Professional Documents

Culture Documents

Answer Final Exam Sem I 1213-Edit

Uploaded by

Amir SafwanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Answer Final Exam Sem I 1213-Edit

Uploaded by

Amir SafwanCopyright:

Available Formats

- 1 -

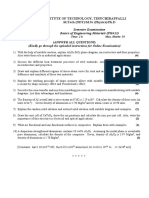

SULIT

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

PEPERIKSAAN AKHIR SEMESTER I

FINAL EXAMINATION SEMESTER I

SESI 2012/2013

SESSION 2012/2013

FAKULTI KEJURUTERAAN MEKANIKAL

ANSWER SCHEME

KOD MATAPELAJARAN : BMCB 1423

SUBJECT CODE

MATAPELAJARAN : SAINS BAHAN

SUBJECT MATERIALS SCIENCE

PENYELARAS : HAMZAH BIN MOHD DOM

COORDINATOR

KURSUS : BMCS/BMCD

COURSE

MASA : 2 JAM 30 MINIT SAHAJA

TIME 2 HOURS AND 30 MINUTES ONLY

TARIKH : 9 JANUARI 2013

DATE 9 JANUARY 2013

TEMPAT : KOMPLEKS SUKAN

VENUE KOMPLEKS SUKAN

ARAHAN KEPADA CALON

INSTRUCTION TO CANDIDATES

(1) Jawab hanya EMPAT (4) dari ENAM (6) soalan.

Answer only FOUR (4) out of SIX (6) questions.

(2) Markah keseluruhan bagi peperiksaan ini adalah 100 markah.

Total marks for this examination is 100 marks.

KERTAS SOALAN INI TERDIRI DARIPADA 21 MUKA SURAT SAHAJA

(TERMASUK MUKA SURAT HADAPAN)

THIS QUESTION PAPER CONTAINS 21 PAGES INCLUSIVE OF FRONT PAGE

SULIT

CONFIDENTIAL

SULIT

CONFIDENTIAL

(BMCB 1423)

- English Version-

- 2 -

SULIT

SULIT

Q1 The atom is a basic unit of matter that consists of a dense central nucleus surrounded

by a cloud of negatively charged electrons. The atomic nucleus contains a mix of

positively charged protons and electrically neutral neutrons (except in the case of

hydrogen-1, which is the only stable nuclide with no neutrons). The electrons of an

atom are bound to the nucleus by the electromagnetic force. Likewise, a group of

atoms can remain bound to each other by chemical bonds based on the same force,

forming a molecule. An atom containing an equal number of protons and electrons is

electrically neutral; otherwise it is positively or negatively charged and is known as an

ion. An atom is classified according to the number of protons and neutrons in its

nucleus: the number of protons determines the chemical element, and the number of

neutrons determines the isotope of the element. In chemistry and physics the idea of

the atom is a key concept. To understand many of the other concepts in chemistry

some knowledge of the atom is necessary.

(a) Primary Inter-atomic Bonds

i. Briefly cite the main differences between ionic, covalent, and metallic

bonding.

(2 marks)

ii. State the Pauli Exclusion Principle.

(2 marks)

(b) Calculate the force of attraction between a K

+

and an O

2

ion the centers of

which are separated by a distance of 1.6 nm.

(6 marks)

(BMCB 1423)

- English Version-

- 3 -

SULIT

SULIT

(c) Compute the percents ionic character of the interatomic bonds for the

following compounds: TiO

2

, ZnTe, CsCl, InSb, and MgCl

2

.

(10 marks)

(BMCB 1423)

- English Version-

- 4 -

SULIT

SULIT

(d) Explain type(s) of bonding would be expected for each of the following

materials: brass (a copper-zinc alloy), rubber, barium sulfide (BaS), solid

xenon, bronze, nylon, and aluminum phosphide (AlP).

(5 marks)

(BMCB 1423)

- English Version-

- 5 -

SULIT

SULIT

Q2 Structural engineering depends on the knowledge of materials and their properties in

order to understand how different materials support and resist loads.

(a) Explain why hydrogen fluoride (HF) has a higher boiling temperature than

hydrogen chloride (HCl) (19.4 C vs. 85 C), even though HF has a lower

molecular weight.

(6 marks)

(b) Show that the atomic packing factor for BCC is 0.68.

(5 marks)

(BMCB 1423)

- English Version-

- 6 -

SULIT

SULIT

(c) Iron has a BCC crystal structure, an atomic radius of 0.124 nm, and an atomic

weight of 55.85 g/mol. Compute and compare its theoretical density with the

experimental value found in Appendix A.

(8 marks)

(BMCB 1423)

- English Version-

- 7 -

SULIT

SULIT

(d) Calculate the radius of an iridium atom, given that Ir has an FCC crystal

structure, a density of 22.4 g/cm

3

, and an atomic weight of 192.2 g/mol.

(6 marks)

(BMCB 1423)

- English Version-

- 8 -

SULIT

SULIT

Q3 (a) Any deviation from the perfect atomic arrangement in a crystal is said to

contain imperfections or defects. Adding alloying elements to a metal is one

way of introducing a crystal defect. Crystal imperfections have strong

influence upon many properties of crystals, such as strength and electrical

conductivity. Thus some important properties of crystals are controlled by as

much as by imperfections and by the nature of the host crystals.

i. Describe what are interstitial and substitutional type defects? Providing

such illustrations is a must in supporting your answer.

(6 marks)

Answer

Interstitial defect impurity atom (smaller size) lie at the position in between of host

atom (larger size).

(BMCB 1423)

- English Version-

- 9 -

SULIT

SULIT

Example of interstitial solid solution defect of Carbon (orange) in Ferum (grey).

Substitutional defect Some impurity atom (prox same size w/host ) replace the

position of some of the host atom.

Example of substitutional solid soln. defect of Cu (orange) in Ni (grey).

ii. List and explain TWO (2) types of Planar Defects in solids.

(4 marks)

Answer

1. Twin Boundry Essentially a reflection of atom positions across the twin plane.

2. Stacking Faults For FCC metals an error in ABCABC packing sequence

become ABCABABC.

(b) Calculate the activation energy for vacancy formation in aluminum, given that

the equilibrium number of vacancies at 500 C (773 K) is 7.55 1023 m

3

. The

atomic weight and density (at 500 C) for aluminum are, respectively,

26.98 g/mol and 2.62 g/cm

3

.

(6 marks)

(BMCB 1423)

- English Version-

- 10 -

SULIT

SULIT

Answer

(c) Crystal imperfections are present in ceramic materials. These imperfections are

classified according to their geometry and shape. Explain and illustrate the

following imperfections that can exist in ceramics crystal lattices:

i. Frenkel imperfection.

(2 marks)

ii. Schottky imperfection.

(2 marks)

Answer

Frenkel imperfection

a cation vacancy-cation interstitial pair.

Schottky imperfection.

a paired set of cation and anion vacancies.

(BMCB 1423)

- English Version-

- 11 -

SULIT

SULIT

Schottky

defect

Frenkel

defect

(d) Using the data in the Table 3, predict the relative degree of solid solubility of

the following elements in aluminum:

(i) copper (ii) manganese (iii) zinc (iv) magnesium

(v) silicon

Use the scale as very high (70 - 100%); high (30 - 70%); moderate (10 - 30%);

low (1 - 10%); and very low ( <1%).

Table 3 Elemental Data

(5 marks)

Answer:

(i) low (ii) very low (iii) moderate (iv) high (v) low

Q4 (a) Solid state diffusion is a mean of matter transport within solid materials by

atomic motion. Two mechanisms are possible, which are vacancy and

interstitial diffusion.

i. Write the equation for Ficks first law of diffusion and define each of the

terms in SI units.

(2 marks)

1

1

(BMCB 1423)

- English Version-

- 12 -

SULIT

SULIT

Answer

dx

dC

D J =

ii. Explain on the factors that affect the diffusion rate in solid metal crystals?

(3 marks)

Answer

Diffusing Species The magnitude of the diffusion coefficient, D is indicative

of the rate at which atoms diffuse.

Temperature It has a most profound influence the coefficients and the

diffusion rates.

(b) With reference to Tabulation of Diffusion Data shown in Appendix B,

i. Calculate the diffusion coefficient for magnesium in aluminum at 450 C.

(2 marks)

Answer

D = D

0

exp

Q

d

RT

|

\

|

.

|

= (1.2 10

-4

m

2

/s)exp

131,000 J / mol

(8.31 J / mol - K)(450 + 273 K)

(

(

= 4.08 10

-14

m

2

/s

ii. Propose the time required at 550 C to produce the same diffusion result

(interms of concentration at a specific point) as for 15 h at 450 C.

(4 marks)

Answer

This portion of the problem calls for the time required at 550C to produce the

same diffusion result as for 15 h at 450C. Equation 6.7 is employed as

D

450

t

450

= D

550

t

550

Now, from Equation 6.8 the value of the diffusion coefficient at 550C is

calculated as

(BMCB 1423)

- English Version-

- 13 -

SULIT

SULIT

(

+

) 273 550 )( - / 31 . 8 (

/ 000 , 131

exp /s m 10 1.2 = ) (

2 4 -

550

K K mol J

mol J

D

= 5.76 10

-13

m

2

/s

Thus,

550

450 450

550

=

D

t D

t

=

(4.08 10

14

m

2

/s)(15h)

(5.76 10

13

m

2

/s)

= 1.06 h

(c) Atomic diffusion occurs in metallic solids mainly by a vacancy or substitution

mechanism and an interstitial mechanism. In fact, the atoms in solid materials

are in constant motion, rapidly changing positions.

i. Explain TWO (2) conditions that allow these atoms motion.

(3 marks)

1. Vacancies or other crystal defects are present which means there must be

an empty adjacent site.

2. There is enough activation energy. The atom must have sufficient energy

to break bonds with its neighbour atoms and then cause some lattice

distortion during the displacement.

ii. Describe why are the rates of diffusion in polymer materials are higher

than the metallic materials.

(3 marks)

Rates of diffusion are greater through amorphous regions than through

crystalline regions; the structure of amorphous material is more open for

which diffusive movements occur through small voids between polymer

chains from one open amorphous region to an adjacent open one. Whilst in

metals, the diffusion mechanism maybe considered to be analogous to

interstitial diffusion.

(BMCB 1423)

- English Version-

- 14 -

SULIT

SULIT

(d) A steel gasket of 2.5 mm thick is to be case-hardened in nitrogen atmosphere at

900

o

C at a steady-state diffusion condition. It is known that the concentration

of nitrogen in the steel at the high pressure surface is 2 kg/m

3

. The diffusion

coefficient for nitrogen in steel at this temperature is 1.2 x 10

-10

m

2

/s, and the

diffusion flux is found to be 1.0 x 10

-7

kg/m

2

-s. How far into the gasket from

this high-pressure side will the concentration be 0.5 kg/m

3

? How long will it

take for the nitrogen to completely reach the low pressure surface of the

gasket? Assume a linear concentration profile. (8 marks)

Q5 Mechanical properties of materials refer to the relationship between its response to an

applied load or force. It plays important roles in the structural applications and

processing of materials. Several material testing techniques, such as tensile test,

impact test and hardness test are used to measure mechanical properties of materials.

(a) Distinguish between:

i. Engineering stress and true stress.

(2 marks)

ii. Engineering strain and true strain.

(BMCB 1423)

- English Version-

- 15 -

SULIT

SULIT

(2 marks)

iii. Elastic and plastic deformation.

(2 marks)

Answer

(a)

i. Engineering stress: average uniaxial force divided by original cross-

sectional area.

o = F/A

o

.

True stress: average uniaxial force divided instantaneous minimum cross-

sectional area.

o = F/A

i

.

ii. Engineering strain: change in length of sample divided by the original length

of sample.

e = l/l

o

True strain:

iii. Elastic deformation: if a metal deformed by a force returns to its original

dimensions after the force is removed, the metal is said to be elastically

deformed.

Plastic deformation: if the metal deformed by a force not returns to its

original dimensions after the force is removed, the metal is said to be

elastically deformed.

(b) A bar of steel alloy that exhibits the stress-strain behavior shown in Figure 5 is

subjected to a tensile load; the specimen is 375 mm long and of square cross

section 5.5 mm on a side.

Figure 5 Tensile stress-strain behavior for alloy steel.

(BMCB 1423)

- English Version-

- 16 -

SULIT

SULIT

i. Compute the magnitude of the load necessary to produce an elongation of

2.25 mm.

(4 marks)

ii. Predict the deformation would be after the load has been released.

(3 marks)

Answer

(i)

This is within the elastic region; from the inset of Figure 5, this corresponds to

a stress of about 1250 MPa. Now,

in which b is the cross-section side length. Thus,

(ii) After the load is released there will be no deformation since the material

was strained only elastically.

(c) A cylindrical specimen of some metal alloy 10 mm in diameter is stressed

elastically in tension. A force of 15,000 N produces a reduction in specimen

diameter of 7 10

3

mm. Compute Poissons ratio for this material if its

elastic modulus is 100 Gpa.

(6 marks)

Answer

From Equations 7.5 and 7.1

c

z

=

o

E

=

F

A

0

E

=

F

t

d

0

2

|

\

|

.

|

2

E

=

4F

t d

0

2

E

Since the transverse strain

x

is just

c

x

=

Ad

d

0

and Poissons ratio is defined by Equation 7.8, then

(BMCB 1423)

- English Version-

- 17 -

SULIT

SULIT

v =

c

x

c

z

=

Ad / d

0

4F

t d

0

2

E

|

\

|

.

|

|

=

d

0

Ad t E

4F

=

(10 10

3

m)(7 10

6

m) (t)(100 10

9

N/ m

2

)

(4)(15,000 N)

= 0.367

(d) Why design/safety factor is important in engineering? List THREE (3) criteria

for which design/safety factors to be based on.

(6 marks)

Answer

It is important in order to avoid, thus to protect the design against

unanticipated failure.

The criteria upon which factors of safety are based are (1) consequences of

failure, (2) previous experience, (3) accuracy of measurement of mechanical

forces and/or material properties, and (4) economics.

(BMCB 1423)

- English Version-

- 18 -

SULIT

SULIT

Q6 (a) Iron-carbon phase diagram contains ferrite, austenite, cementite (Fe

3

C) and

o ferrite as solid phases is shown in Figure 6.1. The phase diagram may be

divided into two parts; an iron-rich portion (0 wt% C to 6.70 wt% C) and the

other (not shown) for composition between 6.70 wt% C to 100 wt% C (pure

graphite).

Figure 6.1 Iron-carbon phase diagram.

i. Define austenite and cementite phases that exist in the iron-carbon phase

diagram.

(4 marks)

ii. Distinguish between hypoeutectoid and hypereutectoid plain carbon

steel.

(4 marks)

(b) Referring to the Pb-Sn phase diagram in Figure 6.2, consider the very slow

cooling (i.e. equilibrium cooling) of a 40 wt% Sn alloy.

+ Fe

3

C

, Austenite

+ L

L

+ Fe

3

C

, Ferrite

Cementite (Fe

3

C)

+

o

727

o

C

1147

o

C

1493

o

C

4.30

2.14

0.76

0.022

1394

o

C

1538

o

C

912

o

C

15 20 10

5

25

0

2500

2000

1500

1000

400

600

800

1000

1200

1400

1600

Composition (at% C)

Composition (wt% C)

1 2 3 4 5 6

6.70

0

(Fe)

T

e

m

p

e

r

a

t

u

r

e

(

o

C

)

T

e

m

p

e

r

a

t

u

r

e

(

o

F

)

(BMCB 1423)

- English Version-

- 19 -

SULIT

SULIT

i. Draw schematic sketches of the microstructures that would be observed

at 300 C, 200 C, 180 C and 100 C. Be sure to label all of the phases

that are present and indicate the composition of each phase.

(4 marks)

ii. Indicate the pro-eutectic (or primary) phase in this alloy.

(2 marks)

iii. At 180 C, determine the phase amounts (or relative amounts) of the:

a) pro-eutectic (or primary) phase

b) eutectic

c) eutectic

(3 marks)

Figure 6.2 Pb Sn Phase Diagram

(BMCB 1423)

- English Version-

- 20 -

SULIT

SULIT

(c) Refer to the isothermal transformation diagram (or TTT curve) for eutectoid steel

is a showed in Figure 6.3. For each of the two cooling sequences outlined below,

indicate the approximate percentages of each phase present after every cooling

step. Assume that the starting microstructure is 100% austenite held at 800 C.

Figure 6.3 Isothermal Transformasi Diagram

i. Rapidly cool to 650 C and hold for 20 seconds, then rapidly cool to 350 C

and hold for 10 seconds, then quench to room temperature.

(4 marks)

ii. Rapidly cool to 630 C and hold for 10 seconds, then rapidly cool to 450 C

and hold for 10 seconds, and then quench to room temperature.

(4 marks)

- END OF EXAMINATION QUESTIONS -

(BMCB 1423)

-Versi Bahasa Malaysia-

- 21 -

SULIT

SULIT

APPENDIX A/LAMPIRAN A

Characteristics of Selected Elements

Aluminum Al 13 26.98 2.71 FCC 0.143 0.053 3+ 660.4

Argon Ar 18 39.95 - - - - Inert -189.2

Barium Ba 56 137.33 3.5 BCC 0.217 0.136 2+ 725

Beryllium Be 4 9.012 1.85 HCP 0.149 0.095 3+ 1278

Cadmium Cd 48 112.41 8.65 HCP 0.149 0.095 2+ 321

Calcium Ca 20 40.08 1.55 FCC 0.197 0.100 2+ 839

Carbon C 6 12.011 2.25 Hex. 0.071 ~0.016 4+

(Sublimes

@3367)

Fluorine F 9 19.00 - - - 0.133 1- -220

Gold Au 79 196.97 19.32 FCC 0.144 0.137 1+ 1064

Helium He 2 4.003 - - - - Inert

-

272(@26atm)

Hydrogen H 1 1.008 - - - - 1+ -259

Iodine I 53 126.91 4.93 Ortho. 0.136 0.220 1- 114

Iron Fe 26 55.85 7.87 BCC 0.124 0.077 2+ 1538

Lead Pb 82 207.2 11.35 FCC 0.175 0.120 2+ 327

Lithium Li 3 6.94 0.534 BCC 0.152 0.068 1+ 181

Magnesium Mg 12 24.31 1.74 HCP 0.160 0.072 2+ 649

Manganese Mn 25 54.94 7.44 Cubic 0.112 0.067 2+ 1244

Mercury Hg 80 200.59 - - - 0.110 2+ -38.8

(BMCB 1423)

-Versi Bahasa Malaysia-

- 22 -

SULIT

SULIT

Molybdenum Mo 42 95.94 10.22 BCC 0.136 0.070 4+ 2617

APPENDIX B/LAMPIRAN B

Tabulation of Diffusion Data

Diffusing

Species

Host Metal D

o

(m

2

/s)

Activation Energy Q

d

Calculated Values

kJ/mol eV/atom T (

o

C) D (m

2

/s)

Fe -Fe (BCC) 2.8 x 10

-4

251 2.60 500 3.0 x 10

-21

900 1.8 x 10

-15

Fe -Fe (FCC) 5.0 x 10

-5

284 2.94 900 1.1 x 10

-17

1100 7.8 x 10

-16

C -Fe 6.2 x 10

-7

80 0.83 500 2.4 x 10

-12

900 1.7 x 10

-10

C -Fe 2.3 x 10

-5

148 1.53 900 5.9 x 10

-12

1100 5.3 x 10

-11

Cu Cu 7.8 x 10

-5

211 2.19 500 4.2 x 10

-19

Zn Cu 2.4 x 10

-5

189 1.96 500 4.0 x 10

-18

Al Al 2.3 x 10

-4

144 1.49 500 4.2 x 10

-14

Cu Al 6.5 x 10

-5

136 1.41 500 4.1 x 10

-14

Mg Al 1.2 x 10

-4

131 1.35 500 1.9 x 10

-13

Cu Ni 2.7 x 10

-5

256 2.65 500 1.3 x 10

-22

(BMCB 1423)

-Versi Bahasa Malaysia-

- 23 -

SULIT

SULIT

EQUATIONS:

% Ionic Character = { 1 exp[-(0.25)(X

A

X

B

)

2

] } x 100

You might also like

- Solutions Manual to accompany Engineering Materials ScienceFrom EverandSolutions Manual to accompany Engineering Materials ScienceRating: 4 out of 5 stars4/5 (1)

- A Sample of The Completed Essential Principles Conformity Checklist MD CCLDocument12 pagesA Sample of The Completed Essential Principles Conformity Checklist MD CCLAyman Ali100% (1)

- Tutorials PT 1 - Materials ScienceDocument19 pagesTutorials PT 1 - Materials ScienceVassish DassagneNo ratings yet

- EEE 307 - Term QuestionDocument17 pagesEEE 307 - Term QuestionsanathNo ratings yet

- 신소재과학 시험문제모음Document9 pages신소재과학 시험문제모음Hanjin SeoNo ratings yet

- 12 Chemistry Important Questions Solid State 01Document7 pages12 Chemistry Important Questions Solid State 01Shahariya ShejeerNo ratings yet

- Engineering Physics - I - PH6151 Important 2 Marks With AnswersDocument23 pagesEngineering Physics - I - PH6151 Important 2 Marks With AnswersZaffu Zealy100% (4)

- Model Test Paper 2Document3 pagesModel Test Paper 2Aman bansalNo ratings yet

- 1st Exam 2013Document2 pages1st Exam 2013Lisa YeohNo ratings yet

- ENT145/3 Materials Engineering Tutorial 1 (Answer)Document9 pagesENT145/3 Materials Engineering Tutorial 1 (Answer)Hữu Danh NguyễnNo ratings yet

- November 2011 Main ExamDocument7 pagesNovember 2011 Main ExamMduduzi Magiva MahlanguNo ratings yet

- Askelandphulenotes Ch02printableDocument53 pagesAskelandphulenotes Ch02printablelucaslirasilveiraNo ratings yet

- Ceramics Engineering Exam Questions on Properties, Processing and ApplicationsDocument15 pagesCeramics Engineering Exam Questions on Properties, Processing and ApplicationsUtpal RoyNo ratings yet

- Lectut-MTN-105-Doc-MT 201A-Tutorial - CH 1 (4 Files Merged)Document9 pagesLectut-MTN-105-Doc-MT 201A-Tutorial - CH 1 (4 Files Merged)Vikhyath KstNo ratings yet

- The Solid State Previous Qns. and AnswersDocument7 pagesThe Solid State Previous Qns. and AnswersSooraj SubhashNo ratings yet

- XII Chemistry Question Bank Chapter 1 Solid StateDocument134 pagesXII Chemistry Question Bank Chapter 1 Solid StateShivam AroraNo ratings yet

- 2k19 6th Sem Final - WatermarkDocument14 pages2k19 6th Sem Final - WatermarkVishal kumarNo ratings yet

- CH205 Test 1 2021Document6 pagesCH205 Test 1 2021avnishnandNo ratings yet

- Assignment 1Document3 pagesAssignment 1MainzaNo ratings yet

- Phy June 10 PDFDocument3 pagesPhy June 10 PDFNivedh VijayakrishnanNo ratings yet

- Nanyang Technological University Continuous Assessment Exam - I CBC111 – Principles of Modern Chemistry with Laboratory I CM1021 – Basic Inorganic Chemistry with Laboratory IDocument4 pagesNanyang Technological University Continuous Assessment Exam - I CBC111 – Principles of Modern Chemistry with Laboratory I CM1021 – Basic Inorganic Chemistry with Laboratory IJoey Tay Wei YingNo ratings yet

- VJT Mumbai Applied Physics 1 ExamDocument2 pagesVJT Mumbai Applied Physics 1 ExamAmbuja senapatiNo ratings yet

- Eg2010 2021 SP2Document8 pagesEg2010 2021 SP2Edwin JomonNo ratings yet

- PHM Question ............. 22222Document4 pagesPHM Question ............. 22222Jonathan LukwichiNo ratings yet

- Chemistry and Aliphatic Hydrocarbons: Questions1 Carry19 Marks and Questions 2, and 3 Carry18.5 Marks EachDocument2 pagesChemistry and Aliphatic Hydrocarbons: Questions1 Carry19 Marks and Questions 2, and 3 Carry18.5 Marks EachIngita DeymunshiNo ratings yet

- 86 95Document167 pages86 95Ashwin KirtaneNo ratings yet

- PG, 1 Sem, Apc, CC-1, Question Paper - Jan 23Document3 pagesPG, 1 Sem, Apc, CC-1, Question Paper - Jan 23Pralay MaitiNo ratings yet

- Class 12 Study Material Chemistry SA-1Document92 pagesClass 12 Study Material Chemistry SA-1VipinVKumarNo ratings yet

- 12th Chemistry Full Study Material em PDFDocument258 pages12th Chemistry Full Study Material em PDFSONANo ratings yet

- 1 Crystal Defects - Ch04Document72 pages1 Crystal Defects - Ch04Kimberly Joy FerrerNo ratings yet

- Ph2161 Engineering Physics IIDocument3 pagesPh2161 Engineering Physics IIClement RajNo ratings yet

- Assignment 1 E FDocument2 pagesAssignment 1 E FSudhananda MallickNo ratings yet

- Chemistry Study Material For CBSE Class-12Document246 pagesChemistry Study Material For CBSE Class-12Apex Institute75% (4)

- Chemistry Study Material - 2011-12Document246 pagesChemistry Study Material - 2011-12Harsh BhambhaniNo ratings yet

- Question Bank For First Year First Sem Question Bank For Physics-I Regulation 20913Document21 pagesQuestion Bank For First Year First Sem Question Bank For Physics-I Regulation 20913PRIYA RAJINo ratings yet

- The Solid State: Unit-1Document7 pagesThe Solid State: Unit-1Rams ChanderNo ratings yet

- BEM PH613 Semester Exam Question PaperDocument1 pageBEM PH613 Semester Exam Question PaperAdarsh ChaturvediNo ratings yet

- ANSWER Final EGMDocument9 pagesANSWER Final EGMAndil MaulanaNo ratings yet

- Study SET 1 SimplfiedDocument2 pagesStudy SET 1 SimplfiedTheMasterOf MCNo ratings yet

- Module I-V MCQs 2 Marks 18CYB101J Virtual ExaminationDocument25 pagesModule I-V MCQs 2 Marks 18CYB101J Virtual ExaminationMAHESHWAR M R (RA2111004010136)No ratings yet

- CHE 1010 Tutorial Sheet 3Document5 pagesCHE 1010 Tutorial Sheet 3Chimuka Onson MapikiNo ratings yet

- Inorganic Chemistry-IiDocument2 pagesInorganic Chemistry-IiNimish GargNo ratings yet

- List of Chemistry Question Bank Members for Class XIIDocument167 pagesList of Chemistry Question Bank Members for Class XIIPrasad YarraNo ratings yet

- Solid State: Subjective Question For Board ExaminationDocument14 pagesSolid State: Subjective Question For Board ExaminationzohaibsalamNo ratings yet

- Chem 150 PS1 2014Document5 pagesChem 150 PS1 2014Jay CaoNo ratings yet

- Chemistry (Paper - Vii) : Bangalore UniversityDocument12 pagesChemistry (Paper - Vii) : Bangalore UniversityMonica SrinivasanNo ratings yet

- 499347059chemistry Question Bank (2013-14)Document94 pages499347059chemistry Question Bank (2013-14)amanverma60% (1)

- Rr10201-Solid State PhysicsDocument8 pagesRr10201-Solid State PhysicsSRINIVASA RAO GANTANo ratings yet

- TCW1202201408 Material Science.Document3 pagesTCW1202201408 Material Science.Tanaka MurekachiroNo ratings yet

- Lab Module - HollowAgAuNP - 2016 VersionDocument8 pagesLab Module - HollowAgAuNP - 2016 VersionMohamed AslamNo ratings yet

- Midterm MTE111 S2014 With SolutionDocument7 pagesMidterm MTE111 S2014 With SolutionVarij GosineNo ratings yet

- Understanding Crystalline Solids and Their PropertiesDocument1 pageUnderstanding Crystalline Solids and Their Propertiesilias19730% (1)

- Tutorial Questions - Physics Component - 11Document5 pagesTutorial Questions - Physics Component - 11CalvinhaoweiNo ratings yet

- Surface Plasmon Enhanced, Coupled and Controlled FluorescenceFrom EverandSurface Plasmon Enhanced, Coupled and Controlled FluorescenceNo ratings yet

- Molecular Modeling of Corrosion Processes: Scientific Development and Engineering ApplicationsFrom EverandMolecular Modeling of Corrosion Processes: Scientific Development and Engineering ApplicationsChristopher D. TaylorNo ratings yet

- Endohedral Metallofullerenes: Fullerenes with Metal InsideFrom EverandEndohedral Metallofullerenes: Fullerenes with Metal InsideNo ratings yet

- Molecular Modeling of Geochemical Reactions: An IntroductionFrom EverandMolecular Modeling of Geochemical Reactions: An IntroductionJames D. KubickiNo ratings yet

- Tcs Gas TurbineDocument3 pagesTcs Gas TurbineAmir SafwanNo ratings yet

- Pampas Malacca Beverage Menu September2015Document1 pagePampas Malacca Beverage Menu September2015Amir SafwanNo ratings yet

- En Gbpjpy 20170802 MDocument1 pageEn Gbpjpy 20170802 MAmir SafwanNo ratings yet

- Archer c1200 (Us) v1 UgDocument111 pagesArcher c1200 (Us) v1 UgAmir SafwanNo ratings yet

- PETRONAS Floating LNG1 (PFLNG SATU) Activity Outlook 2018-2020Document35 pagesPETRONAS Floating LNG1 (PFLNG SATU) Activity Outlook 2018-2020ssgkooiNo ratings yet

- Assignment 1 2016Document1 pageAssignment 1 2016Amir SafwanNo ratings yet

- SV 100 Percent Credit BonusDocument5 pagesSV 100 Percent Credit BonusAmir SafwanNo ratings yet

- TA-Ingles IX - UAPDocument10 pagesTA-Ingles IX - UAPmanuel brennerNo ratings yet

- Practice of Epidemiology Performance of Floating Absolute RisksDocument4 pagesPractice of Epidemiology Performance of Floating Absolute RisksShreyaswi M KarthikNo ratings yet

- Chennai's 9 sewage treatment plants process 486 MLDDocument5 pagesChennai's 9 sewage treatment plants process 486 MLDmoni_john_1No ratings yet

- Scaffolding Control & MeasuresDocument3 pagesScaffolding Control & Measuresviswamanoj100% (1)

- Forest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundDocument4 pagesForest Fire Detection and Guiding Animals To A Safe Area by Using Sensor Networks and SoundAnonymous 6iFFjEpzYjNo ratings yet

- Grade 3 science syllabus 1st and 2nd semesterDocument2 pagesGrade 3 science syllabus 1st and 2nd semesterelyzabeth SibaraniNo ratings yet

- Medpet Pigeon ProductsDocument54 pagesMedpet Pigeon ProductsJay Casem67% (3)

- Cellular Basis of HeredityDocument12 pagesCellular Basis of HeredityLadyvirdi CarbonellNo ratings yet

- Hinduism Today April May June 2015Document43 pagesHinduism Today April May June 2015jpmahadevNo ratings yet

- Cell City ProjectDocument8 pagesCell City ProjectDaisy beNo ratings yet

- MR23002 D Part Submission Warrant PSWDocument1 pageMR23002 D Part Submission Warrant PSWRafik FafikNo ratings yet

- Treatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Document5 pagesTreatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Victoria LeahNo ratings yet

- Himalayan University Fees Structure 1-1-19Document8 pagesHimalayan University Fees Structure 1-1-19Anonymous F4GQLmyPZNo ratings yet

- A. Kumar Aswamy Job Offer LetterDocument1 pageA. Kumar Aswamy Job Offer LetterHimanshu PatelNo ratings yet

- M-LVDT: Microminiature Displacement SensorDocument2 pagesM-LVDT: Microminiature Displacement Sensormahdi mohammadiNo ratings yet

- InjectorDocument23 pagesInjectorBac Nguyen100% (1)

- DPW Series Profile Wrapping Application HeadDocument2 pagesDPW Series Profile Wrapping Application HeadNordson Adhesive Dispensing SystemsNo ratings yet

- Business Startup Practical Plan PDFDocument70 pagesBusiness Startup Practical Plan PDFShaji Viswanathan. Mcom, MBA (U.K)No ratings yet

- Family MedicineDocument156 pagesFamily MedicinedtriggNo ratings yet

- Manual Masina de Spalat Slim SamsungDocument1,020 pagesManual Masina de Spalat Slim SamsungPerfectreviewNo ratings yet

- 2016.05.16 - Org ChartDocument2 pages2016.05.16 - Org ChartMelissaNo ratings yet

- History of The Stethoscope PDFDocument10 pagesHistory of The Stethoscope PDFjmad2427No ratings yet

- Gebauer 2012Document26 pagesGebauer 2012Seán GallagherNo ratings yet

- Calm Your Aggressive DogDocument58 pagesCalm Your Aggressive DogASd33475% (4)

- Health 6 Q 4 WK 6 Module 6 Version 4Document16 pagesHealth 6 Q 4 WK 6 Module 6 Version 4Kassandra BayogosNo ratings yet

- Female Reproductive System Histology IDocument5 pagesFemale Reproductive System Histology ISolomon Seth SallforsNo ratings yet

- Dr. Namrata Misra Head of Bioinnovations at KIIT UniversityDocument1 pageDr. Namrata Misra Head of Bioinnovations at KIIT Universitymanisha maniNo ratings yet

- Ucg200 12Document3 pagesUcg200 12ArielNo ratings yet

- Reach Out and Read Georgia Selected For AJC Peachtree Road Race Charity Partner ProgramDocument2 pagesReach Out and Read Georgia Selected For AJC Peachtree Road Race Charity Partner ProgramPR.comNo ratings yet