Professional Documents

Culture Documents

Psychrometry Exp2

Uploaded by

Mohamed AshrafOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Psychrometry Exp2

Uploaded by

Mohamed AshrafCopyright:

Available Formats

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

MEP 451 Refrigeration & Air Conditioning

Experiment Title: Analysis of Air Conditioning Processes A: Cooling, De-humidifying & Reheat B: Humidifying and heating

June 2009.

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

1. Introduction

Moist air is a mixture of dry air (gases such as O2, N2, CO2, etc) and water vapor. A useful tool for studying and analyzing thermodynamics properties of moist air is the psychrometric chart. To provide thermal comfort conditioning in occupied spaces, air must be conditioned. Depending on the climate conditioning and the indoor requirement, air conditioning processes could be sensible heating or cooling, de-humidifying, humidifying etc. The purpose of this experiment is to practically show some of the uses of the psychrometric chart, and thermodynamically analyze some of the air conditioning processes.

2. Apparatus

Air conditioning Laboratory Unit A660 manufactured by P.A. Hilton Company. Figure (1) shows the layout of the unit. Numbered components list is shown on Fig. (2).

3. Objective

To be able to use the psychrometric chart. To draw the processes on the psychrometric chart and analyze them thermodynamically.

4. Process description

One of the basic air conditioning processes that is applied frequently in humid hot areas is cooling and dehumidifying process. To achieve this process cooling coil is used. Cooling coil can be either direct expansion (DX) type or chilled water type. When moist air is to be cooled and dehumidified, it passes over a cooling coil whose surface temperature is equal or lower than the dew point temperature of the incoming air. Figure (3) shows a sketch of this process, and Figure (4) shows how the process looks on a psychrometric chart. Air at state B is passed over a DX cooling coil. The air leaving the coil at state C passes over an electric heater, and exits at state D. Notice that the vapor which condensate over the coil is collected at the bottom and drained out. In order to locate any of the states B, C or D, two properties must be known. For our experimental unit two thermometers are installed at each state to measured dry and wet bulb temperatures. This will facilitate locating the states on the chart. Since the air damper [see component 42 on Figure (1)] is closed, i.e. the air system is configured as a once through arrangement. The mass flow rate of air can be found from the inclined manometer measurement at state E. If the manometer reading is ZE, and the specific volume of air at this state is E, then the air mass flow rate is given by & a = 0.0517 m ZE vE (1)

where ZE is the inclined manometer reading at state E [mm H2O], and E is the specific volume of air at state E ( to be found from psychrometric chart) [m3/kg] The heat extracted from air when passing from B to C is given by & =m & a (hB hC ) m & w hw Q BC Where & m is the rate of mass liquid condensed m hw is the enthalpy of the condensate water 2 (2)

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

The second term in equation (2) above is the energy carried by the condensate, and since it is very small it can be neglected. The amount of heat added to the air in the re-heater can be found using & =m & a (hD hC ) Q CD

(3)

The heat extracted from air when passing from B to C is the same heat that is added into the evaporator of the vapor compression refrigeration cycle. This heat can be found once the refrigerant flow rate and the inlet and exit enthalpies are found. Figure (5) is a P-h diagram for R-134a that can be used to find the properties & ref (h13 h15 ) QE = m (4) Where h13 is the enthalpy of refrigerant at the evaporator exit, and h15 is the enthalpy at the evaporator inlet, which equals to the enthalpy at the condenser exit.

5. Procedure

1-Inspect the apparatus and its main components. You should locate the following parts: a-Air intake b-Fan c-Pre-heater d-Humidifier e-Cooling coil f-Re-heater g-Thermometers h-Inclined manometers i- Temperature indicator k-Refrigeration cycle and its components Check to see that pure water is provided to all wet bulb thermometers. 2-Make sure that the air circulation is once through system by shutting off the damper on the re-circulated duct. 3-Make sure that all heaters, the compressor are set off. Also set the system control to manual. 4-Turn the fan on, and set its speed to be intermediate position 5-Turn the compressor on 6-Turn on the 1 kW of the electric re-heater 7-Wait for steady state to provide by watching the variation of temperature at location 7 (i.e. t7). Usually 10-20 minutes are enough to achieve steady state condition. 8) Record the data on table (1). You may need to take two set two data to make sure that steady state condition has be reached. 9) Locate state B, C, D, and E on the psychrometric chart, and fill table (2) below 10) Locate states 13 and 15 on R-134a P-h chart 11) Compare the values of QE with QBC and comment on the difference 12) Comment on you results

Figure 3 A schematic showing the cooling coil and the heating coil.

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

Figure (4) Representation of cooling and dehumidifying process [BC], and sensible heating process [CD] on the psychrometric chart.

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

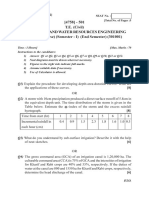

Table (1) Observed data

Atmospheric pressure ( Heater input power ( Test Reference A Air at fan inlet ) mm Hg ) kW Units Dry Wet B C After Pr-heater and Steam Dry injector Wet After Dehumidification After Re-heater Return Cooling/ Dry Wet Dry Wet E Dry Wet F Fresh Air Intake Dry Wet Evaporator Outlet Condenser inlet Condenser outlet Supply voltage Evaporator outlet pressure Condenser inlet pressure Condenser outlet pressure Fresh air intake Diff. manometer reading Duct Differential manometer reading Fan supply voltage Condensate Collected Time interval to collect condensate Mass flow rate of condensate water R-134a mass flow rate*

* Divide by 1000 to get the mass flow rate in kg/s

Mean

T1 T2 T3 T4 T5 T6 T7 T8 T9 T10 T11 T12 T13 T14 T15 VL P1 P2 P3 ZF ZE VF mw t

C C C C C C C C C C C C C C C Volts kPa (gage) kPa gage) kPa (gage) mm mm Volts grams s `

m w/(1000)t kg/s & ref m g/s

King Abdulaziz University Faculty of Engineering, Mechanical Engineering Thermal Engineering and Desalination Technology Department

Table (2) Air properties State B C D E Table (3) Summary of calculated parameters Variable &a m & Q

BC

t [C]

t* [C]

h [kJ/kg]

W [kg/kg]

[m3/kg]

Value

Units

Remarks

& Q CD h13 h15 & Q

E

(Q BC Q E ) *100 / Q E

Marks distribution for the report No. 1 2 3 4 5 6 7 Item Attend the lab. session and fill experimental data Locate correctly state 13 & 15 on R-134a P-h chart Locate correctly air states (A,B, C, D, & E) on psychrometric chart Show details of your calculations and correct units Calculate the percentage difference between QBC and QE Discussion of results, remarks, conclusions and comments Neatly and well presented report Marks 1 1 2 2 1 2 1

6. Conclusions & Comments

{Each student should write at least one paragraph about conclusions and comments}

You might also like

- Ac t680 CompletoDocument124 pagesAc t680 Completojamca100% (2)

- ESP Failure Analysis of Forties Experience ApacheDocument14 pagesESP Failure Analysis of Forties Experience ApacheMohamed AshrafNo ratings yet

- VSD ComponentsDocument20 pagesVSD ComponentsTanya Singh75% (4)

- Eu 1 Module 1 Part IIIDocument50 pagesEu 1 Module 1 Part IIIglaineNo ratings yet

- Onesubsea Overview - AshxDocument24 pagesOnesubsea Overview - AshxMohamed Ashraf100% (1)

- Moment of Inertia PDFDocument18 pagesMoment of Inertia PDFBernalyn ManaogNo ratings yet

- Refrigeration SystemsDocument50 pagesRefrigeration SystemsSneha RajasekarNo ratings yet

- Magoosh GRE Math Formula EbookDocument33 pagesMagoosh GRE Math Formula EbookLavina D'costa100% (1)

- 02 STRUCTURAL STEEL DESIGN IntroDocument21 pages02 STRUCTURAL STEEL DESIGN IntroRi MarkuNo ratings yet

- Chapter 3: Flows Around Submerged BodiesDocument65 pagesChapter 3: Flows Around Submerged BodiesPrya Suthan Sathiananthan100% (2)

- Fourier's Law and the Heat Diffusion EquationDocument34 pagesFourier's Law and the Heat Diffusion EquationrafsanNo ratings yet

- 1 IntroductionToArtificialLiftMethodsDocument29 pages1 IntroductionToArtificialLiftMethodsMahesh MahajanNo ratings yet

- Ohmeda Ohio - Service ManualDocument62 pagesOhmeda Ohio - Service ManualsambadeeNo ratings yet

- Science8 - q1 - Mod7 - Heat and Temperature - v3Document24 pagesScience8 - q1 - Mod7 - Heat and Temperature - v3RUTH PIANG100% (5)

- 06 Forum v10n3Document3 pages06 Forum v10n3Mohamed AshrafNo ratings yet

- Astm D3575-2000 PDFDocument9 pagesAstm D3575-2000 PDFErangaNo ratings yet

- Blank Tema SheetDocument1 pageBlank Tema SheetMohamed AshrafNo ratings yet

- FMM Question BankDocument56 pagesFMM Question BankSaravanan MathiNo ratings yet

- Computational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992From EverandComputational Wind Engineering 1: Proceedings of the 1st International Symposium on Computational Wind Engineering (CWE 92) Tokyo, Japan, August 21-23, 1992S. MurakamiNo ratings yet

- Engineering MechanicsDocument15 pagesEngineering Mechanicsapi-26349602100% (1)

- Moment of Inertia LectureDocument26 pagesMoment of Inertia LectureMohdmuslim AbdkohaNo ratings yet

- Basic Fluid Concepts and Properties (μ, ρ, γDocument41 pagesBasic Fluid Concepts and Properties (μ, ρ, γMiraJo-LingNo ratings yet

- Beams On Elastic FoundationDocument15 pagesBeams On Elastic FoundationIngeniero EstructuralNo ratings yet

- Bs Experiment 1Document5 pagesBs Experiment 1Hui Zhi100% (2)

- Eccentric loading stress calculationDocument5 pagesEccentric loading stress calculationconfederateyankeeNo ratings yet

- Thermal Engineering - I Jntua Question PapersDocument15 pagesThermal Engineering - I Jntua Question PapersHimadhar SaduNo ratings yet

- Relation Between Elastic ConstantsDocument5 pagesRelation Between Elastic Constantsnitin_johri100% (1)

- Mechanics of Materials: Chapter 9: Buckling of ColumnsDocument53 pagesMechanics of Materials: Chapter 9: Buckling of Columnsاحمد يوسفNo ratings yet

- TA CarburationDocument5 pagesTA Carburationrajmalhotra167No ratings yet

- Homework 1 3Document6 pagesHomework 1 3inisdeprawn100% (2)

- Mf7017 Materials Testing and Characterlation TechniquesDocument1 pageMf7017 Materials Testing and Characterlation TechniquesSudhir Chakravarthy KatragaddaNo ratings yet

- Finite Difference HeatDocument6 pagesFinite Difference HeatGilberto Roman0% (1)

- Homework 2Document8 pagesHomework 2jinx50100% (1)

- Final Exam CEE 211: Fluid Mechanics Total Marks: 60 Time: 2.0 HoursDocument2 pagesFinal Exam CEE 211: Fluid Mechanics Total Marks: 60 Time: 2.0 HoursAvijit SahaNo ratings yet

- 1.0 Introduction (CE-312) PDFDocument17 pages1.0 Introduction (CE-312) PDFHussain AbidNo ratings yet

- Fuel Technology - Tutorial QuestionsDocument5 pagesFuel Technology - Tutorial QuestionsHisyamAl-MuhammadiNo ratings yet

- 8echapter02 SMDocument115 pages8echapter02 SMAnonymous mXicTi8hBNo ratings yet

- Advanced Fluid Dynamics Midterm ExamDocument3 pagesAdvanced Fluid Dynamics Midterm Exam陳芊宇No ratings yet

- T.E Question Papers (2012 Pattern) May 2015Document297 pagesT.E Question Papers (2012 Pattern) May 2015Prof. Avinash MahaleNo ratings yet

- Tutorial 1 (Question)Document4 pagesTutorial 1 (Question)Muhd IlyasNo ratings yet

- Cive2400 2007Document4 pagesCive2400 2007Gert Duniceri0% (1)

- Building Systems Design ManualDocument24 pagesBuilding Systems Design ManualJulian DeleonNo ratings yet

- A 03 DemoDocument21 pagesA 03 DemoLo Shun FatNo ratings yet

- WWW - Incar.tw-Advanced Fluid Mechanics Solution ManualDocument5 pagesWWW - Incar.tw-Advanced Fluid Mechanics Solution ManualAhmedNo ratings yet

- Equivalent Moment Factor C1Document2 pagesEquivalent Moment Factor C1baharfka7423No ratings yet

- Principles of Reinforced Concrete Design: Arlegui, Quiapo, ManilaDocument10 pagesPrinciples of Reinforced Concrete Design: Arlegui, Quiapo, ManilaMary Scarlette CenaNo ratings yet

- Exp-9 Bending Test On Wooden BeamDocument8 pagesExp-9 Bending Test On Wooden BeamsushilkumarNo ratings yet

- Sewer design and water quality parametersDocument2 pagesSewer design and water quality parametersMike SyNo ratings yet

- Pakistan Council of Renewable Energy Technologies (PCRET)Document10 pagesPakistan Council of Renewable Energy Technologies (PCRET)Faiza IqbalNo ratings yet

- Closed System ExercisesDocument2 pagesClosed System ExercisesMareta DanarNo ratings yet

- Mott 4e Applied Strength of Materials Solutions Chapter 13Document20 pagesMott 4e Applied Strength of Materials Solutions Chapter 13kmantillaNo ratings yet

- HW 3 Cven 212 SP2015 PDFDocument3 pagesHW 3 Cven 212 SP2015 PDFMazen KhaledNo ratings yet

- IS875 (Part3) - Wind Loads On Buildings and Structures - IIT Kanpur-Part 6Document7 pagesIS875 (Part3) - Wind Loads On Buildings and Structures - IIT Kanpur-Part 6Adam Michael GreenNo ratings yet

- Complex Eng Prob in CE PDFDocument6 pagesComplex Eng Prob in CE PDFMonirul IslamNo ratings yet

- 15 MLD STP ScopeDocument186 pages15 MLD STP ScopeAnonymous d6tUk8QZNo ratings yet

- Engg MechanicsDocument151 pagesEngg MechanicsMartin De Boras PragashNo ratings yet

- University of Mindanao College of Engineering EducationDocument42 pagesUniversity of Mindanao College of Engineering EducationLi LiNo ratings yet

- TOS 06 Student's PDFDocument1 pageTOS 06 Student's PDFCed Calzado0% (1)

- Fluid Mechanics & Machinery: Pumps and Their PerformanceDocument52 pagesFluid Mechanics & Machinery: Pumps and Their PerformanceThiruvasagamoorthy KaNo ratings yet

- Module 5 - Properties of Fluid FlowDocument4 pagesModule 5 - Properties of Fluid FlowRochelleNo ratings yet

- MIN-305 Heat & Mass Transfer Tutorial - 1Document2 pagesMIN-305 Heat & Mass Transfer Tutorial - 1Ayush JaiswalNo ratings yet

- HW#2 Solutions ME363 Fall 2007 PDFDocument8 pagesHW#2 Solutions ME363 Fall 2007 PDFjessicaHannaNo ratings yet

- Stresses in BeamsDocument9 pagesStresses in BeamsAyad SlabyNo ratings yet

- Steel Structure Design in SAP 2000Document31 pagesSteel Structure Design in SAP 2000Ahmad Mukhtar 164-FET/BSCE/F17100% (1)

- Plate No. 1 ST314 - Structural Theory: Don Honorio Ventura State UniversityDocument4 pagesPlate No. 1 ST314 - Structural Theory: Don Honorio Ventura State UniversityRamil T. TrinidadNo ratings yet

- CH 07Document60 pagesCH 07IlhamBintang100% (1)

- Civil Dept. Lab Syllabus BookDocument277 pagesCivil Dept. Lab Syllabus BookMariwan MirNo ratings yet

- Performance Evaluation of Air ConditionersDocument11 pagesPerformance Evaluation of Air Conditionershybri8No ratings yet

- Me2121 2Document12 pagesMe2121 2Wei QuanNo ratings yet

- SBS5225 1718 Lab AC ProcessesDocument8 pagesSBS5225 1718 Lab AC ProcessesSam C M HuiNo ratings yet

- Performance Assessment of Wet-Compression Gas Turbine Cycle With Turbine Blade CoolingDocument5 pagesPerformance Assessment of Wet-Compression Gas Turbine Cycle With Turbine Blade Coolingasp9924No ratings yet

- (Fan G., Chunsheng L.) Failure Warning Model For ESP Based On Regression Analysis (2014)Document6 pages(Fan G., Chunsheng L.) Failure Warning Model For ESP Based On Regression Analysis (2014)Mohamed AshrafNo ratings yet

- Macary2003 2Document8 pagesMacary2003 2Mohamed AshrafNo ratings yet

- Fluent Tutorial Sites Cornell University: Other Sites Listed BelowDocument1 pageFluent Tutorial Sites Cornell University: Other Sites Listed BelowMohamed AshrafNo ratings yet

- Downloaded From Scribd - Mohamed DewidarDocument1 pageDownloaded From Scribd - Mohamed DewidarMohamed AshrafNo ratings yet

- Application To Watch Out For (VSD)Document3 pagesApplication To Watch Out For (VSD)Mohamed AshrafNo ratings yet

- Wo Artificial Lift Tech UpdateDocument3 pagesWo Artificial Lift Tech UpdateMohamed AshrafNo ratings yet

- Pump SimulationDocument9 pagesPump Simulationkarthikraja21No ratings yet

- AL Selection - Draft of Document - 3b - Selection ToolsDocument10 pagesAL Selection - Draft of Document - 3b - Selection ToolsMohamed AshrafNo ratings yet

- Shell and Tube Heat ExchangersDocument4 pagesShell and Tube Heat ExchangersMohamed Ashraf0% (1)

- Mechanics of An Electric Submersible Pump Failure Mode: Maston L. Powers, SPE, ConsultantDocument6 pagesMechanics of An Electric Submersible Pump Failure Mode: Maston L. Powers, SPE, ConsultantMohamed AshrafNo ratings yet

- Final Thesis 26-11-2008 James WallDocument95 pagesFinal Thesis 26-11-2008 James WallMohamed AshrafNo ratings yet

- SPE Newsletter - April 2011Document14 pagesSPE Newsletter - April 2011Mohamed AshrafNo ratings yet

- 2300Document12 pages2300Mohamed AshrafNo ratings yet

- FTCS Stability ProofDocument2 pagesFTCS Stability ProofMohamed AshrafNo ratings yet

- 006-0211-00 Rev CDocument64 pages006-0211-00 Rev CMohamed AshrafNo ratings yet

- ODE AngolDocument191 pagesODE AngolMohamed AshrafNo ratings yet

- BookDocument176 pagesBookkamal hameed tayyNo ratings yet

- ODE AngolDocument191 pagesODE AngolMohamed AshrafNo ratings yet

- MATLAB Functions for Vectors and ArraysDocument5 pagesMATLAB Functions for Vectors and ArraysMohamed AshrafNo ratings yet

- Magoosh GRE1 Month GREStudy Schedule Daily ScheduleDocument15 pagesMagoosh GRE1 Month GREStudy Schedule Daily ScheduleBrianJ200No ratings yet

- Command Window: HistoryDocument7 pagesCommand Window: HistoryMohamed AshrafNo ratings yet

- Ch05a EquilibruimDocument25 pagesCh05a EquilibruimMohamed AshrafNo ratings yet

- Latham Dean A 200812 MScEDocument279 pagesLatham Dean A 200812 MScELei SunNo ratings yet

- Astm D572 PDFDocument4 pagesAstm D572 PDFPriyadarshini KrishnaswamyNo ratings yet

- Comparing Stability of Metal and Fused Silica SPRTsDocument8 pagesComparing Stability of Metal and Fused Silica SPRTsAlexandraAndreeaNo ratings yet

- 02 Broschuere WitepsolDocument25 pages02 Broschuere WitepsolDomitian PascaNo ratings yet

- Specific Heat Is Another Physical Property of MatterDocument8 pagesSpecific Heat Is Another Physical Property of MatterMarie-Joi PauletteNo ratings yet

- Carrier 24ACC6 PDFDocument20 pagesCarrier 24ACC6 PDFJojo FernandezNo ratings yet

- Hvac Prob 1 FINALDocument6 pagesHvac Prob 1 FINALDatu JonathanNo ratings yet

- Thermodynamic Properties of Oxygen From 20-100KDocument2 pagesThermodynamic Properties of Oxygen From 20-100Kwesileh981No ratings yet

- Silo - Tips - Instruction Manual Digital Manifold For Hvac R Systems Manual de Instrucciones Manifold Digital Hvac RDocument12 pagesSilo - Tips - Instruction Manual Digital Manifold For Hvac R Systems Manual de Instrucciones Manifold Digital Hvac RfeletnorNo ratings yet

- Thermal Expansion PowerpointDocument19 pagesThermal Expansion PowerpointNicholasNo ratings yet

- Green House Intelligent Control System PDFDocument15 pagesGreen House Intelligent Control System PDFMuhammadAbbasJafriNo ratings yet

- Titus Diffuser Catalog 2013Document216 pagesTitus Diffuser Catalog 2013bacalado100% (2)

- Heating Belt FCH FLEXBELT GBDocument1 pageHeating Belt FCH FLEXBELT GBbenjaminfarfarNo ratings yet

- Department of Chemical Engineering Indian Institute of Technology RoorkeeDocument2 pagesDepartment of Chemical Engineering Indian Institute of Technology RoorkeePramanshu RajputNo ratings yet

- Optical Properties of Plastic Mulches Affect The Field Temperature RegimeDocument6 pagesOptical Properties of Plastic Mulches Affect The Field Temperature RegimeHamzarudin HikmatiarNo ratings yet

- Gas Laws ExplainedDocument10 pagesGas Laws ExplainedM Rizki MaulanaNo ratings yet

- SCHWING Fluidized Bed Process Technique enDocument6 pagesSCHWING Fluidized Bed Process Technique enariefNo ratings yet

- ASTM D 852 - 02 Solidification Point of BenzeneDocument4 pagesASTM D 852 - 02 Solidification Point of Benzenealin2005100% (1)

- Catalogue5 1Document32 pagesCatalogue5 1mealysrNo ratings yet

- BDVDocument3 pagesBDVJason ThomasNo ratings yet

- BR Lyoquest en 0111 - 0 PDFDocument4 pagesBR Lyoquest en 0111 - 0 PDFmarcelloairesNo ratings yet

- Radiateur Cat 320c - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCDocument3 pagesRadiateur Cat 320c - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCMehdi ChakrouneNo ratings yet

- IntelligAIRE II Diagnostic Procedures Using Drivers Display ModuleDocument2 pagesIntelligAIRE II Diagnostic Procedures Using Drivers Display ModuleNino PamindoNo ratings yet

- 1 Katalog Hicop Heat Pump Type Aw New 2016Document3 pages1 Katalog Hicop Heat Pump Type Aw New 2016Joko SubagyoNo ratings yet

- Imas 37Document8 pagesImas 37Shahadat Hussain ParvezNo ratings yet