Professional Documents

Culture Documents

Us 18455 Notes Final

Uploaded by

salamrefighOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 18455 Notes Final

Uploaded by

salamrefighCopyright:

Available Formats

National Diploma in Drinking Water Assessment

April 2002 Tutor Notes and Home Assignment for Unit Standard 18455 Demonstrate knowledge of process control in a water treatment plant, and management of critical points

Otago Polytechnic

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 2 of 54

Contents

1. Introduction.............................................................................................................................................3 1.1 Process Control Overview.................................................................................................................3 1.2 The Need For Automated Process Control........................................................................................3 1.3 Manual and automated process control .............................................................................................3 Piping and Instrumentation Diagrams (P&IDs) ..................................................................................5 2.1 Overview ...........................................................................................................................................5 2.2 Instrumentation symbols ...................................................................................................................6 2.3 Plant symbols ....................................................................................................................................7 2.3.1 Process and signal lines.............................................................................................................8 2.4 Using P&ID Drawings ......................................................................................................................9 Types of Process Control ......................................................................................................................10 3.1 Analogue Control Equipment..........................................................................................................10 3.1.1 Analogue Input Devices ..........................................................................................................10 3.1.2 Analogue Output Devices .......................................................................................................11 3.1.3 Analogue Signal Forms...........................................................................................................13 3.1.4 Analogue to Digital Conversion..............................................................................................14 3.1.5 Sources of Error in Analogue Systems....................................................................................14 3.2 Analogue Control Configurations ...................................................................................................16 3.2.1 Open and Closed Loop Controls .............................................................................................16 3.2.1 Control Action.........................................................................................................................18 3.3 Common Analogue Control Methods .............................................................................................18 3.3.1 Proportional Control................................................................................................................19 3.3.2 On/Off Control ........................................................................................................................19 3.3.3 PID Controllers .......................................................................................................................20 3.3.4 Custom Controls......................................................................................................................22 Digital Control Systems ........................................................................................................................24 4.1 PLC Control Systems ......................................................................................................................24 4.1.1 Introduction .............................................................................................................................24 4.1.2 Processing of Data Within a PLC ...........................................................................................24 4.1.3 Interacting with a PLC ............................................................................................................25 4.1.4 Programming PLC's ................................................................................................................25 4.1.5 Status Monitoring....................................................................................................................25 4.1.6 Safety Interlocks......................................................................................................................25 4.2 Computer Based Control.................................................................................................................26 4.2.1 Distributed Control Systems ...................................................................................................26 4.2.2 SCADA Systems .....................................................................................................................26 Critical :Points.......................................................................................................................................30 5.1 Definition of Critical Points ............................................................................................................30 5.2 Power Supply ..................................................................................................................................30 5.3 Process Monitoring: ........................................................................................................................30 Assignment.............................................................................................................................................32 Glossary of Terms .................................................................................................................33 Analogue to digital signal conversion ..............................................................................37 PID Controllers .....................................................................................................................39 Programmable Logic Controllers Notes..............................................................................46 SCADA Notes ........................................................................................................................50

2.

Appendix 1 Appendix 2 Appendix 3 Appendix 4 Appendix 5

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 3 of 54

1. Introduction Unit Standard 18455 builds on Unit Standard 17873 which forms part of the Water and Wastewater Site Operator Certificates. The first two elements of US 18455 are similar to US 17873 which may be used as assessment (or Recognition of Prior Learning) for the first two elements of US 18455. The third element deals with the types of control most suitable for various drinking water treatment processes. Different processes have different responses to control systems and the control processes are set out in these notes. The fourth element deals with the risks of poor control responses in a treatment plant, the causes of poor control and the remedies to minimise these risks. Some additional technical material is appended to these notes for information only - it does not form part of the assessment of this Unit Standard. These notes may be of assistance where a control system is not responding well to conventional expectations. 1.1 Process Control Overview

The principles of automated process control are the same for any process, in any industry. These notes set out the basics of automated process control with an emphasis on their application to water treatment processes, using as examples processes found in water treatment, such as pH control. Although this manual is intended for operators of water treatment plants, much behind the scenes information is provided. The purpose of this is twofold: 1.2 To help the operator understand how the system the controls works. To provide the tools to monitor the overall performance of a control system. The Need For Automated Process Control

Manual control has been the only form of process control in many treatment plants in this country for many years. However, changes have occurred and are continuing to occur. The ability to measure different contaminants, has improved. This ability is dependent on the development and refinement of instruments to measure process parameters. The allowable level of various contaminants is reducing. Automated process control will reduce the risk of plant failure/malfunction and possible risk to public health. 1.3 Manual and automated process control

When given accurate data, a human operator can control process parameters very well. There are two reasons for this:

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 4 of 54

1. The operators knowledge of the system is much greater than that of an automatic controller. A controller is only aware of the data provided to it and processes it with no knowledge of its accuracy. An operator, on the other hand, can gather data from other areas, or even the entire plant, and verify its accuracy. 2. The operator has a knowledge base of past events (remembers), whereas a controller does not. This enables the operator to anticipate the action required for circumstances that have been observed in the past. Thus the human operator can act to reduce the effect of a disturbance, whereas an automatic controller can only react to a disturbance. Research and development into expert systems that record past events and use historical ("remembered") data for controlling processes is ongoing. However, rules for applying this data for control are not well defined. "Smarter" systems can make plant-wide data available to all connected devices including process controllers. The state of an earlier process can be fed forward to subsequent processes and used for control, providing a cascaded control system. Such systems can now access and use most of the data available to an operator. Automated process control has three advantages over manual control: 1. It is consistent. 2. It is continuous: an automatic controller does not require time off to rest. 3. An automatic controller can react more quickly to change than a human operator. However, accurate control relies on regular maintenance. Sensors must be maintained and calibrated and their response time checked as necessary. Similarly, a controller assumes an actuator will respond in a predictable way to the signal provided to it. In most cases, mechanical wear over time ensures it does not. Actuators too need to be monitored and maintained as part of normal loop maintenance procedures. It is noted above that automatic control is consistent. Whether it is consistently good, or consistently poor, is a function of process design and loop tuning.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 5 of 54

2. Piping and Instrumentation Diagrams (P&IDs) 2.1 Overview

P&IDs are a specialised form of drawing used to document processes. They are often drawn according to in-house rules based on the current standard(s) in the country of origin. These rules should be appended to any documents produced. P&IDs employ at least two identification/symbol systems one for processes and another for common elements such as valves, pumps and tanks etc and a variety of lines styles to denote process connections and signal types. They seldom show dimensions unless these are critical to the process operation. This next two diagrams shows how P&ID symbols are used to represent a more conventional "schematic" diagram. In this first "schematic" diagram, a lime dosing system is being depicted. In words, lime slurry is pumped into a mixing (or "process") tank to be mixed with the main water flow. The amount of lime slurry is controlled by the water flow meter (the "feed forward" loop) and adjusted by the pH probe in the process tank.

Feedforward Loop

pH controller

Slurry prep

pH Slurry pump

Flow

Process tank

to downstream process

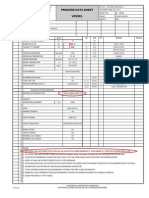

Fig 3.1 Schematic of Lime dosing System In the PID, the elements are numbered. These numbers should be tied in to the plant maintenance procedures as well. The numbers assigned below are: FT 601 Water flow meter - provides the primary lime control flow rate AT 601 pH probe - provides the feedback signal for the lime feed controller MX 601 Mixing tank mixer (electric powered stirrer) TK 601 Mixing Tank AIC 601 pH controller - adjusts speed of pump (actuator) to maintain pH. YC 601 Summing relay combining pH and flow control signals to the pump motor. MX 602 Slurry tank mixer TK 602 Slurry tank P 601 Lime slurry dosing pump

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 6 of 54

AIC 601 pH AT 601 FT 601 MX601

YC601

MX602

TK602 Slurry Prep TK601 P601

to

downstream

Fig 3.2 - PID of Lime Dosing System 2.2 Instrumentation symbols

Items marked FT601, AT601 and AIC601 are process symbols. Some common process symbols are shown below.

The symbols at right are typical of those found in P&IDs. The description defines the function represented by each symbol. Variations on these involve the number and style of lines across the symbol. No line indicates a field mounted device. A single line denotes a device mounted on the front of a central control panel. Two solid lines ( ) across the symbol denote a device located on a remote (from the central) control panel. Dashed lines may be used to indicate a device located behind a panel or in a cabinet. Lines are usually placed across the centre of the symbol but may be shifted up to accommodate plant identification codes. The symbols can be expanded horizontally to accommodate plant identification codes. Discrete instrument

Display and Control

Computer function

Programmable Logic control

Process symbols and their usage are found in standards such as ANSI/ISA s5.1 and AS1101.6. This last was a combined Australian-New Zealand standard, but has now been withdrawn as an NZ standard. All instruments have basic function code letters, e.g. FT, AIC, which should appear within the upper portion of the symbol A numeric identification code appears in the lower part of the symbol. This is referred to as the loop number and usually consists of 3 or 4 digits. Frequently, the first one or two digits identify a processing stage or area in the plant. The last two digits indicate items in, or associated with, the control loop. Function code letters may vary, or alternatives may exist. For an electromagnetic flowmeter (FT601 above), the following variations have been found in different drawings:

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 7 of 54

Symbols: Function codes: FE (Flow Element), EE (Electrical Element) and FT (Flow Transmitter). Letter codes are allocated in a manner similar to this:

Letter

A B C D E F G H

First letter (measured or initiating variable)

Analysis Burner, flame

Modifier (display or output function)

Succeeding letter

Alarm State or status display Control

Density All electrical variables Flow rate Gauging position or length Hand operated

Difference

Sensing element

Ratio

I

J K L M N 0 P Q R S T U V W X Y Z

Glass High (alarm) Indicating

Scan

Time or time program Level Moisture or humidity Users choice Users choice Pressure or vacuum

Barrier Low (alarm) Users choice Users choice

Users choice

Integrate or totalise

Radiation Speed or frequency Temperature Multivariable Vibration Weight or force Unclassified variables Users choice

Test point connection Integrating or summating Recording Switching Transmitting Multifunction Unit Valve, damper, louvre, actuating element Wells Cathode ray tube, etc Computing relay, relay Emergency or safety acting

Note that some letters may be assigned to any required function. Any users assignments must be shown on the drawing. 2.3 Plant symbols

Common symbols and letter codes for piping symbols are:

Valve - generic valve symbol. Other symbols for particular valve types such as globe, needle, ball e.t.c. abound. Filled symbol may be used to indicate a normally closed valve. Pump - generic pump symbol. May be accompanied by letter code for type of pump, i.e. CP for centrifugal pump. Centrifugal pump - a more literal representation Pump - an old generic symbol for a pump. Still in common use with variations to denote specialised pump types. Variations on the symbol itself can be found. i.e. or

Electric motor - generic symbol. This symbol is commonly used in conjunction with the valve symbol above to denote an electric motor driven valve actuator. eg

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 8 of 54

Diaphragm actuator - generic symbol for diaphragm valve actuator. e.g. Signal type is indicated by connecting lines (see later) except that ti li d h ti t d b t ll d fl id Spring biased pneumatic actuator - generic symbol with one or two horizontal lines to indicate single or double action. A means of indicating action (air to open / air to close) may be incorporated within the symbol or added externally. Use as for diaphragm actuator. Manual actuator - indicates hand operated device. i.e. Hand operated valve

Stirrer - generic symbol for blade or vane mixer. See MX 601 and MX 602 in fig 3.2 above

Common plant letter codes are:

Letter(s) A B C M MX P T TK V Meaning Mixing equipment (see MX below) Blower (Air pump) Compressor Motor Commonly used for Motor mixers/stirrers Pump - any type Used for any vessel or tank. Common alternative to T. Valve - any type

driven

Variations on the above are common. e.g. CP to denote a Centrifugal Pump; CV a Control Valve, MV or MOV to identify a Motor Operated Valve and HV a Hand operated Valve. 2.3.1 Process and signal lines

Process connections and signal types are designated by line styles.

Line style Function

Process line, flow line of process (AS/NZS 1100.101) Instrument connection, mechanical link or instrument supply (AS/NZS 1100 101) Pneumatic signal Electric or undefined signal Capillary tubing Hydraulic signal Guided signal (electromagnetic, optical) Software / data link sonic or

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 9 of 54

2.4

Using P&ID Drawings

Plant schematic drawings will set out the overview of what is going on in the treatment plant. The PID diagrams will show precisely which piece of equipment is connected to which. If you need to know what sets the level of water in say the contact tank, the P&ID will show whether there is a level transmitter present, which controller it sends a signal to and what the controller will open, shut, start or stop when the level is too high or too low. If there is a control problem (e.g. the pH keeps going up and down - never settles down to a good steady value), the P&ID will show what needs to be looked at. In the example quoted, the following items should be checked: The flowmeter- is the signal correct? The dosing pump - when the flow meter shows twice the flow (and the pH meter is held constant), does the dosing pump put out twice the flow? If not, the pH meter circuit may be trying to do most of the work and this may be the problem. Is pH meter calibrated properly?

These potential sources of the problem are much easier to isolate and understand using the P&ID than using the schematic.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 10 of 54

Types of Process Control

There are a substantial number of control processes going on in most water treatment plants. Each type of control process needs to be selected to suit the treatment process section they are controlling to provide steady control. Many process controls are "analogue" - i.e. a signal is generated and transmitted in a form that can be measured with a voltmeter, current meter or pressure gauge. The plant item actuator reacts to this analogue signal. Other controls may be digital - i.e. the original signal is converted to a number (in binary) and transmitted, processed in a PLC or computer and usually converted back into an analogue signal for the actuator. 3.1 3.1.1 Analogue Control Equipment Analogue Input Devices

An analogue input device senses some function and converts its value into an analogue signal (usually electrical). This conversion is done by a "transducer" which senses some process variable (e.g., pressure, pH etc.) and reports it as an electrical (or pneumatic) signal. Examples usually found in water treatment plants include: Flowmeters Pressure meters Turbidity meters pH meters Streaming current meters Chlorine residual analysers

In each of these transducers, a signal is generated, often at a very small voltage or other electrical variable. This signal is usually too weak to be suitable for transmission very far. It is usual to convert this to a stronger signal for transmission. This is done in a signal processor which converts the original signal to a voltage (or current) proportional to the original signal. This signal then passes to the signal converter, which scales it to provide the required range and format for transmission to the control system. Analogue signals move continuously (i.e. no steps or gaps) through the specified range of values. An ideal analogue signal would be in direct proportion (i.e. linear) to the process quantity being measured.

Otago Polytechnic Drinking Water Assessors Course US18455

Transducer

Process Control

Page 11 of 54

Signal converter

Signal Processor Process Q V V/ I

f (v

IN)

Calibration controls

The transmitted signals are usually one of a standard range being: 4 - 20 milliamps (ma.) 1 - 5 volts

There are other ranges but 4 - 20 ma has become the industry standard. The first part of these standard signals ( viz. the signal value before the standard range i.e. the 0 - 4 ma or 0 - 1 volts) is used to provide a live zero for calibration. It is also used to power most transmitters. The calibration controls allow the system to be set for "Empty = 4 ma" and "Full = 20 ma". This setting of the zero and full scale points (and sometimes intermediate points) is the procedure of calibration. 3.1.2 Analogue Output Devices

Output devices are plant items that respond to a signal received by carrying out an action (e.g. changing position, speed or pressure) to make the desired change happen. Typical examples in water treatment plants include: Valve actuators Electric motors on pumps of various types

As with input devices, ideally the output devices will respond continuously and linearly to the signal received. Actuators If a controller wants to reduce the flow in a pipeline, it may send a signal of 12 ma to an actuator which will respond by closing halfway (12 being halfway between 4 and 20 ma). The actuator itself will have a deadband a range of values over which no control or corrective action will take place. This may be inherent in the design of the actuator; for example, in the case of a motorised flow control valve it will consist of the backlash in the mechanical drive train.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 12 of 54

Analogue driven actuators incorporate a positioner which is a simple controller that moves an actuator to a position proportional to the received analogue signal. Positioners are usually incorporated within an actuator but may be found as separate items. The following diagram is of an electric valve positioner for a butterfly or ball valve.

Resistive feedback signal = PV

Loop Controller output = SP

Positioner

OPEN

CLOSE

The positioner uses the output from the loop controller as its setpoint. It compares this value with the position value returned from the potentiometer mounted on the valve shaft. According to the result of this comparison, the controller will drive the valve open or closed as required until the difference in value is less than the control deadband.

Diagram of Butterfly Valve with Positioner Feedback Loop An adjustable deadband will be provided within the positioner. This deadband should be set at the minimum value that will cause the controller to respond to the smallest change in signal without continually moving (hunting) about one position when the controller is receiving a steady signal. (A valve that is hunting may appear to provide good control, the small changes being smoothed out by the process itself. Valve and/or actuator life will, however, be short.) Too large a deadband will result in loss of, or poor, control of the process. Operators should remember that the controller assumes the actuators response will be timely and accurate an assumption that is not always correct. Of all the components of a control system, actuators are the most unreliable, subject to wear and with backlash (hysteresis) in their motion. Often, they are non-linear over part or all of their range of movement but are driven by signals that assume they have a linear characteristic. This can cause loss of control near the limits of actuator travel. Electric Motors Controlled electric motors fall into two types - speed controlled (where the actual speed of rotation is controlled) and on/off (where how long they run between stops is controlled). Older dosing pumps have a fixed speed motor with adjustments made to the amount of chemical pumped by changing the mechanical drive train - a gearbox and/or adjusting piston stroke travel. Many newer pumps have a motor speed controller (usually as a separate unit) which electronically adjusts the frequency of the alternating current driving the motor. By altering the frequency from the standard 50 hz (50hz = 3,000 rpm) up or down, the motor will rotate faster or slower. Should a controller require a chemical dose rate to be lowered 10%, it may change the process signal from 15 ma to 13.5 ma. The speed controller would then adjust the motor speed from say 2,000 rpm to 1,800 rpm, effectively reducing pumped chemical.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 13 of 54

On/off power supply is used for on/off control as described below. 3.1.3 Analogue Signal Forms

Analogue data transmission is unidirectional, over a single data path. The signal travels from the field device to the connected controller(s) and a separate path is required for each signal. There are four media for analogue signal transmission paths: Electrical Mechanical Fluid Electromagnetic radiation.

Electrical Early electrical controllers used purely analogue control circuitry to process data. This led to the development of several standard signal types such as 1 5 Volt, 4 20 mA and 10 50 mA for data transfer via a pair of conductors, with 4 20 mA becoming the predominant format. For each type, the lower value represents 0% and the higher value 100% of a variables range. Mechanical This is not normally used other than in the internal mechanisms of actuators and pneumatic controllers. Fluid There are two sub-types: hydraulic and pneumatic. Hydraulic: Hydraulic (liquid) control systems are commonly found in distribution networks as pressure control or flow control valves. These valves are also used in treatment plants for hydraulic control - often on the plant inlet or outlet. Pneumatic: Pneumatic systems capable of executing complex control functions have existed for some time and may still be purchased. These devices use a pneumatic signal, the standard being 3 15 psi (0.2 1 Bar, 20 - 100 kPa) with the lower pressure representing 0% and the higher pressure representing 100% of a variables range. Because they require only a continuous supply of clean, dry, compressed air, they provide a degree of inherent safety in explosive atmospheres compared to electrical signals. Pneumatic actuators for valves are substantially cheaper then electrical actuators and are often used on say a block of four or more filters for economy. The air is normally "wired" around the equipment in nylon or polyethylene pipes about 6 - 10 mm in diameter. Since air consumption is low, the size of the compressor required is small - perhaps a kilowatt or two motor and a small (10 litres) compressed air vessel. Electromagnetic radiation Fibre optics use a modulated light beam transmitted through a glass fibre. It requires conversion to and from electrical signals at each end. This medium is immune to electrical interference and data transfer rates are much higher than for electrical cable. This medium

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 14 of 54

is used for digital data, so analogue need to be converted into digital form before transmission. Radio is employed as a medium for serial data transfer, generally with remote sites. Again, only digital data may be transmitted by this medium. 3.1.4 Analogue to Digital Conversion

As many controllers are digitally based, and many of the signal transmission systems use digital data, conversion from analogue to digital (and vice versa) is a common requirement. Appendix 2 sets out the detail of how this conversion is done. Note that there is always a small amount of error - but the conversion is usually well within 0.1% of the signal. Analogue to digital converters are known as A/D converters - D/A are the reverse. 3.1.5 Sources of Error in Analogue Systems

The main sources of error in analogue control systems are: Within the primary sensing element/ transducer Transmission errors (noise primarily) Signal processing (usually very small) Actuator response (particularly hysteresis) Non linearity of process response

Below are notes on noise, hysteresis and process response- the major sources of error. Noise Noise, as applied to process control, refers to invalid signals or data within a system. In process signals noise is usually due to external interference.

A signal without noise (ideal).

The same signal with noise present.

Filtered noisy signal.

Noise can be induced in signal lines in four ways; capacitive coupling, inductive coupling, electromagnetic radiation and resistive effects. The first three require that the interfering signal is changing its value over time. The last requires a conductive path to the signal wiring.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 15 of 54

Techniques for reducing noise pickup include shielding signal cables and routing them separately and apart from power cables. Cable construction also plays a part; for example, twisted pair cable reduces susceptibility to noise pickup. Noise can also be introduced within a controller. In analogue controllers, careful circuit design, shielding of low-level circuitry and choice of components minimises the generation of internal noise and provides some protection against induced noise. In digital controllers, similar attention must be paid to the design of the A/D and D/A conversion circuitry. Filtering a signal can reduce the effect of noise but introduces additional lag into the control loop. Hysteresis The ideal output device will always provide the same output signal for a given input value. (this also applies to input devices). It will have no hysteresis or in the conversion process and will respond instantaneously to changes. Such a device does not exist. The following diagram shows the "real world" response of a hypothetical device (or transducer) converting pressure to a 4-20 mA signal.

FS The two solid lines represent the (exaggerated) response of the transducer to a rise, then fall, in pressure. The dashed line represents the ideal response. The broken lines represent the specified accuracy (%fs) for the device. The loop formed by the solid lines is a measure of the hysteresis of the device. In product specifications, this characteristic is expressed as repeatability of the device. This sort of response curve is typical of transducers, such as pressure to current (P/I) devices, that rely on mechanical motion to sense a quantity. 4 current (mA) 20

Pressure

Repeatability is a measure of the accuracy with which a device duplicates its output under identical conditions. Non Linearity of Process Very few processes carried out in water treatment are simply linear. For example: The flow through a butterfly valve does not correspond linearly with the "% open" reading - but butterfly valves are more linear than gate valves. The change in pH that results from lime addition is not linear. There are some "nearly straight" parts of the curve but it flattens fairly abruptly. The flow pumped by a speed controlled pump is not linear with pump rotating speed.

Finding the correct ratio between the input changes and the desired output results may be a tedious procedure. The use of a piece of graph paper with a simple manual plot of change and effect may save considerable time in finding the ranges of values where change happens quickly.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 16 of 54

3.2

Analogue Control Configurations

Set out below are the different types of control that can be used for analogue based process control. The choice of which type of control is appropriate for which process (or part of the process) depends on the constraints of the fluid and chemical/mechanical actions occurring. The correct choice will provide the best chance for process control to be steady and effective. However, if the fluid, mechanical or chemical actions are inherently unstable, the fanciest controllers available will not be able to achieve control. For example, it is virtually impossible to achieve very small flow rate changes with a very large valve. 3.2.1 Open and Closed Loop Controls All analogue control systems fall into one of two broad categories: open loop and closed loop control. Open Loop Open loop is a control method in which the controller cannot monitor the effect of its output on the process. Open loop control is rarely, if ever, found in analogue process control.. Though a controller itself may have no provision to compensate for any errors arising from a change in output, the operator provides the necessary feedback to modify the controller parameters if the output error is unacceptable; i.e., the operator manually closes the loop. From here on, open loop will refer only to controller action and takes no account of operator action. Closed loop In closed loop control, a signal showing the effect of the controller action is fed back to the controller. This feedback loop enables the controller to monitor and modify its output to maintain a process at a preset value, or setpoint. The controlled process variable is compared with the setpoint, generating an error value that drives the controller. Open and Closed loop control are illustrated below:

flowmeter

4 - 20 ma signal (input) controller

lime pump 4 - 20 ma (output)

Open Loop Control - a Flow Paced Lime Pump

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 17 of 54

pH meter feedback signal of 4 - 20 ma flowmeter

4 - 20 ma signal (input) controller

lime pump 4 - 20 ma (output)

Closed Loop Control - a Flow Paced Lime Pump with pH Correction

3.2.2

Feed Forward and Feed Back Control

Feed Forward Feed forward control is a form of open loop control in which a change in one measured variable (e.g. the flow) is used to adjust a subsequent process (e.g. the amount of chemical dosed). It is used to anticipate the effect of a disturbance on a process. In water treatment, feed forward control is found primarily as paced-to-flow control. For example, in a chemical dosing system, the flow rate signal goes to the dose pump speed controller output to compensate for changes in the flow. In dosing systems, a chemical dosing pump may have both stroke length and frequency control. One of these functions may be controlled using the plant flow rate (feed forward) and the other with a controller monitoring the effect of the dose - as a feedback control. Feed Back As the name implies, feed back control is where the effect of an action is measured and the action is adjusted to meet the set point required. Many control loops combine feed forward and feed back loops. The following diagram of a pH control system shows a common method of feed forward and feed back control. The signal from the flowmeter is summed with the output of the pH controller and controls the speed of the slurry pump. Any errors introduced by the feed forward action will be compensated for by the (closed loop, feed back) pH controller.

Otago Polytechnic Drinking Water Assessors Course US18455

Feedback Loop

Process Control

Page 18 of 54

Feedforward Loop

pH controller

Slurry Prep

pH Flow Slurry pump

Process tank

to downstream process

Diagram of Feed Forward Flow control with Feed Back pH Control 3.2.3 Control Action

When dealing with control systems, the term control action is often encountered. Control action describes the relationship between input and output signals for any controller. 1. Direct action - Output signal increases with increase in measured value. 2. Reverse action - Output signal decreases with increase in measured value. For example if the process is maintaining the water level in a tank, this can be achieved by changing the flow into the tank or by changing the flow out of the tank. The measured value in both cases is the tank level. With direct action, as the tank level increases, the flow out of the tank is increased. With reverse action, as the tank level increases, the flow into the tank is decreased. A float valve on the tank inlet would be a reverse action control. 3.3 Common Analogue Control Methods

Set out below are some of the methods by which controllers process data. This processing is essentially taking the input signal, doing some arithmetic on it and putting out an output signal. For example, if the input signal from a flowmeter is "7 ma", the processor will calculate from the input fixed parameters, that the output signal should be "12 ma" to instruct the lime dosing pump to pump the correct amount of chemical into the flow to maintain the desired chemical concentration. The "7ma" is the input signal; the "12 ma" is the output signal. In the example above, the feed back parameters may be:

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 19 of 54

Desired pH = 7.8 This is the process setpoint and the signal for this may be 9 ma. Actual pH = 8.1. The signal from the meter for this pH may be 10 ma.

The difference = (9 - 10) is the error. It is this error ( of - 1 ma) that is used to calculate a correction to the output signal (to the lime pump), changing it from 12 ma to perhaps 11.3 ma. How these calculations are made and how the error is used is set out below. 3.3.1 Proportional Control For any value of the input signal, there can be only one output signal value. The output signal is a function of the input signal and the gain (G). Gain is the ratio of the output signal to the input signal and is set by the operator. Typically controller gain ranges in value between 0.2 and 2. It is the "multiplying constant". The practical implementation of proportional control is Ratio-Bias control. In Ratio-Bias control an offset is added to the output signal so the output becomes (Input x Gain) + Bias Bias is an offset that may be added to the output. This value typically lies between 100% and +100% of signal range. It is a "fixed offset" used to correct some fixed error or step.

100% A Input This diagram shows how a ratio-bias controller acts. The slope of the line BA is a function of the gain of the controller. The value represented by point B is the bias added to the output. The bias value can be positive (as shown here) or negative. 100%

B Bias 0 Output (CO)

Diagram of a Ratio-Bias Signal Change 3.3.2 On/Off Control On/Off control is used mainly for pumps feeding a reservoir or similar "keep the tank within "X m" of full. It is also used for heating control, such as in the thermostat of a domestic heater or stove element, and is suited only to controlling processes that have a large inertia or buffer capacity so that additions to the system (e.g. heat or chemicals) only bring about a small change in its condition and in which precise control is not required. The figure below shows how a controller closes a relay as the measured process value (PV) falls below the lower control value and opens it when the PV rises to the upper control value.

Output turns off

PV

Control deadband

Output turns on

Time

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 20 of 54

Time proportional control is an enhanced form of On/Off control in which a discrete output turns on for only a fraction of the total cycle time. The fraction is proportional to the difference between the actual state and its setpoint. In water treatment, it is found primarily in dry powder feeders, where material may be fed into a solution tank for a fraction of the total period of each revolution of a feed screw.

Controller Output

On Off On Off As the input to the controller increases, the proportion of the output cycle during which the output is active increases (direct action). Another common example of time proportional control is in incandescent lamp dimmers. Here, the cycle time is 10 mS (for 50 Hz supply) and energy is supplied to the lamp for a part of this time. The thermal inertia of the lamp filament averages the energy supplied to it.

Controller input

On Off Output Cycle Time

Time Proportional Diagram of Inverse Controller (more in, less out) Time proportional control is useful only where the capacity of the process is such that intermittent control does not significantly affect output quality; for example, dry powder feeders where the capacity of the solution tank is very large in relation to the outflow from it. Differential Control Differential control can be considered an extension of on/off control. Here two outputs control the process.

Output 1 ON/OFF As the error rises above the upper deadband value, Output 1 turns ON. It turns OFF when the error falls below this value.

SP PV (Error)

Control As the error falls below the lower deadband value, deadband Output 2 turns ON. It turns OFF when the error rises above this value. Outputs may be named as Raise/Lower or Open/Close. shown or as

Output 2 ON/OFF

Time

Differential control is most often found as the positioner in electric actuators. 3.3.3 PID Controllers

PID controllers combine three types of control action: Proportional, Integral and Derivative. Often, they are found configured as PI controllers, with the derivative function disabled.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 21 of 54

Also known as multi-term or three term controllers, PID (capable) controllers are common and inexpensive. Most use digital processing to execute their PID algorithm. To achieve this, the analogue signals are converted to digital, the controller changes the value digitally and the signal is then re-converted to an analogue signal for transmission onwards. PI (or PID) controllers are used to establish better control response than proportional control offers. A simple example is a valve which is being used to control flow. With purely proportional control, half open would represent half the maximum flow being passed. Valves do not work linearly - half open may provide 70% of the flow. To allow for these "non-linearity's", PI or PID controllers are used. Proportional Control is the linear control shown above as Ratio bias control - with or without Gain and Bias. Proportional control goes on all of the time - the Integral and Derivative actions below are used to correct the proportional control output signal. Integral (I) Action Integral action adds up the error that has occurred over the integral (or "reset" time). This integral can be thought of as the average error. It uses this value to adjust the output signal from the controller. Integral action requires feed back signals to identify the error to be summed up. If there is no error, there is no integral correction to be made. In t e g r a l A c t io n D i a g r a m

8 .6 8 .5 Feed back signal - ma 8 .4 8 .3 8 .2 8 .1 8 .0 7 .9 7 .8 0 5 10 T i m e - se c o n d s 15 20

In this diagram, the set point = 8.0. The feed back signal varies from 7.9 to 8.55 ma and the average is 8.21 ma. The integral error is (8.21 - 8.0) = 0.21 ma. For process controllers, monitoring the controller output signal can give warning of wear in actuators. If a controllers output increases over time for similar operating conditions then the actuator should be examined. Feedback control is excellent at masking wear in actuators - the loss in movement due to wear is compensated for by Integral feedback.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 22 of 54

Incorrect settings of the integral value can lead to a condition known as reset windup. Reset windup occurs when the output signal exceeds the lower or upper output value of the controller (0, 100%), and can hold the controllers output at the limit value for a considerable period of time. Modern controllers provide an anti-reset windup function that limits the maximum and minimum values the integral function may generate. Reset may also be achieved manually. In manual reset, the operator removes the offset by shifting the output range. Appendix 3 shows how these differ. Derivative Action Derivative action calculates how quickly the output signal is being changed. It uses this rate to increase (or decrease) the output signal to allow a "bit extra" to anticipate the change occurring. Derivative action is present only when the input is changing. If there is no change occurring, there will be no derivative action. This input signal may be the process variable or may be the feed back error. Whichever is being used does not matter as the D parameter is tuned accordingly. So Derivative may be used with or without a feed back loop. Derivative control can be tricky to set up due to non-linearity in the process control loop. A derivative value that provides good control of a process for a given range of values can lead to instability if this range is exceeded. See appendix 3 for more details. 3.3.4 Custom Controls Control programmes can be written for almost any combination of conditions and arithmetic desired using digital devices such as PLC's set out in the next section. Without digital capability, complex control systems may still be set up (using analogue). Differential control, as with on/off, time proportional, analogue 4-20 ma linear or characterised (e.g. square root) are really just output options for any controller. They are classed as control methods as they are in common use and describe the manner in which the process is manipulated. Cascade control is used to improve control where long process time delays are present. Here the output of one controller provides the setpoint for a second which provides the output to the actuator. These are not often found in water treatment. For a chlorine control system, 60 minute residual would be controlled by one controller (probable PID) and the output of this controller would provide the setpoint for a 5 minute residual controller (also PID) which controlled the chlorine dosing. Any adjustment to allow for changes in flow ("pacing to flow") would be additional to this and would only be applied to the 5 minute controllers output. Some processes may not be controlled by a single control loop, particularly where control over a large range is required. Deadbands, turndown ratios, plant design, the control system and the process itself are the factors that dictate the type of control required.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 23 of 54

For a flow control system operating over a large range of flows a small bypass valve (V2) in parallel with the larger valve (V1) may be required to control low flows as follows:

Controller FC_1 controls the opening of V1 in response to changes in level TK_1. When PLC_1 controlling V1 senses that V2 is near the limit of its travel it adjusts V1 by a small amount less than the maximum flow through V2. V2 will then respond to the subsequent change in level.

PLC_1 V1

V2 TK_1 LT_1 FC_1

Ideally, plant would be designed and plant components chosen to avoid the need for this type of control system. Often this is the case but this type of control may need to be put in place when upgrading existing plant.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 24 of 54

Digital Control Systems

Digital control systems include computer based and programmable logic controller (PLC) based systems. 4.1 4.1.1 PLC Control Systems Introduction

PLCs were originally developed to replace hard wired (electromechanical) control systems. Analogue capabilities were limited to internal timers and counters. PLCs could be reprogrammed more quickly, and at less cost, than the systems they replaced. They are industrially hardened computers designed for reliability in harsh environments. Modern PLCs are capable of performing functions such as floating point mathematics and PID control. Their input and output (I/O) capability has increased and is no longer restricted to hard wired processes. One or more communication ports can transfer data to and from other PLCs or computer based workstations and display panels. Analogue control with PLCs is now commonplace. Programmed control methods for analogue control are very similar to those set out for dedicated controllers described earlier. This section will concentrate on the discrete control functions of PLCs. 4.1.2 Processing of Data Within a PLC

The PLC scans data - i.e. it reads the information coming in and the output data settings at a rate determined mainly by the size of the control program (logic). A typical PLC will then process data in a similar manner to this:

I/O

processin Internal Functions

(housekeeping)

logic

solving

PLC Data Processing Schematic At the start of each scan cycle, inputs are read and outputs written. Housekeeping tasks, such as updating I/O status and system time, are performed next. The PLC now has all the information it needs to start solving the programmed logic in order to send a signal to the actuator. Once the logic is solved the cycle is complete and a new cycle begins. The PLC repeats scan cycles as long as: The PLC is supplied with power. No internal faults are detected. No command to stop processing is received.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 25 of 54

4.1.3

Interacting with a PLC

Operator control panels provide a limited means to display and modify PLC data. They are often text based displays though panels having primitive graphics capabilities are available. The control panels fill the need for a device with which operators can change operational parameters without needing to re-programme the PLC using a programming device or software. They are used as local display devices for PLCs. 4.1.4 Programming PLC's

PLC programming is often performed with a graphical language called (Relay) Ladder Logic, which uses the symbols from electrical relay wiring diagrams. The name comes from the manner in which these wiring diagrams are drawn, with the power supply rails as vertical lines on each side of the drawing and the contacts, timers, relays etc drawn across the page between the rails, looking much like the rungs of a ladder. Special control languages and proprietary versions of BASIC have also been used to program PLCs. The attraction with ladder logic is the similarity with electrical wiring diagrams. Maintenance staff with a background in electrical servicing can understand programs written in this way. A programmer needs to be familiar with the functions provided within the PLC to be programmed. A detailed description of the process that the program is to control is also required, so that interlocks necessary for the safety of the plant and personnel can be included in the program. 4.1.5 Status Monitoring

Monitoring the operational status of actuators is a common function of PLCs. In order to ensure reliable operation, status monitoring logic forms a part of the PLC program. e.g. Typical electric valve actuators will have open and close control inputs and provide open and closed status to the PLC. The PLC needs to know whether or not the valve is operational. Failure of a switch (open or closed valve status) could cause the sequencing logic to wait indefinitely for this input to be sensed. It may be preferable to use status monitoring to abort the sequence. An example of how this may be achieved is shown in appendix 4 4.1.6 Safety Interlocks

Safety interlocks are provided to respond to plant failures or dangerous states occurring in a plant or process. Interlocks can be programmed to shut down a process or an entire plant under certain conditions. e.g. power failure. In this case the PLC program would include logic to (attempt to) drive all actuators to a rest or safe condition and to reset or reinitialise internal status flags and register values. Restart after such a shutdown would usually require action by a plant operator. Maintenance overrides disable interlocks. As their name suggests, these are provided for plant maintenance purposes only not operational work-arounds. Bypassing safety interlocks with maintenance overrides may be required to re-commission items after repair

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 26 of 54

but before returning them to service. It is often desirable to place interlocks on maintenance overrides to, say, prevent automatic operation while a maintenance override is active. 4.2 Computer Based Control

Computer based control systems include Distributed Control Systems (DCS) and Supervisory Control And Data Acquisition (SCADA) systems. 4.2.1 Distributed Control Systems

Distributed Control System (DCS) is a system in which control of a process is provided by multiple interconnected (networked) units. Typically a DCS combines SCADA and process control into one system. The components of the system are designed for reliability in service and include redundant data paths, operator interfaces and control processors. Individual controllers within the system are, as far as possible, capable of independent control. The main control processors can provide real-time and historical data to each loop controller. Each controller within the system is able to operate using the last received data should a failure occur elsewhere in the system. DCSs have a high initial cost, though maintenance costs should be lower. DCS architecture

Operator consoles

Multiple data paths Control processors I/O processors I/O

Schematic of Distributed Control System Components 4.2.2 SCADA Systems SCADA is an acronym for Supervisory, Control and Data Acquisition. Modern SCADA software provides many of the functions of DCSs at a lower cost. The following paragraphs examine some of the elements of a modern SCADA system. SCADA software has four basic components: a database, a means of collecting and transferring data to and from the control system, a means of displaying this data and the ability to manipulate this data. SCADA systems also raise and transmit alarms.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 27 of 54

Database The database is the heart of the software. It holds all the information for: Each input tag (database entry) System information such as time and date Flags that indicate the state of internal software functions Field data Data collection and transfer This takes place in three ways: Operator display and input To and from the control system through one or more network connections To and from files. Files may contain historical data or selected data from the system that can be read by other programs. Data collection in SCADA software involves the use of networks: Local Area Networks (LAN) over wire or fibre-optic cable and/or Wide Area Networks (WAN) via radio or landline. The differences between these are few. With both types, data will not be current, but will be subject to delay. In the case of LANs, delays will be measured in seconds or less and will be affected by PLC internal Input / Output (I/O) polling rates and update times configured in software. WANs will have update times measured in minutes. These delays are unavoidable. In networks that handle large amounts of traffic, data collisions can increase these delays. In each case, data from each network enters the computer through a single point. The integrity of this link should be monitored by the software and invalid or obsolete data should be flagged on displays. Data display This may be graphical, text based or a combination. Data display format is user defined within a system and is limited only by the capabilities of the software. At the time of writing, there is no standard for data display format. However, there are a number of generally accepted guidelines for designing graphics-based displays. Such displays or mimics, are graphical representations of the process or system. SCADA software imposes few limits on the format of these. Mimics should be designed to be user friendly for the various users of the system. Different classes of users have differing requirements for data presentation. Management might require data to be exported to a spreadsheet or report generation program. Maintenance personnel might want to monitor, say, data link integrity or internal PLC registers, for which text-based screens are usually more appropriate.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 28 of 54

It may be useful to have a series of illustrative screens, using pictures of the different areas of a plant, for display to visiting groups. The bottom line is that displays must satisfy the requirements of each user group. Data manipulation Data manipulation is performed by programs, or scripts, generated as part of the configuration of the software and run under control of the SCADA software. Firstly, raw data from a PLC on a network is converted to engineering units. This happens in the background - the data source, raw values and scaling data are defined, or programmed, within the database when the tag is created. The resultant value is stored in the database. Secondly, the stored data is converted to the attributes, such as block fill level, that have been programmed for data display on workstation mimics. Thirdly, the data is used in scripts (programs run under control of the SCADA software). Common types of script are: System or application scripts, which run whenever the software is running. Mimic or window scripts, which run whenever the associated mimic is displayed. Key scripts, which run whenever the associated key is activated. Data change scripts, which run when the associated tagname changes in value. Other types of scripts, e.g. condition scripts, may be provided. Time-based data is also held in tags in the tagname database as some of the default tags provided. These default tags may be used in the same manner as any other tag. Thus, selected data could be written to a disk file under control of the SCADA software at regular intervals. For example, a time-based data change script could write a summary of all motor run hours data in the system to a disk file or printer at midnight each day. Data could be selected for export to a file by an operator at any time and for any period and interval, subject to the limitations of the software or hardware. Alarms Alarm generation within SCADA software may be performed in several ways. Alarm values may be entered in the database for each alarm associated with individual tags. These include alarms such as limit values (high/low). Alarms for points on the system may also be generated with scripts that combine operational values. e.g. a script could be used to generate an alarm should a reservoir level be falling while its supply pump is running.

For display purposes, an alarm may be treated as any other tag in the system. Any display attributes that can be assigned to a tag can be applied to alarm display. Typically alarms use colour and blink, or flash, attributes to draw attention to themselves though they are not limited to these.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 29 of 54

Alarm logging functions may be included in software, allowing a record of recent alarms and/or currently active alarms to be displayed in formatted text. Formatting here will include the data displayed, the colours used for alarm states such as active alarms, acknowledged alarms and alarms returning to normal. Filtering of alarms by source and priority may also be provided.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 30 of 54

5 5.1

Critical :Points Definition of Critical Points

The critical points are those points where process or equipment failure could lead to a public health hazard. For control systems, this means that any control failure which would result in the primary process main process failing is a critical point. Both main systems and controls systems fail from time to time - there is no "fail-proof" system. However, efforts to fail to a safe condition can be made. 5.2 Power Supply

It is essential that alarm systems are powered and monitored separately from the main control system. Many systems will use SCADA for reporting main systems results and for transmitting alarms. The SCADA system centre must be separately powered so any power failure alarms can be generated and transmitted. It is usual to back this alarm system transmitter up with battery power for this reason. Power supply to both the main process systems and to the control and alarms systems is a critical point. Some larger water treatment plants have stand-by power generators to provide process capability during mains power failure. (Most of these were installed for the Y2K concerns). Many plants will shut down and rely upon stored water to supply for the relatively short time the mains supply is unavailable. Typical power losses are well under 2 hours although this may vary in different locations. 5.3 Process Monitoring:

Process monitoring is a means to determine that a process or plant is operating efficiently and safely. A plant operation log is the basic form of process monitoring and of verifying the correct implementation of a Public Health risk Management Plan. Process monitoring thus provides the plant operator with: A record of plant operation - Verification that the plant has been operating within its specifications, i.e. good control within limits and safe operation are achieved. A troubleshooting tool that may allow faults or problems to be detected before alarms or hazards occur. A record of any changes and the outcome, that are made within a plant A record of events that lead to alarms. This data may be useful to determine any changes that may be made to prevent or minimise future failures.

Without monitoring, alarms cannot be detected, generated, transmitted and reacted to. Process monitoring is thus a critical point in water treatment.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 31 of 54

A continuous recording of plant data is preferable. This may take the form of a paper-chart recorder or data logged and displayed on a computer based system. In each case the following are required: Accurate data sensors and recording instruments calibrated and operational. Sufficient data operational records can be valuable fault-tracing tools.

Both of these issues are critical points in water treatment. The frequency of instrument calibration will vary from plant to plant as well as instrument to instrument. Typical frequency of on-site comparisons with portable check equipment would be around one week. Full calibration frequencies are often monthly provided the weekly comparisons are good.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 32 of 54

Assignment

1. Analogue control: Either; a) Identify the controlled processes within a plant you are familiar with. Identify the type of controller and the control method actually used for each process. (Where several parallel process trains are present, use only one train per process.) Briefly describe the performance of at least two of the controlled processes and note any changes to the control system that might improve performance. Or b) In figure 8.1, reproduced here, a pH control system is shown. Not shown is any detail of the slurry preparation process in TK602. Assume a dry powder feeder is used to feed hydrated lime into the slurry tank. This dry powder feeder uses a rotating feed screw to dispense lime. Describe one method by which the feed rate can be varied, what type of controller might be used to automate this process and the control signals used. Include any assumptions made about the various components of the system.

YC601 MX602

AIC 601 pH AT 601 FT 601 MX601

TK602 Slurry Prep

TK601

P601

to downstream process figure 8.1

2. PLC Control: A treatment plant has three filters (of unspecified type) operating in parallel with each other that are to be automatically washed under PLC control. Under normal conditions a filter wash will begin after a set volume of water has been treated, the filter to be washed will be sequentially selected by the PLC. The conditions that must exist for a wash to start are to be identified in order that the required interlocks within the wash start logic may be programmed. Identify i) the conditions that must be present for a filter wash to proceed. ii) any conditions, in addition to treated water volume, that may be required to initiate a wash cycle. Include any assumptions you make about the filters characteristics.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 33 of 54

Appendix 1

Glossary of Terms

Note: Section 5.4 of Appendix 5 also lists some standard terms used in computer based control systems Accuracy: In process control, the limits within which an indicated value matches the actual value of a measured quantity. Normally expressed as a percentage of full scale (100%) value, e.g. 0.1% full scale. This method (% full scale) can cause confusion. It is not the same as accuracy expressed in percent of reading. Actuator: An output device that will produce mechanical movement in response to a suitable signal. Often prefixed with the type of signal required, e.g. Pneumatic Actuator. A/D: Short for Analogue to Digital. Describes the action of converting an analogue value to a digital representation (binary number) of that value. Analogue: As used here, describes data that may take any value between specified limit values, or a control system that processes this type of data. Bias or Manual Reset: An offset applied manually to an output signal in order to eliminate error resulting from proportional action. Burnout: The action performed when a failure of the input signal is detected. It drives the controller input to maximum (upscale) or minimum (downscale) input signal value. The action is user selectable. This function may apply only to certain input types within a controller. Burnout is intended to drive the controller output to a safe value on input signal failure. Other options such as move to a set value or hold last good value may also be found. Cascade Control: The use of two controllers to control a process where the output of one controller is the setpoint for the second. The output of the second controller manipulates the process. Usually employed where there are long process times. Closed loop: A control method in which a controller monitors a process to maintain the PV at setpoint. D/A: Short for Digital to Analogue. Describes the action of converting a binary number to an analogue value, or a device that performs this function. Deadband: The range of values over which no control or corrective action will take place. This can be useful to reduce the effect of noise in a control system. A deadband may be applied to a controller output to prevent hunting of the controlled device. It is usually an adjustable parameter. See also Hysteresis. Derivative (D) or Rate: Time interval by which derivative action advances proportional action. Indicates that a controller is capable of differential control action or the value of this parameter. Derivative control: Control action in which the output is proportional to the rate of change of the input.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 34 of 54

Deviation: The absolute difference in value between SP and PV (error) in a control loop. Deviation includes errors from all changes within a loop and includes offset. (see Offset.) Digital: As used here, refers to a method of signal processing that combines discrete bits into groups to represent a range of data values. The term is sometimes used to describe control signals that can take one of two values (see Discrete). Discrete: a) Describes a data value that may have one of two states, OFF or ON, such as a switch or a relay contact. b) Denotes a control system that processes data of this type. Distributed Control System: a control system in which control of a process is provided by multiple units. Disturbance: A change within a process. Error: The difference between the desired value (controller setpoint) and the actual value (PV). Feedback: The mechanism by which the result of a change in controller output is returned to the controller. Feedforward: A means of anticipating the effect of a disturbance on a process whereby a portion of a parameter change is added to the output of a controller. Fieldbus: A bi-directional digital communication protocol for field devices. Data is transferred over a common signal path to and from the addressed device(s). Reference: Fieldbus Technical Information. Yokogawa publication TI38K3A01-01E, 1st edition March 1998 Gain (G): The amplification factor of a controller. It is numerically equal to % change in output value / % change in input value for a controller. Hysteresis: A deadband, usually one that is inherent in the process or device. Integral (I) or (automatic) Reset: Indicates that a controller is capable of integral action, or denotes the value of this parameter. Integral control action: Control action in which the rate of change of output is proportional to the input. Loop: Denotes the scope of a single controller within a process. Includes the associated input and output devices and the process itself. Manipulated or Controlled Variable (MV or CV): The process parameter that is changed in order to maintain a process value at setpoint. In a gas chlorination control system, this would be the chlorine gas feed rate.

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 35 of 54

Mimic: A graphical representation of a process or system. Noise: In relation to process controllers, describes invalid signals or data in a system, usually resulting from fault conditions or external interference. Offset: The difference (error) between PV and SP arising from proportional action in a controller. (see Deviation) On/Off: Describes the state of a discrete input or output and a means of controlling a process variable. On/Off Control: On/Off control is useful only in systems that have sufficient capacity to average changes within them. Open loop: A control method in which the controller has no provision to monitor the effect on a process of its output. PID: Proportional Integral Derivative. Three types of control action often combined within one controller. PLC (Programmable Logic Controller): A computer that is purpose built to perform control functionality. These devices may be self contained with a set I/O configuration or they may be expandable by the addition of I/O modules to suit the application. Potentiometer: A variable resistor having three connections; one to each end of the resistive element and to a moving contact that moves on it. It is used in actuators to provide a signal proportional to the position of the output shaft. Also called a slidewire. Positioner: A simple controller that converts an analogue control signal to a suitable form of signal to control an associated actuator. Uses feedback from the actuator or final control element to determine actual position. Process Variable (PV): The process parameter that is being measured by the input sensor/transmitter/transducer; e.g. chlorine residual in a chlorination control system. This parameter is sometimes referred to as the Measured Variable (MV), which may lead to confusion with Manipulated Variable. Proportional Band (PB): i) A measure of the gain of a controller. Proportional Band is the percentage change in the input value (PV) required to produce a 100 percent change in the output and is expressed as a ratio. The term Proportional Gain is often used in place of Proportional Band. Proportional Band is related to gain by the expression: Gain = 100/Proportional Band. ii) Proportional Band is sometimes used to describe the input value, expressed as a percentage, that will produce a 100% output change. The correct term for this is Proportioning Band. Repeatability: A measure of the accuracy with which a transducer or instrument output duplicates its output under identical conditions. For most devices an error exists between

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 36 of 54

the output values for a given input value when approaching this value from above or below. SCADA (Supervisory Control And Data Acquisition): Computer software for the display and manipulation of control system data. Sensor: The device that senses the measured parameter, such as a pH electrode. Most sensors are also transducers. Setpoint (SP): The control target value for a process. The value at which a controller will attempt to maintain a process variable. Signal Transmitter: A Signal Transmitter, often just transmitter, is a device that conditions a signal for transmission to a controller or to another control system. Commonly used to denote the unit that senses and transmits a PV, as in pressure transmitter. Slidewire: See potentiometer Time proportional control: A control method for analogue process control where a discrete output turns on for a period of time, proportional to the setpoint and error values, of the total cycle time. Transducer: A Transducer converts a signal from one signal type to another; e.g. Pressure (P) to electrical current (I). True/False: Logical state of a discrete point. Frequently corresponds to On/Off state of the point, but this sense may be inverted. Turndown ratio: For any device, full scale value : minimum controllable value. For a pressure transmitter that can be calibrated between 50 and 1000 kPa, the turndown ratio is 20 : 1 (1000 / 50 : 1).

Otago Polytechnic Drinking Water Assessors Course US18455

Process Control

Page 37 of 54

Appendix 2

Analogue to digital signal conversion

Analogue to Digital (A/D) and Digital to Analogue (D/A) conversion are the terms used to describe the process of converting signals between digital and analogue formats. 1 D/A conversion

Digital to analogue conversion is fairly straightforward. The digital value is converted to an electric current by a network of resistors. In the following illustration, a four bit D/A converter (DAC) is used, though 12 - 16 bit (4096 - 65536 counts) converters are common.

VREF Bit 3 Bit 2 Bit 1 Bit 0 r 2r 4r 8r summed output This is a basic DAC, known as a weighted resistor DAC. Each bit of the digital number controls an electronic switch, which will be open when the bit is off, or zero, allowing no current to flow. For any bit that is on, the switch will be closed and a current equal to VREF / r, where r is the resistor value in ohms, will flow to the output. Note the ratios of the resistors used: the largest value is eight times the lowest here

A more practical type of DAC for use in an integrated circuit (IC) is the ladder network DAC. This uses only two values of resistor, one twice the value of the other.

VREF 2r Bit 3 2r Bit 2 r 2r Bit 1 2r Bit 0 2r r r This type of DAC can be readily incorporated in an integrated circuit and most DACs are based on this circuit. Operation of this circuit is more complex than the weighted resistor DAC above as all resistors contribute to the value output for all bit combinations.

The effect of D/A (and A/D) conversion is to create a signal that can take a finite range of values between upper and lower limits. The minimum increment for 12 bits is 1 in 212 = 4096. For 4 - 20 mA digitised as 12 bits, this minimum increment is equal to (20mA 4mA)/4096 or 0.0003.91 mA (0.024%). The only way this can be improved is by increasing the number of bits used for the conversion. 2 A/D conversion