Professional Documents

Culture Documents

1

Uploaded by

Sharat ChandraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1

Uploaded by

Sharat ChandraCopyright:

Available Formats

1

33

Earlier Topics

Introduction to Cryogenic Engineering

Properties of Cryogenic Fluids

Properties of Materials at Cryogenic Temperature

Gas Liquefaction and Refrigeration Systems

Gas Separation

Cryocoolers

2

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Current Topic

Topic : Cryogenic Insulation

Why Insulation?

Different types of Cryogenic Insulations

A comparative study

Applications

The current topic will be covered in 3 lectures.

Tutorials and assignments are included at the end

of each lecture.

3

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Topic : Cryogenic Insulations

Why Insulation?

Types of Insulation

Expanded Foam and Powder Insulations

Radiation Fundamentals

4

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Outline of the Lecture

5

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Introduction

Storage of a cryogen (say, LN2) is difficult, as

there is a continuous boil off due to heat in leaks.

These vessels cannot be sealed as boil off

generates huge volumes of vapour, resulting in

large pressure rise. This may lead to bursting.

For example, vapor to liquid volume ratio for a

general cryogen is 175 (1600 for water).

To avoid the pressure rise, the need of insulation is

vital. Insulation or a combination of insulations,

minimize all these modes of heat transfer.

6

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Heat Transfer

Consider a LN2 container as shown in

the figure.

The inner vessel is housed inside an

outer vessel and these vessels are

separated by some form of insulation.

Also, the inner vessel is supported

using lateral beams as shown.

The liquid boils off continuously due to

the various modes of heat transfer.

300 K

77 K

7

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Heat Transfer

Different modes of heat transfer are

Conduction: The heat is

conducted through lateral beams,

neck and residual gas conduction.

Convection: The air between

inner and outer vessels convect

heat into the liquid.

Radiation: The radiation heat

transfer from 300 K outer vessel to

77 K inner vessel.

300 K

77 K

8

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Types of Insulation

Insulation

Mass Reflective Vacuum

Granular Fibrous Cellular

Multi Layer

Insulation

Metal

Foils

9

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Types of Insulation

Expanded Foam Mass

Gas Filled Powders & Fibrous Materials Mass

Vacuum alone Vacuum

Evacuated Powders Mass + Vacuum

Opacified Powders Mass + Vacuum + Reflective

Multilayer Insulation Vacuum + Reflective

10

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Types of Insulation

The choice of insulation for a particular application

is a compromise between the following factors.

Thermal Conductivity

Temperature

Effectiveness of Insulation

Cost

Ease of application

Weight and reliability

A combination of insulations is used to prevent

different modes of heat transfer.

11

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Apparent Thermal Conductivity

As seen earlier, the different modes of heat

transfer are Gas and Solid Conductions, Convection

and Radiation.

Consider an element of insulation, separated by

two temperatures (T

1

> T

2

) as shown below.

Let Q be net heat transferred across this element

by all possible modes of heat transfer mentioned

above.

T

1

T

2

Q

12

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Apparent Thermal Conductivity

If A and L be the area of the cross section and

length of the element respectively, the apparent

thermal conductivity (k

A

) is defined as

In other words, this apparent thermal conductivity

is calculated based on all possible modes of heat

transfer.

( )

1 2

A

QL

k

A T T

=

T

1

T

2

Q

L

A

13

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Expanded foam is a low density, cellular structure

which is formed by evolving gases during the

manufacturing process.

Gases that are generally used are CO

2

and Freon.

In other words, it is a solid gas matrix with void

spaces. The solid connections together with gas

trapped in cellular spaces form a continuous path.

The heat is transferred only by conduction (solid

conduction). The contribution by convection and

radiation are negligible.

14

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Examples are polyurethane foam, polystyrene

foam, rubber, silica glass foam.

k

A

and density are as shown below. The operating

temperature is between 77 K to 300 K.

Foam (kg/m

3

) k (mW/mK)

Polyurethane 11 33

Polystyrene 39

46

33

26

Rubber 80 36

Silica 160 55

Glass 140 35

15

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Mean Cell Diameter - m

The k

A

of the foam depends

on the type of gas used and

also the temperature of the

insulation.

For a given gas, the

performance of the foam is

improved by varying the

void size and bulk density.

The adjacent figure shows

the variation of k

A

with the

mean cell diameter.

16

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Mean Cell Diameter - m

With the decrease in the

mean cell diameter, the solid

conduction path increases in

the foam insulation.

From the above equation,

the Q decreases and hence

the k

A

decreases.

( )

1 2

A

QL

k

A T T

=

17

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Mean Cell Diameter - m

At the same time, with the

decrease in the mean cell

diameter, the bulk density of

the foam increases.

Therefore, k

A

is also a

function of bulk density and

it increases with the increase

in bulk density.

18

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

The major advantage of an expanded foam is that

it offers an ease of fabrication.

The foam is directly blown onto the surface of the

vessel to be insulated. It forms a self supporting

structure.

The cost of this insulation is also low as compared

to other types of insulations.

19

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Exposure of a CO

2

expanded foam to LN2

temperatures, increases the thermal conductivity.

At LN2 temperature, the vapor pressure of CO

2

is

less. As a result, most of CO

2

is condensed within

the insulation and caters for the heat transfer.

Also over a period of time, air, hydrogen or helium

diffuse into foam from external atmosphere.

The k

A

of the foam increases due to increase in the

gas conduction at room temperature.

20

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Expanded Foams

Expanded foams have large thermal contractions,

which pose a major disadvantage.

A rigid foam has a large thermal contraction

between -30

o

C to +30

o

C.

For example, coefficients of linear expansion are

Polystyrene Foam

: 7.20 x 10

-5

/

o

C

Carbon Steel

: 1.15 x 10

-5

/

o

C

The foam when closely fitted around a LN2 vessel,

crack due to difference in shrinkages.

Gas Filled Powder & Fibrous

Insulations

21

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

A gas filled powder or a fibrous insulation reduces

or eliminates the gas convection due to the small

size of voids within the material.

This is because, the distance between the powder

particles within the insulation is much smaller

than the gas mean free path.

As a result, the gaseous conduction mechanism

shifts from continuum to free molecular

conduction decreasing the apparent thermal

conductivity, k

A

.

Gas Filled Powder & Fibrous

Insulations

22

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

The commonly used insulations of this type are

Fiber Glass, Perlite (Silica Powder), Santocel,

Rockwool, Vermichlitine.

k

A

and density are as shown below. The operating

temperatures are between 77 K to 300 K.

Insulation (kg/m

3

) k (mW/mK)

Perlite 50 26

Silica Aerogel 80 19

Fiber glass 10 25

Rockwool 160 35

Gas Filled Powder & Fibrous

Insulations

23

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

The advantages of a gas filled powder are low

thermal conductivity, low density and low particle

distribution to minimize the vibration effects.

The insulation can either be evacuated or non

evacuated. Heat transfer by residual gas is further

minimized by low vapor pressure of the gas.

Finely divided particulate materials make solid

conduction paths disjointed and discontinuous.

Gas Filled Powder & Fibrous

Insulations

24

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

The disadvantage is that moisture and air diffuse

through the material to the cold surface unless a

vapor barrier is used. N

2

purging is used.

Fill gas should be unreactive and compatible

with powder material.

Powder tends to settle and packs due to

vibrations, thermal contraction and expansion.

This creates increased solid conduction.

Gas Filled Powder & Fibrous

Insulations

25

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Nusselt & Bayer developed the following

expression for k

A

for a gas filled powder.

V

r

Ratio of solid particulate to total volume.

k

s

& k

g

Thermal conductivity of Solid and Gas.

T Mean temperature.

d Mean diameter of fiber or powder.

( )

1

1

3

4

1

g

r

A

s r r

k

V T d

k

k V V

(

(

(

= + +

(

(

Gas Filled Powder & Fibrous

Insulations

26

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

At cryogenic temperatures, two assumptions are

made

T

3

term is very small relative to k

g

term.

k

s

>> k

g

Therefore, the equation is

( )

1

1

3

4

1

g

r

A

s r r

k

V T d

k

k V V

(

(

(

= + +

(

(

( )

1

g

A

r

k

k

V

=

Gas Filled Powder & Fibrous

Insulations

27

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Therefore, as V

r

tends to zero, k

A

approaches k

g

.

This is the lowest possible thermal conductivity of

this insulation.

( )

1

g

A

r

k

k

V

=

28

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Radiation Fundamentals

Consider two flat surfaces maintained

at different temperatures (T

1

> T

2

) as

shown in the figure.

There is continuous heat transfer

between the two plates due to the

radiation.

This mode of heat transfer does not

require any medium and is given by

the following equation.

1

T

2

T

( )

4 4

1 2 1 2 1 e

Q F F A T T

=

29

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Radiation Fundamentals

( )

4 4

1 2 1 2 1 e

Q F F A T T

=

1

T

2

T

In the above equation, it is clear that

for a given A

1

, T

1

, T

2

, F

12

, Q is

directly proportional to the emissivity

factor F

e

.

The F

e

is reduced by introducing the

radiation shields in the path of

radiation heat transfer as shown.

The effect of these shields is as

explained in the next slide.

1

T

2

T

30

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Radiation Shields

The effective emissivity factor F

N

after

introduction of N shields is as given below.

For the sake of understanding, let the values of

e

1

, e

2

, and e

s

be 0.8, 0.8, 0.05 respectively.

Students are advised to calculate and compare F

N

for following cases.

Case 1: N=0

Case 2: N=10

( )

1 2

1 1 1 2 1 1

1 1 1 1

N s s s

N

F e e e e e

| | | | | |

= + + + +

| | |

\ . \ . \ .

31

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Radiation Shields

Case 1 : N=0

Case 2 : N=10

It is clear that the F

N

decreases drastically with

the introduction of radiation shields.

These shields are aluminum foils with a very high

reflectivity.

0.667

N

F =

0.00255

N

F =

32

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Summary

Cryogenic vessels need insulation to minimize all

modes of heat transfer.

The apparent thermal conductivity is calculated

based on all possible modes of heat transfer.

Expanded foam is a low density, cellular

structure. The heat is transferred only by solid

conduction.

With the decrease in the mean cell diameter, the

k

A

decreases. With the increase in the bulk

density, the k

A

also increases.

33

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Summary

A gas filled powder or a fibrous insulation reduces

gas convection due to the small size of voids. The

heat is transferred by free molecular conduction.

Fill gas should be unreactive and compatible with

powder material.

Radiation heat transfer does not require any

medium. It is reduced by introduction of radiation

shields.

These shields are aluminum foils with a very high

reflectivity.

34

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

A self assessment exercise is given after

this slide.

Kindly asses yourself for this lecture.

Self Assessment

1. The vapor to liquid volume ratio for a general

cryogen is ____.

2. The liquid boils off continuously due to _____.

3. ________ is calculated based on all possible modes

of heat transfer.

4. In an expanded foam, gases that are used are ___.

5. In an expanded foam, the heat is transferred only

by _____.

6. With the decrease in mean cell diameter, the solid

conduction path _____in the foam insulation.

7. In a Gas Filled powder insulation, fill gas should

be _____.

8. ___ does not require any medium.

35

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Answers

36

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

1. 175

2. Heat in leaks

3. Apparent thermal conductivity

4. CO

2

and Freon

5. Conduction

6. Increases

7. Unreactive

8. Radiation

37

Prof. M D Atrey, Department of Mechanical Engineering, IIT Bombay

Thank You!

You might also like

- Stainless Steel InformationDocument6 pagesStainless Steel InformationSharat ChandraNo ratings yet

- Iso 13053 Lead Implementer Four Page BrochureDocument4 pagesIso 13053 Lead Implementer Four Page BrochureSharat ChandraNo ratings yet

- Six Sigma Near PerfectionDocument4 pagesSix Sigma Near PerfectionSharat ChandraNo ratings yet

- Phillip: Stochl, Joseph E. Maloy, Masters, A D Richard LDocument63 pagesPhillip: Stochl, Joseph E. Maloy, Masters, A D Richard LSharat ChandraNo ratings yet

- AWS R I C P: Adiographic Nterpreter Ertification RogramDocument4 pagesAWS R I C P: Adiographic Nterpreter Ertification RogramSharat Chandra100% (1)

- Six Sigma Near PerfectionDocument4 pagesSix Sigma Near PerfectionSharat ChandraNo ratings yet

- Ultrasonic Measurements of Solid Propellant Burning Rates in Nozzleless Rocket MotorsDocument8 pagesUltrasonic Measurements of Solid Propellant Burning Rates in Nozzleless Rocket MotorsSharat ChandraNo ratings yet

- Developments in and Implementation of Gas Generators For Fire SuppressionDocument16 pagesDevelopments in and Implementation of Gas Generators For Fire SuppressionSharat ChandraNo ratings yet

- Technical Notes.: Determination of Thermal Transport Properties in Ammonium PerchlorateDocument3 pagesTechnical Notes.: Determination of Thermal Transport Properties in Ammonium PerchlorateSharat ChandraNo ratings yet

- 140639main ESAS 08 PDFDocument60 pages140639main ESAS 08 PDFEdwinHarNo ratings yet

- 697661Document213 pages697661Sharat ChandraNo ratings yet

- Simulation of A Cold Gas Thruster System and Test Data CorrelationDocument20 pagesSimulation of A Cold Gas Thruster System and Test Data CorrelationSharat ChandraNo ratings yet

- MIL STD 120 Gage InspectionDocument216 pagesMIL STD 120 Gage Inspectionokamo100% (4)

- 030 Propellant CharacterizationDocument11 pages030 Propellant CharacterizationSharat ChandraNo ratings yet

- Crogenic Tank Pressurant ReqsDocument104 pagesCrogenic Tank Pressurant ReqsSharat ChandraNo ratings yet

- Numerical Methods For Modeling Transient Flow: in Distribution SystemsDocument0 pagesNumerical Methods For Modeling Transient Flow: in Distribution Systemsjones0055No ratings yet

- Final Compressible Flow MQP PaperDocument76 pagesFinal Compressible Flow MQP PaperSharat ChandraNo ratings yet

- Richard Nakka's Guide to Rocket Propellant AnalysisDocument8 pagesRichard Nakka's Guide to Rocket Propellant AnalysisSharat ChandraNo ratings yet

- Regulator Basics - To B EprintedDocument14 pagesRegulator Basics - To B EprintedSharat ChandraNo ratings yet

- Flexible HoseDocument8 pagesFlexible HoseAttila CsehNo ratings yet

- NL Master Specification Guide For Public Funded Buildings: Re-Issued 2009/10/01Document4 pagesNL Master Specification Guide For Public Funded Buildings: Re-Issued 2009/10/01Sharat ChandraNo ratings yet

- Home Tech Support Gauge CalibrationDocument1 pageHome Tech Support Gauge CalibrationSharat ChandraNo ratings yet

- Interpretations To Asme b31 3Document17 pagesInterpretations To Asme b31 3Phornlert WanaNo ratings yet

- Connection Bulletin: Vogt ValvesDocument12 pagesConnection Bulletin: Vogt ValvesSharat ChandraNo ratings yet

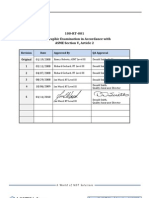

- 100 RT 001 (Rev5)Document47 pages100 RT 001 (Rev5)aristafirsantoroNo ratings yet

- FinalThesisWork TransientDocument111 pagesFinalThesisWork Transientger80100% (2)

- Welding Procedure Acceptance CriteriaDocument4 pagesWelding Procedure Acceptance Criteriatoru101No ratings yet

- QHP CatalogDocument7 pagesQHP CatalogsanjeevvangeNo ratings yet

- PHD Thesis FDMDocument254 pagesPHD Thesis FDMHamedHamediNo ratings yet

- Simkin FinalReportDocument51 pagesSimkin FinalReportSharat ChandraNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pyrotek - SIVEX - Ceramic FoamDocument2 pagesPyrotek - SIVEX - Ceramic FoamajoilhamNo ratings yet

- How Foam Firmness AffectsDocument5 pagesHow Foam Firmness AffectsirwanchemNo ratings yet

- Australian Standard: Liquefied Natural Gas-Storage and HandlingDocument10 pagesAustralian Standard: Liquefied Natural Gas-Storage and HandlingSalim Chohan100% (1)

- Horizontal Bladder Tank: Data Sheet #Npr022Document4 pagesHorizontal Bladder Tank: Data Sheet #Npr022Luis Joel Ramos RamosNo ratings yet

- Epoxy Foam Encapsulant Processing"TITLE"Dielectric Properties of Epoxy Foams" TITLE"Characterization of Epoxy Foam Encapsulants"TITLE"Processing and Testing of Epoxy Foam EncapsulantsDocument63 pagesEpoxy Foam Encapsulant Processing"TITLE"Dielectric Properties of Epoxy Foams" TITLE"Characterization of Epoxy Foam Encapsulants"TITLE"Processing and Testing of Epoxy Foam EncapsulantsEugene PaiNo ratings yet

- Croda - Crothix Thickner For ShampoosDocument14 pagesCroda - Crothix Thickner For ShampoosMartin Velez LozanoNo ratings yet

- BioEx.D.Foam Anglais Web PDFDocument2 pagesBioEx.D.Foam Anglais Web PDFhectorNo ratings yet

- Foam BrochureDocument32 pagesFoam BrochureChristian Emmanuel Gallardo Rivera100% (1)

- Material PropertiesDocument3 pagesMaterial PropertiesmialitaNo ratings yet

- List of Things That Affect Keyboard Sound ? (Serious Buisnesz) ?Document53 pagesList of Things That Affect Keyboard Sound ? (Serious Buisnesz) ?RadityaNo ratings yet

- EOR NotesDocument53 pagesEOR NotesArpit PatelNo ratings yet

- 117CP - Drying and Storage Engineering PDFDocument8 pages117CP - Drying and Storage Engineering PDFvenkiscribd444No ratings yet

- Hyfoama VersawhipDocument16 pagesHyfoama Versawhipbalaji19745100% (2)

- Soil Conditioning For EPB Shield Tunneling in Argillaceous Siltstone With High Content of Clay Minerals: Case StudyDocument8 pagesSoil Conditioning For EPB Shield Tunneling in Argillaceous Siltstone With High Content of Clay Minerals: Case StudyMoez SelmiNo ratings yet

- IALA Guideline Plastic Buoy ConstructionDocument17 pagesIALA Guideline Plastic Buoy ConstructionCan Yigit DincNo ratings yet

- BS en 489 PDFDocument34 pagesBS en 489 PDFGorast KolevNo ratings yet

- Optimization of foam concrete masonry blocksDocument25 pagesOptimization of foam concrete masonry blocksanbunilavanNo ratings yet

- Ultra High-pressure Extinguishing Unit UHP 250Document4 pagesUltra High-pressure Extinguishing Unit UHP 250Narendra Reddy BhumaNo ratings yet

- Technical Bulletin: 3M VHB DurabilityDocument6 pagesTechnical Bulletin: 3M VHB DurabilityAlvin Dela CruzNo ratings yet

- Ics 12439Document15 pagesIcs 12439Rima AgustinaNo ratings yet

- Tuan Noor Hasanah Tuan IsmailDocument84 pagesTuan Noor Hasanah Tuan IsmailJitender SinghNo ratings yet

- Rosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & MunicipalitiesDocument12 pagesRosenbauer Turrets: Reliable Firefighting Equipment for Airports, Industry & Municipalitiesdiegoh_silvaNo ratings yet

- Storage Tank SystemsDocument35 pagesStorage Tank Systemskvramanan_1No ratings yet

- The Lost Foam Method - Pre-Expansion Process: Archives of Foundry EngineeringDocument6 pagesThe Lost Foam Method - Pre-Expansion Process: Archives of Foundry EngineeringQuimicosgenericosgaffaro GaffaroNo ratings yet

- Glycerol Monooleate: Executive SummaryDocument16 pagesGlycerol Monooleate: Executive SummaryMarcelo Bacchetta100% (1)

- Sieve-Tray Tower Design and Operation PrinciplesDocument61 pagesSieve-Tray Tower Design and Operation PrinciplesM.H vafaeiNo ratings yet

- Dopag DynamicLine enDocument14 pagesDopag DynamicLine enULTISOL ENGINEERINGNo ratings yet

- Foam Concrete BrickDocument2 pagesFoam Concrete BrickAnil PurohitNo ratings yet

- Aerospace MGD v12-1 PDFDocument151 pagesAerospace MGD v12-1 PDFDenis DalliNo ratings yet

- Formulation, Preparation, and Characterization of Polyurethane FoamsDocument4 pagesFormulation, Preparation, and Characterization of Polyurethane FoamsDiligenceNo ratings yet