Professional Documents

Culture Documents

Robotics Welding Brochure

Uploaded by

Ivan AvramovOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Robotics Welding Brochure

Uploaded by

Ivan AvramovCopyright:

Available Formats

Robotic Welding Solutions

Why Automation? Why Miller?

Workforce transitions

As the workforce shifts from manual labor to highly technological jobs, Miller offers a solution that addresses the shortage of skilled welders robotic automation. Although the prospect of automation can be intimidating, companies large and small are turning to robotic welding because it: r Increases productivity r Prevents over-welding r Improves rst-pass weld quality r Produces less scrap and rework r Complies with safety regulations r Lowers the cost of doing business

Simple Solutions with Pre-Engineered Performance

Your one-stop resource

r Automate with just a single point of contact a Miller welding professional can guide you through every step of the automation process. r Work with partners you know and trust your Miller representative and local welding distributor. r Choose from among the industrys best automation system integrators and robot suppliers. r Bene t from real system intelligence and partnership that delivers all the performance you need. Businesses of all sizes can bene t from automation. Companies with as few as two employees have purchased Miller robotic welding automation equipment and experienced great success on many levels, including performance, payback and new technology applications. We have developed a family of pre-engineered solutions integrating Panasonic robots, servo positioners and Miller welding technology to solve your fabrication challenges. This seamless integration makes learning the process easier, allowing you to concentrate on other areas of your business.

Your trusted welding partner

Miller provides unparalleled customer support and partners with welding distributors to improve your business and provide solutions for the toughest welding challenges. As your guide every step of the way, we can evaluate all the automation options available to you, then recommend the robot system and integration partner that ts your needs. We can also provide upgrade options and explain their costs versus bene ts.

Reach and Capacity for Any Application

TA-1000G2/WG

Max reach: 1068 mm 6 kg (13 lb.) payload

TA-1400G2/WG

Max reach: 1374 mm 6 kg (13 lb.) payload

Unlimited Applications

TA and TB Series robots

The latest generation of robotic manipulators incorporates 3D design and nite element analysis (FEA) to optimize rigidity and speed in the TA and TB Series robotic lines. Larger motors and drives, together with high-end servo control algorithms, make the TA Series more than 50 percent faster than our previous generation of robots while the TB Series features a through-arm design for tight-access applications. With unlimited exibility, these robotic manipulators are ready to work in your toughest applications. r Advanced sensitivity When servo control algorithms detect undue load on the robot during motion, they drop servo power to a soft state to protect the robot from collisions. r Less interference A curved arm design, offset wrist and slim pro le reduce robot self-interference, allowing for larger overall working ranges. r Safety compliance The most rigorous safety standards ensure your investment is not only productive, but safe for your employees (RIA, UL and c-UL compliant). r Easy to operate Each teach pendant runs Microsoft Windows CE with a 7-inch color thin lm transistor (TFT) display and uses common computer commands, which makes learning the process easier. r Adaptive ll When combined with Multi-Pass software and Root Pass Memorization, the robot can repeat a weld pattern while adapting to the changing part. The specialized programming menus on the robot are designed speci cally for this process. The visual macros and graphical prompts make this software easy to understand and easy to use. The robot can weld real-world parts with variation. Your quality goes up and your teaching time goes down. Adaptive ll senses the edges of the weld joint as the robot weaves back and forth. The robot then adjusts the amplitude of the weave points based on the arc sensing at the weaving edges. The robot will adjust welding travel speed based upon the changing weaving amplitude and the feedback from the welding arc, giving a consistent ll, even though the joint dimensions are changing.

TA-1600G2/WG

Max reach: 1598 mm 8 kg (17.6 lb.) payload

TA-1800G2/WG

Max reach: 1796 mm 8 kg (17.6 lb.) payload

TA-1900G2/WG

Max reach: 1895 mm 6 kg (13 lb.) payload

TB-1400G2/WG

Max reach: 1437 mm 4 kg (8.8 lb.) payload

TB-1800G2/WG

Max reach: 1802 mm 4 kg (8.8 lb.) payload

TA CONTROLLER

TEACH PENDANT 4 5

Technical Innovation

Continuous evolution with MIG

Using Embedded Arc Control Technology (EAC)

EAC technology creates new opportunities

TAWERS comes standard with EAC technology, which eliminates the need for three control systems by combining the robot, welder and servo wire feeder controls into a single unit. Contained inside the robot controller, this new system is monitored by the TAWERS 64-bit main CPU. EAC technology controls the robot motion path, and synchronizes the welding power supply and servo wire feeder to adjust for dynamic changes in the welding process. TAWERS soars beyond conventional digital communication systems, delivering the rst generation of fully software-controlled robotic welding solutions. r Robot lift start When the robot senses current ow during the arc start process, it creates the arc using voltage not current to dramatically limit ignition spatter and increase rst arc strike ef ciency. r Robot lift end The robot lifts to end the weld cratering process, eliminating wire-stick detection and burnback times, while simultaneously sharpening the welding wire. r Optional embedded arc data monitoring By screening variables and data for quality control, you can nd root causes to problems that could result in a suspect part reaching the end customer.

TAWERS aluminum MIG r Aluminum package can be retro tted to any existing TAWERS robot. r Servo wire feed system is ultra-stable. r Lift-start function improves arc starting. r Low-pulse function allows for oscillation between two parameters (highlow) during welding, producing the Pro le Pulse stacked dime weld bead appearance without back-stepping. r Synchro-weave function provides true synchronous and instantaneous control of wire feed, parameter control and robot motion while weaving between plates of unequal thicknesses.

Continuous evolution with TIG

TAWERS high deposition TIG r TIG package can be retro tted to any existing TAWERS robot. r Touch-start function eliminates high-frequency noise during arc starts. r Unique ller wire arrangement reduces feeding-related issues. r Wire can enter puddle from any position. r Current shunt function preheats ller metal to improve wire deposition. r Embedded arc control function provides true synchronous control of wire feed, parameter control and robot motion. Pro le Pulse stacked dime weld bead appearance without back-stepping is easily achieved. r Torch design is compact. r Arc voltage height-control function is optional.

External Welding Power Supplies

GBII-350

r Spatter-controlled High-end waveform algorithms control welding spatter during the MIG (CV) process, minimizing the ball size and adhesion of the spatter and increasing the deposition ef ciency, especially when welding with 100% CO2.

Auto-Axcess E with Insight

r Defect detection Auto-Axcess E with Insight weld data monitoring can detect when welding feedback is outside its predetermined limits. On a weld-by-weld basis, Insight can monitor current, voltage, wire feed speed, gas ow and duration to ensure that all welds are applied according to speci cations and it can shut down the system when critical faults occur. r Management information Insight Reporter drives welding process improvement using productivity, totalization and quality information, including robot cell state, arc time, parts produced, welds produced, wire used, gas used, downtime and overall equipment effectiveness (OEE). r Ethernet Using the Auto-Axcess E custom dashboard, you can monitor as many as 10 critical system attributes at one time from virtually anywhere in the world. You can even change system con guration settings and update rmware via Ethernet connection.

External Welding Power Supplies

Auto-Axcess systems for robotic automation

r Fully digital Digital communication is possible via a connection to any Panasonic robot system PC tools (RSPCT) robot controller with plug-and-play capability and full waveform control from the teach pendant. r Capable of low-voltage and thin-gauge welding The optimized waveform control allows stable arc control at low voltages for excellent thin-gauge welding.

HMII-350/HMII-500

r Flexible Three interactive Pulse control modes (soft, hard, hybrid) accommodate various applications and help cover gaps, reduce spatter and customize the arc to your speci cations. r Quick and clean Two starting modes (MIG [CV] and Pulse) use a patented two-step high current impulse routine for virtually instantaneous spatterfree arc starts. r High quality Patented dip Pulse technology clears shorts caused by puddle interference, minimizing spatter adhesion in a real-time routine to provide higher travel speeds and improved welding quality. r Fully digital Digital communication is possible via a connection to any Panasonic Series robot controller with plug-and-play capability and full waveform control from the teach pendant.

Auto-Axcess offers seamless integration of digital control technology by combining an inverter welding power source with a robotic interface. AA-40GB wire drive motor assembly with over current protection (OCP) to protect against current surges. New design uses an improved sheet metal enclosure including printed circuit board. It features a threaded gas connection and a direct-panel-mounted, quarter-turn motor control cable connection that eliminates motion stress on the motors power and tachometer feedback wires. 72-pin HARTING connector for quick, easy connection to common analog robot controllers. DeviceNet connector for quick, easy connection to common robot controllers with standard DeviceNet cables. Auto-CAL, a patented automatic calibration feature that uses the Auto-Axcess internal digital technology to allow simple, automatic scaling and synchronization to analog robot controllers. This assures consistent and repeatable results with minimal downtime when installing Auto-Axcess power sources into existing robot cells. Auto-Line power management technology for any input voltage hookup (208 575 V) with no manual linking. Assures rock-solid, consistent output on uctuating primary lines.

Pre-Engineered Performance

A Full Range of Products

PerformArc products are built on a core foundation of Panasonic robots, servo positioners and Miller welding technology. Designed speci cally for your fabrication environment, each PerformArc product incorporates a fully welded steel frame and base structure with sheetmetal-skinned walls. PerformArc offers: r Flexibility PerformArc products are pre-wired and pre-assembled for fast installation and relocation.

r Central location Full system control, diagnostics, and programming capabilities in one easy-to-access location makes learning the process easier and increases cell uptime. r Safety features All models include a fully integrated safety environment with light curtains and door interlocks. r Support Your PerformArc system is pre-engineered and backed by Miller.

PA 750 S

PA 550 H

PA 750 S

r r r r r High-speed servo turntable Platen style 750 lb. per side 92 in. table diameter Length 4724 mm (186 in.) Width 2489 mm (98 in.) Height 2286 mm (90 in.)

PA 550 H

r r r r r r High-speed servo turntable H-frame style Two outboard servo positioners 550 lb. per side 48 in. between face plates, 34 in. turning diameter Length 4724 mm (186 in.) Width 2489 mm (98 in.) Height 2286 mm (90 in.)

PRODUCT DETAILS Typical part sizes (in inches): 12 x 87, 24 x 76, 36 x 53

PA 250 M

r r r r r

PA 250 M

PRODUCT DETAILS Maximum part size (in inches): 34 x 48

PA 350 S

r r r r r High-speed servo turntable Platen style 350 lb. per side 60 in. table diameter, equally divided Length 3988 mm (157 in.) Width 1727 mm (68 in.) Height 2286 mm (90 in.)

PA 350 S

Manually activated turntable Platen style 250 lb. per side 60 in. table diameter, equally divided Length 2870 mm (113 in.) Width 1676 mm (66 in.) Height 2286 mm (90 in.)

PA 750 SW

r r r r r High-speed servo turntable Platen style 750 lb. per side 107 in. table diameter Length 5131 mm (202 in.) Width 2896 mm (114 in.) Height 2286 mm (90 in.)

PA 550 HW

r r r r r r High-speed servo turntable H-frame style Two outboard servo positioners 550 lb. per side 60 in. between face plates, 40 in. turning diameter Length 5131 mm (202 in.) Width 2896 mm (114 in.) Height 2286 mm (90 in.)

PRODUCT DETAILS Typical part sizes (in inches): 12 x 53, 18 x 45, 24 x 30

PRODUCT DETAILS Typical part sizes (in inches): 12 x 53, 18 x 45, 24 x 30

r Fast installation A fully welded frame, shipped to you

pre-wired and pre-assembled, eliminates assembly time and is up and running in minutes.

r Fast installation A fully welded frame, shipped to you

pre-wired and pre-assembled, eliminates assembly time and is up and running in minutes.

PRODUCT DETAILS Typical part sizes (in inches): 12 x 104.5, 24 x 95, 36 x 77, 48 x 43

r Fast installation A fully welded frame, shipped to you prewired and pre-assembled, eliminates assembly time and is up and running in minutes.

PRODUCT DETAILS Maximum part size (in inches): 39.37 x 60

r Integrated controls An integrated interface and

full-color teach pendant provide full system control, diagnostics and programming capability in one location, which makes learning the process easier for the operator.

r Repeatability A standard platen design with bolt and

dowel holes allows multiple xtures to be exchanged on the same work cell.

r Fast installation A fully welded frame, shipped to you prewired and pre-assembled, eliminates assembly time and is up and running in minutes.

r Repeatability A standard platen design with bolt and dowel

holes allows multiple xtures to be exchanged on the same work cell.

r Maximum accessibility Outboard servo positioners allow

for easy loading or load-and-tack operations while maximizing torch accessibility.

r Productivity The Panasonic AC servo positioner turns

180 in under 2.2 seconds, minimizing index time and maximizing productivity.

r Productivity and versatility The manually activated

table allows for high output-to-investment ratio, which is ideal for rst-time users and companies with a low volume of automation projects. 10

r Flexibility A large work area and 725 pound-per-side

payload accepts larger parts, nest-type processing of smaller parts and progressive xtures.

r Safety Outboard axis power is disconnected during

xture loading to prevent unexpected motion while the robot maintains production. 11

Pre-Engineered Performance

A Full Range of Products

PRODUCT DETAILS Maximum part size (in inches): 43 x 118 PA 1100 FW

r High productivity A high-speed Ferris wheel positioner

using three independent servo drives provides industryleading indexing speed, minimizing cycle-time impact.

PA 1100 HW

PA 1100 SS

PA 1100 FW*

r r r r r r

PA 1100 HW

r r r r r High-speed servo turntable H-frame style Two outboard servo positioners 1100 lb. per side 60 in. between faceplates 40 in. turning diameter r Length 5309 mm (209 in.) Width 3085 mm (121.5 in.) Height 2337 mm (92 in.)

PRODUCT DETAILS Maximum part size (in inches): 40 x 60

PA 1100 SS*

r r r r r r Two opposing welding stations Independent style Two outboard servo positioners 1100 lb. per side 120 in. between faceplates, 44 in. turning diameter Width 4987 mm (196 in.) Depth 4254 mm (167.5 in.) Height 2286 mm (90 in.)

High-speed servo sweep Ferris wheel style Two outboard servo positioners 1100 lb. per side 120 in. between faceplates, 40 in. turning diameter Width 5618 mm (221 in.) Depth 4567 mm (180 in.) Height 2286 mm (90 in.)

r Maximum accessibility Outboard servo positioners

allow for easy loading or load-and-tack operations while maximizing torch accessibility.

r Safety Outboard axis power is disconnected during

xture loading to prevent unexpected motion while the robot maintains production.

* Multi-robot con guration available

PA 2200 SS*

r r r r r r Two opposing welding stations Independent style Two outboard servo positioners 2200 lb. per side 120 in. between faceplates, 60 in. turning diameter Width 5357 mm (211 in.) Depth 4991 mm (196.5 in.) Height 2286 mm (90 in.)

Servo-Controlled Positioners

Our servo-controlled positioners are designed for precision welding on round tubes and pipes. Simply clamp each end of the material to a positioner for 360 degrees of access. r Built-in safety All Panasonic servo positioners come standard with servo disconnect technology and a host of software commands that allow exibility while maintaining operator safety. r Versatility These positioners are applicable to MIG, Pulsed MIG, and TIG welding with built-in rotary ground (500 A capacity) and through-hole design to pass air and I/O cabling. r Ef ciency and ease of use Optional harmonized external axes control software makes setting welding speeds and other system parameters easy, reducing the number of taught points and ensuring the optimum welding position. r Flexible positioning Panasonic 1000 kg servo positioners can be used as building blocks in system designs as main indexers, supplemental outboards, or in combination as skyhook-style positioners.

RJB31 RJR41

r Production exibility A larger rotation diameter, increased

length, heavier payload and open overhead construction accommodate larger parts and multiple or progressive xturing.

RJC71

r Maximum accessibility Outboard servo positioners allow

for easy loading or load-and-tack operations while maximizing torch accessibility.

r Safety Outboard axis power is disconnected during

xture loading to prevent unexpected motion while the robot maintains production.

PRODUCT DETAILS Maximum part size (in inches): 60 x 120 Optional sizes (in inches): 66 x 120, 66 x 44

r Open design The sidewall design allows for heavier

weldments to be crane-loaded, while standard load station jog allows unlimited positioning for multi-side part loading of nal weldout.

r Maximum accessibility Outboard servo positioners allow

for easy loading or load-and-tack operations while maximizing torch accessibility.

r Safety Outboard axis power is disconnected during

PA 2200 SS 12 xture loading to prevent unexpected motion while the robot maintains production.

RJB1121

RJR51 13

Continuous Evolution with HEAT

HEAT (High-Ef ciency Advanced Tip) bene ts include:

r Up to 40% higher deposition than conventional welding processes. r Less burn-through ideal for thinner metals. r Improved gap handling without sacri cing travel speed. r Consistent tip-to-wire electrical contact for improved process control.

Welding Software

Robot system PC tools

r Accessibility Full access to system setup information and le management is available via removable PC card or Ethernet hookup. r Transferability The software allows for quick and easy le exchange between robot installations. r Time savings Programs can be edited of ine, and program structure can be included in staff training. r Security Regular system backup is automatic, and access is password-protected.

Optimized for productivity

TAWERS arc welding robots combine TA Series manipulators with WG welders by fusing them together using embedded arc control (EAC) technology. With larger motors and drives, increased acceleration and a high rigidity FEA optimized design, TAWERS robots offer exceptional speed, maximizing your performance by minimizing cycle downtimes. r Bus communication This system helps reduce cycle times, advance quality and improve exibility of the welding process. r Advanced sensitivity When servo control algorithms detect undue load on the robot during motion, they drop servo power to a soft state to protect the robot from collisions. r Ultra-low spatter Advanced arc physics analysis and control can save more than 100 lb. of wire per arc versus conventional MIG (CV) processes. r Better performance The robot controller and welder share a cabinet that does not exchange outside air with the welding environment, eliminating failure due to welding dust (WG only).

TECHNICAL SUPPORT

Applications engineering The applications department within Miller uses the latest in robotic, arc welding, system and simulation capabilities to offer a comprehensive analysis of your potential welding projects. We can perform a thorough analysis by providing tangible results on the viability of your project. Training Within your organization, we can help you develop productivity specialists by sharing our unique experience and extensive knowledge. An investment in training is an investment in your organization that can offer tremendous operations expertise, productivity gains and ROI. Maintenance services Even the best, most reliable equipment and software need maintenance, care and upgrades over time. We provide a variety of services to maximize your productivity, extend the useful life of your production lines and reduce total operating costs. Our technical staff is available 24/7 through our technical assistance center. Genuine parts Ordering a replacement part for your robot is fast and easy. You can order through our customer care center, by phone or online. Well ll your order and have it on its way to you immediately. And youll have the con dence of knowing it is a quality part, meeting the speci ed need of your machine.

TAWERS WG

350 A @ 80% CV. 350 A @ 60% CV, and Pulse

DTPS 3D simulation

r Dedication A simulation package for Panasonic robot system PC tools (RSPCT), robots and external axes with full tooling and work cell support available. r Compatibility Simulation is merged with Panasonic RSPCT for complete program editing capability with no translation required. r Ef ciency Of ine program analysis and editing manage welding process programs over multiple robot systems.

Auto-Axcess

450 A @ 100% CV, and Pulse

14

15

Robotic Welding Automation

As the workforce transitions from manual labor to highly technological jobs, Miller offers robotic automation to address the shortage of skilled welders. Our regulation compliant robotic welding increases productivity and rst-pass weld quality, reduces over-welding and rework, offers increased protection and safety for operators and lowers the cost of doing business. For more information, visit MillerWelds.com/automation.

16

MillerWelds.com/automation

# 250707 2011 Miller Electric Mfg. Co. | Miller Welding Automation | 281 E. Lies Rd. | Carol Stream, IL 60188 | 888-843-7693

The Power of Blue

You might also like

- Humanoid RobotsDocument17 pagesHumanoid RobotsIvan AvramovNo ratings yet

- The Definition of IntelligenceDocument2 pagesThe Definition of IntelligenceIvan AvramovNo ratings yet

- The Anatomy of A Humanoid RobotDocument8 pagesThe Anatomy of A Humanoid RobotIvan AvramovNo ratings yet

- 06 Mobilerobotics - WS1718 1Document79 pages06 Mobilerobotics - WS1718 1Ivan AvramovNo ratings yet

- Invitation To Topological RoboticsDocument143 pagesInvitation To Topological RoboticsIvan AvramovNo ratings yet

- Intro RoboticsDocument49 pagesIntro Roboticsariff05100% (2)

- !!! Denavit-Hartenberg ConventionDocument17 pages!!! Denavit-Hartenberg ConventionIvan AvramovNo ratings yet

- RobotLocomotion PDFDocument25 pagesRobotLocomotion PDFIvan AvramovNo ratings yet

- InTech-Towards A Realistic and Self Contained Biomechanical Model of The HandDocument31 pagesInTech-Towards A Realistic and Self Contained Biomechanical Model of The HandIvan AvramovNo ratings yet

- Prismatic Joint WikipediaDocument1 pagePrismatic Joint WikipediaIvan AvramovNo ratings yet

- Robot Assist Users Manual PDFDocument80 pagesRobot Assist Users Manual PDFIvan AvramovNo ratings yet

- 31-Telerobotics !!!!!Document17 pages31-Telerobotics !!!!!Ivan AvramovNo ratings yet

- !!!! Anatomy of Humanoid RobotsDocument17 pages!!!! Anatomy of Humanoid RobotsIvan AvramovNo ratings yet

- Teaching Robot Kinematic in A Virtual Environment PDFDocument4 pagesTeaching Robot Kinematic in A Virtual Environment PDFIvan AvramovNo ratings yet

- Mechanical Arm Teleoperation Control System by Dynamic Hand Gesture Recognition Based PDFDocument4 pagesMechanical Arm Teleoperation Control System by Dynamic Hand Gesture Recognition Based PDFIvan AvramovNo ratings yet

- Development of A Six-Axis Force-Moment Sensor For Wind Tunnel Model Test PDFDocument11 pagesDevelopment of A Six-Axis Force-Moment Sensor For Wind Tunnel Model Test PDFIvan AvramovNo ratings yet

- Development of A Six-Axis Force-Moment Sensor For Wind Tunnel Model Test PDFDocument11 pagesDevelopment of A Six-Axis Force-Moment Sensor For Wind Tunnel Model Test PDFIvan AvramovNo ratings yet

- T-Test and ANOVA: Appendix FDocument1 pageT-Test and ANOVA: Appendix FIvan AvramovNo ratings yet

- Robot Assist Users Manual PDFDocument80 pagesRobot Assist Users Manual PDFIvan AvramovNo ratings yet

- Kinematical Analysis of Wunderlich MechanismDocument16 pagesKinematical Analysis of Wunderlich MechanismIvan AvramovNo ratings yet

- A Tele Robot Assistant For Remote Environment Management PDFDocument4 pagesA Tele Robot Assistant For Remote Environment Management PDFIvan AvramovNo ratings yet

- A Closed-Loop Neurobotic System For Fine PDFDocument17 pagesA Closed-Loop Neurobotic System For Fine PDFIvan AvramovNo ratings yet

- Sheth-Uicker Convention RevisitedDocument30 pagesSheth-Uicker Convention RevisitedIvan AvramovNo ratings yet

- Design of An Anthropomorphic Robotic FingerDocument8 pagesDesign of An Anthropomorphic Robotic FingerIvan AvramovNo ratings yet

- MIT OCW CEE 1-964 - Design For Sustainability - Energy in BuildingsDocument61 pagesMIT OCW CEE 1-964 - Design For Sustainability - Energy in BuildingsIvan AvramovNo ratings yet

- RoboticsDocument17 pagesRoboticsIvan AvramovNo ratings yet

- Climatology: Introduction To Course OutlineDocument10 pagesClimatology: Introduction To Course Outlineannie_jalaliNo ratings yet

- Personal Edu RoboticsDocument4 pagesPersonal Edu RoboticsIvan AvramovNo ratings yet

- Uses On Artificial IntelligenceDocument40 pagesUses On Artificial IntelligenceIvan AvramovNo ratings yet

- UJ ARC 364 Climate and Design Course Outline 120311aDocument5 pagesUJ ARC 364 Climate and Design Course Outline 120311aIvan AvramovNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Electrical & Civil-1resume PDFDocument2 pagesElectrical & Civil-1resume PDFanjar alamNo ratings yet

- Bhanu Brose Excursion ReportDocument6 pagesBhanu Brose Excursion ReportBhanu Pratap SinghNo ratings yet

- Annex A - Technical SpecificationsDocument52 pagesAnnex A - Technical SpecificationsNikko MontoyaNo ratings yet

- 3000w Inverter Parts ListDocument6 pages3000w Inverter Parts ListayoowuyeNo ratings yet

- CS1 Course OutlineDocument2 pagesCS1 Course Outlineapi-27149177No ratings yet

- Elmer TutorialsDocument65 pagesElmer TutorialsmariomatoNo ratings yet

- 2013 OSPE Salary Survey PDFDocument20 pages2013 OSPE Salary Survey PDFdarinscottjohnsonNo ratings yet

- LSV-08-2 NCPDocument2 pagesLSV-08-2 NCPishtiaqNo ratings yet

- Centrifugal PumpDocument56 pagesCentrifugal Pumpchandraa2208No ratings yet

- A Control System For DC Arc Furnaces For Power Quality ImprovementsDocument8 pagesA Control System For DC Arc Furnaces For Power Quality ImprovementsgtgreatNo ratings yet

- Cramkshaft Main Bearimg InstallDocument5 pagesCramkshaft Main Bearimg InstallNimNo ratings yet

- Investigating The Effect of Liquid Viscosity On Two Phase Gas Liquid FlowDocument252 pagesInvestigating The Effect of Liquid Viscosity On Two Phase Gas Liquid FlowAnonymous DMh6pdl0aNo ratings yet

- 000-Za-E-M09403 - C-MS For Cable Tray InstallationDocument15 pages000-Za-E-M09403 - C-MS For Cable Tray Installationsyam prasad100% (1)

- TSM SmokeDocument2 pagesTSM SmokeSudin AmatyaNo ratings yet

- Asme eDocument41 pagesAsme eAnonymous wWOWz9UnWNo ratings yet

- RA 7920 Section 33Document1 pageRA 7920 Section 33Renz Emil ReyesNo ratings yet

- Comparison Between Zvs and ZVS-ZCS Bidirectional DDocument6 pagesComparison Between Zvs and ZVS-ZCS Bidirectional DSUNIL MANJHINo ratings yet

- DW-143 - Leakage Factor As Per Calculation FormulaDocument2 pagesDW-143 - Leakage Factor As Per Calculation Formulasandeep7426No ratings yet

- Refrigerator: Service ManualDocument44 pagesRefrigerator: Service ManualBetileno QuadAlexNo ratings yet

- IEC Systems Manual - SCRDocument102 pagesIEC Systems Manual - SCRgabriel100% (3)

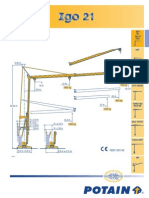

- Potain Igo 21 PDFDocument4 pagesPotain Igo 21 PDFMarco CruzNo ratings yet

- Brilliance - 64 - (ct101) - Site - Guidefor TrailerDocument19 pagesBrilliance - 64 - (ct101) - Site - Guidefor Trailerbody2030No ratings yet

- Upload Photosimages Into Custom Table & Print in Adobe FormDocument14 pagesUpload Photosimages Into Custom Table & Print in Adobe FormEmilSNo ratings yet

- 2007 Volkswagen Jetta Fuse Box Diagram (Inside and Outside) Needed PDFDocument7 pages2007 Volkswagen Jetta Fuse Box Diagram (Inside and Outside) Needed PDFGuillermo Nájera MolinaNo ratings yet

- Gestrast 6Document3 pagesGestrast 6iran1362No ratings yet

- Survey MODULE 4Document16 pagesSurvey MODULE 4InsurrectionNo ratings yet

- The PA Bible Addn 03 Microphones PDFDocument4 pagesThe PA Bible Addn 03 Microphones PDFjosiasns5257100% (1)

- Design of A 30 Storey Office Building With Reinforced Concrete Design Using Etabs Structural SoftwareDocument51 pagesDesign of A 30 Storey Office Building With Reinforced Concrete Design Using Etabs Structural SoftwareAyodele Oluwaseyi Dina100% (1)

- AA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFDocument746 pagesAA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFPeterNo ratings yet

- EVI DC Inverter Technical Manual 2 Capacity TableDocument67 pagesEVI DC Inverter Technical Manual 2 Capacity TableMouyed Al QasemNo ratings yet