Professional Documents

Culture Documents

Frfa Inspection Report Rev 7 Final

Uploaded by

api-223133991Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Frfa Inspection Report Rev 7 Final

Uploaded by

api-223133991Copyright:

Available Formats

FARM INSPECTION REPORT

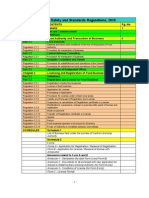

Revision 7 @ June 2013 This revision Compliance Code of Practice AG1143 Gazetted Victoria 27.11.2003 www.dpi.vic.gov.au

Applicant Information

Full Name:

First Last Last Last Last Ownership % Ownership % Ownership % Ownership %

Full Name:

First

Full Name:

First

Full Name:

First

NOTE: If ownership % column does not equal 100%, further information to be provided.

Company name: Brand name: Address of farm being inspected:

Street Address

City

State

Post Code

Postal address (or same as above):

Street Address

City

State

Post Code

Home phone: Mobile phone: Email address: FRFA farm #:

Office phone: Mobile phone: Website address: PIC #:

Disclosure Information

Parallel production systems will not be accepted as meeting the requirements of the Free Range Farmers Association standard. No other types of system of egg production shall be established, maintained, used or managed on any property under the producers control. All animals must be managed under the requirements of the Free Range Farmers Association (Vic) Standard.

First

Last

Signature accepts acknowledgement of above requirement

www.freerangefarmers.com.au

Page 1 of 11

FRFA Inspection Form v7 2013.doc

Part A Housing Standards

Part A HOUSING 1. Hens must have permanent access to weatherproof housing with either slatted, mesh or deep litter floors and contain sufficient perches to enable normal roosting for all birds. Housing type; Deep Litter a. ; Slatted floor ; Perchery Mesh ; Other ; Fixed ; Moveable

; ; ; ; ; In the event that a hens mobile house only has partially slatted floors, please advise whether it is evident that the shed is being frequently moved to fresh pasture to ensure that the up is M M manure build M M M not a cause for concern? How often are sheds moved? Housing type should not allow buildup of manure auditor to check odour and manure build up. Does the farm have a shed rotational system in place? Y / N Adequate fresh air, sunlight, insulation and ventilation? Y / N Housing, pens and equipment are clean? Y / N Is litter purchased from reputable suppliers? Y / N An egg producer must take all reasonable measures to ensure inputs do not make the eggs unsafe or unsuitable. Inputs include feed, water, litter and chemicals.

b. c. d. e. f. g.

Comments:

Part A HOUSING 2. Stocking density in housing shall not exceed 8 mature hens per square metre of available area. a. b. Are poultry able to move freely without interference? Y / N Housing has sufficient exits to allow ready access to the outdoors for all birds? Y / N

c. Housing density does not exceed standard? Y / N (Code of Practice AG1143 plus FRFA standard does not exceed 15kg/m2 of available area) Comments:

Part A HOUSING 3. The minimum acceptable number of perches or minimum allotted perching space will be that which is sufficient to allow all birds housed in a particular house to comfortably perch in that house. a. All layer hens able to roost? Y / N

b. Sufficient perches are available for all birds to roost at the same time? Y / N (Code of Practice AG1143 CI 2.43>15cm/bird) c. Comments: www.freerangefarmers.com.au Page 2 of 11 FRFA Inspection Form v7 2013.doc Perches are positioned to prevent fouling of other birds? Y / N

Part A HOUSING 4. Maximum flock size per house shall not exceed 1000 hens a. b. c. Comments: The individual flock number does not exceed 1,000 birds per house? Y / N Has the farm egg collection log sheet been sighted to confirm the above if in doubt? Y / N There is room to carry out natural behavior? Y / N

Part A HOUSING 5. Clean dry nesting boxes and hen friendly safe access must be provided. Nesting to allow for 20% of laying hens to nest at any one time. a. Nest boxes are provided for laying hens? Y / N

b. Is the nest space sufficient and with safe entry? Y / N (Code of Practice AG1143 CI 2.4.4 colony nests 1 m2/120 hens or single bird nests @ 1 for every 7 birds) c. Poultry do not come into contact with toxins from paint, wood preservatives or disinfectants Y / N Note: Old sheds can contain lead paint on timbers that the poultry may chew. d. Broken eggs are removed from nest boxes/nesting material Y / N Broken eggs are a contamination hazard if left in nesting material. e. Are nest boxes or nesting material cleaned on a regular basis? Y / N If nesting material is used, change frequently to minimize faecal contamination of eggs. Comments:

Part B Feeding & Drinkers

Part B FEEDING & DRINKERS 1. In accordance with the Code of Practice for the Welfare of Domestic Poultry, adequate drinking and feeding facilities containing clean fresh drinking water and feed must be available at all times. a. Are the feed and drinking supply locations sufficient? Y / N (Code of Practice AG1143 CI 9.0 Food & CI 10.0 water) b. c. d. e. All poultry have access to an adequate supply of clean, fresh drinking water? Y / N Drinking troughs and bowls are clean? Y / N Drinkers are checked daily to ensure function and flow? Y / N Are there sufficient feeders to allow poultry to feed without competition? Y / N Page 3 of 11 FRFA Inspection Form v7 2013.doc

www.freerangefarmers.com.au

f. g. h. i.

Is feed flowing freely or readily available? Y / N Are feeders checked daily? Y / N Is feed equipment clean and in good repair? Y / N Water source? i. Town Supply ii. Dam supply iii. Roof catchment iv. Other

(taste / appearance) Comment: (treated?) Y / N (taste / appearance) Comment: (taste / appearance) Comment:

j.

Is feed purchased from a reputable supplier? Y / N An egg producer must take all reasonable measures to ensure inputs do not make the eggs unsafe or unsuitable. Inputs include feed, water, litter and chemicals. Have you tested your water pH Levels in the past 12 months? pH levels that are too high can have an impact on our production rates, therefore testing this annually is a recommended business practice. Are bulk storage bins, feed conveyors, hoppers and chain feeders clean and exclude rodents, insects and wild birds from accessing feed? Y / N

k.

l.

m. Is a cleaning and maintenance schedule for storage silos and feed delivery systems in use? Y / N Comments:

Part B FEEDING & DRINKERS 2. The use of growth promotants, hormones and artificial colourings is not permitted, however naturally derived pigments may be used. 3. The feeding of unprocessed animal residue is not allowed. 4. Clean dry feed comprising natural products, grains, grain feeds, heat-treated meat by-products and natural sources of vitamins and minerals may only be used. a. b. Is all the feed likely to be clean and natural? Y / N Where is feed sourced from and in what form is it purchased?

c. Poultry are not fed hormones, growth promotants or antibiotics Y / N (Antibiotics are allowed, not systematically, but for therapeutic purposes and under veterinary supervision in the event of flock sickness). d. Comments: Has a copy of the farms feed formula been collected to attach to the inspection record? Y / N

Part C Free Range Run

Part C FREE RANGE RUN 1. The maximum stocking rate is 750 hens per hectare (300 per acre) 2. Hens must have unrestricted access to free range runs during the daylight hours. a. Does the farm comply with hen ranging requirements? Y / N www.freerangefarmers.com.au Page 4 of 11

FRFA Inspection Form v7 2013.doc

(Code of Practice AG1143 CI 2.4.5 plus FRFA Standard not exceed 750/ha)

b. All poultry have access to grazing? Y / N (All poultry must have access to grazing, except pullets under 8 weeks of age) c. d. Erosion in the paddock is monitored and rectified? Y / N Runoff into waterways is not occurring? Y / N

e. Are there any signs of aggressive behavior in the flock? Y / N (Birds must be given enough space to escape bullying and be able to exhibit natural behaviours such as foraging, scratching, dust bathing, running, and wing flapping without undue interference from other birds). f. g. Comments: A farm map is available? Y / N Are birds locked up in sheds at night? Y / N

Part C FREE RANGE RUN 3. The area where the hens are permitted to range should have adequate natural ground cover. If vegetation disappears under adverse seasonal conditions then alternative natural food sources and range should be implemented until ground cover can be re-established. 4. Adequate shade and wind protection must be provided. a. Is the range shade and weather protection sufficient in all paddocks? Y / N (Code of Practice AG1143 CI 8.0) b. Poultry have access to a comfortable, shaded, dry lying area large enough for all poultry in that paddock to use at the same time? Y / N Shade and shelter are sufficient in the paddock to encourage the birds to go outside? Y / N All animals must have access to forage (vegetative growth) Y / N

c. d. Comments:

Part D Husbandary Practices

Part D HUSBANDARY PRACTICES 1. Antibiotics are not allowed except under veterinary supervision. Eggs from treated birds must be withdrawn from sale. Records must be maintained of all treatment programs. a. b. If any poultry suffer disease or injury appropriate veterinary treatment is not withheld Y / N Sick birds are isolated from the rest of the flock? Y / N

www.freerangefarmers.com.au

Page 5 of 11

FRFA Inspection Form v7 2013.doc

c.

Is there evidence of external parasites? Y / N i. Mites ii. Lice iii. Feather pecking iv. Distraught v. Nervous vi. Flighty species Do the hens look happy and friendly? Y / N (AG1143 CI 12)

d.

e. Is there evidence of sick or suffering poultry? Y / N (Suffering of sick or injured poultry will not be prolonged unnecessarily). f. g. h. Comments: Has a veterinary prescription been sighted if flock has been treated with an antibiotic? Y / N Have the treated birds vaccination record been sighted to ensure records are up to date? Y / N If the antibiotic has a no-withholding period, eggs can continue to be sold.

Part D HUSBANDARY PRACTICES 2. All bird mutilation practices are unnecessary and are prohibited (Beak trimming, toe clipping etc.) a. b. Has it been confirmed that animal mutilations are not permitted? Y / N Are any of the following surgical treatments carried out? Y / N i. De-beaking ii. Beak trimming iii. Wing cutting iv. Toe trimming v. De-snooding

Comments:

Part D HUSBANDARY PRACTICES 3. Withholding feed and water to induce moulting is not permitted. 4. Reasonable precautions must be taken to protect hens from predators at all times. 5. Proper practices must be in place to ensure that under extreme temperature conditions the hens have access to cool drinking water and other keep cool types of environmenta l relief (e.g. Wet-downs, misters and sprays etc.). 6. Artificial lighting to extend normal daylight hours beyond 16 hours in a day is not permitted. a. b. c. d. Is the applicant aware that withholding feed and water to induce moulting is not permitted? Y / N How are poultry protected from predation? Is the predator protection sufficient? Y / N Have provisions been made for an emergency water supply? Y / N

e. Is artificial lighting used in the sheds? Y / N (Minimum of 8 dark hours required) www.freerangefarmers.com.au Page 6 of 11 FRFA Inspection Form v7 2013.doc

Comments:

Part E General Requirements

Part E GENERAL REQUIREMENTS 1. Free range egg producers buying point of lay pullets should purchase stock from recognised farms that practice ground rearing and perching habits. Age dated vaccination certificates are required at delivery. a. Are bought day old / pullet vaccination certificates on record? Y / N (Refer to Dept of Primary Industries www.dpi.vic.gov.au Newcastle mandatory over certain flock size) When receiving birds, you should seek a written assurance from the breeder or hatchery regarding the disease and vaccination status of the birds that are being purchased. b. c. Are day old/ pullet stock purchased from reputable suppliers? Y / N Are rearing records kept up to date (such as vaccinations, lice and worming treatments recorded) Y / N

d. Does the farm have a New Shed Setup checklist in place? Y / N Does the checklist include the following: i. Shed & equipment clean? ii. Sheds placed on fresh pasture? iii. New shed (flocks) separated from older stock? iv. Feeding and watering equipment working and adjusted? v. Birds loaded into transport crates in an appropriate manner? vi. Bird transport crates loaded onto trailer in an appropriate manner? vii. Birds placed in sheds (closed doors) at correct stocking density? viii. Condition and behavior of birds checked soon after placement? ix. Birds are kept locked overnight to adjust to new surroundings and released the next morning? It is good practice to keep newly purchased birds quarantined from existing stock in case new stock is infected. Thoroughly cleaning and disinfecting shed and equipment (including internal surfaces of sheds, especially brooding sheds) at batch depletion. e. Records of deaths, births, sales and purchases of poultry kept? Y / N Confirm the above records are available for inspection and that they are up to date. f. Comments: Bought in poultry are accompanied by a vendor declaration? Y / N

Part E GENERAL REQUIREMENTS 2. Housing management and bird husbandry must be to a high standard to avoid hen stress and poor egg quality. a. Are poultry handled quietly and with minimal stress? Y / N (Do poultry seem afraid of human contact?) b. Is there a procedure in place for catching of poultry? Y / N

c. Are poultry monitored daily by a stockperson? Y / N (Poultry should sight a human on a daily basis) www.freerangefarmers.com.au Page 7 of 11

FRFA Inspection Form v7 2013.doc

d.

All people involved in the care, handling and management of the poultry have received and read the Free Range Farmers Association Standard? Y / N

e.

There is a training program in place for all staff to ensure implementation and compliance with the Free Range Farmers Association Standard? Y / N (Is there a procedure for staff induction?) f. Does this farm keep a Daily Critical Checklist which includes monitoring and recording of water, feed and temperatures? Y / N Are paddocks checked daily for sick or dead poultry? Y / N Does the farm make every effort to prevent wild birds and rodents from entering the shed and minimise the attraction of wild birds and rodents into areas where birds and pullets range and where eggs are processed or stored? Y / N Is there a baiting log and bait map available? Y / N Does the farm collect and dispose of dead birds promptly and in a way that they wont contaminate eggs? Y / N For example: place in waterproof, leak proof containers prior to incineration, composting or burial away from the poultry shed. Does the farm have a written procedure in place on correct method of bird disposal? Y / N How does the farm manage litter and/or poultry manure?

g. h.

i. j.

k. l.

It is recommended that litter &/or poultry manure be removed off site, or spread on surrounding land, or stored on site with an effective buffer distance to the poultry shed. Composting manure before spreading. This will kill most pathogens and further reduce the risk of disease. Comments:

Part E GENERAL REQUIREMENTS 3. New egg cartons must only be used and labelled with Labelling Standards markings which require producer or packager identification, content weights, egg production method and best before date. a. Does the producers egg carton include the following information (minimum ) legibly printed on the packaging: i. Name and business address of producer or packing shed? Y / N ii. A best before date (35 days from date of packing is recommended)? Y / N iii. A form of identification such as lot identification or batch number? Y / N iv. A nutritional information panel? Y / N v. A reference to the number of eggs in the package? Y / N vi. A reference to the minimum total mass of all eggs in the package? Y / N vii. A statement regarding the country of origin? Y / N Auditor has received an egg carton sample from producer to keep? Y / N Are eggs packed and sold in new egg cartons and/or trays? Y / N Does the farms website or packaging make additional farming method claims? Y / N i. No meat meal ii. No egg yolk colour additives

b. c. d.

Comments: www.freerangefarmers.com.au Page 8 of 11 FRFA Inspection Form v7 2013.doc

Part E GENERAL REQUIREMENTS 4. Audit trail records are necessary for all eggs stored on farm and sold. Where accredited eggs are sent to other farms or packing stations for processing the producer shall ensure a record system where the sequential numbered accreditation labels reconcile with the quantity of eggs sent in each shipment. Egg substitution is an offence under the Free Range Farmers Association Inc. Statement of Purposes. This association does not allow unpackaged hen eggs produced by other systems including non-accredited members to be brought onto or held at its accredited farms. Independent non-member packing stations will be subject to inspection. a. b. c. d. e. f. g. h. Can the farm show an audit trail for his/her produce in and out? Y / N No of laying hens at todays date: No of chicks / pullets at todays date: No of birds culled in the past 12 months: How many eggs have been sold in the past 12 months? (doz) How many eggs have been produced by this farm in the past 12 months? (doz) How many eggs have been bought in from other farms in past 12 months? (doz) If eggs have been bought in from other farms list the name of the accredited farm (s) and list the number of dozens that have been purchased in the past 12 months from each egg supplier: 1. 2. 3.

i.

Does producer have a supply agreement with the accredited farm as per specific requirements of supply? Y / N Note: Although farms may hold accreditation from the same accreditation body, this does not mean that all farming principals are aligned. Ensure that any farming methods align across all aspects in order to ensure that your specific packaging and/ or website claims are not misleading. This will ensure Truth in Labelling compliance and is why having a supply agreement is recommended. Comments:

Part E GENERAL REQUIREMENTS 5. All farmers must be able to demonstrate egg storage and transport compliant temperature and hygiene provisions to the Shell Egg Code and requisite Food Safety Victoria provisions. a. b. Are eggs collected at least once a day, more often in hot weather? Y / N On collection are eggs sorted into clean first grade eggs or dirty eggs? Y / N Separate dirty eggs into another container for cleaning or disposal. Discard heavily soiled and broken eggs. How are dirty eggs cleaned? Dry cleaning or wet washing? Give details please.

c.

d.

What temperature is the water during egg washing? Page 9 of 11 FRFA Inspection Form v7 2013.doc

www.freerangefarmers.com.au

Wash water should be in the range of 40-45C

e. f.

Is there an egg washing procedure available to sight? Y / N Are there records listing number of eggs washed, egg machine cleaned & water temperature of cleaning water (if applicable) at each date of wash? Cleaning and sanitizing products for the wash water is purchased from a reputable supplier? Y / N Does the farm have on farm grading facilities? Y / N If No, list the name of the grading floor to which the eggs are consigned:

g. h.

i. j.

Have you sighted that the grading machine is actually in working order? Does it turn on? Y / N Is equipment used in the grading process maintained and in a clean condition to prevent the buildup of bacteria? Y / N Are records maintained for the following: a. number of eggs graded Y / N b. source of eggs (egg purchases) Y / N c. date of grading Y / N d. number of A grade & second/reject eggs Y / N e. best before date? Y / N f. grading equipment cleaning log? Y / N How are cracked & rejected eggs disposed of? Give details please.

k.

l.

Appropriate waste disposal mechanism, for example burial or composting. Cracked and/or dirty eggs must not be sold for human consumption unless you are selling on to a processor for pasteurization or an equivalent process. For example, they cannot be sold for wholesaling, catering purposes or retail. Apart from being an offence under the Food Act, cracked and/or dirty eggs are the most likely culprits for causing food bourne illness. m. Does the farm pack eggs into clean cartons or trays? Y / N n. How are eggs stored after collection? Give details please.

o.

Does the farm have a cool-room onsite? Y / N Visually sight that the cool room temperature is below 20C. Does the farm keep and maintain a daily cool room temperature record sheet? Y / N How are eggs delivered to the customer? It is recommended that eggs are delivered to the customer in a suitable vehicle at a temperature of less than 20C. Does the egg delivery vehicle used keep a vehicle cleaning and temperature log? Y / N Visually sight the temperature log to ensure it is maintained. Does the farm provide adequate hand washing facilities and instructions to ensure staff understand and carry out good personal hygiene practices? Y / N A register of visitors to the farm is kept? Y / N

p. q.

r.

s.

t.

u. Unauthorised vehicles are not permitted free access to areas in the vicinity of the poultry? Y / N Example: signage Comments: www.freerangefarmers.com.au Page 10 of 11 FRFA Inspection Form v7 2013.doc

Inspectors Comments and Advice to the Committee

Would you support accreditation of this farm? Yes Conditional ; M No ; M ; What is the overall appearance of the farm? (Rate from 1 - 10) M If NO, which items need to be addressed?

If CONDITIONAL, what are the conditions?

Inspected by:

First

Last

Signature accepts acknowledgement of above requirement

Farm Owner Acknowledgement

THE FARM OWNER/MANAGER WAS PRESENT DURING THE CONDUCT OF THIS AUDIT. Note 1 The audit form is confidential between the committee and the farmer and held for safe keeping by the Accreditation Officer. The farmer is permitted to take a copy of the inspection form upon audit completion. Note 2 It is not always practical to stipulate poultry best practice welfare in hard and specific measurements so the committee relies on the experienced inspector as to what looks right. Should the farmer be dissatisfied with any of the recorded observations he shall refer the matter to the Accreditation officer. In consideration or independent appeal, the committee would look at Code of Practice AG1143 and ask what is the equipment manufacturers or the hen breeders recommendations as to what is normal. The approving committee brief is to credibly protect in the public forum; hen welfare; Association and its membership; and the Queensland Trade Mark Agreement. Note 3 NUMBER OF EGGS DURING A SET PERIOD Accreditation is conditional on your signed agreement below that the egg production and sales records can be validated at any time (random audits may also be conducted). Note 4 I acknowledge by the signing of this form, that I am aware of the advice for my farm to have both a Product Liability Insurance and a Public Liability Insurance and that in any failure to do so, the Association practice(s) to its published procedures are indemnified from claim. Note 5 I acknowledge by the signing of this form, that I am aware that if re-inspection of my farm is required at any time within a 12 month period that it will be at my own expense. This includes re-inspection which may pertain to a conditional requirement as stipulated above or resulting from a Corrective Action (CAR) issued for any noncompliance of Standards etc. The FRFA membership annual fee covers one inspection per 12 month period. Note 6 Farm must comply with Department of Primary Industry Food Safety for Egg Producers as per National Primary Production and Processing Standard for Eggs and Egg Product (standard) which has been developed by Food Standards Australia New Zealand (FSANZ). The standard is a national standard that all states are required to adopt and implement.

Dated:

First

Last

Dated: Signature accepts acknowledgement of above requirement

www.freerangefarmers.com.au

Page 11 of 11

FRFA Inspection Form v7 2013.doc

You might also like

- Syngenta SwotDocument2 pagesSyngenta SwotArslanFarooqNo ratings yet

- Layer Chicken FarmingDocument18 pagesLayer Chicken FarmingKhampa Ngawang Phuntsho100% (4)

- Integrated Pest Management (IPM) : Beverage Plus PVT Ltd-Quality & Food SafetyDocument36 pagesIntegrated Pest Management (IPM) : Beverage Plus PVT Ltd-Quality & Food SafetyKhurrum RahimNo ratings yet

- Agmark App FormDocument34 pagesAgmark App FormramcatNo ratings yet

- Slaughtering Process FlowDocument2 pagesSlaughtering Process Flowjas rovelo100% (2)

- Ante Mortem ExaminationDocument38 pagesAnte Mortem ExaminationWAQAS SHAHIDNo ratings yet

- Laboratory Cleaning and MaintenanceDocument8 pagesLaboratory Cleaning and MaintenanceJenner ButlongNo ratings yet

- Cocoa ProcessingDocument4 pagesCocoa ProcessingcjachemNo ratings yet

- Gap Analysis ChecklistDocument7 pagesGap Analysis ChecklistJulius MuhimboNo ratings yet

- Rural Entrepreneurship and Marketing: National Institute of Rural Development and Panchayati RajDocument7 pagesRural Entrepreneurship and Marketing: National Institute of Rural Development and Panchayati RajSreekanth reddy100% (1)

- Slaughtering AustraliaDocument47 pagesSlaughtering AustraliaEpic ProcrackNo ratings yet

- 21 Animal Nutrition and FeedsDocument59 pages21 Animal Nutrition and FeedsDr Anais AsimNo ratings yet

- USDA Meat Inspection and The Humane Methods of Slaughter ActDocument6 pagesUSDA Meat Inspection and The Humane Methods of Slaughter ActMd. Naim KhanNo ratings yet

- Code of Hygienic PracticeDocument29 pagesCode of Hygienic Practicenitu_gNo ratings yet

- WAHA Monthly Halal Checklist AbattoirDocument9 pagesWAHA Monthly Halal Checklist Abattoirhoanam2009No ratings yet

- Dairy IndustryDocument30 pagesDairy IndustryHamza KhanNo ratings yet

- Agmark 1937Document26 pagesAgmark 1937Parul Madaan100% (1)

- Rice Milling Industry: Diagnostic Study ReportDocument62 pagesRice Milling Industry: Diagnostic Study ReportVigneshwaran AiyappanNo ratings yet

- Dairy FarmingDocument26 pagesDairy FarmingHassanMubasherNo ratings yet

- Republic Act 1556Document8 pagesRepublic Act 1556melNo ratings yet

- Development of Small Millet Processing Technology by TNAU DR VaradharajuDocument38 pagesDevelopment of Small Millet Processing Technology by TNAU DR VaradharajuBabu CNo ratings yet

- FAO Herbs and Spice ProductsDocument10 pagesFAO Herbs and Spice ProductsUsman CheemaNo ratings yet

- RACS SOP 01 Rev 08 Procedure of Control The Use of RACS MarkDocument8 pagesRACS SOP 01 Rev 08 Procedure of Control The Use of RACS MarkrahmathNo ratings yet

- 04 3 - Halal Slaughtering Ama EdittedDocument86 pages04 3 - Halal Slaughtering Ama EdittedVanessa LimNo ratings yet

- Poultry Slaughtering in Perspective of Halal Slaughther PDFDocument16 pagesPoultry Slaughtering in Perspective of Halal Slaughther PDFRajivShahNo ratings yet

- Bakels MSDSDocument4 pagesBakels MSDSMd. Hafijur Rahman PlabonNo ratings yet

- Module Food ProcessingDocument87 pagesModule Food Processingivy bontrostroNo ratings yet

- Indian Dairy IndustryDocument39 pagesIndian Dairy IndustryAmrish GargNo ratings yet

- NPOP Certification BodiesDocument5 pagesNPOP Certification Bodieslpumsun1100% (1)

- Philippine National Standard: Animal Feed IngredientsDocument42 pagesPhilippine National Standard: Animal Feed IngredientsDino Adormeo100% (1)

- FishCrustFarm Issue 2 App Rev 5 November 2016 PT 2Document12 pagesFishCrustFarm Issue 2 App Rev 5 November 2016 PT 2DeddyKurniawanNo ratings yet

- BAP - Sampling & Testing Requirements - SPS 5.1 Farmed - Issue 2.1 - 30-March-2022Document6 pagesBAP - Sampling & Testing Requirements - SPS 5.1 Farmed - Issue 2.1 - 30-March-2022PATRICIA SABORIONo ratings yet

- Poultry Industry: Beef Industry Swine Industry Equine Industry Aquaculture Industry Poultry Industry Other IndustriesDocument3 pagesPoultry Industry: Beef Industry Swine Industry Equine Industry Aquaculture Industry Poultry Industry Other IndustriesNasimNo ratings yet

- FSSAI Final Regulations 2010Document681 pagesFSSAI Final Regulations 2010parihar.jitendra80% (5)

- Technical Handbook On Edible Oil Fortification: FortifiedDocument4 pagesTechnical Handbook On Edible Oil Fortification: FortifiedramcatNo ratings yet

- Meat Hygiene Assessment 2nd EdDocument131 pagesMeat Hygiene Assessment 2nd EddoctorraslanNo ratings yet

- Part 4 - Annex 4 Audit Reporting TemplateDocument4 pagesPart 4 - Annex 4 Audit Reporting Templateivonastrid552No ratings yet

- Animal Feed MillDocument33 pagesAnimal Feed MillEdgar Diaz NietoNo ratings yet

- Nabl 180Document15 pagesNabl 180Shakambari GaneshanNo ratings yet

- Export Meat Systems Audit ChecklistDocument88 pagesExport Meat Systems Audit Checklisthoanam2009No ratings yet

- Role of Microbes in Dairy IndustaryDocument34 pagesRole of Microbes in Dairy IndustaryShubham Dwivedi0% (1)

- Final DPR Bareilly PDFDocument197 pagesFinal DPR Bareilly PDFPatan Abdul Mehmood Khan100% (1)

- Module 16 Livestock Killing Animals Disease ControlDocument43 pagesModule 16 Livestock Killing Animals Disease ControlKenesaNo ratings yet

- Case Study Meat ProcessingDocument2 pagesCase Study Meat ProcessingChirag GoelNo ratings yet

- Presentation UME For MalaysiaDocument36 pagesPresentation UME For Malaysiaapi-3772864No ratings yet

- Export Strategies For The Halal MarketDocument14 pagesExport Strategies For The Halal MarketNur IskandarNo ratings yet

- GMP 2Document18 pagesGMP 2j.k.kumar100% (3)

- SLAUGHTER HOUSE WASTE AND DEAD ANIMALS: PARAMETERS: Punjab Constitutes Committee To Implement Who's Parameters in Slaughter Houses - Naresh KadyanDocument8 pagesSLAUGHTER HOUSE WASTE AND DEAD ANIMALS: PARAMETERS: Punjab Constitutes Committee To Implement Who's Parameters in Slaughter Houses - Naresh KadyanNaresh KadyanNo ratings yet

- Salt Large Internal Monitoring QAQCDocument28 pagesSalt Large Internal Monitoring QAQCHenok DireNo ratings yet

- (PRPS) ListDocument9 pages(PRPS) ListDeepak MoreNo ratings yet

- FMTK 2 PremixDocument23 pagesFMTK 2 PremixGokul KarwaNo ratings yet

- ISO TS 22002 5 2019 Transport and StorageDocument24 pagesISO TS 22002 5 2019 Transport and Storageyemeknazar100% (1)

- Protein Contribution of Feedstuffs for Ruminants: Application to Feed FormulationFrom EverandProtein Contribution of Feedstuffs for Ruminants: Application to Feed FormulationNo ratings yet

- Halal Food Certification and Business Performance in MalaysiaFrom EverandHalal Food Certification and Business Performance in MalaysiaNo ratings yet

- 2013 08 19 Frfa Standard 2013 Rev 12Document2 pages2013 08 19 Frfa Standard 2013 Rev 12api-223133991No ratings yet

- Lecture Poultry Chicken NC IiDocument34 pagesLecture Poultry Chicken NC IiNichole Kyla Enriquez100% (1)

- MODEL PROJECT REPORT For Broiler Farming On Contract SystemDocument42 pagesMODEL PROJECT REPORT For Broiler Farming On Contract SystemVijay Kumar82% (11)

- Prevention Control of Poultry DiseasesDocument64 pagesPrevention Control of Poultry Diseasessigra100% (3)

- Bio SecurityDocument18 pagesBio SecurityRameez SarwarNo ratings yet

- I. Executive SummaryDocument11 pagesI. Executive SummaryHorace Jeffrel OngNo ratings yet

- Good Agricultural Practice (GAP) / Good Animal Husbandry (GAHP) For Poultry FarmDocument30 pagesGood Agricultural Practice (GAP) / Good Animal Husbandry (GAHP) For Poultry FarmNgan SonledaNo ratings yet

- WomblesDocument12 pagesWomblesdaschawatNo ratings yet

- Eva's Edibles Executive Summary: A Personal Chef ServiceDocument14 pagesEva's Edibles Executive Summary: A Personal Chef ServiceAnonymous WkcFxIgNo ratings yet

- Joint - DTI-DA-DOE Administrative Order No 001-17Document5 pagesJoint - DTI-DA-DOE Administrative Order No 001-17chrissa magatNo ratings yet

- Big Retail BrandsDocument5 pagesBig Retail Brandsrohitgoel.iipm6952No ratings yet

- Newly Opened - Untamed Chef RestaurantDocument2 pagesNewly Opened - Untamed Chef RestaurantPR.comNo ratings yet

- Filipino Dishes RecipesDocument13 pagesFilipino Dishes RecipesReginald Quimba100% (2)

- ContemporaryAgriculturevol 593-4Document206 pagesContemporaryAgriculturevol 593-4Djordje NedeljkovicNo ratings yet

- Asian Regionalism-Drv PDFDocument40 pagesAsian Regionalism-Drv PDFJan Kenneth PanchoNo ratings yet

- Composition and Direction of India's Foreign TradeDocument39 pagesComposition and Direction of India's Foreign TradeAvanish KumarNo ratings yet

- Choose The Correct Answer84orenDocument14 pagesChoose The Correct Answer84orenTenthnia Putri PratiwiNo ratings yet

- Functional and Symbolic Attributes of Product Selection: University of Kent, Canterbury, UKDocument11 pagesFunctional and Symbolic Attributes of Product Selection: University of Kent, Canterbury, UKRohit RatheeNo ratings yet

- READING (17.09) The Role of Accidents in BusinessDocument6 pagesREADING (17.09) The Role of Accidents in BusinessTrangNo ratings yet

- Emeals Clean Eating For2 PlanDocument3 pagesEmeals Clean Eating For2 PlanBorana LaciNo ratings yet

- Sabouraud Dextrose BrothDocument2 pagesSabouraud Dextrose Brothrdn2111No ratings yet

- Protected-Upload - 2019-10-03T054721.393 PDFDocument3 pagesProtected-Upload - 2019-10-03T054721.393 PDFAnonymous iwTtu7i5VNo ratings yet

- Practical Aspects of Incorporation of CompanyDocument16 pagesPractical Aspects of Incorporation of CompanyshanikaNo ratings yet

- Feasibility Report On Opening A Juice Bar Shop in Bathinda: Punjabi UniversityDocument11 pagesFeasibility Report On Opening A Juice Bar Shop in Bathinda: Punjabi UniversityRanjuSinglaNo ratings yet

- Group 7: Lecture: Nguyễn Đăng Quang HuyDocument6 pagesGroup 7: Lecture: Nguyễn Đăng Quang HuyThy Nguyễn Mai HoàngNo ratings yet

- BITTER SWEET POLVORON Business PlanDocument21 pagesBITTER SWEET POLVORON Business PlanShahanie Joy ReyesNo ratings yet

- PanPinoy Delights FINALDocument44 pagesPanPinoy Delights FINALjmmoralejoNo ratings yet

- Hotpoint Dishwasher - Model BFV62 ManualDocument20 pagesHotpoint Dishwasher - Model BFV62 ManualMartin Lee SmithNo ratings yet

- Unit 7: Consumers: 7.1. VocabularyDocument4 pagesUnit 7: Consumers: 7.1. Vocabularyapi-19966509No ratings yet

- Make Peace With Fat by Mihaela TelecanDocument357 pagesMake Peace With Fat by Mihaela Telecanaadi77100% (2)

- American Adventures Pre-IntermediateDocument47 pagesAmerican Adventures Pre-IntermediateThanhnhan Mai100% (1)

- Seminar Topics PDFDocument8 pagesSeminar Topics PDFvijaya choudharyNo ratings yet

- EasternDocument16 pagesEasternJithin ShajiNo ratings yet

- Lemon LemoniesDocument10 pagesLemon LemoniesEarl ConcepcionNo ratings yet

- 18 QuestionnaireDocument15 pages18 Questionnaireyogi100% (2)