Professional Documents

Culture Documents

Script:-.Air Condition Script

Uploaded by

aimri_cochinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Script:-.Air Condition Script

Uploaded by

aimri_cochinCopyright:

Available Formats

Air conditioning

Marine air conditioning Marine air conditioner is also the same as the other conditioners available in today's market. It has bought a revolution in the air conditioning industry introducing one in the marine system. It involves almost in all the fields. Marine air systems are a leading supplier in the chilled water systems for more yachts on a worldwide basis. They are designed by the domestic environment corporation, which was developed by Taylor made group. Along with this marine chilled water system, domestic environmental corporation also launched its air conditioners and refrigerators.

This uses the HVAC system of cooling the temperature. Domestic Corporation serves as one of the leading suppliers in accessory and air conditioning products. This also works same as the other conditioners. It also helps in controlling the temperature of the room and the humidity of the air.

It maintains a constant temperature once it is regulated. This air conditioner almost works under the same mechanism and its components comprised in the central cooling unit. Advantages and disadvantages in marine air conditioners There are both the advantage and the disadvantages with this system. The main advantage is that it is located in the less occupied areas and it requires no pipe line to connect with the other. This system is used for any size of boat or any size budget. It has made the marine air conditioners more adaptable and easy to install. This would be the smallest, lightest and the quietest conditioner in the market. It uses varies digital controls to keep track of the system. Marine air conditioning lowers the noise levels and it eliminates the zoning of central equipment. Marine air conditioning helps in controlling the temperature and to maintain the quality of the air. It works more than the other cooling central equipment. The total life cycle of the equipment is favorably more than the central equipment. It also cost less than other system. Air conditioning Air conditioning is the process of altering the properties of air. It is meant of human comfort. Air conditioning and ventilation is the simultaneous process of heating or cooling of air, humidity control as per human comfort, air filtration, air circulation and odor control

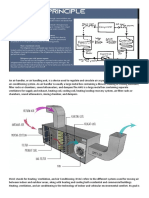

AHU of ductable AC Air conditioning and refrigeration are provided through the removal of heat. Heat can be removed through radiation, convection, and by heat pump systems through the refrigeration cycle. Refrigeration conduction media such as water, air, ice, and chemicals are referred to as refrigerants. An air conditioning system, or a standalone air conditioner, provides cooling, ventilation, and humidity control for all or part of a building. The refrigeration cycle uses four essential elements to cool. The system refrigerant starts its cycle in a gaseous state. The compressor pumps the refrigerant gas up to a high pressure and temperature. From there it enters a heat exchanger (sometimes called a "condensing coil" or condenser) where it loses energy (heat) to the outside, cools, and condenses into its liquid phase. The liquid refrigerant is returned to another heat exchanger where it is allowed to evaporate; hence the heat exchanger is often called an "evaporating coil" or evaporator. A metering device regulates the refrigerant liquid to flow at the proper rate. As the liquid refrigerant evaporates it absorbs energy (heat) from the inside air, returns to the compressor, and repeats the cycle. In the process, heat is absorbed from indoors and transferred outdoors, resulting in cooling of the building.

In variable climates, the system may include a reversing valve that switches from heating in winter to cooling in summer. By reversing the flow of refrigerant, the heat pump refrigeration cycle is changed from cooling to heating or vice versa. This allows a facility to be heated and cooled by a single piece of equipment by the same means, and with the same hardware. Central, 'all-air' air conditioning systems (or package systems) with a combined outdoor condenser/evaporator unit are often installed in modern residences, offices, and public buildings, but are difficult to retrofit (install in a building that was not designed to receive it) because of the bulky air ducts required. An alternative to central systems is the use of separate indoor and outdoor coils in split systems. These systems, although most often seen in residential applications, are gaining popularity in small commercial buildings. The evaporator coil is connected to a remote condenser unit using refrigerant piping between an indoor and outdoor unit instead of ducting air directly from the outdoor unit. Indoor units with directional vents mount onto walls, suspended from ceilings, or fit into the ceiling. Other indoor units mount inside the ceiling cavity, so that short lengths of duct handle air from the indoor unit to vents or diffusers around the rooms. Dehumidification (air drying) in an air conditioning system is provided by the evaporator. Since the evaporator operates at a temperature below dew point, moisture in the air condenses on the evaporator coil tubes. This moisture is collected at the bottom of the evaporator in a pan and removed by piping to a central drain or onto the ground outside. A dehumidifier is an

air-conditioner-like device that controls the humidity of a room or building. It is often employed in basements which have a higher relative humidity because of their lower temperature (and propensity for damp floors and walls). In food retailing establishments, large open chiller cabinets are highly effective at dehumidifying the internal air. Conversely, a humidifier increases the humidity of a building. Air conditioned buildings often have sealed windows, because open windows would work against an HVAC system intended to maintain constant indoor air conditions. All modern air conditioning systems, even small window package units, are equipped with internal air filters. These are generally of a lightweight gauzy material, and must be replaced or washed as conditions warrant. For example, a building in a high dust environment, or a home with furry pets, will need to have the filters changed more often than buildings without these dirt loads. Failure to replace these filters as needed will contribute to a lower heat exchange rate, resulting in wasted energy, shortened equipment life, and higher energy bills; low air flow can result in "iced-up" or "iced-over" evaporator coils, which can completely stop air flow. Additionally, very dirty or plugged filters can cause overheating during a heating cycle, and can result in damage to the system or even fire. Because an air conditioner moves heat between the indoor coil and the outdoor coil, both must be kept clean. This means that, in addition to replacing the air filter at the evaporator coil, it is also necessary to regularly clean the condenser coil. Failure to keep the condenser clean will eventually result in harm to the compressor, because the condenser coil is

responsible for discharging both the indoor heat (as picked up by the evaporator) and the heat generated by the electric motor driving the compressor. Outside, fresh air is generally drawn into the system by a vent into the indoor heat exchanger section, creating positive air pressure. The percentage of return air made up of fresh air can usually be manipulated by adjusting the opening of this vent. Heat pump It is a reversible device that does mechanical work to extract heat from a cooler place and deliver heat to a warmer place. The heat delivered to the warmer place is, approximately, the sum of the original heat and the work done. Greater temperature differences between the warm and cold regions require greater amounts of work. In warm weather the heat pump acts like a traditional air conditioner, removing heat from the indoors and delivering heat to the outdoors. In cool weather, it removes heat from the outdoors and delivers heat to the indoors. The efficiency of a heat pump as a heating device depends upon the outdoor temperature. At 50F; (10C;) a heat pump is more efficient than a traditional heating system. Below 32F; (0C;) it is less efficient and requires augmenting with conventional heaters. In the construction of office buildings in the United States, air-conditioning systems are commonly included as integral parts of the structure. First used c.1900 in the textile industry, air conditioning found little use outside factories until the late 1920s. It is of great importance in chemical,

pharmaceutical and other industrial plants where air contamination, humidity, and temperature affect manufacturing processes. Dew point temperature (DPT) It is that temperature at which a moist air sample atthe same pressure would reach water vapor saturation. At this saturation point,water vapor would begin to condense into liquid water fog or (if below freezing)solid hoarfrost, as heat is removed. The dew point temperature is measured easilyand provides useful information, but is normally not considered an independentproperty. It duplicates information available via other humidity properties and thesaturation curve. Tonnage of refrigeration It is the amount of heat required to change one matric ton of water to ice in 24 hours 1 TR = 12000 btu/hr = 3000kcal/hr BTU (British thermal unit) Refrigeration cycle

Diagram of a refrigeration cycle consisting of 1) Condensing coil 2) Expansion valve 3) Evaporator coil 4) Compressor

Relative Humidity (RH) It is the ratio of the mole fraction of water vapor to the mole fraction of saturated moist air at the same temperature and pressure. RH is dimensionless, and is usually expressed as a percentage. Lines of constant RH Reflect the physics of air and water: they are determined via experimental measurement. Note: the notion that air "holds" moisture, or that moisture dissolves in dry air and saturates the solution at some proportion, is an erroneous concept Humidity Ratio It is the proportion of mass of water vapor per unit mass of dry air at the given conditions (DBT, WBT, DPT, RH, etc.). It is typically the ordinate or vertical axis of the graph. For a given DBT there will be a particular humidity ratio for which the air sample is at 100% relative humidity: the relationship reflects the physics of water and air and must be measured. Humidity Ratio is dimensionless, but is sometimes expressed as grams of water per kilogram of dry air or grains of water per pound of air.

Air conditioner maintain the humidity,temp,pressure,sound,air velocity,dust control. If we have to maintain more than 2-4 rooms at a time with one air conditioner then we are using this type of air conditioner. In this system one duct or line have to go through all rooms to flow the pure & cooled air to the rooms & one duct or line have to bring all corrosive air outside the rooms & flows into outwards. This type of conditioner called ductable air conditioner.

Chilled water air conditioner

Chilled water air conditioning systems are commonly used in applications that need large cooling capacity such as hypermarket, industrial process, commercial air conditioning such as offices and factories. More and more homes are using this system to air conditioned their entire house because of its costeffectiveness and no hazard of having refrigerant piped all over the house. Chiller is used to remove heat from the water which is then circulated through other components to absorb heat from the space.

Cooling tower

In most chiller applications, a water-cooled condenser uses a cooling tower to reduce the temperature of the condenser. The water is then sent to the cooling tower by the use of a pump to be cooled by evaporation of the water in the cooling tower.

Air cooled chiller

A chiller is a machine that removes heat from a liquid via a vaporcompression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. In air conditioning systems, chilled water is typically distributed to heat exchangers, or coils, in air handling units or other types of terminal devices which cool the air in their respective space(s), and then the water is re-circulated back to the chiller to be cooled again.

Advantages of marine air conditioners It is located in the less occupied areas and it requires no pipe lines to connect with the other. This would be the smallest, lightest and the quietest conditioner in the market. This system can be used for any size of the boat and it has made the marine air conditioners more adaptable and easy to install. Marine air conditioners lowers the noise level and it eliminates the zoning of central equipment. It helps in controlling the temperature and to maintain the quality of the air. Works more than other cooling central equipment. Total life cycle of the equipment is favorable more than the central equipment. It costs less than other systems.

Submitted by Niaz v shanavaz

You might also like

- Air Conditioning Plant (BSME 5B)Document128 pagesAir Conditioning Plant (BSME 5B)Marvin ArnaizNo ratings yet

- Co2 Heat Pump SystemsDocument7 pagesCo2 Heat Pump SystemsAmine Yahiaoui100% (1)

- ASHRAE - STD 90.1 - 2007 Energy Standar For BuildingsDocument80 pagesASHRAE - STD 90.1 - 2007 Energy Standar For BuildingsJohn Henry Ramos SantosNo ratings yet

- Ppt:-Fire Fighting SystemDocument29 pagesPpt:-Fire Fighting Systemaimri_cochin92% (25)

- FINAL ThesisDocument143 pagesFINAL ThesisPrince AbanidNo ratings yet

- Top 10 Airports Philippines GuideDocument37 pagesTop 10 Airports Philippines GuideJoyce Cua-BarcelonNo ratings yet

- Military Science 2: The Home of Naval Reservists in The Southen LuzonDocument27 pagesMilitary Science 2: The Home of Naval Reservists in The Southen Luzonmrscode 002100% (1)

- Mapua Institute of Technolog1Document15 pagesMapua Institute of Technolog1Ian KasaiNo ratings yet

- On Air ConditioningDocument26 pagesOn Air ConditioningTej KalyanNo ratings yet

- Air Conditioning SystemDocument12 pagesAir Conditioning SystemShahanajshanu100% (1)

- Sem Vi - Paper ViDocument32 pagesSem Vi - Paper ViankushNo ratings yet

- Airconditioning Feb 2018 Rev 4 Presentation-7Document59 pagesAirconditioning Feb 2018 Rev 4 Presentation-7darius james del mar86% (7)

- Technical Career Institute (Tci) Hvac Interview QuestionsDocument2 pagesTechnical Career Institute (Tci) Hvac Interview QuestionsSYED MUDASSIR NAZARNo ratings yet

- Architectural ModelmakingDocument192 pagesArchitectural ModelmakingvaladiaporiNo ratings yet

- Selection Tips For HVAC SystemsDocument41 pagesSelection Tips For HVAC SystemsImtiaz Ahmed100% (1)

- Long Range Identification and Tracking System: What Is L.R.I.T.?Document10 pagesLong Range Identification and Tracking System: What Is L.R.I.T.?Reetam BoseNo ratings yet

- Introduction Air ConditionersDocument5 pagesIntroduction Air Conditionersbentarigan77No ratings yet

- ECM216 BUILDING SERVICES Bab 2.2 Air ConditioningDocument8 pagesECM216 BUILDING SERVICES Bab 2.2 Air ConditioningAZUAN BIN AHMAD FAUZI100% (3)

- CWTS Module IDocument33 pagesCWTS Module Iellen100% (3)

- Ppt:-Piping SystemDocument35 pagesPpt:-Piping Systemaimri_cochin64% (11)

- Boost Boiler Efficiency with EconomizersDocument5 pagesBoost Boiler Efficiency with Economizersreyalene gallegos100% (1)

- Dectron Indoor Pool Design GuideDocument28 pagesDectron Indoor Pool Design GuideMuhammad Sajid100% (2)

- Merriam-Webster Dictionary Online: 12/09/2021 by Gilbert W Techer 1Document47 pagesMerriam-Webster Dictionary Online: 12/09/2021 by Gilbert W Techer 1Guilbert TecherNo ratings yet

- Ppt:-Sanitary SystemsDocument16 pagesPpt:-Sanitary Systemsaimri_cochin0% (2)

- Script:-Types of ShipyardDocument6 pagesScript:-Types of Shipyardaimri_cochin100% (1)

- Ppt:-Types of ShipyardsDocument20 pagesPpt:-Types of Shipyardsaimri_cochin100% (3)

- Port ProceduresDocument50 pagesPort ProceduresPaul Saquido CapiliNo ratings yet

- Caisson Production On Floating DockDocument19 pagesCaisson Production On Floating DockThet Naung OoNo ratings yet

- Chartering TermsDocument8 pagesChartering Termsaimri_cochinNo ratings yet

- Obe Mar Env MT 2015juneDocument93 pagesObe Mar Env MT 2015juneJohn R. JaromahumNo ratings yet

- 5 Things You Need To Know Before Buying A Marine Air Conditioning SystemDocument16 pages5 Things You Need To Know Before Buying A Marine Air Conditioning SystemiBusinessLogicNo ratings yet

- Agricultural Inoculants Corp. Conversion of Municipal Trash Into Organic FertilizerDocument12 pagesAgricultural Inoculants Corp. Conversion of Municipal Trash Into Organic FertilizerGene GregorioNo ratings yet

- Tropical Design: Introduction To Environmental / Climatic DesignDocument16 pagesTropical Design: Introduction To Environmental / Climatic DesignSprinklesof Love0% (1)

- Sailing Directions 2014Document354 pagesSailing Directions 2014Christmas PeneyraNo ratings yet

- Nautical Publication (Print WEEK 2)Document1 pageNautical Publication (Print WEEK 2)Sspider mannnNo ratings yet

- Ecdis: Electronic Chart Display and Information SystemDocument47 pagesEcdis: Electronic Chart Display and Information SystemRADU DANIEL TEODORU100% (1)

- Competency Assessment of Batangas Marine Protected Area and Bantay Dagat NetworksDocument12 pagesCompetency Assessment of Batangas Marine Protected Area and Bantay Dagat NetworksIOER International Multidisciplinary Research Journal ( IIMRJ)No ratings yet

- Introduction To Global Maritime Distress & Safety System (GMDSS)Document25 pagesIntroduction To Global Maritime Distress & Safety System (GMDSS)navyeyeNo ratings yet

- Definitions: Sailing Directions Are Updated When New Data RequiresDocument12 pagesDefinitions: Sailing Directions Are Updated When New Data Requireskitap kitapNo ratings yet

- Brisbane River Ferry Terminal Rebuild Design CompetitionDocument5 pagesBrisbane River Ferry Terminal Rebuild Design CompetitionEmilia PavelNo ratings yet

- Formerly City College of LucenaDocument3 pagesFormerly City College of LucenaShonnel LagustanNo ratings yet

- Marina Thesis ReportDocument9 pagesMarina Thesis ReportAswanth Allu M JNo ratings yet

- The Data Processing CycleDocument22 pagesThe Data Processing CycleAnum KhursheedNo ratings yet

- What Is The Meaning of Diesel EngineDocument31 pagesWhat Is The Meaning of Diesel EngineaguzkupridNo ratings yet

- Basic Principles of Marine EchoDocument5 pagesBasic Principles of Marine EchoMark Vinson Matira Garcia100% (2)

- Chapter 1-3Document29 pagesChapter 1-3Darryl VelascoNo ratings yet

- 04 Passenger Terminal Facility RequirementsDocument41 pages04 Passenger Terminal Facility RequirementsEllamicha SoqNo ratings yet

- 7 Technologies To Reduce Fuel Consumption of ShipsDocument6 pages7 Technologies To Reduce Fuel Consumption of ShipsAVINASH ANAND RAONo ratings yet

- Operational Use of AISDocument23 pagesOperational Use of AISBerbaño, Jan JoshuaNo ratings yet

- Badminton Court DimensionsDocument3 pagesBadminton Court Dimensionssujan723No ratings yet

- Ship Ship Routine and ConstrutiosDocument9 pagesShip Ship Routine and ConstrutiosJj GonzalesNo ratings yet

- HVAC Systems Guide: Types, Components & How AC WorksDocument3 pagesHVAC Systems Guide: Types, Components & How AC WorksDen Mas DeepNo ratings yet

- Topic:-Applications of Hvac in Industries: Submitted By:-Sandeep Kumar B4802B29 REG - NO 10807893Document6 pagesTopic:-Applications of Hvac in Industries: Submitted By:-Sandeep Kumar B4802B29 REG - NO 10807893shailesh singhNo ratings yet

- Air Conditioning BasicsDocument47 pagesAir Conditioning BasicsVIJUKUMARNo ratings yet

- ENERGY AUDIT AND CONSERVATION: 11 WAYS TO CREATE ENERGY EFFICIENT HOMESDocument39 pagesENERGY AUDIT AND CONSERVATION: 11 WAYS TO CREATE ENERGY EFFICIENT HOMESNmg KumarNo ratings yet

- Oel HvacDocument21 pagesOel HvacFurqan AhmadNo ratings yet

- Cooling Towers Improve HVAC EfficiencyDocument18 pagesCooling Towers Improve HVAC EfficiencyHarjo Wiyono100% (1)

- Air ConditioningDocument5 pagesAir ConditioningDC1234No ratings yet

- Principle of VRFDocument5 pagesPrinciple of VRFghazanfarhayat456No ratings yet

- OJT Outputs: Raphael Justine D. Hismana Bsme 5Document27 pagesOJT Outputs: Raphael Justine D. Hismana Bsme 5Khaster NavarraNo ratings yet

- HuhDocument8 pagesHuhVaishnavi KambleNo ratings yet

- Study On Air-Conditioning and Its ProcessDocument5 pagesStudy On Air-Conditioning and Its Processsdeep1990No ratings yet

- How Do Chillers Work by Nathan SchumacherDocument5 pagesHow Do Chillers Work by Nathan SchumacherNathan SchumacherNo ratings yet

- Building Services - Iii: 3 Year BS - Semester 1Document32 pagesBuilding Services - Iii: 3 Year BS - Semester 1TaanayaNo ratings yet

- Air ConditioningDocument11 pagesAir ConditioningBrilliantJohnMalandacRubiaNo ratings yet

- ChillersDocument7 pagesChillersBRANDONNo ratings yet

- M&E Assignment 3Document12 pagesM&E Assignment 3han0701No ratings yet

- Class-1-HVAC GLOSSARYDocument7 pagesClass-1-HVAC GLOSSARYAmrit BaniyaNo ratings yet

- 4.2 Principles of The CoolingDocument10 pages4.2 Principles of The CoolingAdam AlexNo ratings yet

- Basics of HVAC SystemDocument9 pagesBasics of HVAC SystemDevarya ChhibberNo ratings yet

- Refrigeration and Air ConditioningDocument7 pagesRefrigeration and Air ConditioningManjunatha EikilaNo ratings yet

- 11th FLNG APAC 2013 Brochure - Website - 31julDocument10 pages11th FLNG APAC 2013 Brochure - Website - 31julaimri_cochinNo ratings yet

- Aries Job DiaryDocument2 pagesAries Job Diaryaimri_cochinNo ratings yet

- Script:-4.boats and DavitsDocument8 pagesScript:-4.boats and Davitsaimri_cochinNo ratings yet

- 5 9 ManoeurabilityDocument17 pages5 9 Manoeurabilityaimri_cochinNo ratings yet

- Script - Sea Keeping ScriptDocument15 pagesScript - Sea Keeping Scriptaimri_cochinNo ratings yet

- Question:-Questions On Shipbuilding ProcessDocument4 pagesQuestion:-Questions On Shipbuilding Processaimri_cochinNo ratings yet

- Ppt:-Propellor EmergenceDocument8 pagesPpt:-Propellor Emergenceaimri_cochinNo ratings yet

- 5.10.major Ship Design FeaturesDocument1 page5.10.major Ship Design Featuresaimri_cochinNo ratings yet

- Ppt:-Propellor EmergenceDocument8 pagesPpt:-Propellor Emergenceaimri_cochinNo ratings yet

- Script - Sea Keeping ScriptDocument15 pagesScript - Sea Keeping Scriptaimri_cochinNo ratings yet

- Lesson:-Ship DesignDocument1 pageLesson:-Ship Designaimri_cochinNo ratings yet

- Script:-Design SpiralDocument2 pagesScript:-Design Spiralaimri_cochinNo ratings yet

- Script:-.Ship DesignDocument15 pagesScript:-.Ship Designaimri_cochinNo ratings yet

- Question: ACDocument4 pagesQuestion: ACaimri_cochinNo ratings yet

- Lesson:-Types of ShipyardDocument1 pageLesson:-Types of Shipyardaimri_cochinNo ratings yet

- Questoon:-Fire Fighting System - DocxquestionsDocument3 pagesQuestoon:-Fire Fighting System - Docxquestionsaimri_cochinNo ratings yet

- Question:-Questions On Sanitary SystemsDocument2 pagesQuestion:-Questions On Sanitary Systemsaimri_cochinNo ratings yet

- Question:-Cript Question-Life Saving SystemDocument3 pagesQuestion:-Cript Question-Life Saving Systemaimri_cochinNo ratings yet

- A. Director of An Authorized OrganizationDocument2 pagesA. Director of An Authorized Organizationaimri_cochinNo ratings yet

- Question:-Piping QuestionsDocument4 pagesQuestion:-Piping Questionsaimri_cochinNo ratings yet

- Question:-dECK MCDocument2 pagesQuestion:-dECK MCaimri_cochinNo ratings yet

- Question: CommunicationDocument2 pagesQuestion: Communicationaimri_cochinNo ratings yet

- Question:-Damage CTRLDocument2 pagesQuestion:-Damage CTRLaimri_cochinNo ratings yet

- Ppt:-Electrical SystemDocument16 pagesPpt:-Electrical Systemaimri_cochinNo ratings yet

- Wet & Dry Cooling TowersDocument2 pagesWet & Dry Cooling TowersAbdullah JavedNo ratings yet

- Geothermal - Operation and Maintenance (Closed Loop)Document2 pagesGeothermal - Operation and Maintenance (Closed Loop)starykltNo ratings yet

- Topic 4.1 Psychometry and Air ConditioningDocument76 pagesTopic 4.1 Psychometry and Air ConditioningCARL IJADE PINONo ratings yet

- Penawaran Harga COLDSTORAGEDocument1 pagePenawaran Harga COLDSTORAGEChannel ArifNo ratings yet

- SCV Series Screw CompressorDocument2 pagesSCV Series Screw CompressorCali MelendezNo ratings yet

- Comfosystems Prices 2013 Ventilation and Air DistributionDocument21 pagesComfosystems Prices 2013 Ventilation and Air DistributionWPenrithNo ratings yet

- Ducane Wall Chart 2018Document1 pageDucane Wall Chart 2018elijah elijahNo ratings yet

- 8.0 Ducted Ceiling Mount High Static FHDC-M 80,000-150,000BTUH 23.4-35.2kW 6.7-10TRDocument4 pages8.0 Ducted Ceiling Mount High Static FHDC-M 80,000-150,000BTUH 23.4-35.2kW 6.7-10TRMoeenulHaqueNo ratings yet

- CA MWCP R407C 2011 50Hz PDFDocument16 pagesCA MWCP R407C 2011 50Hz PDFHoàngViệtAnhNo ratings yet

- Estimating Exteranl and Internal Pressure Drop For AHU and FCUDocument6 pagesEstimating Exteranl and Internal Pressure Drop For AHU and FCUfghabboonNo ratings yet

- Calculation and Selection ResultDocument18 pagesCalculation and Selection ResultNery TorresNo ratings yet

- 04 ConvCtrl E 05Document42 pages04 ConvCtrl E 05Meher YoussfiNo ratings yet

- Hvac General Notes Hvac Legend Hvac Legend: (CPD) EDocument4 pagesHvac General Notes Hvac Legend Hvac Legend: (CPD) EF. A AhmedNo ratings yet

- Spare Part Catalogue: Star Cool Refrigeration Unit Model SC - MCI40, SCU and SCIDocument40 pagesSpare Part Catalogue: Star Cool Refrigeration Unit Model SC - MCI40, SCU and SCIJose ManuelNo ratings yet

- 2.3operator Manual of SDLF-80Document27 pages2.3operator Manual of SDLF-80pachara sarntiyakulNo ratings yet

- Premium: Set-Free Fsn2Document14 pagesPremium: Set-Free Fsn2Loe NgNo ratings yet

- # Split AC Components and Their FunctionsDocument8 pages# Split AC Components and Their FunctionsElgaham RossianantoNo ratings yet

- Refrigeration and Air Conditioning 2nd Ed. - W. Stoecker, J. Jones WWDocument440 pagesRefrigeration and Air Conditioning 2nd Ed. - W. Stoecker, J. Jones WWSBW100% (25)

- Catalog Aeoflex-FO R5Document2 pagesCatalog Aeoflex-FO R5Tung LeNo ratings yet

- YVAA0490 - DataSheetSpec. - Rev01pdfDocument2 pagesYVAA0490 - DataSheetSpec. - Rev01pdfMohamed AskarNo ratings yet

- Purge gas process flow diagramDocument4 pagesPurge gas process flow diagramRahmasari Nur SetyonoNo ratings yet

- AM220JXVANHTLDocument4 pagesAM220JXVANHTLaandresleo86No ratings yet

- Centrifugal Liquid ChillerDocument28 pagesCentrifugal Liquid ChillerSiTh LorDNo ratings yet

- How Higher Chilled Water Temperature Can Improve Data Center Cooling System EfficiencyDocument15 pagesHow Higher Chilled Water Temperature Can Improve Data Center Cooling System EfficiencyCarlo Ray SelabaoNo ratings yet

- New Lennox VRF Sales CatalogDocument92 pagesNew Lennox VRF Sales CatalogHENRY80% (5)