Professional Documents

Culture Documents

Lampiran Servis & Penyelenggaran Motorsikal Tahap 2

Uploaded by

En BongOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lampiran Servis & Penyelenggaran Motorsikal Tahap 2

Uploaded by

En BongCopyright:

Available Formats

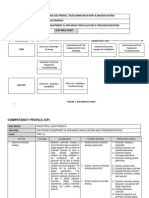

`JOB PROFILE CHART (JPC)

SECTOR SUB SECTOR JOB AREA JOB LEVEL TRANSPORTATION AUTOMOTIVE MAINTENANCE MOTOCYCLE SERVICING TWO (2) JOB AREA CODE

COMPETENCY Hydraulic brake system overhaul Cooling system maintenance

COMPETENCY UNIT Multiple carburettor servicing Multi cylinder top overhaul

CORE

Multiple cylinder engine overhaul

Suspension system overhaul (Up set down)

Tyre and wheel inspection

Electrical and electronic system troubleshooting and maintenance

COMPETENCY PROFILE (CP)

Sub Sector Job Area Level CU Title 1. Hydraulic Brake system Overhaul

AUTOMOTIVE MAINTENANCE MOTOCYCLE SERVICING

TWO (2) CU Code CU Descriptor

Hydraulic brake system overhaul competency is a set of skills to carry out hydraulic brake system overhaul that includes knowledge about various types of brake calliper overhaul, brake master pump overhaul, anti-lock brake system and troubleshoot brake system. The person whom is competent in hydraulic brake system overhaul works must be able to prepare hydraulic brake system overhaul requirement, perform brake system overhaul, perform troubleshoot brake system and record hydraulic brake system overhaul activities according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP) 1.

CU Work Activities

Prepare hydraulic brake system overhaul requirement

Performance Criteria

1.1 Manufacturers hydraulic brake system overhaul manual interpreted 1.2 Hydraulic brake system overhaul tools and equipment selected correctly 2.1 Types of troubleshoot brake system determined according to specification 2.2 Troubleshooting on brake system carried out according to procedure 3.1 Types of brake caliper components determined 3.2 Overhaul braked caliper according to procedure 3.3 Faulty brake caliper component replaced according to manufacturers manual 4.1 Types of brake master pump component determined according to requirement

2.

Perform brake system troubleshooting activities

3.

Perform brake calliper overhaul

4.

Perform brake master pump overhaul

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

4.2 Overhaul braked master pump according to procedure

5.

Perform hydraulic brake system functionality check

5.1 Test ride carried out on serviced motorcycle 5.2 Hydraulic brake system performance checked according to manufacturers specification 6.1 Servicing activities recorded according to correct format 6.2 Report submitted according to procedure 1.1 Manufacturers hydraulic brake system overhaul manual interpreted 1.2 Hydraulic brake system overhaul tools and equipment selected 2.1 Types of troubleshoot cooling system determined 2.2 Cooling system servicing troubleshoot according to procedure 2.3 Cooling system component troubleshoot according to manufacturers manual 3.1 Types of component for radiator determined 3.2 Types of component for radiator determined 3.3 Radiator Cleaned according to procedure 3.4 Faulty component on radiator

6.

Record hydraulic brake system overhaul

2.

Cooling system Maintenance

Cooling system maintenance competency is a set of skills to carry out cooling system maintenance that includes knowledge about various types of troubleshoot cooling, cooling system component, cooling system servicing and component for radiator. The person whom is competent in cooling system maintenance works must be able to prepare cooling system servicing requirement, perform cooling system troubleshooting, perform radiator servicing and record cooling system servicing activities according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP)

1.

Prepare cooling system servicing requirement

2.

Perform cooling system troubleshooting

3.

Perform radiator servicing

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

system Clean radiator replaced according to procedure 3.5 Component replaced faulty on radiator system

4.

Record cooling system servicing activities

4.1 Servicing activities recorded according to correct format 4.2 Report submitted according to procedure 1.1 Manufacturers single cylinder engine overhaul manual interpreted 1.2 Single cylinder engine overhaul tools and equipment selected 2.1 Types of troubleshoot fuel system determined 2.2 Fuel system troubleshoot according to procedure 2.3 Fuel system component troubleshoot according to manufacturers manual 3.1 Types of multiple carburetor components determined 3.2 Multiple carburetors component cleaned according to procedure 3.3 Replaced multiple carburetor faulty component replaced according to manufacturers manual 4.1 Procedure to carry out multiple carburetor synchronization determined

3.

Multiple Carburettor Servicing

Multiple carburettor servicing competency is a set of skills to carry out multiple carburettor servicing that includes knowledge about various types of troubleshoot fuel system, fuel system component and fuel system component. The person whom is competent in multiple carburettor servicing works must be able to prepare multiple carburettor servicing requirement, perform troubleshoot fuel system, perform multiple carburettor overhaul, perform multiple carburettor synchronisation, perform multiple carburettor operation performance check and record multiple carburettor servicing according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP)

1.

Prepare multiple carburettor servicing requirement

2.

Perform troubleshoot fuel system

3.

Perform multiple carburettor overhaul

4. 4

Perform multiple carburettor synchronisation

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

4.2 Synchronization multiple carburetor according to procedure 5.1 Test ride carried out on serviced motorcycle 5.2 Single carburetor operation performance checked according to manufacturers specification 6.1 Servicing activities recorded according to correct format 6.2 Report submitted according to procedure 1.1 Manufacturers Record multiple cylinder top overhaul manual interpreted 1.2 Multiple cylinder top overhaul tools and equipment selected 2.1 Types of service multiple cylinder head determined 2.2 Cylinder head component dismantling and installation carried out 2.3 Cylinder head component cleaning carried out 2.4 Faulty parts on cylinder head component replaced according to manufacturers manual 3.1 Types of service multiple cylinder block determined

5.

Perform multiple carburettor operation functionality check

6.

Record multiple carburettor servicing

4.

Multi Cylinder Top Overhaul

Multi cylinder top overhaul competency is a set of skills to carry out multi cylinder top overhaul that includes knowledge about various types of service multiple cylinder head, cylinder head component, cylinder head cleaning and faulty parts on cylinder head component. The person whom is competent in multi cylinder top overhaul works must be able to prepare multiple cylinder top overhaul requirement, perform multiple cylinder head servicing, perform multiple cylinder block servicing, perform multiple engine compression inspection, perform multiple timing chain/belt servicing, perform multiple cylinder performance check and record multiple cylinder top overhaul according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and

1.

Prepare multiple cylinder top overhaul requirement

2.

Perform multiple cylinder head servicing

3.

Perform multiple cylinder block servicing

CU Title

CU Code

CU Descriptor

Standard Operating Procedures (SOP)

CU Work Activities

Performance Criteria

3.2 Multiple cylinder block components cleaning carried out according to procedure 3.3 Bore for scratch checked 3.4 Multiple cylinder block re-bore carried out

4.

Perform multiple engine compression inspection

4.1 Types of check multiple engine compression determined 4.2 Multiple engine compression checked according to procedure and manufacturers manual 4.3 Leakage on multiple cylinder head checked 5.1 Types of service multiple timing chain / belt determined 5.2 Multiple timing chain / belt serviced according to procedure 5.3 Multiple timing chain / belt component replaced according to manufacturers manual 6.1 Supervisor that motorcycle ready for test ride informed 6.2 Test ride on serviced motorcycle carried out 6.3 Multiple cylinder performance checked according to manufacturers specification 7.1 Servicing activities recorded according to correct format 7.2 Report submitted according to

5.

Perform multiple cylinder timing chain/belt servicing

6.

Perform multiple cylinder top overhaul functionality check

7.

Record multiple cylinder top overhaul

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

procedure

5.

Multi Cylinder Engine overhaul

Multi cylinder engine overhaul competency is a set of skills to carry out multi cylinder engine overhaul that includes knowledge about various types of clutch servicing, oil pan and oil pump servicing, crankcase servicing and transmission servicing. The person whom is competent in multi cylinder engine overhaul works must be able to perform multiple cylinder engine overhaul requirement, perform clutch servicing, perform shift shaft servicing, perform oil pan and oil pump servicing, perform crankcase servicing and transmission servicing according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP)

1.

Prepare multiple cylinder engine overhaul requirement

1.1 Manufacturers single cylinder engine overhaul manual

interpreted

1.2 Single cylinder engine overhaul

tools and equipment Selected 2. Perform clutch servicing 2.1 Types of clutch servicing determined 2.2 Tools and equipment used for clutch servicing selected 2.3 Servicing Clutched according to procedure 2.4 Servicing component clutched according to manufacturers manual 3.1 Meeting notice and agenda prepared 3.2 Unit of meeting conducted 4.1 Types of oil pan and oil pump servicing determined 4.2 Oiled pan and oiled pump servicing according to procedure 4.3 Oiled pan and oiled pump servicing according to manufacturers manual 5.1 Types of crankcase servicing determined 5.2 Servicing crank cased according to procedure

3.

Perform shift shaft servicing

4.

Perform oil pan and oil pump servicing

5.

Perform crankcase servicing

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

5.3 Servicing crank cased according to manufacturers manual

6.

Perform transmission servicing

6.1 Types of transmission servicing determined 6.2 Servicing trans missed according to procedure 6.3 Servicing trans missed according to manufacturers manual 1.1 Manufacturers suspension system overhaul manual interpreted 1.2 Suspension system overhaul tools and equipment selected 2.1 Types of fork cartridge overhaul determined 2.2 Fork cartridge component dismantled according to procedure 2.3 Fork cartridge component cleaned 2.4 Faulty parts on fork cartridge replaced 2.5 Fork cartridge component according to manufacturers manual installed 3.1 Types of rear suspension overhaul determined 3.2 Rear suspension component Dismantled according to procedure 3.3 Rear suspension component cleaned 3.4 Replace faulty parts on rear suspension 3.5 Refill suspension fluid on rear

Suspension System Overhaul (Up set down)

Suspension system overhaul (up set down) competency is a set of skills to carry out suspension system overhaul that includes knowledge about various types of fork cartridge overhaul, fork cartridge component, rear suspension overhaul and suspension tune up. The person whom is competent in suspension system overhaul works must be able to prepare suspension system overhaul requirement, perform fork cartridge overhaul, perform rear suspension overhaul, suspension tune up, suspension system performance check and record suspension system overhaul activities according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP)

1.

Prepare suspension system overhaul requirement

2.

Perform fork cartridge overhaul

3.

Perform rear suspension overhaul

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

suspension 3.6 Install rear suspension component according to manufacturers manual

4.

Perform suspension tune up

4.1 Types of suspension tune up determined 4.2 Tune up suspension according to procedure and manufacturers manual 5.1 Supervisor that motorcycle ready for test ride informed 5.2 Test ride on serviced motorcycle carried out 5.3 Suspension system performance checked according to manufacturers specification 6.1 Servicing activities recorded according to correct format 6.2 Report submitted according to procedure 1.1 Manufacturers performance tyre and wheel servicing manual interpreted 1.2 Performance tyre and wheel servicing tools and equipment Selected 2.1 Procedure to carry out test free wheel rotation determined 2.2 Free wheel tested rotation according to procedure and manufacturers manual

5.

Perform suspension system functionality check

6.

Record suspension system overhaul activities Prepare performance tyre and wheel servicing requirement

Performance Tyre And Wheel Servicing

Performance tyre and wheel servicing competency is a set of skills to carry out performance tyre and wheel servicing that includes knowledge about various types of service front and rear wheel bearing, service tube type performance, tyre thread depth, service tubeless performance tyre, wheel spokes components and cast wheel pattern. The person whom is competent in performance tyre and wheel servicing works must be able to prepare performance tyre and wheel servicing requirement, perform

1.

2.

Perform test free wheel rotation

CU Title

CU Code

CU Descriptor

test free wheel rotation, perform front and rear wheel bearing servicing, perform tube type performance tyres servicing, tubeless performance tyre servicing, perform tubeless performance tyre servicing, perform wheel spokes servicing, perform cast wheel servicing, perform performance tyre and wheel servicing performance check and record performance tyre and wheel servicing according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP)

CU Work Activities

Performance Criteria

2.3 Types of defect on performance tyre and wheel determined

3.

Perform front and rear wheel bearing servicing

3.1 Types of service front and rear wheel bearing Determined 3.2 Front and rear wheel bearing serviced according to procedure 3.3 Front and rear wheel bearing component serviced according to manufacturers manual 4.1 Types of service tube type performance tyres determined 4.2 Performance tyre thread depth checked 4.3 Tube type performance tyre replaced according to manufacturers manual 4.4 Performance tyres tube Replaced according to manufacturers 5.1 Types of service tubeless performance tyre determined 5.2 Tubeless performance tyre Patched according to procedure 5.3 Tubeless performance tyre thread depth checked 5.4 Tubeless performance tyre replaced according to manufacturers manual 5.5 Tubeless performance tyre component checked according to manufacturers manual

4.

Perform tube type performance tyres servicing

5.

Perform tubeless performance tyre servicing

10

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

6.

Perform wheel spokes servicing

6.1 Types of wheel spokes components determined 6.2 Tools and equipment used for servicing wheel spokes prepared 6.3 Wheel spokes according to procedure and manufacturers manual replaced 7.1 Types of cast wheel pattern 7.2 Tools and determined equipment used for servicing cast wheel prepared 7.3 Cast wheel according to procedure and manufacturers manual replaced 8.1 Tools and equipment used for performance tyre and wheel balancing prepared 8.2 Performance tyre balancing machine according to operation manual operated 8.3 Performance tyre and wheel balancing according to procedure and manufacturers manual carried 9.1 Supervisor that motorcycle ready for test drive informed 9.2 Test drive on serviced motorcycle carried out 9.3 Performance tyre and wheel performance checked according to

7.

Perform cast wheel servicing

8.

Perform performance tyre and wheel balancing

9.

Perform performance tyre and wheel servicing performance check

11

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

manufacturers specification

10. Record performance tyre and wheel servicing

10.1Servicing activities recorded according to correct format 10.2Report submitted according to procedure 1.1 Manufacturers electrical and electronic system troubleshooting manual Interpreted 1.2 Electrical and electronic system troubleshooting tools and equipment Selected 2.1 Types of starting system components determined 2.2 Starting system checked according to procedure 2.3 Faulty parts on starting system according to manufacturers manual Replaced 2.4 Starting system functionality checked 3.1 Types of starter motor components determined 3.2 Starter motor faulty according to procedure checked 3.3 Faulty on starter motor component according to manufacturers manual rectified 3.4 Starter motor functionality checked

Electrical and electronic system troubleshooting and maintenance

Electrical and electronic system troubleshooting and maintenance competency is a set of skills to carry out electrical and electronic system troubleshooting and maintenance that includes knowledge about various types of starting system components, faulty parts on starting system, starter motor components, charging system components, ignition system components and motorcycle electrical wiring. The person whom is competent in electrical and electronic system troubleshooting and maintenance works must be able to prepare electrical and electronic system troubleshooting requirement, perform starting system servicing, perform service starter motor, perform charging system inspection, perform ignition system servicing, perform motorcycle electrical wiring and record schedule maintenance activities according to manufacturers specification, regulation requirement, vehicle specification, safety requirement and Standard Operating Procedures (SOP)

1.

Prepare electrical and electronic system troubleshooting requirement

2.

Perform starting system servicing

3.

Perform starter motor servicing

12

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

4.

Perform charging system inspection

4.1 Types of charging system components determined 4.2 Charging system faulty checked according to procedure 4.3 Charging system faulty component rectified according to manufacturers manual 4.4 Charging system functionality checked 5.1 Types of check ignition system components determined 5.2 Faulty of ignition system checked according to procedure 5.3 Ignition system component rectified according to manufacturers manual 5.4 Ignition system functionality checked 6.1 Procedure to carry out wiring determined 6.2 Wiring carried out according to procedure and manufacturers manual 6.3 Electrical and electronic system functionality checked 7.1 Servicing activities recorded according to correct format 7.2 Report submitted according to

5.

Perform ignition system servicing

6.

Perform motorcycle electrical wiring

7.

Record schedule maintenance activities

13

CU Title

CU Code

CU Descriptor

CU Work Activities

Performance Criteria

procedure

14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Grey Nomads Guide To AustraliaDocument3 pagesThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Competency Profile Ee Level 2Document11 pagesCompetency Profile Ee Level 2En BongNo ratings yet

- Job Profile Chart & Competency UnitDocument13 pagesJob Profile Chart & Competency UnitEn BongNo ratings yet

- Lampiran Servis & Penyelenggaran Motorsikal Tahap 2Document14 pagesLampiran Servis & Penyelenggaran Motorsikal Tahap 2En BongNo ratings yet

- Competency Profile Ee Level 2Document11 pagesCompetency Profile Ee Level 2En BongNo ratings yet

- Job Profile Chart & Competency UnitDocument13 pagesJob Profile Chart & Competency UnitEn BongNo ratings yet

- Stavanger Tourist SpotDocument96 pagesStavanger Tourist Spotregupathi6413No ratings yet

- MPC-006 DDocument14 pagesMPC-006 DRIYA SINGHNo ratings yet

- Sony HCD-GTX999 PDFDocument86 pagesSony HCD-GTX999 PDFMarcosAlves100% (1)

- Finals-Insurance Week 5Document19 pagesFinals-Insurance Week 5Ryan ChristianNo ratings yet

- My Medications ListDocument5 pagesMy Medications Listhussain077No ratings yet

- Hot Tub BrochureDocument124 pagesHot Tub BrochureMai Tuan AnhNo ratings yet

- Palm Wine SpecificationDocument10 pagesPalm Wine SpecificationUday ChaudhariNo ratings yet

- Revised fire drill performance standardsDocument47 pagesRevised fire drill performance standardsKartikeya GuptaNo ratings yet

- Mycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Document10 pagesMycbseguide: Cbse Class 10 Social Science Sample Paper - 08 (MCQ Based)Abdul MuqsitNo ratings yet

- Vincent Hoa's English 101 PortfolioDocument24 pagesVincent Hoa's English 101 PortfoliovincentNo ratings yet

- Standardization Parameters For Production of Tofu Using WSD-Y-1 MachineDocument6 pagesStandardization Parameters For Production of Tofu Using WSD-Y-1 MachineAdjengIkaWulandariNo ratings yet

- Plow Moldboard or Disc PlowDocument7 pagesPlow Moldboard or Disc PlowAdewaleNo ratings yet

- LOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorDocument1 pageLOGARITHMS, Exponentials & Logarithms From A-Level Maths TutorHorizon 99No ratings yet

- Is Revalida ExamDocument11 pagesIs Revalida ExamRodriguez, Jhe-ann M.No ratings yet

- Digestion Unit 1 QDocument15 pagesDigestion Unit 1 QKajana Sivarasa ShenthanNo ratings yet

- DGPS Sensor JLR-4331W Instruction ManualDocument42 pagesDGPS Sensor JLR-4331W Instruction ManualantonioNo ratings yet

- المحاضرة الرابعة المقرر انظمة اتصالات 2Document31 pagesالمحاضرة الرابعة المقرر انظمة اتصالات 2ibrahimNo ratings yet

- Dimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutDocument11 pagesDimensional Analysis Similarity Lesson2 Dimensional Parameters HandoutRizqi RamadhanNo ratings yet

- Company Profile 2Document7 pagesCompany Profile 2R Saravana KumarNo ratings yet

- Grade 11 Holiday Homework Part 1Document7 pagesGrade 11 Holiday Homework Part 1Jashfa SaboorNo ratings yet

- Bajaj Auto Company NewDocument94 pagesBajaj Auto Company Newbhas_786No ratings yet

- GMsetDocument8 pagesGMsetdilo001No ratings yet

- Daftar Harga Airway PT. Surgika 2017Document16 pagesDaftar Harga Airway PT. Surgika 2017Syaofi SofiNo ratings yet

- Solid Waste ManagementDocument26 pagesSolid Waste ManagementPamela MendozaNo ratings yet

- Shanidham - In-Shanidham Pacify Lord ShaniDocument3 pagesShanidham - In-Shanidham Pacify Lord ShanisubramanyaNo ratings yet

- EiaDocument14 pagesEiaRamir FamorcanNo ratings yet

- Desiderata: by Max EhrmannDocument6 pagesDesiderata: by Max EhrmannTanay AshwathNo ratings yet

- DCI-2 Brief Spec-Rev01Document1 pageDCI-2 Brief Spec-Rev01jack allenNo ratings yet

- Exercise Stress TestingDocument54 pagesExercise Stress TestingSaranya R S100% (2)