Professional Documents

Culture Documents

Dezasamblare Cutie Viteze Lada Niva

Uploaded by

CatalinSSCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dezasamblare Cutie Viteze Lada Niva

Uploaded by

CatalinSSCopyright:

Available Formats

NIVA-FAQ

Gearbox Disassembly

By Volodjushka

NOVELTIES FAQ | THE SITEMAP | SEARCH ON THE SITE

" . " NIVA-FAQ undefined

Its convenient to clamp the gearbox in a vice with the bottom cover facing upwards to perform the disassembly procedure. It is also possible to put it on the bellhousing. Remove the bottom cover: Ten 6mm studs with 10mm wrench nuts. Try to shake the countershaft in longitudinal direction:

If theres any longitudinal movement either the countershaft or its bearings are faulty, due to heavy wear or destruction. This condition could be cause of a loud rumbling gearbox noise. Remove the rear nut and take off the flexible coupling flange. Remove the reverse light switch. Do not lose the copper sealing washer. Shift the gearbox into reverse gear and remove the shifting mechanism assembly from the rear cover (three 6mm studs with 10mm wrench nuts). Be careful to only remove the outer nuts. Also remember the gearbox is turned:

Wipe from oil and examine the shifting mechanism for presence of cracks. Remove the rear cover: Six 8 mm studs with 13mm wrench nuts, remember that one of the nuts is removed from inside the gearbox case:

Tap the rear cover with a rubber mallet to loosen its gasket and pull the cover out with a turn to clear the gear cluster, using only the hands force:

Two outer bearing races must remain in the rear cover casting. If the inner race of the rear main shaft bearing remains in the bearing itself, removal of the rear cover will be impossible. In this case it will be necessary to push the inner race with a screwdriver so it can remain on the shaft. Its not mandatory to remove the bearings from the rear cover. The condition of the bearings and need of their replacement can be defined by inspecting the roller cages. One will be removed later on the text; the other will remain on the gear cluster. If defects call for replacement the main shaft bearing can be removed after removing the rear oil seal. The countershaft rear bearing is removed after taking the black plastic cover out. Remove the bellhousing: Six 10mm studs with 17mm wrench nuts and one 8mm stud with a 13mm wrench nut. Force down the gasket and remove completely by hand:

Wipe and inspect the spring (thrust) washer. It may look intact, but we check it by breaking and twisting:

Start the disassembly of the rear part with the removal of the secondary shaft rear bearing inner race, the spacer bushing and the oil slinger. Remove the shift rail detent cover (two 8mm bolts, 13mm wrench).Take out the three detent springs. The 5th-reverse detent spring is longer than the other two (first from the left in the right picture):

Shift the 5th-reverse gear shift rail into neutral. Insert a piece of soft metal between the countershaft and main shaft gears and turn off the gear cluster bolt with a 17 mm wrench or socket. Insert the soft metal piece on the other side of the gears and turn off the countershaft front bolt with a 19 mm wrench or socket:

Remove the gear cluster and the bearing race ring:

Remove simultaneously the 5th-speed gear, the 5th-reverse gear shift fork and rail and the reverse idler gear:

Inspect the 5th-speed gear. For this purpose remove the locking ring and then remove the synchronizer and its spring:

Push the detent ball of the 5th-reverse shift rail into the shift rail bore and remove it from the rear end of the bore:

Turn off the 3rd-4th gear shift fork with a 10 mm socket:

Turn the 3rd-4th shift rail horizontally so as the small interlock retainer doesnt fall off; and pull the shift rail out a little:

Take the retainer out and pull the shift rail completely out. Remove the fallen interlock retainer through the 3rd-4th shift rail bore:

Remove the 3rd-4th shift rail detent ball. Similarly turn off the 1st-2nd gear shift fork bolt, take out the shift rail, the interlock retainer and detent ball. The gear retaining/locking mechanism: Interlock retainers, detent balls, springs and the cover plate bolts:

Insert the 5th-reverse shift rail in its place and turn off the fork fastening bolt:

Remove the reverse drive gear:

Check that the gear key has no play in the main shaft groove. This play could cause the reverse gear to jump out spontaneously. The main shaft intermediate bearing retainer plate is removed with the aid of an impact screwdriver:

Use a flat screwdriver to push out the countershaft rear bearing from the casing:

Caution! Do not rest the screwdriver against the countershaft gear teeth as they may break. With the help of two flat screwdrivers the countershaft front bearing is removed:

Raise the countershaft a little, move it backwards so the 1st countershaft gear gets through the casing bore and finally incline and raise to remove the countershaft out from the gearbox casing:

Use a cold chisel to force out the front bearing inner race remaining in the countershaft:

Remove the 1st -2nd and 3rd-4th gear shift forks. Pull out the input shaft and remove the bearing lockring:

If the ring is hard to remove, it is possible to loosen it out by striking gently with a chisel to relieve the pressure imposed by the spring washer. The input shaft bearing can be removed in two ways: Using a puller with long paws or striking with a hammer as shown in the left picture. Use pliers to remove the snap ring from the bearing groove:

We check the integrity of the needle bearing plastic cage and the needles themselves for signs of pitting or scoring:

Shaking and displacing back the main shaft, take the intermediate bearing out of the casing:

Move the main shaft backwards, incline and raise it out of the gearbox casing:

Remove the 1st speed gear, the 1st-2nd gear synchronizer sleeve and hub, the 2nd speed gear and the 3rd-4th gear synchronizer sleeve. The 3rd-4th gear hub and the 3rd gear sprocket will remain on the main shaft; they are removed only in case of malfunctions in the 3rd and/or 4th speed gears. For this purpose its necessary to remove the locking and spring washer:

Remove the oil seals if theyre damaged:

Volodjushka, 13.03.03.

You might also like

- 11528918-Ford Tw10 Tw20 Tw30 Workshop ManualDocument111 pages11528918-Ford Tw10 Tw20 Tw30 Workshop Manualmrbazha80% (15)

- K6a WiringDocument198 pagesK6a WiringKelvin Sanchez Bastida79% (14)

- Cadillac 1971-1985 Catalog USA PARTSDocument92 pagesCadillac 1971-1985 Catalog USA PARTSCatalinSS100% (5)

- 2016 Technical Reference Guide Final InteractiveDocument150 pages2016 Technical Reference Guide Final InteractiveDean JohnsonNo ratings yet

- Stihl MS 210 Service ManualDocument74 pagesStihl MS 210 Service ManualDražen KlisurićNo ratings yet

- Kinroad Motor LJ276ML J276MT 2Document30 pagesKinroad Motor LJ276ML J276MT 2api-26422514No ratings yet

- Nissan Frontier Vq40 v6 Despiece MotorDocument210 pagesNissan Frontier Vq40 v6 Despiece Motorerik rojasNo ratings yet

- Machine Design Shaft DesignDocument8 pagesMachine Design Shaft DesignJer LaguitanNo ratings yet

- 5-Cylinder Diesel Engine (AXD AXE BLJ BNZ BPC)Document145 pages5-Cylinder Diesel Engine (AXD AXE BLJ BNZ BPC)TintinPicasoNo ratings yet

- Lifan Owner Manual: - Lifan LF125GY-5 - Lifan LF150GY-5 - Lifan LF200GY-6Document23 pagesLifan Owner Manual: - Lifan LF125GY-5 - Lifan LF150GY-5 - Lifan LF200GY-6Cristian HermanNo ratings yet

- Kisssoft - Calculation of The Gear and Bearing FrequenciesDocument11 pagesKisssoft - Calculation of The Gear and Bearing FrequenciesHüseyin SüzükNo ratings yet

- VW Passat b6 Heating Air Conditioning System EngDocument174 pagesVW Passat b6 Heating Air Conditioning System EngFadel B ChNo ratings yet

- LADA Niva 1700 Part2Document80 pagesLADA Niva 1700 Part2g-simsNo ratings yet

- 5hsdlu, Qvwuxfwlrqv: Downloaded From Manuals Search EngineDocument107 pages5hsdlu, Qvwuxfwlrqv: Downloaded From Manuals Search EngineSantiago CarrilloNo ratings yet

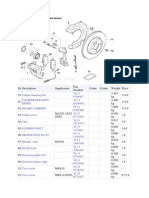

- Rear AxleDocument6 pagesRear AxleThomas A. EDISSONNo ratings yet

- Jeep CJ-2A Willys Operation and Care ManualDocument40 pagesJeep CJ-2A Willys Operation and Care ManualOsman Rešidović100% (2)

- Timing Belt Mazda Millenia S 2002Document5 pagesTiming Belt Mazda Millenia S 2002Carlos MendozaNo ratings yet

- Hand Operated Can CrusherDocument60 pagesHand Operated Can CrusherParen Trivedi100% (2)

- Catálogo de Repuestos Originales Suzuki Ignis 2000 - 2005Document270 pagesCatálogo de Repuestos Originales Suzuki Ignis 2000 - 2005Gabriel Avilez GonzalezNo ratings yet

- Puch Korado Owners ManualDocument32 pagesPuch Korado Owners Manualrdf12345100% (3)

- Engine 250 10 006 PDFDocument24 pagesEngine 250 10 006 PDFPrashanthKumarNo ratings yet

- Sensors and Senders in SkodaDocument48 pagesSensors and Senders in SkodaAntónio FernandesNo ratings yet

- Massey Ferguson Tractor Service Manual MH S mf25 130 PDFDocument11 pagesMassey Ferguson Tractor Service Manual MH S mf25 130 PDFNikos MakrisNo ratings yet

- 2 Gear LinkageGolf Mk1Document46 pages2 Gear LinkageGolf Mk1SteggosNo ratings yet

- b6 70 PDFDocument81 pagesb6 70 PDFVlad ZahiuNo ratings yet

- VOLVO EC460B LR EC460BLR EXCAVATOR Service Repair Manual PDFDocument17 pagesVOLVO EC460B LR EC460BLR EXCAVATOR Service Repair Manual PDFfjjsjekdmmeNo ratings yet

- Haendle Extrution UnitsDocument0 pagesHaendle Extrution UnitsMohan ShanmugamNo ratings yet

- 1600 Lada UserDocument38 pages1600 Lada UserLucian Leonte100% (1)

- M 9 R Training ManualDocument4 pagesM 9 R Training ManualMihaela GeorgescuNo ratings yet

- 1.4 Golf Fluctuating Idle and Poor StartingDocument23 pages1.4 Golf Fluctuating Idle and Poor StartingEngine Tuning UPNo ratings yet

- ML 1660 Parts CatalogDocument22 pagesML 1660 Parts Catalogegel2458100% (1)

- Mounting & ProofingDocument55 pagesMounting & ProofingSudhakar Joshi100% (1)

- Satelis Service Manual Body Panels PDFDocument83 pagesSatelis Service Manual Body Panels PDFdemoracingeduNo ratings yet

- ReparatiiHonda GX200Document164 pagesReparatiiHonda GX200Valentin IonitzaNo ratings yet

- Lada Niva LiftDocument26 pagesLada Niva LiftFelipe EffeNo ratings yet

- BlueberryDocument50 pagesBlueberryruderboskovic555No ratings yet

- IJ IZH Planeta 5 Manuale de Reparatie WWW - ManualedereparatieDocument60 pagesIJ IZH Planeta 5 Manuale de Reparatie WWW - ManualedereparatieLiviu100% (3)

- Demontare Cutie Viteze NivaDocument10 pagesDemontare Cutie Viteze NivaCatalinSSNo ratings yet

- Lada Niva Dakar Preparation Part2Document16 pagesLada Niva Dakar Preparation Part2Claudio MoranteNo ratings yet

- Lada Niva GEARBOX AssemblyDocument17 pagesLada Niva GEARBOX Assemblyektoras49No ratings yet

- Diagnose Timing Chain Fault: How To Diagnose A Timing Chain Fault in The YD25 D40, D22 Navara & R51 Pathfinder EngineDocument4 pagesDiagnose Timing Chain Fault: How To Diagnose A Timing Chain Fault in The YD25 D40, D22 Navara & R51 Pathfinder EngineJuan VarelaNo ratings yet

- SuzukiDocument5 pagesSuzukiRaka AjaNo ratings yet

- Lada Niva Alignment DataDocument1 pageLada Niva Alignment DataEric WolfNo ratings yet

- Weber DMTR DATR DATRA TuningDocument2 pagesWeber DMTR DATR DATRA TuningmaxNo ratings yet

- 5060 ExtremeDocument52 pages5060 ExtremeSaharaMCNo ratings yet

- CJZC Engine Cylinder HeadDocument51 pagesCJZC Engine Cylinder HeadDaniel100% (1)

- Stihl MS 441 IPL PDFDocument34 pagesStihl MS 441 IPL PDFAnonymous PiS1vmij0% (1)

- Madass Parts ManualDocument59 pagesMadass Parts ManualDario Gabriel Coz RojasNo ratings yet

- Suzuki LianaDocument23 pagesSuzuki Lianawebscanz100% (2)

- Correa de Distribución 1.4 - Tdci Ford FiestaDocument9 pagesCorrea de Distribución 1.4 - Tdci Ford FiestaFrancisco José MarotoNo ratings yet

- RIM Application For OE Replace-20141226Document6 pagesRIM Application For OE Replace-20141226mohawxz357No ratings yet

- Uputstvo - Sprint ExactlyDocument24 pagesUputstvo - Sprint ExactlyvladomiljNo ratings yet

- Lancia Scorpion Tecnhnical TipsDocument11 pagesLancia Scorpion Tecnhnical Tipsphantom fiatNo ratings yet

- Honda 70 Dax Parts Catalog WiringDocument135 pagesHonda 70 Dax Parts Catalog WiringHugo Ponce100% (1)

- Mini R50 Break Parts ManualDocument32 pagesMini R50 Break Parts Manualdaz7691100% (1)

- Piaggio Mp3 400 I.E Service Station Manual-8Document20 pagesPiaggio Mp3 400 I.E Service Station Manual-8H. KeithNo ratings yet

- Niva D SuspensionDocument14 pagesNiva D SuspensionSamsonNo ratings yet

- SM - Kymco Vitality 50 - Chapter 11 (Crankcase - Crankshaft)Document14 pagesSM - Kymco Vitality 50 - Chapter 11 (Crankcase - Crankshaft)jose sousa oliveiraNo ratings yet

- Pg1 and Pg2 GearboxDocument48 pagesPg1 and Pg2 GearboxYarg NitramNo ratings yet

- Mazda bt50 Workshop Manual570Document1 pageMazda bt50 Workshop Manual570Alejandro Muñoz Patiño0% (2)

- F500 ManualDocument128 pagesF500 ManualBruno Pilieci100% (1)

- 1954 M72 Manual English TransDocument71 pages1954 M72 Manual English Transgwinn23No ratings yet

- 90-94 Passat Engine Lubrication SystemDocument15 pages90-94 Passat Engine Lubrication SystemAales WeldingNo ratings yet

- Constant Mesh Gear BoxDocument10 pagesConstant Mesh Gear BoxSummer Nelson0% (1)

- J160 6th Gear ReplacementDocument6 pagesJ160 6th Gear ReplacementdensasNo ratings yet

- M5 R2 DisassemblyDocument18 pagesM5 R2 DisassemblyRussell ReedNo ratings yet

- DIY For Rebuilding An S2000 Transmission by Ronnuke of S2ki - Com (7.30.13)Document38 pagesDIY For Rebuilding An S2000 Transmission by Ronnuke of S2ki - Com (7.30.13)Bruce BruceNo ratings yet

- A8 TimingbeltreplacementDocument21 pagesA8 TimingbeltreplacementIvo Miguel Almeida CardosoNo ratings yet

- The Novak Guide To Dana 20Document9 pagesThe Novak Guide To Dana 20Hunter HincksNo ratings yet

- Range Rover Manual Suspension PDFDocument14 pagesRange Rover Manual Suspension PDFsleepyninjitsuNo ratings yet

- Cranberry ProPagationDocument4 pagesCranberry ProPagationCatalinSSNo ratings yet

- c6386b4a-b94c-4d39-ae80-be2c9e8b66cdDocument36 pagesc6386b4a-b94c-4d39-ae80-be2c9e8b66cdEnnyFernandoNo ratings yet

- Mechanics of MachinesDocument8 pagesMechanics of MachinesVikram RaoNo ratings yet

- Optimizing Powered Haulage Investment in Surface Coal ApplicationsDocument17 pagesOptimizing Powered Haulage Investment in Surface Coal ApplicationsanilshardaNo ratings yet

- Orkshop Engine Manual: Mvagusta Brutale 910 SDocument112 pagesOrkshop Engine Manual: Mvagusta Brutale 910 SRicardo XlvNo ratings yet

- Unit I&II Gear DesignDocument130 pagesUnit I&II Gear DesignVishal JaiswalNo ratings yet

- Jimma Institute of Technology Faculty of Mechanical EngineeringDocument38 pagesJimma Institute of Technology Faculty of Mechanical EngineeringIsmail Ibn BehailuNo ratings yet

- Section E - Hydraulics Pressure Reducing Solenoid Valve (To Serial No. 752462)Document34 pagesSection E - Hydraulics Pressure Reducing Solenoid Valve (To Serial No. 752462)Marcelo Elói De Amorim SilvaNo ratings yet

- 4-181030-Practice Drawing Involute Gear Using MathematicaDocument15 pages4-181030-Practice Drawing Involute Gear Using MathematicaPradita FirmansyahNo ratings yet

- Ais Kacang Ceraian ContohDocument5 pagesAis Kacang Ceraian Contohhisham1983No ratings yet

- Atlas Copco Air Motors UKDocument47 pagesAtlas Copco Air Motors UKsanvae123No ratings yet

- Red CoronaDocument78 pagesRed CoronaWalther Ernesto Molina DominguezNo ratings yet

- ME LAB MANUAL RevisedDocument64 pagesME LAB MANUAL RevisedClint Baring ArranchadoNo ratings yet

- Philippine Agricultural Engineering Standard Paes 308: 2001 Engineering Materials - Straight Bevel Gears For Agricultural Machines - Specifications and ApplicationsDocument13 pagesPhilippine Agricultural Engineering Standard Paes 308: 2001 Engineering Materials - Straight Bevel Gears For Agricultural Machines - Specifications and ApplicationsRachel AustriaNo ratings yet

- Strip Cladding SolutionDocument12 pagesStrip Cladding SolutionKoshy JohnNo ratings yet

- Pulsar 200 NS - MANUAL DE PARTESDocument77 pagesPulsar 200 NS - MANUAL DE PARTESLorenaHernandezNo ratings yet

- Gearbox - Dongfeng - Datong 12 Speeds - Dc12J150T: CEI High Fidelity Spare Parts E-Catalogue - Catalogue Table PrintDocument4 pagesGearbox - Dongfeng - Datong 12 Speeds - Dc12J150T: CEI High Fidelity Spare Parts E-Catalogue - Catalogue Table PrintzamyadNo ratings yet

- Spur Gears: Catalog Number of KHK Stock GearsDocument134 pagesSpur Gears: Catalog Number of KHK Stock GearsaditNo ratings yet

- Everest BrochureDocument2 pagesEverest BrochurelongcyNo ratings yet

- Arb 4x4 Accessories 1 Arb Product Catalogue 2015 PDFDocument188 pagesArb 4x4 Accessories 1 Arb Product Catalogue 2015 PDFMeigallomanNo ratings yet

- DISD SD300 - SD200 Wheel Loader Technical SpecificationDocument10 pagesDISD SD300 - SD200 Wheel Loader Technical SpecificationIslam ShoukryNo ratings yet

- Simogear Motor Reduktori Katalog Na Engleskom PDFDocument660 pagesSimogear Motor Reduktori Katalog Na Engleskom PDFBegicHalid0% (1)