Professional Documents

Culture Documents

Bab 13 - Lighting

Uploaded by

masgrahaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bab 13 - Lighting

Uploaded by

masgrahaCopyright:

Available Formats

PT.

PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

LIGHTING

13. LIGHTING

13.1 BACKGROUND

The major objectives of energy audit in lighting system include: Measurement and comparison of illumination levels at various locations Measurement of total power consumption of all lighting feeders Calculate the installed load efficacy in terms of lux/watt/m (existing vs design) for general lighting installation. Compare calculated value with the norms for specific types of interior installations for assessing improvement options. To suggest ways and means to optimize the illumination levels and to optimize the power consumption at different locations. To identify energy saving measures and quantifies the energy and cost savings.

13.2 STEPS INVOLVED IN CONDUCTING THE ENERGY AUDIT

The steps involved in conducting energy audit of lighting plant are: Data collection Observations, measurement and Analysis Exploration for calculations energy conservation measures with detailed techno-economic

Report preparation

13.3 DATA COLLECTION

Collect the single line diagram of electrical drawing pertaining to lighting Obtain the lighting fixture details for each section Typical format for data collection of lighting details is given Table 13-1

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta Nilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

LIGHTING

Table 13-1: Typical Data parameters Fixture Wattage Section/ Type & of each Department ballast type fitting Total Other energy No of Room Feeder Illumines Consumer connected fixtures dimensions required details wattage details Remarks

In case if the details are not available it is suggested to conduct a survey and obtain the above details. In the above table under other energy consumers column provide the details of fans, air conditioners, computers, photocopiers, etc which are connected to lighting circuit to be given. For illumination level required refer Annexure-13.1, where recommended illumination values as per IS: 3646 (Part-1) 1992 for various areas in power stations are provided. If the plant has separate transformers for lighting circuit, provide the details of transformer Details of energy saving retrofits installed in the plant (such as voltage controllers, sensors, controllers, timers, etc) Details of on & off mechanism of lighting circuits Details of energy meters provided in the lighting circuit and sections served by these meters Details of energy consumption monitoring of lighting systems Energy consumption of lighting circuit

13.4 Instrument Required

The following instruments are required for conducting the energy audit of lighting system Power Analyzer: Used for measuring electrical parameters such as kW, kVA, pf, V, A and Hz of class 0.5 accuracy Lux meters Measuring tape On line energy meter instruments (calibrated)

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta Nilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

LIGHTING

13.5 Measurements & Observation to Be Made

While conducting the audit carryout a detailed survey for the following Monitor the condition of lighting fixtures Lux measurements at various places (Number of measurement to be carried out is given in the following sections) Measurement of power parameters kW, kVA, Current, Voltage, power factor, harmonics, frequency of all feeders Room dimensions Counting of installed fixtures Vs number of fixtures in operation Maintenance practices for cleaning, replacement, etc

13.6 Observations And Analysis

13.6.1 System familiarization and operational details

Detailed interactions with the plant personnel have to be carried out to get familiarization for system detail and operational details. Pre visit to the plant can be made to get familiarization of lighting system

13.6.2 Measurements & Evaluation

The summary of lighting measurements and calculations are shown Table 13-2.

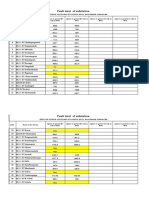

Table 13-2: Summary of lighting measurements and calculations

Location/ Room No

Type of lamps

Measured Average Lux level

Standard Lux level (as per I S 3646)

Measured Power (kW)

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta Nilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

LIGHTING

Observations on housekeeping and maintenance practices Interactions and surveys to be carried out on House keeping measures in up keeping of luminaries Failure rate of lamps and ballasts Replacement procedure of failed lamps Procurement options Maintenance practices Operational practices (on / off controls) If any energy saving retrofits are installed in the plant then the operational status of the retrofits can be assessed Identify the areas where poor illumination and excess illumination is provided Assess the various alternate lamps / luminaries applicable for various sections Type of panel lamps or sign lamps used to explore possibility of using LED lamps Observations on other loads which are connected to the lighting circuit and their energy consumption

13.6.3 Exploration of energy conservation possibilities

While conducting the energy audit explore for various energy conservation measures such as Look for natural lighting opportunities through windows and other openings. Derive way to improve natural lighting during the day time In the case of industrial lighting, explore the scope for introducing translucent sheets Use of energy efficient lighting methods / products / equipment / retrofits Maximize sunlight use through use of transparent roof sheets, north light roof, etc. Examine scope for replacements of lamps by more energy efficient lamps, with due consideration to luminaries, color rendering index, lux level as well as expected life comparison. Replace conventional magnetic ballasts by more energy efficient ballasts, with due consideration to life and power factor apart from watt loss. Select interior colours for light reflection. Assess scope for delamping Assess scope for re-arrangement of lighting fixtures Modify layout for optimum lighting. Providing individual / group controls for lighting for energy efficiency such as: On / off type voltage regulation type (for illuminance control) Group control switches / units 4

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta Nilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

LIGHTING

Occupancy sensors Photocell controls Timer operated controls Modify switches / electrical circuit Install input voltage regulators / controllers for energy efficiency as well as longer life expectancy for lamps where higher voltages, fluctuations are expected. Replace energy efficient displays like LED's in place of lamp type displays in control panels / instrumentation areas, etc. Opt for better reflector in lighting Cleaning of reflector at regular interval In power plant, locations like HT/LT switchgear rooms, cable galleries etc which sites / locations are rarely visited, lighting circuits may be modified in such a way that keeping 25% to 30% lights always ON and remaining lights controlled by simple ON /OFF switch provided at the entrance of the room / hall Opportunities to reduce the power consumption/ improve the energy efficiency of other loads which are connected to the lighting circuit

Some good practices in lighting are: Installation of energy efficient fluorescent lamps in place of "Conventional" fluorescent lamps. Installation of Compact Fluorescent Lamps (CFL's) in place of incandescent lamps. Installation of metal halide lamps in place of mercury / sodium vapour lamps. Installation of High Pressure Sodium Vapour (HPSV) lamps for applications where colour rendering is not critical Installation of LED panel indicator lamps in place of filament lamps. Light Control Grouping of lighting system, to provide greater flexibility in lighting control Installation of microprocessor based controllers Optimum usage of day lighting Installation of "exclusive" transformer for lighting Installation of servo stabilizer for lighting feeder Installation of high frequency (HF) electronic ballasts in place of conventional ballasts

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta Nilai-Nilai Perusahaan

PT. PLN (PERSERO) PUSAT PENDIDIKAN DAN PELATIHAN

LIGHTING

13.6.4 Recommendations

Each energy conservation measure should discuss

The back ground Analysis and suggestion Energy savings evaluation (Estimated before and after) Impact on energy consumption after implementation Economic feasibility Investment required and payback period Monitoring and verification of energy savings after implementation Efforts and resources required for sustainability of energy savings The vendors/ suppliers/ manufactures details

Berbagi dan Menyebarkan Ilmu Pengetahuan Serta Nilai-Nilai Perusahaan

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Toyota 1NZ - IgnitionDocument7 pagesToyota 1NZ - IgnitionMaycol Pauccarima Alfaro100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Motor Caterpillar 3044ctDocument2 pagesMotor Caterpillar 3044ctOscar Pardo Pardo67% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 2011 TB WB Merged PDFDocument115 pages2011 TB WB Merged PDFthequranthekoranNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- JSA TemplateDocument3 pagesJSA TemplateJob MateusNo ratings yet

- Boiler Management EPRIDocument3 pagesBoiler Management EPRImasgrahaNo ratings yet

- PASS55 - PerformanceDocument16 pagesPASS55 - Performancemasgraha100% (1)

- Boiler Maintenance Management SystemDocument3 pagesBoiler Maintenance Management SystemmasgrahaNo ratings yet

- Pass55 ChartDocument4 pagesPass55 ChartmasgrahaNo ratings yet

- Design and Implementation of Well TestingDocument33 pagesDesign and Implementation of Well TestingMuhammad Tahir100% (1)

- Plug in Electric Vehicles in Smart Grids Integration TechniquesDocument355 pagesPlug in Electric Vehicles in Smart Grids Integration Techniqueseng_alhemyari100% (3)

- Innovation For Boiler TubeDocument2 pagesInnovation For Boiler TubemasgrahaNo ratings yet

- PAS55 Assessment ExerciseDocument28 pagesPAS55 Assessment ExercisemasgrahaNo ratings yet

- Air Heater Powermag 101 - CoalDocument36 pagesAir Heater Powermag 101 - CoalmasgrahaNo ratings yet

- Asset Management: Review and CloseDocument3 pagesAsset Management: Review and ClosemasgrahaNo ratings yet

- Asset Management: Review and CloseDocument3 pagesAsset Management: Review and ClosemasgrahaNo ratings yet

- Asset Management: Review and CloseDocument3 pagesAsset Management: Review and ClosemasgrahaNo ratings yet

- Boiler Feed Water Treatment Oxgenated Power Plant in ChinaDocument11 pagesBoiler Feed Water Treatment Oxgenated Power Plant in Chinamasgraha100% (1)

- Journal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFDocument6 pagesJournal of Power Engineering and Power Equipment Ppchem-02-2008-5-Errata PDFmasgrahaNo ratings yet

- BS 7346-8 - Smoke VentilationDocument56 pagesBS 7346-8 - Smoke VentilationHelen Othen100% (1)

- Geothermal Energy Status ReportDocument64 pagesGeothermal Energy Status ReportmasgrahaNo ratings yet

- Session VI EHa and LTR Mechanical Equipment and Operation and MaintenanceDocument59 pagesSession VI EHa and LTR Mechanical Equipment and Operation and MaintenancemasgrahaNo ratings yet

- Exfoliation TestexDocument26 pagesExfoliation TestexmasgrahaNo ratings yet

- Exfoliation TestexDocument26 pagesExfoliation TestexmasgrahaNo ratings yet

- Incipient & Hidden Failure From Relevance ReferencesDocument3 pagesIncipient & Hidden Failure From Relevance ReferencesmasgrahaNo ratings yet

- PASS55 - QuestionsDocument2 pagesPASS55 - QuestionsmasgrahaNo ratings yet

- Boiler Management Reliable & AvailableDocument3 pagesBoiler Management Reliable & AvailablemasgrahaNo ratings yet

- Sustaining Power Plant Life Through Rehabilitation As A Part of Life Cycle Management Program r02Document14 pagesSustaining Power Plant Life Through Rehabilitation As A Part of Life Cycle Management Program r02masgrahaNo ratings yet

- When Generator Rewind in GeneralDocument4 pagesWhen Generator Rewind in GeneralmasgrahaNo ratings yet

- Air Heater PerformanceDocument6 pagesAir Heater PerformancemasgrahaNo ratings yet

- Handout Pass55Document27 pagesHandout Pass55masgrahaNo ratings yet

- Pass 55 CBRMDocument18 pagesPass 55 CBRMmasgrahaNo ratings yet

- Tools, Facilities and EquipmentDocument3 pagesTools, Facilities and EquipmentmasgrahaNo ratings yet

- PASS55 WorkshopDocument9 pagesPASS55 WorkshopmasgrahaNo ratings yet

- PASS55 WorkshopDocument9 pagesPASS55 WorkshopmasgrahaNo ratings yet

- Pass 55 CBRM2Document33 pagesPass 55 CBRM2masgrahaNo ratings yet

- PAS 55 ReviewDocument8 pagesPAS 55 ReviewmasgrahaNo ratings yet

- VCBDocument3 pagesVCBMitesh GandhiNo ratings yet

- Plano Electrico DD 311Document18 pagesPlano Electrico DD 311logan villanueva melquiadesNo ratings yet

- Workshop Small NewDocument36 pagesWorkshop Small Newesteban marinkovicNo ratings yet

- AHSP - SDA - Basis Permen 28 TH 2016Document16 pagesAHSP - SDA - Basis Permen 28 TH 2016BagusPrambudiNo ratings yet

- T-23 BOQ (Katol)Document40 pagesT-23 BOQ (Katol)rajesh kumarNo ratings yet

- Wheel Loader For Batching PlantDocument12 pagesWheel Loader For Batching PlantAnonymous z4Fe39jNo ratings yet

- Organic Oil Recovery and The Miracle of Microbes: JANUARY 2019Document17 pagesOrganic Oil Recovery and The Miracle of Microbes: JANUARY 2019Andrei IvanovichNo ratings yet

- Concentrate Control System: Operating, Maintenance, and Filling ManualDocument24 pagesConcentrate Control System: Operating, Maintenance, and Filling ManualWacoman RazanNo ratings yet

- Manual Aspiradora LG Luv200rDocument75 pagesManual Aspiradora LG Luv200rrukaiserNo ratings yet

- Forty Years of Heat Integration: Pinch Analysis (PA) and Mathematical Programming (MP)Document14 pagesForty Years of Heat Integration: Pinch Analysis (PA) and Mathematical Programming (MP)Raviranjan Kumar SinghNo ratings yet

- Minecraft: Creating A Digital Model of A FarmDocument5 pagesMinecraft: Creating A Digital Model of A FarmMonica SevillaNo ratings yet

- Generation Transmission and DistributionDocument137 pagesGeneration Transmission and Distributionsathya2040No ratings yet

- Subtopic: Oxidation Objectives: - Identify and Justify Oxidation As Exothermic ReactionDocument10 pagesSubtopic: Oxidation Objectives: - Identify and Justify Oxidation As Exothermic ReactionChalise SupremeNo ratings yet

- Argus European ProductsDocument14 pagesArgus European ProductsMihaElla_07No ratings yet

- VMC Ideo 325Document9 pagesVMC Ideo 325Patrick CarapinhaNo ratings yet

- Energy Attacks: Energy Manipulation Attack PowersDocument3 pagesEnergy Attacks: Energy Manipulation Attack PowersSunčica NisamNo ratings yet

- 5070 s03 QP 1 PDFDocument16 pages5070 s03 QP 1 PDFAnonymous wFLGHQ6ARNo ratings yet

- Pumps Rotary Gear Pump Selection GuideDocument1 pagePumps Rotary Gear Pump Selection GuidewidhisaputrawijayaNo ratings yet

- Weber Q3000Document44 pagesWeber Q3000Marius MullerNo ratings yet

- KD2250-F-SDMO (Alternator Data Sheet SDMO 2000KVA Prime Generator Set)Document6 pagesKD2250-F-SDMO (Alternator Data Sheet SDMO 2000KVA Prime Generator Set)schraz4575No ratings yet

- Fault Level of SubstationDocument2 pagesFault Level of SubstationrtadNo ratings yet

- Pulsar Extreme 3200CDocument28 pagesPulsar Extreme 3200CGuillermoNo ratings yet

- Studying The Operation of A Smart Grid With The MyGrid MiniSystem For NI MyDAQ (Piomeer Release)Document4 pagesStudying The Operation of A Smart Grid With The MyGrid MiniSystem For NI MyDAQ (Piomeer Release)Jobin VargheseNo ratings yet