Professional Documents

Culture Documents

Shepherd 1987 Aquacultural-Engineering

Uploaded by

Jorge RodriguezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shepherd 1987 Aquacultural-Engineering

Uploaded by

Jorge RodriguezCopyright:

Available Formats

Aquacultural Engineering 6 (1987) 155-169

A Review of Practical Emergency Procedures for Fish Culturists

B. G. Shepherd and J. G. Morris

SalmonidEnhancementProgram,Departmentof Fisheriesand Oceans, 1090 W. Pender St., Vancouver,BritishColumbia,V6E 2P1, Canada

ABSTRACT The development of an effective emergency-response system requires care both in the planning of procedures and the selection of equipment. The Opes of emergencies that may arise in hatcheries are manifold, but can be categorized as external (such as weather or independent activities in the watershed), general to the hatchery (relating to human activities and fire, power and freezer failures), or specific to the water supply (flow, level, or water quali O, concerns). Systems suggested for British Columbia federal salmon hatcheries to handle or avoid these various types of emergencies are outlined. The combined importance of careful design, a strong preventive maintenance program, and contingency planning for emergencies is emphasized.

INTRODUCTION Obviously, catastrophes such as the 1980 Mount St Helens, Washington eruption which destroyed the Washington State Department of Fisheries' Toutle River Hatchery, are beyond the control of hatchery'staff. However, the majority of hatchery emergencies can be successfully handled or even avoided, given proper foresight and funds. Senn et al. (1984), among others, have previously detailed the alarm and security equipment used in salmonid culture facilities. Our purpose in this paper is to outline desirable and practical design and operational attitudes to emergencies. It is the combination of careful planning of procedures, together with the right equipment, that results in an effective emergencyresponse system. 155 .4quacultural E11gineering 0144-8609/87/S03.50-- Elsevier Applied Science Publishers Ltd. England. 1987. Printedin Great Britain

156

B. G. Shepherd, J. G. Morris

TYPES OF EMERGENCIES Some of the common types of emergencies that a hatchery operation might face are listed in Table 1. Overall, emergencies can be categorized as external or internal to the hatchery operation, with continuity of the water supply being of paramount concern within the hatchery.

TABLE 1 Common Types of Emergencies that May Arise in Hatcheries

Category

External

General area

Elements Human Staff

Specific type of emergency

Damage from flood, drought, wind, snow, ice Pollution or other damage resulting from upstream activities (e.g. train wreck, dam spills) Operator error (see below for specific examples) Maintenance ignored Injury Intrusion Vandalism (see below for examples) Electrical Fuel Lightning Loss of line service Failure of hatchery generator Failure of electrical component (e.g. relay) Timers or automatic controls shut off Air temperature too warm Compressor failure Valve shut Valve opened too wide, robbing flow from another are a Pipe or valve plugs, breaks or freezes Pump failure Well failure Intake screens plug Drain valve opened Stoplog removed or leaking Overflow due to plugging, vandalism, etc. Water demand exceeds supply Siltation (e.g. failure of filters) Ineffective aeration (low O, or high N,) Pollution (e.g. leak in heat exchanger) Chemical spill within hatchery Water too cold Water too hot

Hatchery (general)

Human Fire

Power

Freezer Water supply Flow

Level

Contamination

Temperature

Emergency proceduresfor fish culturists

157

EMERGENCY EQUIPMENT AND PROCEDURES This section must be prefaced with a caution. In reviewing the experiences of federal hatchery managers to date, alarm systems have given them many problems. This is an area in which it is easy to go overboard, both in terms of technological complexity and sheer numbers of alarms and monitors. One is well advised to keep the acronym K.I.S.S. (Keep It Simple, Stupid) strongly in mind when choosing alarms and monitoring systems. Funds expended on alarms that end up disarmed by the hatchery staff because of unreliability, false alarms or inconvenience, are dollars that could have been better spent elsewhere. Further, the presence of an operating fail-safe protection system may be a critical assumption in the design of other components of the hatchery. Therefore, consider and question your needs very carefully before committing to any system. There are a number of factors that will affect choice of emergency systems and procedures, including: The type of facility (e.g. spawning channel, pilot hatchery, production hatchery, gravity or pumped water supply from wells or surface water). The types and numbers of incubation, rearing and adult holding containers in the facility. The number and value of different stocks of fish that will be present. The location and mode of operation of the facility (remote or near town; are staff on the site full-time, part-time or seasonally?). The budget. There are many alarm and monitoring systems available. We have attempted below to expose the reader to systems ranging from the simple. through those in common use in British Columbia, to the more exotic for each type of emergency.

External influences

Many of these types of problems can be reduced or avoided if the location of the facility is considered carefully in relation to access, water levels, climate, upstream activities, etc. during the early planning stages. Shepherd (1984) gives more details with regard to this. Certain large7 scale events such as the Mount St Helens eruption may be impossible to deal with, aside from establishing a contingency plan for staff evacuation. Other types of external events may be controlled somewhat through

158

B. G. Shepherd, J. G. Morris

careful layout and design of the facility. Examples include firebreaks around the facility; wide powerline and access corridors to avoid service interruption due to windfalls; attention to snowloads in relation to roof design and yard clearances; siting of the facility or protective dyking above the 200-year flood level; self-draining valves in locations susceptible to freezing.

Hatchery -- general

Staff

Regardless of the sophistication of the alarm and monitoring system, staff preventive maintenance and emergency response procedures are essential to the reduction and successful handling of emergencies. In the development of such procedures, Maintenance Management (Mann, 1983) and the Maintenance Engineering Handbook (Higgins and Morrow, 1977) would be useful additions to a hatchery's basic reference library. Components for a preventive maintenance program should include: A maintenance manual prepared by the engineering staff responsible for construction of the facility. A rapid-reference file card system collating all essential specifications, part numbers, dealers, etc. for equipment items. A weekly/monthly/yearlymaintenance scheduling system (on pin-sort cards or computer) and files of major service records (Monday a.m. routine for scheduled maintenance, to allow time to order parts. etc.). Daily/weekly/monthlyinstrument check sheets. Area check sheets and a formal rounds sequence for operators. Vibration Histories on pumps (monthly monitoring, quarterly records/graphing). Regular circuit tests of the complete system, including: trigger each sensor; check lights at collector panels; check signal at main annunciator panel; check operation of dialer; check response time of answering service. Establishment of a water supply management plan for both surface and ground water supplies. Frequent site inspections by engineering staff. All staff should have a thorough knowledge of the facility's physical operation. Training aids to achieve this include:

Emergency procedures for fish culturists

15 9

Familiarization tour of complete facility for each new employee. An operator's manual (often combined with the maintenance manual). Regular emergency drills. Posting of schematic of water supply system in key locations. Labeling and color-coding of pipes, valves and operators. Posting of specific emergency and safety procedures at point of potential problem (e.g. generator room, intake pump chamber, incubation room, etc.). Establishment of fixed stations with keys and tools for valve operation, and with dedicated equipment for first aid, fire, emergency lighting, etc. A stepwise emergency response procedures manual to allow the operator to consistently and efficiently respond to alarms. The manual should contain the following: identification of the meaning of each alarm; the possible reasons for the alarm being triggered; a priorized check/solution procedure. For all of the manuals, it is helpful if the text is stored on a wordprocessor, allowing immediate update whenever changes are made. This updating is also facilitated if looseleaf binders are used. Most important, all staff have to be evaluated frequently as to their emotional and physical capabilities in an emergency situation. This is difficult to assess, but not impossible. The ability to respond effectively to an emergency is largely dependent on the person's maturity and personal reliability; without these traits, technical knowledge and training may prove to be to no avail. There is a tendency, which should be avoided, to emphasize fish culture experience at the expense of mechanical capability. Staff selection and development procedures should incorporate the following: Place a verv high importance on personal suitability (i.e. reliability, commitment) during staffing. Frequently discuss and encourage questions about the hatchery's mechanical systems (particularly the water supply) with the staff. Give each staff member 'hands-on' operating experience. Discipline staff who are lax in the performance of stand-by duties.

Intrusion and vandalism

The electronic security system technology is presently undergoing rapid development, and many types of sensors are available (e.g. photoelectric

160

B. G. Shepherd, J. G. Morris

or ultrasonic beams, sound 'bugs', window tapes, and door trips). The system must be chosen carefully to suit the hatchery operation, and to ensure that servicing, parts and spares will remain easily available. Use of window tapes, for example, means many sensors are required for complete coverage, and windows cannot be left open overnight to allow the building to cool down during hot weather. A few judiciously-placed beam alarms in interior corridors may be simpler and more suitable in this situation. Even minor occurrences, such as a moth settling on a photoelectric cell, can trigger an alarm. This can result in considerable wasted staff time due to call-outs, and eventually to a lack of confidence in the system. There are alternate security systems that can be considered, ranging widely in cost and effectiveness. Complex facilties may require the presence of trained operators around the clock anyway (this is very costly). Staff can live in residences with visual control over the site. Security firms or commissionaires can provide coverage during off hours. During unmanned periods, guard-dogs can be very effective deterrents. However, the use of dogs also requires an escape-proof perimeter fence, and access out of ponds or channels must be provided to avoid drowning in the event that the dog falls in. Also, the dog must be familiarized with all staff that may have to enter during off-hours, which can reduce effectiveness where there is a large hatchery staff or where staff turnover is heavy. Perimeter fencing alone provides a lower level of security. Use of locking devices on valves, standpipes and stoplogs also aids in reducing vandalism.

Fire

Fire response systems are relatively straightforward, in that their scope is specified by the building code applicable to the area. Consideration should be given to the type and location of sensors, in relation to the area of the hatchery (i.e. the needs for a welding area differ from those for the incubation room). Halon fire suppression systems should be considered for powerhouses, particularly if they are the primary power source for the facility.

Po wer

The original design of the facility in most cases incorporates back-up generators that start up automatically in the event of failure of the main power supply (normally a time-delay switch is used, to avoid start-up when power is only lost momentarily). Depending on electrical loads, the back-up system may automatically supply priority areas (i.e. pumps) only, and require manual switching to supply other areas. Normal alarming for

Emergencyproceduresfor fish culturists

161

generator systems is of the mechanical automotive type, and should include undervoltage, high oil and water temperature, low oil pressure, high RPM, overcranking in start-up, and phase. Power supplies are particularly prone to failure due to individual components. A strong preventive maintenance and routine testing program is essential.

Freezer Compressor function alarms are in common use for walk-in freezers. In addition, high-temperature alarms are necessary with the storage of large amounts of fish food, particularly in the sub-zero freezer section. A maximum-minimum thermometer, read and reset daily, is a less satisfactory but inexpensive approach. In the cooler, which is held just at freezing, or in small chest freezers, an even simpler method to check for thawing is to keep several ice cubes in a container; in the event of temporary failure, the ice cubes will melt and refreeze as a single mass.

Water supply

A failure in the water supply immediately jeopardizes all the eggs and fish in the hatchery. Thus this particular emergency is emphasized in this paper.

Wawrflow

Of the various flowmeters available in British Columbia (Lukyn, 1982), there are two main types capable of being coupled into a hatchery alarm system. The propellor or paddlewheel type (e.g. the 'Spading' flowmeter) is used most commonly. "Annubar' or 'Eagle Eye' flowmeters, which operate on the differential-pressure principle, are also in use. The advantage of the flowmeter, of course, is that flow can also be measured. For a simpler flow/no flow alarm, paddle switches (e.g. 'Gem' brand) are in common use. Pressure sensors are used infrequently, due to the fluctuations experienced during normal operation of valves. Main valves should be easy to reach and operate, and should be kept well greased. Passageways to valves should be kept clear. Pressurized water systems that are controlled by valves are potentially hazardous. Main valves should be opened or closed very slowly to avoid a pressure surge that could rupture a pipe. Locks are advised on valves that might be subject to tampering, but keys have to be readily available to staff. Valves should be exercised regularly to ensure that corrosion or debris does not jam the mechanism. Also to avoid jamming, valves should be turned back slightly from the full open or close modes.

162

B. G. Shepherd, J. G. Morris

Self-draining valves are r e c o m m e n d e d wherever there is a chance of freezing. Otherwise, it may be a good idea to keep all valves at least slightly open when freezing conditions are expected. T h e need for a water supply management plan has always been obvious for facilities with d a m m e d reservoirs. That need is much less obvious, but just as great, for the facility that uses wells. Special care must be taken in servicing, start-up and shutdown to avoid contamination and plugging of the well, through physical damage to the screens or plugging with fines or bacterial slime growths. It is recommended that wells not be run at maximum capacity continuously; it would be much better to continuously run a well at 6 0 - 7 0 % of its design capacity, or to 'rest' wells run at the 100% level. The temperature, flow and level of each well should be routinely monitored, to give advance warning of any potential problems and to allow timely switching to other wells in the field or to a surface supply. Plugging of surface water intake screens can be monitored using low level alarms (see below) in the forebay. Cleaning plugged screens of debris can be by manual brushing or by backwashing. For the latter, rotating spray arms are mounted behind the intake screens, and are driven by an independent pump that is supplied with water from the forebay. A more expensive alternative is the travelling screen; a continuous belt of screen panels is carried up out of the water, and a fixed spray bar behind the belt blows debris and live fish off the screen and into a collection trough for disposal downstream. Plugging with frazil ice can be avoided by delivering relatively small amounts of warmer water (e.g. from a well) to the intake screen area.

Water level

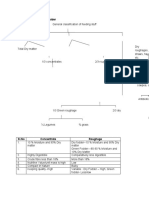

There are a number of different types of water level alarms presently in use in British Columbia. Commercial types that are in common use (Fig. 1 ) include: floats with an internal mercury switch (e.g. 'Flygt') similar to those found on thermostats; low level only; conductivity alarms (e.g. 'Rosemount' brand); high and/or low levels possible; small magnet-equipped floats on a rod, which can activate a switch in both high level and low level situations (e.g. 'Gem' brand). A level alarm also can be constructed using a paddle-type flow switch installed in a small overflow standpipe. Low-cost 12V high/low level alarms can be fabricated on site using easily available automobile and plumbing parts; a set of contact points can serve as the switch, wired to a car horn and activated by a toilet float arm.

Emergency proceduresfor fish culturists

163

CABLE

JUN

SUPPORT_ BRACKET-,.~

/I

f CAPPED ~ 30q> ALUM. TUBE

WELDED TO .ATE

[ | 6ram ALUM. IL'P3 WIDE FASTEN TO HEAD TANK WITH 4-6dP

"-

/ l LACTUATION REED TYPE J I [ "LEVELS LEVEL SWITCHES'-" ",.~-L(LOW )

TROUGH LEVEL SWITCH MOUNTING

CABLE---~ MOVABLE

LOATSW,TC.

WATER LEVEL--4ga~'~-I----

IFLOAT

JUNCTION BOX FASTENED TO SIDE OF RACEWAY .------- RACEWAY APPROX. 1900 WIDE NQTE: LEVEL SWITCH TO BE LOCATED IN OUTLET COMPARTMENT OF RACEWAY

SWITCH IN "NOT IN USE POSITION

;'72:::2"

"ALARM" POSITION

RACEWAY LEVEL SWITCH MOUNTING

Fig. 1.

Sketches of level switches commonlyused in BritishColumbia, showingtypical mounting details.

Level or flow switches also can be hooked into solenoid-controlled valves on both main and back-up supply lines if desired. For smaller operations, mechanically-operated float pressure valves of the type used for livestock watering troughs might provide acceptable back-up. As with valves, locking devices on standpipes, drain valves, and stoplogs will discourage tampering.

164

B. G. Shepherd, J. G. Morris

Contamination

Water turbidity is seldom monitored on a routine basis in British Columbia hatcheries. The condition is visually obvious, and normally takes days to result in fish culture problems. Response to a siltation situation basically consists of switching to a cleaner supply if available, or dropping flows to a minimum to reduce the amount of silt deposited. Silt is removed by siphon or pool vacuum from rearing containers, and by gentle stirring or back-flushing from incubators. It is only recently that it has been possible to monitor dissolved gas supersaturation continuously (Bouck, 1982). A number of recent studies also indicate that even moderate supersaturation of 103-105% may be responsible for many previously unexplained mortalities at our facilities (Alderdice and Jensen, 1983; Wright and McLean, 1985). Thus monitoring of this aspect deserves more attention in the future, particularly when pumped groundwater is used. Oxygen levels can be monitored continuously using readily-available meters and recorders, but the normal procedure to date has been to measure oxygen just at key times of the day, using a calibrated .portable meter or the Winkler titration method. Unless one is using water supplies that are dangerously low in oxygen without artificial aeration (a characteristic of many well supplies), this approach probably is sufficient. Where artificial aeration is used, there should be at least flow or level alarms installed in the aeration system. All above-ground fuel tanks should be installed inside a leakproof catch basin; location of below-ground fuel tanks should take into consideration potential contamination of rearing channels o r groundwater supplies in the event of a leak. Otherwise, aside from establishing guidelines for the handling of potentially dangerous chemicals on the hatchery site, this area normally is of concern only at facilities that are technologically relatively complex. For example, hatchery water may be heated using industrial effluent via a heat exchanger. In this case, potential contamination because of a leak in the exchanger can be guarded against by using a conductivity sensor coupled to solenoid-controlled valves on the regular and back-up water lines. In most situations, this type of alarming is specialized and should be part of the basic design.

Temperature

Sensors are normally the resistivity bulb type; these are readily available from a number of firms, and can be coupled to alarms and solenoidactivated valves. Again, this sort of system is required only in specialdesign situations where water is being artificially heated. Monitoring on a daily basis is usually sufficient with normal water supplies.

Emergency procedures for fish cuhurists

16 5

Transmission of alarms Staff can be alerted on-site by audible or visual alarms, usually a combination of both, mounted in central or key interior and exterior areas. Where alarms are mounted externally, one also has to consider the potential disturbance to neighbours. When the facility will not be manned around the clock, a standby system incorporating alarm forwarding often is used. In choosing such a system, one must first decide who has to know about the alarm -answering service, off-duty staff, police, fire department, etc. Alarms can be transmitted by radio or by regular telephone lines. Alarms can be received as a taped message in a number of ways: by pager; by teledialer to one location (e.g. an answering service), or to several locations in a predetermined sequence. There should be a time delay relay incorporated into the transmission system, which allows on-site staff to intercept the signal within three minutes or so.

Action when the water supply fails Uneyed eggs, if kept moist, live longer out of water than in stagnant water. However, they will survive in stagnant water for an hour or two. During that time, a temporary water supply to the incubation area should be set up if possible. It should be used to fill head troughs in rotation if there is not enough water for a steady flow to all. A flow of water through each stack of Heath trays every 10 rain is enough. If it is evident that there will be no water for several hours, the drain plugs on all Heath trays should be pulled and the water allowed to drain slowly. The eggs should then be kept moist by periodically sprinkling water over them. Three days is about the maximum that uneyed eggs can be kept alive using this procedure. Eyed eggs, if kept moist, will also live longer in air than in stagnant water. However, they need more oxygen than uneyed eggs and should not be left in stagnant water foe more than one half hour. Within that time, the drain plugs on Heath trays should be pulled. The eggs should be moistened every 3 h by sprinkling or by immersing the trays in water. Alevins in incubation containers generally should not be kept in stagnant water for more than 15 min. However, plugs should not be pulled when Heath trays contain alevins. Without a flow of water, alevins will only survive if moved elsewhere within the hour. If they cannot be transferred to an operating pond, they could be held or released in the wild environment.

166

B. G. Shepherd, J. G. Morris

In the case of fish ponds, the first consideration is to restore a flow of water by any means possible, perhaps by portable pumps and hoses. Unless the flow can be .restored immediately, the appropriate action depends on crowding rate, water temperature, and other factors. In crowded ponds at high temperatures, the best action may be to immediately release some or all fish to the wild environment. If fish are held in ponds without water flow, the water must be aerated. Possible means are: recirculating water from the ponds, returning it as a spray or with much splashing; using compressed air; or having staff dip water with pails and dash each pailful against a fixed surface within the pond.

Considerations in safe design

It has been mentioned in earlier sections that care taken in the planning and construction phases of a facility will pay off in the reduction in severity, or even the elimination of many emergencies. The complexity of alarm response and monitoring systems generally varies as follows: MOST COMPLEX LEAST COMPLEX INDUSTRIAL COMMERCIAL ~ HATCHERIES RESIDENTIAL

For instance in industrial systems, alarm sensors often signal both actuation and alarm; in the hatchery situation, sensors most often go to alarms only, and the staff must make the corrective action manually. It should be noted that it is unrealistic to use the emergency procedures at large industrial complexes as models for hatcheries. Large companies are able to muster far greater resources than the average hatchery can. The average pulpmill, for instance, will employ a number of tradesmen solely to stand by for emergencies; few hatcheries could afford this. General considerations during planning and installation should include:

Alarm systems To avoid false alarms, choose alarm sensors to suit the operating conditions (e.g. if the water is turbulent where a level alarm is to be installed, the sensor should react only to gross changes, or should be installed in a stilling well). Make sure the sensor installation suits the working environment (e.g. all electrical boxes must be sealed against moisture in the incubation room). Mount sensors where they are visible and easily accessible for servicing and adjustment.

Emergency proceduresfor fish culturists

167

Clearly label the sensor's armed and disarmed modes, and install a light at each sensing station that will indicate that the alarm is on or off. Choose sensors that have the correct range of sensitivity and that are calibrated easily. Choose sensors, systems and annunciators that are common in the hatchery locale, such that parts and spares will remain available. Make sure each sensor can be disarmed without shutting the entire system down. Use the fewest number of sensors possible (e.g. rather than putting level alarms in every rearing trough, consider a single flow switch in the main supply line, or a single level alarm in an open head tank that feeds all troughs). 'Zone' the alarm system to reduce electrical complexity (e.g. all raceway low-level sensors can be fed to a local collector panel near the ponds which will display the status of each sensor, but only one alarm for raceway low level is run to the main annunciator panel in the control room). However, note that it is essential to retain the capability to test individual sensors in the event of malfunction. Include expansion capability in all components of the alarm system: have extra sensors on hand; oversize the electrical conduits; oversize the collector panels; leave blank displays in the annunciator panel. Choose your electrical system designers carefully and make sure they are aware of the level of sophistication desired. Get examples of past designs. Make sure you have carefully thought out the conceptual design of the systems before proceeding with electrical design: what will be alarmed and where; how many sensors are needed; what signals will be sent from zones; type of alarm transmission required, etc. Solicit comments of suppliers and installers on the practicality of any electrical or mechanical alarm system early in design.

Supply systems Incorporate flexibility into the original design, both to handle emergency situations as well as to allow routine maintenance with a minimum of disruption. Design capacity for future expansion into the water supply and piping; in the short term, this can be helpful in emergencies.

168

B. G. Shepherd, J. G. Morris

Design pipe supply lines with interconnections, to provide either two water sources or two directions to get water to each hatchery component. Keep piping labelled, color-coded, and visible wherever possible. Inside buildings, overhead piping is particularly suited to this and reduces risk from vehicle damage as compared to standpipes. Net additional cost to do this can be surprisingly low in some instances. Provide back-up pumps or power. Pipes should be properly vented to prevent air locks. Situate raceways, head tanks, etc. such that flow to them can be easily seen during routine checks. Locate valves so that their operating position can be easily checked visually.

ACKNOWLEDGEMENTS The framework for this paper was taken from a chapter on emergencies contained in a proposed salmonid hatchery manual for British Columbia; the original draft of this manual was written by W. A. Kennedy and W. Griffioen under contract to the Department of Fisheries and Oceans, Pacific Biological Station, Nanaimo, BC. The authors are especially indebted to the Ore-Aqua hatchery staff at Springfield, Oregon for their advice on the development of preventive maintenance programs. We thank R. A. Harvey, H. Genoe, J. W. C. McNally, F. K. Sandercock, J. R. Wild, and especially D. McNeil, for their careful review of the manuscript. The use of trade names mentioned in this paper is for information purposes only, and does not imply endorsement of the products.

REFERENCES Alderdice, D. F. & Jensen, J. O. T. (1983). Gas supersaturation in hatchery water supplies. Info Memo No. 68, In: 'Salmonid Enhancement Program -- preliminary notes on new information in salmonid hatchery propagation' (eds D. E Alderdice, F. E. A. Wood and D. W. Narver), Can. Data Rep. Fish. Aquat. Sci., No. 496, p. 68. Bouck, G. R. (1982). Gasometer: an inexpensive device for continuous monitoring of dissolved gases and supersaturation. Trans. Am. Fish. Soc., 111, 5O5-16.

Emergency proceduresfor fish culturists

169

Higgins, L. R. & Morrow, L. C. (1977). Maintenance Engineering Handbook (3rd Edn), McGraw-Hill, Toronto. Lukyn, B. V. (1982). An assessment of water measurement techniques used in the Vancouver Island Salmonid Enhancement projects. Can. Man. Rep. Fish. Aquat. Sci., No. 1734. Mann, L. Jr. (1983). Maintenance Management (Revised Edn), D. C. Heath and Co., Toronto. Senn, H., Mack, J. & Rothfus, L. (1984). Compendium of low-cost Pacific salmon and steelhead trout production facilities and practices in the Pacific Northwest. Contract No. DE-AC79-83BP12745, Project No. 83-353, by Fish Management Consultants for Bonneville Power Admin., US Dept Energy, Portland. Shepherd, B. G. (1984). The biological design process used in the development of federal government facilities during Phase I of the Salmonid Enhancement Program. Can. Tech. Rep. Fish. Aquat. Sci., No. 1275. Wright, P. B. & McLean, W. E. (1985). The effects of aeration on the rearing of summer chinook fry (Oncorhynchus tshawytscha) at the Puntledge Hatchery. Can. Tech. Rep. Fish. Aquat. Sci., No. 1390.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Poxton 1987 Aquacultural-Engineering 1Document3 pagesPoxton 1987 Aquacultural-Engineering 1Jorge RodriguezNo ratings yet

- Coconut-In Support of Good Health in The 21st CenturyDocument27 pagesCoconut-In Support of Good Health in The 21st CenturyDan RoneyNo ratings yet

- Poxton 1987 Aquacultural-EngineeringDocument22 pagesPoxton 1987 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- (First Author) 1987 Aquacultural-EngineeringDocument2 pages(First Author) 1987 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Wang 1986 Aquacultural-EngineeringDocument2 pagesWang 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Huggins 1987 Aquacultural-EngineeringDocument17 pagesHuggins 1987 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Twu 1986 Aquacultural-EngineeringDocument16 pagesTwu 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- McSweeny 1986 Aquacultural-EngineeringDocument8 pagesMcSweeny 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Shleser 1986 Aquacultural-EngineeringDocument15 pagesShleser 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Morse 1986 Aquacultural-EngineeringDocument9 pagesMorse 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Lam 1986 Aquacultural-EngineeringDocument11 pagesLam 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- Losordo 1986 Aquacultural-EngineeringDocument15 pagesLosordo 1986 Aquacultural-EngineeringJorge RodriguezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 15 Eco TourismDocument8 pages15 Eco TourismManoj SatheNo ratings yet

- Chodoshguide 2010 PT 2Document76 pagesChodoshguide 2010 PT 2shasdafNo ratings yet

- Meseret ChaneDocument84 pagesMeseret ChaneTaddese GashawNo ratings yet

- Study The Consumer Awareness About Nandini Milk and Milk Products and Impact of Promotional Activities On Creating AwarenessDocument75 pagesStudy The Consumer Awareness About Nandini Milk and Milk Products and Impact of Promotional Activities On Creating AwarenessManjunath@116No ratings yet

- Teaching Greenhouse and Floral Skills Management Hort 4040 SyllabusDocument3 pagesTeaching Greenhouse and Floral Skills Management Hort 4040 SyllabusLee SellersNo ratings yet

- Classification Feed and FodderDocument4 pagesClassification Feed and FoddermathiNo ratings yet

- June 2014 GlobalDocument9 pagesJune 2014 GlobalMissFabulousNo ratings yet

- Sample Detailed Lesson PlanDocument5 pagesSample Detailed Lesson PlanMary Ann PateñoNo ratings yet

- D - Sheet1Document44 pagesD - Sheet1SD KECIL REMONo ratings yet

- UNIT 8 - Soil ErosionDocument47 pagesUNIT 8 - Soil ErosionMaria Lourdes samontinaNo ratings yet

- Here Is Some Info On SalicylatesDocument13 pagesHere Is Some Info On SalicylatesprofdrgenNo ratings yet

- Antagonistic Effects of Plant Growth Promoting Bacteria Against Bacterial Diseases of Black GramDocument5 pagesAntagonistic Effects of Plant Growth Promoting Bacteria Against Bacterial Diseases of Black GramAcademic JournalNo ratings yet

- Memories of ScipioDocument12 pagesMemories of ScipioDanNo ratings yet

- 4th Grade Vocabulary WordsDocument2 pages4th Grade Vocabulary WordsBenTenAveryEmmaNo ratings yet

- 3 Cornmill Project Presentation - MakinaSaka2015Document17 pages3 Cornmill Project Presentation - MakinaSaka2015The Municipal AgriculturistNo ratings yet

- Report LAPA DesignDocument452 pagesReport LAPA DesignslakheyNo ratings yet

- SSIGL-2 Site Identification and Prioritization Ver-6Document106 pagesSSIGL-2 Site Identification and Prioritization Ver-6Amiira AbdumalikNo ratings yet

- Uganda Grain Dealers LTD Business PlanDocument48 pagesUganda Grain Dealers LTD Business PlanRohinNo ratings yet

- 19Th Century Philippines: As Rizal'S ContextDocument17 pages19Th Century Philippines: As Rizal'S ContextMisor FireNo ratings yet

- Broadening The Genetic Base of Crop ProductionDocument460 pagesBroadening The Genetic Base of Crop ProductionAnastasiya AnknownNo ratings yet

- Carbon and Stainless Steel Pipe DimensionsDocument1 pageCarbon and Stainless Steel Pipe DimensionsRaju Saravanan100% (1)

- 03 Rapeseed MustardDocument4 pages03 Rapeseed Mustardashes kumar jenaNo ratings yet

- SanMark Masons Training ManualDocument44 pagesSanMark Masons Training ManualMarian MihalacheNo ratings yet

- Twenty Sixth Annual Willem C. Vis: International Commercial Arbitration MootDocument53 pagesTwenty Sixth Annual Willem C. Vis: International Commercial Arbitration MootMatheus MeirelesNo ratings yet

- Agb.15 01 (Agr 405)Document4 pagesAgb.15 01 (Agr 405)Muhammad kalimullahNo ratings yet

- Ra 8550 PDFDocument32 pagesRa 8550 PDFVance CeballosNo ratings yet

- Organic Manifesto: How Organic Farming Can Heal Our Planet, Feed The World, and Keep Us SafeDocument19 pagesOrganic Manifesto: How Organic Farming Can Heal Our Planet, Feed The World, and Keep Us SafekenleyneufeldNo ratings yet

- Chapter 2 - Setup of A Tissue Culture Laboratory - 2013 - Plant Tissue Culture PDFDocument7 pagesChapter 2 - Setup of A Tissue Culture Laboratory - 2013 - Plant Tissue Culture PDFLuis Bermudez0% (1)

- What Is Biome? Biomes Are Very Large Ecological Areas On The Earth's Surface, With Fauna and FloraDocument2 pagesWhat Is Biome? Biomes Are Very Large Ecological Areas On The Earth's Surface, With Fauna and FloraMaria Zyra De MesaNo ratings yet

- Measurement and Use of PH and Electrical Conductivity For Soil Quality Analysis.Document17 pagesMeasurement and Use of PH and Electrical Conductivity For Soil Quality Analysis.Salomon Saravia TorresNo ratings yet