Professional Documents

Culture Documents

Lost Foam Cast Procemss

Uploaded by

Sebastian Peter0 ratings0% found this document useful (0 votes)

86 views22 pagesmmmmm

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentmmmmm

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

86 views22 pagesLost Foam Cast Procemss

Uploaded by

Sebastian Petermmmmm

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 22

THE LOST FOAM CASTING PROCESS

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 1. Mold Foam Pattern Sections

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 2. Age Patterns

The foam material used to create the pattern shrinks in much the same manner as a typical casting. Patterns are aged by allowing them to rest at room temperature for a period of 5 to 7 days. Patterns may also be force aged in a drying oven to allow for quicker use.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 3. Assemble the Pattern

Production patterns are assembled using a precision, automated gluing machine. Glue is printed to one section of the foam and then pressed against the adjoining piece. Multiple piece parts can be built up in this way and produce very complex geometry

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 4. Clustering

Glue individual patterns to sprue. Number of patterns per sprue is dependent on part size and/or configuration. Molded sprue is manufactured similar to foam pattern

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 5. Coating

Coating parameters are verified before coating cluster. Coating is mixed continuously to maintain properties. Cluster may be hand dipped or by automated robot station.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 6. Drying

Coating is dried in an oven at 120-140F(4960C) for 3 to 5 hours.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 7. Compaction

Cluster is delivered to the pouring line by conveyor. Cluster is placed into flask and held in position by a fixture Fixture is timed to release the cluster during the compaction cycle.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 7. Compaction (Cont.)

Sand is rained into flask from overhead bin. Compaction tables can be either vertical or horizontal in orientation and vibrate the flask during filling. Sand is compacted from approximately 90lb/ft to 100 lb/ft by the compaction table.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 8. Metal Pour

Metal is poured to displace the polystyrene pattern. Metal may be poured by hand or with an automatic ladle.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS Process Steps

1. 2. 3. 4. 5. 6. 7. 8. 9. Mold foam pattern sections. Age pattern to allow dimensional shrinkage. Assemble pattern if it is a multiple piece pattern. Build cluster (multiple patterns per cluster). Coat cluster. Dry coating. Compact cluster in flask. Pour metal. Extract cluster from flask.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 9. Extraction

Casting is allowed to cool in sand for a predetermined period. Flask is then dumped on to a shakeout conveyor. Loose sand around the casting cluster helps protect the parts from damage.

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS 9. Extraction (Cont.)

Castings proceed through shakeout to remove loose sand and coating

Copyright 2003 Austin Group, LLC. All rights reserved.

THE LOST FOAM CASTING PROCESS

Final Casting

Copyright 2003 Austin Group, LLC. All rights reserved.

You might also like

- Casting Processes: DR Ajay BatishDocument46 pagesCasting Processes: DR Ajay BatishAlisha GuptaNo ratings yet

- Item No. Qty Unit Unit Cost Total Cost Material Description: Page 1 of 2Document2 pagesItem No. Qty Unit Unit Cost Total Cost Material Description: Page 1 of 2Greens Mac100% (1)

- MTech Production Thesis on Advanced Casting ProcessesDocument42 pagesMTech Production Thesis on Advanced Casting ProcessesPrikshit Gothwal100% (1)

- Manufacturing Process - CastingDocument81 pagesManufacturing Process - CastingArnab HazraNo ratings yet

- Riser Casting ReportDocument47 pagesRiser Casting Reportganesh0% (1)

- Mold CastingDocument55 pagesMold CastingSumit SharmaNo ratings yet

- Metal Casting ProcessesDocument98 pagesMetal Casting ProcessestmcoachingcentreNo ratings yet

- Advanced Lost Foam Casting Technology PHDocument54 pagesAdvanced Lost Foam Casting Technology PHSUNDRAMNAGANo ratings yet

- Office Cost Study PDFDocument16 pagesOffice Cost Study PDFandyoch86No ratings yet

- Thermal Spray Coating For BoilerDocument26 pagesThermal Spray Coating For BoilerHoang Thang100% (1)

- Is The Lost Foam Process The Future of Metal CastingDocument7 pagesIs The Lost Foam Process The Future of Metal Castingjmtindia100% (2)

- 3475331Document41 pages3475331Nguyen Trong TanNo ratings yet

- Learn Critical Aspects of Pattern and Mould Making in FoundryFrom EverandLearn Critical Aspects of Pattern and Mould Making in FoundryNo ratings yet

- Siavashi 12 PHDDocument231 pagesSiavashi 12 PHDVikash SinghNo ratings yet

- Sess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Document7 pagesSess 9 (Ceramic Mould - Pressure Die Casting - Centrifugal Casting)Prakash RagupathyNo ratings yet

- CastingDocument21 pagesCastingGajanan KaneNo ratings yet

- Lost Foam Casting (LFC)Document26 pagesLost Foam Casting (LFC)Gurudutta Mishra100% (3)

- Casting Process GuideDocument74 pagesCasting Process Guidevinu1977No ratings yet

- Metal CastingDocument22 pagesMetal CastingANKIT RAJNo ratings yet

- Casting IntroDocument94 pagesCasting IntroJith ViswaNo ratings yet

- Powder Metallurgy: Basics & Applications Powder MetallurgyDocument11 pagesPowder Metallurgy: Basics & Applications Powder MetallurgyVivek BajpaiNo ratings yet

- Dr. Babasaheb Ambedkar Technological University, LonereDocument36 pagesDr. Babasaheb Ambedkar Technological University, LonereNikhil PawarNo ratings yet

- VacuumDocument6 pagesVacuum03sri03No ratings yet

- 256412Document68 pages256412tabibkarim100% (1)

- Unit-1 Metal Casting ProcessDocument261 pagesUnit-1 Metal Casting ProcessDharun PrakashNo ratings yet

- GAS PROBLEM in Steel Sand CastingsDocument7 pagesGAS PROBLEM in Steel Sand CastingsVasu RajaNo ratings yet

- FP 238Document32 pagesFP 238Mahmoud Atia100% (2)

- 01 CastingDocument31 pages01 CastingSports GloballyNo ratings yet

- Special CastingDocument24 pagesSpecial CastingManohara ErlaNo ratings yet

- Positioning Ceramic Foam Filters in Gating SystemsDocument8 pagesPositioning Ceramic Foam Filters in Gating SystemsSiddharth GuptaNo ratings yet

- Difference Between Forging and CastingDocument2 pagesDifference Between Forging and CastingMOHAMMAD ALINo ratings yet

- CastingDocument74 pagesCastingParth Maldhure100% (1)

- GEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Document114 pagesGEM Series - Fire Fighting Booster Sets in Egypt, Technical Catalog Part 1Rheoserve Industrial SolutionsNo ratings yet

- Curso Moldes InglesDocument153 pagesCurso Moldes Inglesandres Villarreal100% (1)

- Roll Forging Process Shapes Metal Parts Under Compressive ForcesDocument6 pagesRoll Forging Process Shapes Metal Parts Under Compressive ForcesSaptarshi SinhaNo ratings yet

- ASTM E1003 13 Hydrostatic Leak Testing 1 PDFDocument3 pagesASTM E1003 13 Hydrostatic Leak Testing 1 PDFAndrea Fabiana BlaschiNo ratings yet

- MIM Design Guide: Complex Metal PartsDocument13 pagesMIM Design Guide: Complex Metal Partsgnk68No ratings yet

- METAL CASTING GUIDEDocument18 pagesMETAL CASTING GUIDEvelavansuNo ratings yet

- Types of Patterns GuideDocument10 pagesTypes of Patterns GuideANIKET ANANDNo ratings yet

- Lost Foam Process Defect AnalysisDocument5 pagesLost Foam Process Defect AnalysisVivek PanseNo ratings yet

- GTU B. E. Mech Sem V MP II Topic 2 Foundry Technology NeDocument401 pagesGTU B. E. Mech Sem V MP II Topic 2 Foundry Technology NebmdbmdbmdNo ratings yet

- Lost Foam CastingDocument31 pagesLost Foam CastingokicirdarNo ratings yet

- GRINDING TechnologyDocument7 pagesGRINDING TechnologyMifzal IzzaniNo ratings yet

- 87 Computer Simulation of Microstructure Evolution during Hot Forging of Waspaloy and Nickel Alloy 718 ریزساختار 718 فورج داغ PDFDocument10 pages87 Computer Simulation of Microstructure Evolution during Hot Forging of Waspaloy and Nickel Alloy 718 ریزساختار 718 فورج داغ PDFAmir JoonNo ratings yet

- FoundryDocument2 pagesFoundryHafiz UdinNo ratings yet

- Gas Defects:: These Are Spherical, Flattened or Elongated CavitiesDocument3 pagesGas Defects:: These Are Spherical, Flattened or Elongated CavitiesmaniNo ratings yet

- Cast Vs ForgedDocument9 pagesCast Vs ForgedSIVANo ratings yet

- Metal-Casting Process and EquipmentDocument18 pagesMetal-Casting Process and EquipmentZulfikarUdenNo ratings yet

- Metal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingDocument7 pagesMetal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingzidaaanNo ratings yet

- NADCA-High Temp DieDocument12 pagesNADCA-High Temp DiejalilemadiNo ratings yet

- Ingot StructureDocument5 pagesIngot StructureklawsisNo ratings yet

- Squeeze Casting - An Overview PDFDocument9 pagesSqueeze Casting - An Overview PDFDian Try SaputriNo ratings yet

- Loose Piece Pattern CastingDocument29 pagesLoose Piece Pattern CastingshuklameNo ratings yet

- Foundry Notes by ShiftyDocument22 pagesFoundry Notes by ShiftyRaiyan Shifty100% (1)

- A Finite Element Method Based Analysis of Casting Solidification Onpermanent Metallic ModelsDocument10 pagesA Finite Element Method Based Analysis of Casting Solidification Onpermanent Metallic ModelsseenisitNo ratings yet

- About Die CastingDocument3 pagesAbout Die CastingJoelNo ratings yet

- MOULDINGDocument35 pagesMOULDINGsumitNo ratings yet

- 10 Rules For CastingDocument2 pages10 Rules For CastingBijendra PrajapatiNo ratings yet

- Different Casting Methods ExplainedDocument14 pagesDifferent Casting Methods ExplainedRamoji Aditya Chary100% (1)

- FoundryDocument10 pagesFoundryAnjana_EdathadanNo ratings yet

- Grains Structure of IngotsDocument6 pagesGrains Structure of Ingotshayder1920No ratings yet

- AbrasivesDocument49 pagesAbrasivesfockewulNo ratings yet

- Chills General RulesDocument36 pagesChills General RulesMuthu KumarNo ratings yet

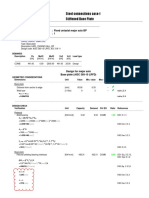

- Quotation For ReferencemDocument12 pagesQuotation For ReferencemSebastian PeterNo ratings yet

- Thuvvur, Kerala To Club Mahindra, Coorg - Google Maps PDFDocument3 pagesThuvvur, Kerala To Club Mahindra, Coorg - Google Maps PDFSebastian PeterNo ratings yet

- Bathroom Selection & Fitting DetailsDocument1 pageBathroom Selection & Fitting DetailsSebastian PeterNo ratings yet

- Building Bye LawsDocument153 pagesBuilding Bye LawsShubham nigamNo ratings yet

- Maria C Kaithakkary's Family DetailsDocument2 pagesMaria C Kaithakkary's Family DetailsSebastian PeterNo ratings yet

- Energy Efficient Buildings Integration of Emerging TechnologiesDocument22 pagesEnergy Efficient Buildings Integration of Emerging TechnologiesKhai Urlanda-LucianoNo ratings yet

- Guide to fiber internet and home services at The MagnoliasDocument1 pageGuide to fiber internet and home services at The MagnoliasSebastian PeterNo ratings yet

- BOQ For Mr. Sudhir Dhingra Apartment 115A Aralias Big Balcony WorkDocument4 pagesBOQ For Mr. Sudhir Dhingra Apartment 115A Aralias Big Balcony WorkSebastian PeterNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentSebastian PeterNo ratings yet

- CorelDRAW Graphics Suite X5Document1 pageCorelDRAW Graphics Suite X5Sebastian PeterNo ratings yet

- Wall Flashing V1Document23 pagesWall Flashing V1Sebastian PeterNo ratings yet

- Sebastian Peter - Thesis Research PaperDocument11 pagesSebastian Peter - Thesis Research PaperSebastian PeterNo ratings yet

- Exp 1 Layout2Document1 pageExp 1 Layout2Sebastian PeterNo ratings yet

- Steel Connections Case-I Stiffened Base Plate: ResultsDocument4 pagesSteel Connections Case-I Stiffened Base Plate: Resultsfreddysalas12No ratings yet

- 05 Test ReportsDocument22 pages05 Test ReportssacdawoodNo ratings yet

- Mechanical Behavior and Elasticity TheoryDocument25 pagesMechanical Behavior and Elasticity TheoryRosni hasanNo ratings yet

- Set Free R410A: Variable Refrigerant Ow Air Conditioning SystemsDocument48 pagesSet Free R410A: Variable Refrigerant Ow Air Conditioning SystemsWal iDNo ratings yet

- Information Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Document2 pagesInformation Sheet 6 - Heat Soak Tested Thermally Toughened Glass - April 2016Khurshed Alam IndiaNo ratings yet

- f84835752 ERECTION PROGRESS REPORT FOR Gulf MallDocument5 pagesf84835752 ERECTION PROGRESS REPORT FOR Gulf MallAbdulrahman AlkilaniNo ratings yet

- Chemistry Form 4 Chapter 9Document6 pagesChemistry Form 4 Chapter 9Suriati Bt A Rashid100% (1)

- Aluminum 6061Document3 pagesAluminum 6061Achmad Rizal MustaqimNo ratings yet

- Flomatic Price-List-2022Document40 pagesFlomatic Price-List-2022Esteban Barboza RiveraNo ratings yet

- Kingspan - Accessories 1 PDFDocument20 pagesKingspan - Accessories 1 PDFR_DraganNo ratings yet

- Uni-Chains: Chain CatalogDocument121 pagesUni-Chains: Chain CatalogOmar SanchezNo ratings yet

- Amp Qb.Document6 pagesAmp Qb.svkarthik83No ratings yet

- Clyde - SB Smart Clean System (Shared by ED - 220928 - 104318Document2 pagesClyde - SB Smart Clean System (Shared by ED - 220928 - 104318Sanjana SanjanaNo ratings yet

- Electrode Classifications 2Document1 pageElectrode Classifications 2aguirretoNo ratings yet

- MECHANICAL SYSTEM DESIGN GUIDEDocument43 pagesMECHANICAL SYSTEM DESIGN GUIDEمعين عزامNo ratings yet

- Load Evaluation PDFDocument9 pagesLoad Evaluation PDFMois DanielNo ratings yet

- New Eurocode For Towers, Masts and ChimneysDocument6 pagesNew Eurocode For Towers, Masts and Chimneysbojana_246941181No ratings yet

- CEMC Module 5Document52 pagesCEMC Module 5Biswajit SamalNo ratings yet

- 2GIG ZWave CT30e Thermostat Installation GuideDocument19 pages2GIG ZWave CT30e Thermostat Installation Guideyamimaker2002No ratings yet

- Basic Comparison Extruder Slipformer enDocument7 pagesBasic Comparison Extruder Slipformer enOmar MahmoudNo ratings yet

- NDT Certificate Inspection ReportsDocument9 pagesNDT Certificate Inspection ReportsikponmwonsaNo ratings yet

- Lim Fire Research 03 2Document351 pagesLim Fire Research 03 2torNo ratings yet

- Types of Building FramesDocument23 pagesTypes of Building FramesimaniNo ratings yet

- 3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor ManualDocument12 pages3-0515.090 Rev 27 (515-2536) English Rotor-X Flow Sensor Manualabbas dehghanNo ratings yet

- 1 s2.0 S2214509522002479 Main PDFDocument23 pages1 s2.0 S2214509522002479 Main PDFHarpreet SinghNo ratings yet