Professional Documents

Culture Documents

Ee Lumber

Uploaded by

Hasen BebbaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ee Lumber

Uploaded by

Hasen BebbaCopyright:

Available Formats

EL-08 [Filename: EELUMBER.

DOC] Lumber Sorter Contributor: Affiliation Address: Phone: Email: Type: Student Time: Location: Mary L. McAllister IET Dept. / Belk Building Western Carolina University Cullowhee, N.C. 28723 (704) 227-7272 mmcallist@wcu.edu Design Problem Five to seven weeks Lab and research time Summary

August 10, 1995

This is intended to be used with junior year electrical engineering students as a design problem that could incorporate either a microcontroller or programmable logic controllers in the solution. The student should have a basic understanding of one of the above. Students should divide into groups of three and brainstorm a solution to the lumber sorting problem in a furniture factory. The lumber for building the furniture frames is delivered to the factory in 3ft., 4ft, 6ft, and 7ft lengths. The operations manager wants an automated conveyor belt system installed so that the three and four foot lengths go to one department and the six and seven foot lengths go to another department. At the moment there is no automated system in place. Report: Five to ten pages plus a sketch of the design and any associated software.

ABET Descriptors Engr Sci Content: Type: Elements: Features: Constraints: Effort: Electrical, microcontroller applications or programmable logic controllers Component, system Synthesis, design evaluation Development of student creativity, open ended problem, alternative solutions, feasibility considerations Time, economic factors, safety Team

EL-08 [Filename: EELUMBER.DOC] Lumber Sorter

August 10, 1995

The Operations Manager of Realistic Furniture Manufacturing wants an automated conveyor belt system installed in the factory. The lumber for making the furniture frames is delivered to the factory in three, four, six, and seven foot lengths. The three and four foot lengths are used in one area of the factory and the six and seven foot lengths are used in another area. He wants a conveyor belt system designed . The system will have a sensor that will sense the length of the lumber. The smaller pieces will automatically be directed to the chair making area and the larger pieces to the sofa making area. The system should also keep track of the total number of pieces of each length. Daily totals will be accumulated. At the end of each day the number of pieces of each size that come into the factory will be downloaded to the main computer. The main computer will keep track of order sizes and inventory control.

In doing this project you are required to do the following: Define the problem and the specifications that need to be met. Brainstorm possible solutions Explore computer simulation, graphics/visualization, microcontroller/PLC programming tools that are relevant to and available at the university to help you with this project. Set up a simulation using the small conveyor belt , PLC workstation or microcontrollers. Conveyor belt Actuator pushes shorter lumber to other conveyor belt

sensor

EL-08 [Filename: EELUMBER.DOC] Lumber Sorter Report your project results :

August 10, 1995

1. A minimum five page written report plus a graphical representation of the design, and copies of any associated software. 2. An oral presentation of the design with visual aids.

EL-08 [Filename: EELUMBER.DOC] Lumber Sorter

August 10, 1995

Engineering Notes: This problem is perhaps best implemented with PLC controls although a microcontroller would certainly work. As the professor you could make this just a simple project of finding a sensor that would sense the length of the wood and then send a signal to an actuator to push the shorter pieces off onto another conveyor belt going to another area of the factory. Or you could tell the students to consider economic factors, safety factors, simulations of alternate designs etc. Also, depending on the equipment you have available, the students could simulate the design implementation with PLCs, small conveyor belts etc. Some issues that could be brought out in class by the professor when the assignment is given.

What happens if two pieces of equal or unequal length are laying on top of each

other? What kind of devices are necessary so that you make sure only one piece of wood is measured at a time? How fast a system is needed? (board ft./second) Techniques that could be used to sense the length of the wood? Safety issues using a conveyor belt. What kind of conveyor belt is necessary? How wide, how long, what kind of material? Cost of conveyor belt system, cost savings over old system? Payback period. What safety features are necessary? What happens if the wood gets jammed? Emergency shutoff systems? Types of motors necessary to drive the conveyor belt system?

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ATLAS HONDA Internship ReportDocument83 pagesATLAS HONDA Internship ReportAhmed Aitsam93% (14)

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - ADocument29 pagesEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- Rehabilitation and Retrofitting of Structurs Question PapersDocument4 pagesRehabilitation and Retrofitting of Structurs Question PapersYaswanthGorantlaNo ratings yet

- KBR Standard Report Template Rev 9.01Document268 pagesKBR Standard Report Template Rev 9.01Hasen BebbaNo ratings yet

- General Requirements For Technical Publication Preparation: 1. ScopeDocument15 pagesGeneral Requirements For Technical Publication Preparation: 1. ScopeHasen BebbaNo ratings yet

- An Introduction To Mechanical EngineeringDocument1 pageAn Introduction To Mechanical EngineeringHasen BebbaNo ratings yet

- What Plumbing Designers Need To Know About Valves, Part 2 PDFDocument4 pagesWhat Plumbing Designers Need To Know About Valves, Part 2 PDFHasen BebbaNo ratings yet

- Me471s03 q1 AnsDocument5 pagesMe471s03 q1 AnsHasen BebbaNo ratings yet

- Me471 Hwk05ansDocument12 pagesMe471 Hwk05ansHasen BebbaNo ratings yet

- Milestone 9 For WebsiteDocument17 pagesMilestone 9 For Websiteapi-238992918No ratings yet

- 7Document101 pages7Navindra JaggernauthNo ratings yet

- Alternator: From Wikipedia, The Free EncyclopediaDocument8 pagesAlternator: From Wikipedia, The Free EncyclopediaAsif Al FaisalNo ratings yet

- Hosts 1568558667823Document5 pagesHosts 1568558667823Vũ Minh TiếnNo ratings yet

- Donation Drive List of Donations and BlocksDocument3 pagesDonation Drive List of Donations and BlocksElijah PunzalanNo ratings yet

- E Nose IoTDocument8 pagesE Nose IoTarun rajaNo ratings yet

- Majalah Remaja Islam Drise #09 by Majalah Drise - Issuu PDFDocument1 pageMajalah Remaja Islam Drise #09 by Majalah Drise - Issuu PDFBalqis Ar-Rubayyi' Binti HasanNo ratings yet

- KV Tripple Eccentric Butterfly Valve-LinDocument12 pagesKV Tripple Eccentric Butterfly Valve-LinWelma JohnsonNo ratings yet

- Safety Data Sheet: Fumaric AcidDocument9 pagesSafety Data Sheet: Fumaric AcidStephen StantonNo ratings yet

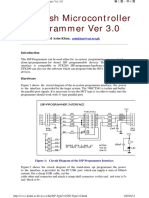

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocument4 pagesISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNo ratings yet

- Document 3Document3 pagesDocument 3AdeleNo ratings yet

- Stock Prediction SynopsisDocument3 pagesStock Prediction SynopsisPiyushPurohitNo ratings yet

- Certification and LettersDocument6 pagesCertification and LettersReimar FerrarenNo ratings yet

- Terms and Conditions 27 06 PDFDocument4 pagesTerms and Conditions 27 06 PDFShreyash NaikwadiNo ratings yet

- Business Testimony 3Document14 pagesBusiness Testimony 3Sapan BanerjeeNo ratings yet

- Minor Ailments Services: A Starting Point For PharmacistsDocument49 pagesMinor Ailments Services: A Starting Point For PharmacistsacvavNo ratings yet

- Scope: Provisional Method - 1994 © 1984 TAPPIDocument3 pagesScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваNo ratings yet

- Salem Telephone CompanyDocument4 pagesSalem Telephone Company202211021 imtnagNo ratings yet

- Bba Colleges in IndiaDocument7 pagesBba Colleges in IndiaSumit GuptaNo ratings yet

- Dreamweaver Lure v. Heyne - ComplaintDocument27 pagesDreamweaver Lure v. Heyne - ComplaintSarah BursteinNo ratings yet

- NIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksDocument15 pagesNIELIT Scientist B' Recruitment 2016 - Computer Science - GeeksforGeeksChristopher HerringNo ratings yet

- Leeka Kheifets PrincipleDocument6 pagesLeeka Kheifets PrincipleAlexandreau del FierroNo ratings yet

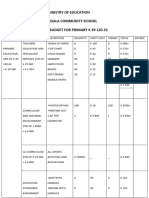

- Ministry of Education Musala SCHDocument5 pagesMinistry of Education Musala SCHlaonimosesNo ratings yet

- Heat Exchanger Designing Using Aspen PlusDocument6 pagesHeat Exchanger Designing Using Aspen PlusMeethiPotterNo ratings yet

- Gravity Based Foundations For Offshore Wind FarmsDocument121 pagesGravity Based Foundations For Offshore Wind FarmsBent1988No ratings yet

- Econ 1006 Summary Notes 1Document24 pagesEcon 1006 Summary Notes 1KulehNo ratings yet

- V Series: Three Wheel, Counterbalanced Lift TruckDocument126 pagesV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинNo ratings yet