) 3 = Stainless Steel 3 = Stainless Steel 5 = TPE

9 = Polypropylene 5 = TPE 6 = Santoprene

C = Aluminum (bsp) A = PVDF 6 = Santoprene 7 = Buna N

D = Stainless Steel (bsp) B = SST with viton seal 7 = Buna N 8 = Fluoroelastomer

C = Santoprene with

viton seal

8 = Fluoroelastomer

D = Urethane Duckbill

Husky 716

Metal Pumps

Ordering Information

FLUID FLOW

(Pump tested in water with inlet submerged

F

L

U

I

D

O

U

T

L

E

T

P

R

E

S

S

U

R

E

p

s

i

(

b

a

r

,

M

P

a

)

A

I

R

C

O

N

S

U

M

P

T

I

O

N

s

c

f

m

(

m

3

/

m

i

n

gpm

(lpm)

80

(5.5, 0.55)

100

(7, 0.7)

60

(4.1, 0.41)

40

(2.8, 0.28)

20

(1.4, 0.14)

6

(0.17)

12

(0.37)

18

(0.50)

24

(0.67)

30

(0.84)

0

4

(15.2)

8

(30)

12

(45.42)

16

(60.56)

0

Husky 716 Performance

AIR PRESSURE LEGEND

= at 100 psi (7 bar, 0.7 MPa) Air Consumption

= at 70 psi (4.8 bar, 0.48 MPa) Fluid Flow

= at 40 psi (2.8 bar, 0.28 MPa)

A

B

C

= at 20 psi (1.4 bar, 0.14 MPa) D

A

B

C

D

D

C

B

A

Performance Chart

Accessories

See page 72 for additional accessories.

D X X X X X

Wetted

Parts

Pump

Size

Seats

Balls/

Checks

Diaphragms

Diaphragm

Pump

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

25

PROCESS EQUI PMENT CATALOG

Husky 716

Metal Pumps

Dimensions

Popular Models

3/4 npt(f) or bspt(f) Fluid Outlet

3/4 npt(f) or bspt(f) Fluid Inlets

4.25 in

(108 mm)

1/4 npt(f)

Air Inlet

7.37 in

(187.2 mm)

10.43 in

(264.9 mm)

9.18 in

(233.2 mm)

7.8 in

(198.1 mm)

4.44 in

(112.8 mm)

6.62 in

(168.1 mm)

2.76 in

(62.5 mm)

3/4 npt(f)

or bsp(f)

Fluid Outlets

3/4 npt(f)

or bsp(f)

Fluid Inlets

4.29 in (109 mm)

6.04 in (153.4 mm)

Aluminum D53211 D43211 D5C211 D4C211 Acetal PTFE PTFE D05211 241657 246946

D53255 D43255 D5C255 D4C255 Acetal TPE TPE D05255 241657 246946

D53277 D43277 D5C277 D4C277 Acetal Buna Buna D05277 241657 246946

D53288 D43288 D5C288 D4C288 Acetal Fluoroelastomer Fluoroelastomer D05288 241657 246946

D53311 D43311 D5C311 D4C311 Stainless Steel PTFE PTFE D05311 241657 246946

D53331 D43331 D5C331 D4C331 Stainless Steel Stainless Steel PTFE D05331 241657 246946

D53355 D43355 D5C355 D4C355 Stainless Steel TPE TPE D05355 241657 246946

D53366 D43366 D5C366 D4C366 Stainless Steel Santoprene Santoprene D05366 241657 246946

D53377 D43377 D5C377 D4C377 Stainless Steel Buna Buna D05377 241657 246946

D53388 D43388 D5C388 D4C388 Stainless Steel Fluoroelastomer Fluoroelastomer D05388 241657 246946

D53911 D43911 D5C911 D4C911 Polypropylene Polypropylene Polypropylene D05911 241657 246946

D53955 D43955 D5C955 D4C955 Polypropylene TPE TPE D05955 241657 246946

D53966 D43966 D5C966 D4C966 Polypropylene Santoprene Santoprene D05966 241657 246946

D53977 D43977 D5C977 D4C977 Polypropylene Buna Buna D05977 241657 246946

D53D05 D43D05 D5CD05 D4CD05 Duckbill TPE D05D05 241657 246946

D53D06 D43D06 D5CD06 D4CD06 Duckbill Santoprene D05D06 241657 246946

D53D07 D43D07 D5CD07 D4CD07 Duckbill Buna D05D07 241657 246946

Stainless Steel D54211 D44211 D5D211 D4D211 Acetal PTFE PTFE D05211 241657 246946

D54311 D44311 D5D311 D4D311 Stainless Steel PTFE PTFE D05311 241657 246946

D54331 D44331 D5D331 D4D331 Stainless Steel Stainless Steel PTFE D05331 241657 246946

D54335 D44335 D5D335 D4D335 Stainless Steel Stainless Steel TPE D05335 241657 246946

D54336 D44336 D5D336 D4D336 Stainless Steel Stainless Steel Santoprene D05336 241657 246946

D54355 D44355 D5D355 D4D355 Stainless Steel TPE TPE D05355 241657 246946

D54366 D44366 D5D366 D4D366 Stainless Steel Santoprene Santoprene D05366 241657 246946

D54377 D44377 D5D377 D4D377 Stainless Steel Buna Buna D05377 241657 246946

D54388 D44388 D5D388 D4D388 Stainless Steel Fluoroelastomer Fluoroelastomer D05388 241657 246946

D54911 D44911 D5D911 D4D911 Polypropylene PTFE PTFE D05911 241657 246946

D54966 D44966 D5D966 D4D966 Polypropylene Santoprene Santoprene D05966 241657 246946

* Requires CycleFlo or external valve control

** Air control includes air regulator and lter with gauge

Part Number Part Number

(NPT Ported) (BSP Ported)

Standard Remote* Standard Remote* Materials for Materials for Materials for Fluid Air

Material Air Valve Air Valve Air Valve Air Valve Seats Balls Diaphragms Kit Air Kit Control**

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

9

PROCESS EQUI PMENT CATALOG

Pump Selection Key

Wetted Parts Material Options

Acetal Material used for seats, balls & wetted body parts

wide range of solvent resistance

withstands extreme fatigue

0ood level of aorasion resistance

0roundaole for use with fammaoles

hot for use with acids or oases

Aluminum Material used for air motor & wetted body parts

Nedium corrosion and aorasion resistance

hot for use with HHC's

Ductile Iron Material used for wetted body parts

High aorasion resistance

low cost alternative to stainless steel

Hardened SST Material used for seats and balls

Noderate chemical resistance

0ood aorasion resistance

Aorasion resistant oalls and seats

PVDF Material used for wetted body parts & seats

8trong chemical resistance. acids and oases

0ood aorasion resistance

High temperature resistance

Polypropylene Material used for air motor, wetted body parts,

seats & balls

wide chemical compatioilit]

0eneral purpose

lnexpensive alternative

Stainless Steel Material used for air motor, wetted body parts,

and seats and balls

High level of corrosion and aorasion resistance

Passivated for use with wateroase coatings

Buna-N Material used for seats, balls and diaphragms

0ood for petroleum-oased fuids

hot for use with strong solvents or chemicals

Food grade

Geolast Material used for seats, balls & diaphragms

0ood aorasion resistance

8ame chemical compatioilit] as Buna-h and TPE

TPE Material used for seats, balls & diaphragms

0ood aorasion resistance

0ften suostituted for Buna-h

Santoprene

Material used for seats, balls & diaphragms

0ood aorasion and chemical resistance

hot for use with solvents

0ften suostituted for EPDN or EPR

Food grade

PTFE Material used for balls & diaphragms

Excellent when used with solvents

Poor aorasion resistance

widest chemical compatioilit] with fuids

Food grade

Fluoroelastomer Material used for seats, balls & diaphragms

High level of corrosion resistance with acids

Resists unleaded fuels

Food grade

All other trademarks mentioned herein are the property of their respective owners.

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

31

Diaphragm Compatibility

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

32

Diaphragm Compatibility

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

40

Material Viscosity Considerations

The Husky 205 can handle up to 500 cps material

The Husky 3275 can handle up to 25,000 cps material

Buy Graco Husky Diaphragm Pumps at http://www.mrostop.com/diaphragm-pumps-c-538_989.html

You might also like

- Parker Hose Fittings Equipment 4400 CatalogDocument418 pagesParker Hose Fittings Equipment 4400 CatalogMROstop.comNo ratings yet

- Hyster H 60 XL SHOP MANUALDocument273 pagesHyster H 60 XL SHOP MANUALjacksonholland833583% (6)

- 404D 22Document8 pages404D 22aiulica20100% (2)

- 1104C 44taDocument8 pages1104C 44taWilmerNo ratings yet

- All Code ListsDocument3,292 pagesAll Code ListsshanzNo ratings yet

- Tailrod Hydraulic Gate ValveDocument2 pagesTailrod Hydraulic Gate ValveTopoilServ100% (1)

- Walker1 PDFDocument2 pagesWalker1 PDFDian SikumbangNo ratings yet

- Graco Husky 2150 Diaphragm Pump Manual: POLYPROPYLENE AND PVDFDocument36 pagesGraco Husky 2150 Diaphragm Pump Manual: POLYPROPYLENE AND PVDFMROstop.comNo ratings yet

- Graco Husky 1590 Diaphragm Pump ManualDocument36 pagesGraco Husky 1590 Diaphragm Pump ManualMROstop.comNo ratings yet

- Multi Purpose Pumping Unit: Pump and Heating UnitDocument2 pagesMulti Purpose Pumping Unit: Pump and Heating UnitNinaNo ratings yet

- 2014 DeepAssurance Cementing - OverviewDocument32 pages2014 DeepAssurance Cementing - OverviewAQUILES CARRERANo ratings yet

- Mitsubishi F700 VFD Instruction Manual-AppliedDocument327 pagesMitsubishi F700 VFD Instruction Manual-AppliedMROstop.com100% (1)

- ACCUMULATORS Part-A Question and AnswersDocument10 pagesACCUMULATORS Part-A Question and Answerssar_tpgitNo ratings yet

- Training Report at TATA MotorsDocument28 pagesTraining Report at TATA MotorsAkarsh60% (5)

- Electrical Motors DetailsDocument195 pagesElectrical Motors Details243avinashNo ratings yet

- Influence of Water Contamination On Bearing Life - FAG PrezDocument6 pagesInfluence of Water Contamination On Bearing Life - FAG PrezAhmad ButtNo ratings yet

- ETL Vs ELT White PaperDocument12 pagesETL Vs ELT White PaperDeepak RawatNo ratings yet

- EHT Application NoteDocument3 pagesEHT Application NoteJuan SanchezNo ratings yet

- Bentonite Grade Details PDFDocument7 pagesBentonite Grade Details PDFZEC LIMITED100% (1)

- HM 35-300 enDocument24 pagesHM 35-300 enairshow19No ratings yet

- Instruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerDocument20 pagesInstruction Manual: Roller Oven With Programmable Timer and Circulating Fan, 5 RollerLuis Gomez JimenezNo ratings yet

- Dm02 FTTM AdvDocument36 pagesDm02 FTTM AdvAnonymous 5cMeyYyxhNo ratings yet

- Graco Husky 2150 Diaphragm Pump Manual: ALUMINUM, STAINLESS, AND DUCTILE IRONDocument34 pagesGraco Husky 2150 Diaphragm Pump Manual: ALUMINUM, STAINLESS, AND DUCTILE IRONMROstop.com100% (1)

- SANJEL PresentDocument26 pagesSANJEL PresentMahmoud AbouzeidNo ratings yet

- NHPC ReportDocument53 pagesNHPC ReportVishal SinghNo ratings yet

- Internship and Project Work at JSW Steel LTD: Title:-Rolled in Scale Defects and Counter MeasuresDocument16 pagesInternship and Project Work at JSW Steel LTD: Title:-Rolled in Scale Defects and Counter MeasuresA V KIRANNo ratings yet

- Digital Filter DesignDocument102 pagesDigital Filter Designjaun danielNo ratings yet

- Um00004 - 01 - 05 - A4 - Noriamat™ H PDFDocument50 pagesUm00004 - 01 - 05 - A4 - Noriamat™ H PDFsatfasNo ratings yet

- Mitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedDocument221 pagesMitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedMROstop.comNo ratings yet

- Aerzen-Process Gas SolutionsDocument26 pagesAerzen-Process Gas SolutionsWesley andrade martins100% (1)

- Chapter 1Document56 pagesChapter 1Surbhi JainNo ratings yet

- Travel Fellowship Application FormDocument4 pagesTravel Fellowship Application FormAsma100% (1)

- Transfer of Solids: 5.1. Slurry TransportDocument8 pagesTransfer of Solids: 5.1. Slurry TransportKevin Alberto Tejera PereiraNo ratings yet

- PB3603 1 Raymond Mechanical Air Separator PDFDocument4 pagesPB3603 1 Raymond Mechanical Air Separator PDFmiraNo ratings yet

- Perkins 1100 Series HDDocument8 pagesPerkins 1100 Series HDSaadNo ratings yet

- 06fuller CPMDocument38 pages06fuller CPMhartNo ratings yet

- Bearings 1Document1 pageBearings 1Joydev GangulyNo ratings yet

- OMM DOBA BrakeDocument24 pagesOMM DOBA BrakeRakhmat yusuf100% (2)

- Blast FurnaceDocument3 pagesBlast FurnaceNarendra Singh ShekhawatNo ratings yet

- Graco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Document24 pagesGraco Xtreme 70 1 Airless Spray Pumps Part Numbers and Schematics Guide 206m539Maulana Mufti MuhammadNo ratings yet

- RG-04 Blast FurnaceDocument8 pagesRG-04 Blast FurnaceAnubhav SarafNo ratings yet

- Sugar HandlingDocument4 pagesSugar Handlingrbrbs7100% (1)

- Preheater Calciner SystemsDocument8 pagesPreheater Calciner SystemsDanni SulaimanNo ratings yet

- Air Operated Grease Ratio Pumps 50-1Document3 pagesAir Operated Grease Ratio Pumps 50-1balasubramanyam kotaNo ratings yet

- Test Report 10034-1 Raw Material Grasim Rawan IndiaDocument6 pagesTest Report 10034-1 Raw Material Grasim Rawan IndiaKenny RuizNo ratings yet

- The Norgren Guide To Specifying Pneumatic ActuatorsDocument34 pagesThe Norgren Guide To Specifying Pneumatic ActuatorssridveiNo ratings yet

- Graco Brochure PDFDocument16 pagesGraco Brochure PDFA MahmoodNo ratings yet

- 102-41260 HPGR Chapitre A Introduction AnglaisDocument17 pages102-41260 HPGR Chapitre A Introduction AnglaismahdieNo ratings yet

- Accessories HydraulicsDocument47 pagesAccessories HydraulicsawfahaddadinNo ratings yet

- GB PelletizingDocument20 pagesGB PelletizingsetavietnamNo ratings yet

- Extruder SDocument28 pagesExtruder SKamran AliNo ratings yet

- PM 372 Roto Packer RVTDocument20 pagesPM 372 Roto Packer RVTLiuel GirmaNo ratings yet

- Cat Hydo Advanced 10WDocument4 pagesCat Hydo Advanced 10Waliosk8799No ratings yet

- Argus Cement EquipDocument4 pagesArgus Cement Equipb4rf100% (1)

- PC010501 0313 0914 en Viking ProductCatalogue Detection MR PDFDocument348 pagesPC010501 0313 0914 en Viking ProductCatalogue Detection MR PDFJiNo ratings yet

- CB Doctor Cat PDFDocument8 pagesCB Doctor Cat PDFChakravarthi NagaNo ratings yet

- DSE Presentation (4 Apr 2012)Document20 pagesDSE Presentation (4 Apr 2012)skimmer05No ratings yet

- NP Pumps BlackmerDocument4 pagesNP Pumps BlackmerrasottoNo ratings yet

- 3 - Arenas Curables y ActivadoresDocument52 pages3 - Arenas Curables y ActivadoresPablo SotoNo ratings yet

- PolarProp ApplicationDocument4 pagesPolarProp ApplicationCristian BarbuceanuNo ratings yet

- H00707Document2 pagesH00707AQUILES CARRERANo ratings yet

- Atac Blowing Film Machines Catalogue 2022Document22 pagesAtac Blowing Film Machines Catalogue 2022Leonardo LiraNo ratings yet

- Witte Poly PumpsDocument5 pagesWitte Poly Pumpsy.s.6saputroNo ratings yet

- O&m RnaaDocument20 pagesO&m RnaaГеннадий ПарфентьевNo ratings yet

- Ancla Antitorque DTA XBDocument2 pagesAncla Antitorque DTA XBalfredozavNo ratings yet

- Rider RingsDocument4 pagesRider Ringspaulsonp_2No ratings yet

- Thyssenkrupp Industries India: Polysius Cement DivisionDocument23 pagesThyssenkrupp Industries India: Polysius Cement DivisionunimarinesNo ratings yet

- Graco Husky 3275 Diaphragm Pump Data SheetDocument8 pagesGraco Husky 3275 Diaphragm Pump Data SheetMROstop.comNo ratings yet

- Graco XT Auto BrusurDocument4 pagesGraco XT Auto Brusurcav4444No ratings yet

- 1006tag2 PDFDocument6 pages1006tag2 PDFMuhammad Ahmad100% (4)

- Ficha Tecnica C 40Document1 pageFicha Tecnica C 40Abrar HussainNo ratings yet

- Cat 3507 LDocument4 pagesCat 3507 LJordan aguilarNo ratings yet

- Cat Pumps Catalog PAGESDocument41 pagesCat Pumps Catalog PAGESMiguel Angel Santos PintadoNo ratings yet

- Ficha Tecnica 1006 GTDocument6 pagesFicha Tecnica 1006 GTJonhatan Duque RamirezNo ratings yet

- MROStop 2015 LineCardDocument2 pagesMROStop 2015 LineCardMROstop.comNo ratings yet

- Mitsubishi D700 VFD POCKET - GUIDE - 2009-03Document2 pagesMitsubishi D700 VFD POCKET - GUIDE - 2009-03MROstop.comNo ratings yet

- Parker Industrial Hose Catalog 4800Document258 pagesParker Industrial Hose Catalog 4800MROstop.comNo ratings yet

- MRO Stop Industrial Fastener CatalogDocument53 pagesMRO Stop Industrial Fastener CatalogMROstop.comNo ratings yet

- Mitsubishi v500 VFD Brochure UpdatedDocument12 pagesMitsubishi v500 VFD Brochure UpdatedMROstop.comNo ratings yet

- A700 Pocket Guide 2006-05Document8 pagesA700 Pocket Guide 2006-05TetsusaigaNo ratings yet

- MRO Stop Industrial Supply LinecardDocument2 pagesMRO Stop Industrial Supply LinecardMROstop.comNo ratings yet

- PowerFilm Solar Energy Product LineDocument9 pagesPowerFilm Solar Energy Product LineMROstop.comNo ratings yet

- Gosol Solar Power BoxDocument2 pagesGosol Solar Power BoxMROstop.comNo ratings yet

- F700 Pocket Guide 2006-05Document8 pagesF700 Pocket Guide 2006-05TetsusaigaNo ratings yet

- Mitsubishi F700 VFD Installation GuidelineDocument29 pagesMitsubishi F700 VFD Installation GuidelineMROstop.com100% (1)

- Mitsubishi v500 VFD Instruction ManualDocument119 pagesMitsubishi v500 VFD Instruction ManualMROstop.com100% (1)

- Mitsubishi FR-V500L VFD Instruction Manual-BasicDocument114 pagesMitsubishi FR-V500L VFD Instruction Manual-BasicMROstop.comNo ratings yet

- IB NA 0600131-C FR-V500L Instruction Manual-DetailedDocument231 pagesIB NA 0600131-C FR-V500L Instruction Manual-DetailedMROstop.comNo ratings yet

- Mitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedDocument243 pagesMitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedMROstop.comNo ratings yet

- Mitsubishi F700 VFD Dimensional DrawingsDocument6 pagesMitsubishi F700 VFD Dimensional DrawingsMROstop.comNo ratings yet

- Mitsubishi F700 VFD Single Phase Input InformationDocument2 pagesMitsubishi F700 VFD Single Phase Input InformationMROstop.comNo ratings yet

- Mitsubishi F700 Series VFD ManualDocument309 pagesMitsubishi F700 Series VFD ManualMROstop.comNo ratings yet

- Mitsubishi F700 VFD BrochureDocument8 pagesMitsubishi F700 VFD BrochureMROstop.comNo ratings yet

- Firestone Air Gripper CatalogDocument42 pagesFirestone Air Gripper CatalogMROstop.comNo ratings yet

- Mitsubishi E700 Variable Frequency Drive (VFD) Instruction ManualDocument322 pagesMitsubishi E700 Variable Frequency Drive (VFD) Instruction ManualMROstop.com75% (4)

- Mitsubishi E700 Variable Frequency Drive (VFD) - POCKET - GUIDEDocument2 pagesMitsubishi E700 Variable Frequency Drive (VFD) - POCKET - GUIDEMROstop.comNo ratings yet

- FR d700, FR E700, FR f700, FR A700 Technical Manual SH (Na) 060014 B (04.09)Document550 pagesFR d700, FR E700, FR f700, FR A700 Technical Manual SH (Na) 060014 B (04.09)Patran ValentinNo ratings yet

- DM No. 312, S. 2021Document3 pagesDM No. 312, S. 2021sherileneNo ratings yet

- t410 600w 4 Amp PDFDocument8 pagest410 600w 4 Amp PDFJose M PeresNo ratings yet

- It Implementation-Issues, Opportunities, Challenges, ProblemsDocument9 pagesIt Implementation-Issues, Opportunities, Challenges, ProblemsAnnonymous963258No ratings yet

- Syntel Mock 2Document18 pagesSyntel Mock 2Ashutosh MauryaNo ratings yet

- Chiller: Asian Paints Khandala PlantDocument19 pagesChiller: Asian Paints Khandala PlantAditiNo ratings yet

- LG Mobile CompanyDocument6 pagesLG Mobile Companymallickantonio6559No ratings yet

- lTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelDocument42 pageslTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelGrupo CardogalNo ratings yet

- African Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-ExaminedDocument9 pagesAfrican Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-Examinedberimbau8No ratings yet

- Aalco StocklistDocument36 pagesAalco StocklistjsfscibdNo ratings yet

- LanDocument5 pagesLanannamyemNo ratings yet

- Sewa bill-AED 559Document1 pageSewa bill-AED 559muhdazarNo ratings yet

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocument8 pagesTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungNo ratings yet

- CSB GP1234 - Hoja de DatosDocument2 pagesCSB GP1234 - Hoja de DatosGermanYPNo ratings yet

- Computer 1Document8 pagesComputer 1marce1909No ratings yet

- 400 InstructionsDocument2 pages400 InstructionsjimmylovelyNo ratings yet

- Leadership and Management 2003Document46 pagesLeadership and Management 2003Ciella Dela Cruz100% (1)

- VM 6083 - 60B1 Data SheetDocument3 pagesVM 6083 - 60B1 Data SheetMinh HoàngNo ratings yet

- Seismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440Document10 pagesSeismic Assessment of RC Building According To ATC 40, FEMA 356 and FEMA 440sobah assidqiNo ratings yet

- Summary Key ParameterDocument18 pagesSummary Key ParameterAndry JatmikoNo ratings yet

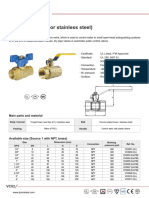

- VC02 Brass Ball Valve Full Port Full BoreDocument2 pagesVC02 Brass Ball Valve Full Port Full Boremahadeva1No ratings yet

- Water Cooled Flooded Vertical Screw ChillersDocument96 pagesWater Cooled Flooded Vertical Screw ChillersaftabNo ratings yet

- Ahmed Zaiba's CV SalehDocument6 pagesAhmed Zaiba's CV SalehSarah ZaibaNo ratings yet