Professional Documents

Culture Documents

Wright Double-Row Cyclone: An American 14-Cyl 1,600 H.P

Uploaded by

jfmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wright Double-Row Cyclone: An American 14-Cyl 1,600 H.P

Uploaded by

jfmanCopyright:

Available Formats

156

FLIGHT

FEBRUARY

IITH,

1943

Wright Double-row Cyclone

An American 14-cyL 1,600 h.p. Radial of 2,603 cu. in* Capacity : Single-speed or Two~speed Blowers

A S early as 1930 the engineers of the Curtiss-Wright A% Corporation of America had developed a double-row * - * radial engine of moderate displacement on which wide experience was gained through extensive tests and flight operations. Subsequent modifications increased its output to approximately 900 h.p., and a basic design was established which eliminated many of the disadvantages previously associated with double-row engines. This engine, however, fell in the same power class as the singlerow Cyclone of that time, and development was held in abeyance until such time as a really great increase in power should be needed. The year 1938 saw the introduction, on a production scale, of an aircraft engine 30 per cent, more powerful than any then available. This engine was the Wright double-row Cyclone 14, of 1,500 h.p., which made possible the design of the Pan American Airways 41-ton Boeing Clippers. These, with the British Short Bristol-engined commercial flying boats, paved the way for the transatlantic operations. Although put to immediate commercial use, the double-row Cyclone 14 remained under U.S. Government restriction and was adopted by the U.S. Navy for its Martin patrol boats and by the U.S. Army for various types of attack and bomber aircraft. Due to these restrictions little became known of the engine except that it was obviously a development of the single-row Cyclone. The engine was remarkably successful from its inception, having passed all its tests in a very short time and emerging as a production engine with practically no change from the original design. It was conservatively rated at 1,500 h.p., which was later increased to 1,600 h.p. for take-off, with 1,350 h.p. available for normal operation. Many parts of the double-row Cyclone 14 are similar to those of the single-row Cyclone. With the exception of the crankshaft and the crankcase, the basic design remains unchanged from that of the engines on which over 500,000,000 operating miles of experience have been gained. Refinements have, however, been incorporated. The cylinders, for example, though similar in appearance to previous Cyclone types, have much greater cooling area.

The cylinders of the Double-row Cyclone are similar to those of the single-row engine, but have larger cooling area. The engine is a staggered radial of 14 cylinders, having a total displacement of 2,603 c u - m - Cylinder bore is the standard 6.125m. of the single-row Cyclone, but the stroke is slightly shorter, being 6.312m. instead of 6.875m. The diameter of 55m. is the same as that of previous Cyclones, but so compact is the construction that the additional row of cylinders has been accommodated in little more than a foot extra in length, which includes an extension of the accessory section to provide a more streamlined passage for the mixture between carburettor and supercharger. Cylinders follow usual Cyclone construction of cast aluminium' alloy heads shrunk on forged nitralloy steel barrels. Head finning is deeper than usual, and intake and exhaust ports are at the rear on all cylinders. Valves are inclined to the centre line of the cylinder at an angle which enables a hemispherical combustion chamber to be used. Valve guides, seats, intake pipe and push rod housing connections are shrunk into the head. Sparking Plug Cooling

Two bronze sparking plug bushings, just above the main horizontal cooling fins of the head, are located at 90 deg. of each other and surrounded by deep vertical cooling fins arranged to permit a free flow of air over the finned sparking plug. The inside of the forged steel cylinder barrel is nitrided to the hardness of glass and given a micro-finish that leaves no point of roughness greater than two millionths of an inch. Cooling .fins are machined on the outside for heat dissipation, and improved CYCLONE 14 C14A and C14BA attachment of the head is provided by ground threads. Dry Engine Model Wt Blower Take-off Sea Level Low Blower High Blower The main section of the crankcase r.p.m. h.p. ft. la. Ratio r.p.m. h.p. r.p.m. h.p. r.p.m. h.p. ft consists of three aluminium forging;, 579C14AC1 (-A2A) 1,935 2400 1600 2300 1350 2300 1350 6200 7.00 1 divided along planes through the GR2600-A2B 1,935 2400 1800 2300 1350 2300 1350 5800 7.00 centre of the cylinder locations. They GR2600-A5A ... 1,950 2400 1600 2300 1350 2300 1350 5000 2300 1275 12000 7.14 1 are bolted together between the 10 ; 1 cylinders of each bank. These comGR2000-A5B 1 1,050 7.14 2400 lfiOO 2300 1350 2300 1350 5000 2300 1275 11500 bined main sections contain the three K) : 1 main crankshaft roller bearings and 585C14BA l.Ofia 7.30 1 2"ion 1700 240(1 1500 2400 1500 C.700 7.0(5 1> 586C14BA 1.H80 support the front and rear cam drive 2500 1700 2400 .1500 2400 1500 f"7()() 2400 1350 1500C an< gear assemblies, the cams, and the 10.02 1 tappet and guide assemblies. The nose The first four models have an airscrew reduction gear ratio of 0.5625. The 585C14BA model section provides for vertical mounting has a ratio of 0.4375, and the last model in the table may have O6625 or 0.4375. The C14A model has a diameter of 55in. and a length of 62.06 in. The corresponding figures of a constant-speed airscrew governor tor the C14B are 54.25 in. and 6H.40in. respectively. Both models have a bore of 6.125in-. and and is machined from an alumipium a stroke of 6.312in.

FEBRUARY IITH, 1943

FLIGHT

WRIGHT DOUBLE-ROW

CYCLONE

alloy casting. This section holds the thrust bearing and houses the airscrew speed reduction gears, which give either 16: 9 or 3 : 2 reduction ratios. To provide outlets for the 14 pipes to the cylinder intake ports the supercharger front housing has been enlarged. In addition to acting as the front wall of the diffuser chamber, this section is provided with seven mounting bosses designed for use with rubber mounting blocks or the Wright Dynamic Suspension mounting. The accessory drive section forms a mounting for the diffuser plate, holds the impellor and impellor drive shafts, and houses the self-turning Cuno oil filter, two gun synchroniser drives, fuel pump and two tachometer drives. The down-draught carburettor is mounted on this section, which also forms the induction passages to the impellor. The rear cover plate for mounting of the other accessories is a magnesium alloy casting similar in most respects to that used for the single-row Cyclone. On this plate are pads for the two magnetos, generator, starter, oil pump and spare accessory drive. It also forms the support for the shafts and gears of these drives. To realise the inherent advantages of single-piece master connecting rods, the crankshaft is designed in three pieces to permit the use of such rods. The three pieces are clamped together with the centre section, consisting of the two crankpins at 180 deg. from each other, with a journal for the centre main roller bearings. The entire shaft is hollow throughout to provide passage for the central oil supply, each crankpin being drilled for two oil outlets to the bearing. This makes an oil cleaning centrifuge of the crankpin chamber. A flat machined on each crankpin carries the oil out along the bearing surface. The rear of the crankshaft has an internally splined extension for insertion of the accessory drive and starter shaft. Counterweights of the crankshaft incorporate the Wright Dynamic Damper, eliminating the effects of torsional vibration on the engine and airscrew.

The Wright Cyclone Model C14A. The large carburettor :S a non-icing Chandler-Groves, and ignition is by two Scintilla magnetos.

Two valve-operating cams are fitted, each of which is supported on journals mounted on the front and rear of the main crankcase. Each cam is an alloy steel forging having two sets of cam lobes which are given a micro-finish. The cams are driven through intermediate gears from two gears, one integral with the airscrew reduction drive gear, and the other attached to the rear end of the crankshaft. Both cams rotate at one-sixth crankshaft speed in a countercrankshaft direction. The cams actuate the valves by a push-rod and rocker-arm system, which incorporates drilled pasages to provide fully internal automatic valve gear lubrication. A solid intake valve and a hollow exhaust Reduction Gearing valve partially filled with sodium follow the usual Cyclone - The 50-spline (S.A.E.) airscrew shaft is machined from, practice. an alloy steel forging and is hollow throughout its length. A single supercharger impellor is used, driven by interIt is supported by two steel-backed copper-lead bushings mediate gears from the accessory drive shaft. The conrunning on the front of the crankshaft, on which is mounted ventional intermediate gears may be replaced b)' the Wright the thrust bearing. The rear of the shaft is forged into a two-speed supercharger drive, giving the same "sea-level six-legged spider, each leg supporting one of the pinions performances and greatly increased power output at high used in the airscrew speed reduction system. The shaft is altitudes. The supercharger drive ratio is 7.00:1, 7.40:1, drilled to provide lubrication channels to these pinion bear- or 7.14:1 and 10.00:1, depending on the model.. Curved ings. The planetary reduction gear is essentially the same intake pipes lead out radially from the diffuser chamber as used on previous Cyclones. to the cylinders. Machined from alloy steel forgings, the one-piece master Lubrication System rods differ in appearance from single-row rods mainly in The lubrication system is of the full-pressure type to all that each accommodates only six articulated rods instead of eight. The shank is an H section, the flanges of which surfaces except the cylinder walls and piston pins. These are a continuation of the flanges at the channel at the are lubricated by oil sprayed from the main crankpin bear-: crankpin end. The steel-backed copper-lead crankpin bear- ings. A single housing on the rear of the engine contains ings are a shrink fit into the bore of the master rod. The both the pressure and scavenge pumps. All engine oil shells are dowelled into place, with six oil holes in each drains to a sump at the bottom of the engine, directly bearing supplying oil from this bearing out through the rod behind the lower front cylinder, whence it is removed to the knuckle pins. The articulated rods are I sections, by the scavenge pump and returned to the external also machined from alloy steel forgings. The split bronze oil supply. knuckle and piston pin bushings are pressed into the rods Non-icing carbuiation is provided by a large Chandlerand the ends spun over. Groves type carburettor, similar in design to those used on Knuckle pins are nitralloy steel, with their nitrided sur- the G-100 Series Cyclones. Ignition is supplied by two faces given a micro-finish. The pins are a press fit into Scintilla magnetos through Breeze shielded ignition cables. the master rod, and are secured by a flange at one end Drives for all accessories and flight instruments are virtually identical with those of previous Cyclones. and locking plates at the other. It may be seen from the above description that the Tile pistons are full trunk type aluminium alloy forgings, the heads strengthened and cooled internally by ribbing. double-row Cyclone 14 cannot be considered a new engine Five ring grooves are used, four above the gudgeon pin except when taken as a whole. Behind its component parts and one in the skirt.. A single compression ring fits in each is the experience of the single-row Cyclone, a background of the three grooves nearest the top of the piston, with two which explains its immediate acceptance. Recent orders vented oil control rings in the fourth groove and an oil by the U.S. Army Air Corps have brought the engine to scraper ring in the bottom groove. The oil ring grooves the forefront as a dominant American military type, a position long held by its single-row predecessor. are drilled to permit drainage into the piston interior.

You might also like

- The V8 Engine For McLaren's New MP4-12CDocument6 pagesThe V8 Engine For McLaren's New MP4-12Cddi11No ratings yet

- Helix Installation Manual Rev 002Document112 pagesHelix Installation Manual Rev 002Edgar Mendoza100% (2)

- Me262 Engine 2Document18 pagesMe262 Engine 2Joao SilvaNo ratings yet

- 0002961-To 1b-52h-1-13 b-52h Ewo Manuala PDFDocument272 pages0002961-To 1b-52h-1-13 b-52h Ewo Manuala PDFjfmanNo ratings yet

- G 81Document7 pagesG 81islamakthamNo ratings yet

- Report of Cam ShaftDocument85 pagesReport of Cam ShaftkotoyayNo ratings yet

- Rocker ArmDocument3 pagesRocker ArmAries M. SuarezNo ratings yet

- Marine Diesel EngineDocument5 pagesMarine Diesel Enginemy generalNo ratings yet

- Final ProjectDocument32 pagesFinal ProjectVirajNo ratings yet

- Free Piston Stirling 7kwDocument8 pagesFree Piston Stirling 7kwmikialeNo ratings yet

- ReacionDocument8 pagesReacionyongonzalezNo ratings yet

- Machine Shop CNCDocument28 pagesMachine Shop CNCSonia rajpuroitNo ratings yet

- Both Internal Combustion Engines and External Combustion Engines Are Known As Heat EnginesDocument70 pagesBoth Internal Combustion Engines and External Combustion Engines Are Known As Heat EnginesBalaji GaneshNo ratings yet

- Britain'S Aero Engines (Continued) : NOVEMBER 3, 1938Document1 pageBritain'S Aero Engines (Continued) : NOVEMBER 3, 1938seafire47No ratings yet

- Crank Shaft: Software Used-Catia V5R20 Submitted To Submitted byDocument47 pagesCrank Shaft: Software Used-Catia V5R20 Submitted To Submitted byYaman Saluja0% (1)

- ASSIGNMENT 2 by b3Document16 pagesASSIGNMENT 2 by b3devmarineacademyNo ratings yet

- Chapter8-Kaplon Turbine10Document10 pagesChapter8-Kaplon Turbine10fazarbadhushaNo ratings yet

- Design of Connecting RodDocument26 pagesDesign of Connecting RodAbijit GudaNo ratings yet

- IceDocument83 pagesIceAJ BantayNo ratings yet

- Forging of CrankshaftDocument4 pagesForging of Crankshaftkhor_yin_1No ratings yet

- Basic Engine: Systems OperationDocument3 pagesBasic Engine: Systems OperationTri WahyuningsihNo ratings yet

- Piston EngineDocument29 pagesPiston Enginejamilahroslien35No ratings yet

- Design and Analysis of Crankshaft of Single Cylinder 4 Stroke C.I EngineDocument13 pagesDesign and Analysis of Crankshaft of Single Cylinder 4 Stroke C.I EnginePratyush Pankaj SrivastavaNo ratings yet

- Flight.: PobjoyDocument1 pageFlight.: Pobjoyseafire47No ratings yet

- Two Stroke Engine 2016Document11 pagesTwo Stroke Engine 2016Happy singhNo ratings yet

- PPD ReportingDocument46 pagesPPD ReportingFernando CruzNo ratings yet

- CRANKSHAFTDocument26 pagesCRANKSHAFTMohammed SaleemNo ratings yet

- Design and Analysis of Rocker Arm: Tools Were UsedDocument52 pagesDesign and Analysis of Rocker Arm: Tools Were UsedWebsoft Tech-HydNo ratings yet

- Flight. 613: C/L Airscrew Three Way Type 5 0 0 0Document1 pageFlight. 613: C/L Airscrew Three Way Type 5 0 0 0seafire47No ratings yet

- CrankshaftDocument5 pagesCrankshaftnguyen xuan minhNo ratings yet

- Pimsat Colleges Engineering Materials 1Document8 pagesPimsat Colleges Engineering Materials 1Sev Anne T. GonzalesNo ratings yet

- Minor ProjectDocument7 pagesMinor ProjectNeeraj Tiwari100% (1)

- Two Stroke EngineDocument13 pagesTwo Stroke EngineAaron PriceNo ratings yet

- Air Gap Piston Design and AnalysisDocument56 pagesAir Gap Piston Design and AnalysisSireeshNo ratings yet

- ChiltonDocument68 pagesChiltonAna Paula MalaquiasNo ratings yet

- Final-Advance Breaking System For Hill Drive VehiclesDocument59 pagesFinal-Advance Breaking System For Hill Drive VehiclesMurali VannappanNo ratings yet

- Piston - WikipediaDocument30 pagesPiston - WikipediaLAliNo ratings yet

- Curtiss Chieftain Engine: Modern Aviation Engines, Vol. 2Document7 pagesCurtiss Chieftain Engine: Modern Aviation Engines, Vol. 2Prus PrusićNo ratings yet

- Beam Engine Mechanism Powered Circular Sawing Machine ReportDocument34 pagesBeam Engine Mechanism Powered Circular Sawing Machine ReportSanjay CrNo ratings yet

- 4 ReportDocument89 pages4 ReportRajesh KesapragadaNo ratings yet

- The Diesel LocomotiveDocument24 pagesThe Diesel LocomotivePool KingNo ratings yet

- How A Four-Stroke Cycle Diesel Engine Works Marine Diesel Engine GuidelineDocument8 pagesHow A Four-Stroke Cycle Diesel Engine Works Marine Diesel Engine GuidelineKarim Sowley DelgadoNo ratings yet

- Rolls Royce GriffonDocument13 pagesRolls Royce GriffonDaniel Armstrong100% (1)

- Paw AnDocument17 pagesPaw Anshakti00000No ratings yet

- MCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Document19 pagesMCE 4780: Mechanical Engineering Lab 1: Fahim Shahrier, 160011052, MCE 16, Group B 2nd February 2020Fahim ShahrierNo ratings yet

- Engine DesignDocument15 pagesEngine DesignAbdul-Wahab Anwar100% (10)

- EngineDocument41 pagesEngineGurmeet Mehma100% (5)

- Thermal Engineering I MANUALDocument35 pagesThermal Engineering I MANUALKalpit KauraseNo ratings yet

- Components or Parts of IC Engine With Its Function PDFDocument9 pagesComponents or Parts of IC Engine With Its Function PDFMilbert Vaz AlfonsoNo ratings yet

- Final Engine ProjectDocument38 pagesFinal Engine Projectvinayharish02002No ratings yet

- Basic Engine: Systems OperationDocument2 pagesBasic Engine: Systems OperationNay SoeNo ratings yet

- KTM Engine Dev enDocument4 pagesKTM Engine Dev enstefan.vince536100% (1)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionFrom EverandA Guide to Motor-Cycle Design - A Collection of Vintage Articles on Motor Cycle ConstructionNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Pitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939From EverandPitman's Motorists Library - The Book of the Austin Ten - A Fully Illustrated Instruction Book for All Owners of Models from 1932 to 1939No ratings yet

- The Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignFrom EverandThe Modern Chassis: A Practical Manual of Automotive Chassis and Suspension DesignRating: 3.5 out of 5 stars3.5/5 (3)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- M4A1 ShermanDocument13 pagesM4A1 ShermanjfmanNo ratings yet

- 0002961-To 1b-52h-1-13 b-52h Ewo ManualaDocument51 pages0002961-To 1b-52h-1-13 b-52h Ewo Manualajfman100% (2)

- M1a1 TuskDocument696 pagesM1a1 Tuskjfman100% (1)

- Review - 1 - 35 T-90A Russian MBT (Meng TS-006) - Military Scale Modelling!Document10 pagesReview - 1 - 35 T-90A Russian MBT (Meng TS-006) - Military Scale Modelling!jfmanNo ratings yet

- M-923 A1 Big Foot: Print FilmDocument7 pagesM-923 A1 Big Foot: Print FilmjfmanNo ratings yet

- M1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72Document4 pagesM1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72jfmanNo ratings yet

- M1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72Document4 pagesM1A1/ A2 Abrams: 1/72 Scale Detail Set For Kit - Sada Detailù Pro Model Dragon 7215 Dragon 7215 1/72jfmanNo ratings yet

- M 113Document8 pagesM 113jfmanNo ratings yet

- M256 120mm Smoothbore GunDocument23 pagesM256 120mm Smoothbore GunjfmanNo ratings yet

- MTVRDocument8 pagesMTVRjfman100% (1)

- Oshkosh MTVR BrochureDocument12 pagesOshkosh MTVR Brochurejfman100% (1)

- RB ModelDocument10 pagesRB ModeljfmanNo ratings yet

- 105mm Gun Tank M1 AbramsDocument21 pages105mm Gun Tank M1 Abramsjfman100% (1)

- Afv 1Document3 pagesAfv 1jfmanNo ratings yet

- LimaTankPlantDocument4 pagesLimaTankPlantpl_junkNo ratings yet

- AeroScale - How To - Homemade Vacuforming Box by Diego M. PaveseDocument5 pagesAeroScale - How To - Homemade Vacuforming Box by Diego M. PavesejfmanNo ratings yet

- B-17G Rear Interior 73 383: 5 SetsDocument4 pagesB-17G Rear Interior 73 383: 5 SetsjfmanNo ratings yet

- M39 A2 A3Document2 pagesM39 A2 A3jfman100% (1)

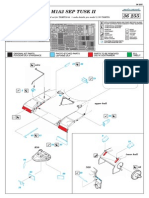

- M1A2 Sep Tusk IiDocument8 pagesM1A2 Sep Tusk IijfmanNo ratings yet

- TDS Pattex Repair Extreme 031223Document2 pagesTDS Pattex Repair Extreme 031223jfmanNo ratings yet

- F/A-18 GRU/SJU Seat Detail Set: 1/32 Scale Detail Set For - Sada Detailù Pro Model 1/32Document3 pagesF/A-18 GRU/SJU Seat Detail Set: 1/32 Scale Detail Set For - Sada Detailù Pro Model 1/32jfmanNo ratings yet

- 389 - Orig Total WorldDocument3 pages389 - Orig Total WorldjfmanNo ratings yet

- A-6 Intruder Interior SetDocument4 pagesA-6 Intruder Interior SetjfmanNo ratings yet

- F/A-18 Hornet Armament: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy Academy 1/32Document3 pagesF/A-18 Hornet Armament: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy Academy 1/32jfmanNo ratings yet

- F/A-18C Hornet Interier: 1/32 Scale Detail Set For Kit 2191 - Sada Detailù Pro Model Academy 2191 Academy 1/32Document5 pagesF/A-18C Hornet Interier: 1/32 Scale Detail Set For Kit 2191 - Sada Detailù Pro Model Academy 2191 Academy 1/32jfmanNo ratings yet

- F/A-18 Hornet Exterior: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy 2191 Academy 2191 1/32Document4 pagesF/A-18 Hornet Exterior: 1/32 Scale Detail Set For Kit - Sada Detailù Pro Model Academy 2191 Academy 2191 1/32jfmanNo ratings yet

- F/A-18 Hornet Exhaust Set: ReferencesDocument3 pagesF/A-18 Hornet Exhaust Set: ReferencesjfmanNo ratings yet

- F-100C Exterior: G6, G7 G1 G17Document2 pagesF-100C Exterior: G6, G7 G1 G17jfmanNo ratings yet

- Drafting Sanitary and Plumbing Layout and DetailsDocument17 pagesDrafting Sanitary and Plumbing Layout and DetailsStewart MagayanoNo ratings yet

- F-MKT-71 J-20Document2 pagesF-MKT-71 J-20Marcos BustamanteNo ratings yet

- Experiment No 6Document4 pagesExperiment No 6LJ IDANE ARANASNo ratings yet

- BPVC Ix qw-483 PDFDocument2 pagesBPVC Ix qw-483 PDFazizNo ratings yet

- Denver Equipment Company Handbook - IndexDocument6 pagesDenver Equipment Company Handbook - IndexCristiam MercadoNo ratings yet

- Center Pivot: End Gun ApplicationDocument2 pagesCenter Pivot: End Gun ApplicationdonnynkNo ratings yet

- MOD 005 Stainless SteelsDocument6 pagesMOD 005 Stainless SteelsDu Xuan BinhNo ratings yet

- Goodfellow SRMs AlloyDocument306 pagesGoodfellow SRMs AlloytqthienNo ratings yet

- Environmental Laws and RegulationsDocument50 pagesEnvironmental Laws and RegulationsPaul Santos NonatNo ratings yet

- Canal Trough DesignDocument18 pagesCanal Trough DesignGarg Tj100% (1)

- High Velocity Oil FlushDocument2 pagesHigh Velocity Oil FlushNatanael CarpelotiNo ratings yet

- Fisher Y690 ValveDocument16 pagesFisher Y690 ValvemadithakNo ratings yet

- Knan, Knaf, Onan, OnafDocument2 pagesKnan, Knaf, Onan, Onafponnarasu8250% (2)

- Material Safety Data Sheet: Global SolutionsDocument5 pagesMaterial Safety Data Sheet: Global Solutionsravikunwar14No ratings yet

- Catalogo Fire 2009Document7 pagesCatalogo Fire 2009Benicio Joaquín Ferrero BrebesNo ratings yet

- Low Pressure Steam Curing of Precast UnitsDocument4 pagesLow Pressure Steam Curing of Precast Unitsdash1991No ratings yet

- MPI Report 009 Sub Structure B668Document1 pageMPI Report 009 Sub Structure B668John DolanNo ratings yet

- Phosphate of SteelDocument23 pagesPhosphate of SteelSathiyaPrakashNo ratings yet

- Masonry: Construction Method and Project ManagementDocument43 pagesMasonry: Construction Method and Project ManagementJQNo ratings yet

- Welding Procedure Specification (WPS)Document0 pagesWelding Procedure Specification (WPS)Oscar Iván Duque DíazNo ratings yet

- Smeaton ProjectDocument18 pagesSmeaton ProjectNemesisRepublic@blogspot.comNo ratings yet

- Standard Price List: Office of The Provincial EngineerDocument27 pagesStandard Price List: Office of The Provincial EngineerJohn Harvy JoseNo ratings yet

- CFAH 30P1200/S14 Capacitive Proximity SensorsDocument2 pagesCFAH 30P1200/S14 Capacitive Proximity SensorscsystemsNo ratings yet

- Pre-Hole Diameter Optimization in High Speed Drilling Considering Machining CostDocument2 pagesPre-Hole Diameter Optimization in High Speed Drilling Considering Machining CostSreejith S NairNo ratings yet

- Liquefied Natural Gas (LNG) Facilities EHS Guideline - 2016 Vs 2007Document30 pagesLiquefied Natural Gas (LNG) Facilities EHS Guideline - 2016 Vs 2007IFC Sustainability100% (1)

- Metals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleDocument18 pagesMetals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleUtkarsh AnandNo ratings yet

- Omega Dishwashers Manual ODW702XDocument22 pagesOmega Dishwashers Manual ODW702XJayme-Lea VanderschootNo ratings yet

- Canon Parts ListDocument14 pagesCanon Parts ListbishoppyrcNo ratings yet