Professional Documents

Culture Documents

Air Compressor Spec

Uploaded by

yoi_123Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Compressor Spec

Uploaded by

yoi_123Copyright:

Available Formats

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

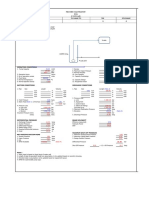

Air Compressor Specification

TABLE OF CONTENTS

1.0 2.0 3.0 PURPOSE .. CODES, STANDARDS, AND SPECIFICATIONS . DESIGN 3.1 Air Compressor . 3.1.1 Compressor Air Intake Filters and Silencer. 3.1.2 Inter/After Coolers. 3.1.3 Drivers. 3.1.4 Reduction Gears and Belt Drives 3.1.5 Coupling and Guards Air Dryer . 3.2.1 3.2.2 3.2.3 3.3 Dryer Adsorbed Towers .. Dryer Pre-filter/After Filter Dryer Inter/After Coolers.. 4 4 5 5 5 5 5 6 6 7 7 7 8 8

3.2

Instrumentation and Controls .. 3.3.1 3.3.2 3.3.3

Interface . 9 Compressor Control/Sequencing System. 10 Air Dryer Controls . 10

3.4 3.5 3.6 3.7 3.8 3.9 4.0 5.0 6.0 7.0

Skid.. 11 Balancing and Vibration 11 Piping .. 11 Painting 12 Insulation and Cladding 12 Noise 12

MATERIAL .. 12 MANUFACTURING 12 INSPECTION AND TESTING 12 PREPARATION FOR SHIPMENT 13

Page 3 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

AIR COMPRESSOR SPECIFICATION

1.0 PURPOSE The purpose of this specification is to define the minimum technical requirement for the design, supply, manufacture, and testing of a skid mounted air compressor / dryer package for MULTI PURPOSE REACTOR PLANT PROJECT at Batam Indonesia. 2.0 CODES, STANDARDS AND SPECIFICATIONS The current version, complete with the latest amendments of the following laws, statutory regulations, codes, standards and specifications shall from part of and shall be read in conjunction with this specification. Indonesian Law Statutory Regulations American Society of Mechanical Engineers (ASME) ASME Section II Section V Section VIII, Div 1 Section IX ASME B1.20.1 ASME B16.11 ASME B19.1 ASME B16.5 ASME B31.3 ASME B36.10 AWS D 1.1 Boiler and Pressure Vessel Code Materials Non Destructive Examination Pressure Vessel Welding and Brazing Qualification Pipe Threads Forged Steel Fittings Socket Welding and Threaded Safety Standard for Air Compressor System Pipe Flanges and Flanged Fittings Process Piping Welded and Seamless Wrought steel Pipe Structural Welding Code

National Fire Protection Association (NFPA) NFPA 70 National Electrical Code 70, Article 500 Hazardous Location

American Petroleum Institute (API) API RP 520 Part I/II Sizing and Installation of Pressure Relieving device in Refineries

Page 4 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

API RP 550 API 619

Installation of Refinery Instrument & Control System Rotary Type Positive Displacement Compressors for Petroleum, Chemical and Gas Industry Services

NEC / NEMA National Electrical Code / National Electrical Manufacturers Association

3.0 DESIGN The air compressor / dryer package shall be designed and constructed for both a minimum service life of 20 years and at least one year uninterruptible continuous service. No proto-type equipment or equipment with less than three (3) years of proven experience shall be used. 3.1 Air Compressor The air compressor shall be twin screw non-lubricated type. All deviations to API 619 shall be stated. The capacity control of the compressor shall steeples. The turndown shall be to at least 20% of the rated capacity. The capacity control requirements shall be as nominated on the compressor data sheet. 3.1.1 Compressor Air Intake Filters and Silencer The air compressor intake shall have a dry type air filter with provision for replaceable cartridge. The filter shall be capable of removing 97% particles of size 1 micron and above. The filter shall have a weather cap. 3.1.2 Inter / After Cooler Inter / after coolers shall be air cooled. Inter / after coolers shall cool the air at the final discharge location to within a maximum of 15 F of the specified ambient air temperature. Inter / after cooler shall have knockout pots and automatic liquid condensate removal traps. 3.1.3 Drivers The drive motors shall comply with compressor specification. The driver shall be suitable for the hazardous area classification stated on the data sheet.

Page 5 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

The driver rating shall be at least 110% of the guaranteed power demand for the rated conditions indicated in the data sheet. The driver starting torque shall be at least 15 percent greater than driven equipment starting torque requirements. The driver shall be able to develop adequate starting torque to start compressor against relief valve set pressure under the worst combination of the specified ambient and utility conditions without margins. The compressor and driver starting torque shall be torsion ally compatible. The driver and driven equipment torque-speed curves shall be prepared for submission to COMPANY. The starting requirement torque requirement and time required to attain full speed shall be agreed with COMPANY. The starting requirement at reduced voltage shall be stated on the compressor data sheet. 3.1.4 Reduction gears and Belt drives The gear unit shall be rated for the maximum horsepower capability of the electric motor. Where the maximum torque occurs at other than the rated speed, this torque and the corresponding speed shall be allowed for in the gear design. The gear unit shall be designed to with stand safely any transient torsion loads imposed during start-up, reacceleration after a power interruption and mal-operation. The drive train including driver, gear, couplings and other drive transmission devices used shall be free of any torsion ally critical speeds within the specified operating range. Where a belt transmission is used, the driver shall be provided with slide rails to facilitate belt tension adjustment. 3.1.5 Coupling and Guards All couplings shall be flexible spacer type. The coupling shall be enable removal of compressor rotor, without disturbing driver, gearbox, other transmission devices and without disconnecting the compressor piping. The coupling design shall prevent the spacer from flying out in case of failure of flexible elements. The coupling guards shall be non-sparkle materials.

Page 6 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

3.2

Air Dryer The dryer type shall be regenerative desiccant with capabilities of supplying dry air while regenerating. Each dryer train shall be provided with inlet and outlet isolation valves. These valves shall be facilities maintenance and outlet check valves shall prevent reverse flow to the dryer train on standby. The dryer train changeover shall be occur automatically without air supply interruption. Within each dryer the tower changeover from drying to regeneration shall be via non-lubricated four way valves. Each valve shall be complete with a discharge muffler. The depressurization of the vessel during regenerative cycles shall not result in blow-out or fragmentation of the desiccants. In case of timer failure or failure of pneumatic actuator, there shall be a provision for manual dryer operation. The regeneration cycle shall be fully automatic. The depressurization and regeneration shall be through a common vent header. The air silencer discharge noise level shall comply with COMPANY Specification. The air outlet pressure dew point temperature shall be nominated on the dryer data sheet A dew point indicator shall be located at each dryer train outlet. There shall be a provision for dew point indication on the local control panel. The desiccant type will be stated on the data sheet. The desiccant quantity calculation basis shall be prepared for submission to COMPANY. The actual desiccant quantity calculation basis shall be prepared for submission to COMPANY. The actual desiccant quantity supplied shall be 20% more than the calculated quantity required. 3.2.1 Dryer Absorber Towers Each dryer train shall have two desiccant filled towers. The towers shall be designed as per ASME Sec. VIII Div.1. The desiccant tower design shall permit desiccant replacement and removal without dismantling the connected pipe work. The desiccant life shall be for min. 1 year. 3.2.2 Dryer Pre-filter / After-filter A pre-filter which shall be located upstream of each dryer shall protect the desiccant material from contamination.

Page 7 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

An after-filter shall prevent desiccant carry over and maintain the required instrument air quality. The filtration efficiency shall be stated on the data sheet.

The filters shall have a differential pressure gauge. The pre-filter shall have an automatic drain trap, isolation and bypass valves. The after-filter shall be provided with isolation and bypass valves. 3.2.3 Dryer Inter / After Coolers Where required, the dryer inter/after coolers shall be manufactures standard. 3.3 Instrumentation and Controls All instrumentation, control and electrical system shall comply with COMPANY specification and shall be suitable for the area classification stated on the data sheet. Minimum rating for instrumentation shall be Class I, Group D, Div.2 All local instruments necessary for standard operational requirements such as pressure, temperature, level gauges, etc, shall be part of the compressor dryer package. All shutdown initiators shall be electronic smart transmitters. Switches shall not be used for shutdown purposes. Transmitter employed for shutdown shall neither be used in monitoring loop nor in control loop. All instrument and transmitter shall be weather proof to NEMA-4X. All controls shall designed to operate in fail-safe mode. All transmitters and field devices operating on electric supply shall be powered from local control panel. Intrinsically Safe (IS) circuits shall not be utilized. All cabling shall be in rigid galvanized steel conduit. Wire transmissions shall be identified with cable numbers that correspond to the package electrical schematic and wiring diagrams. Cabling, tubing and all interconnections within the skid shall be completed prior to shipment. Tubing shall be a installed tray with the skid. All analogue control signals to or from COMPANYs Plant Control system shall be 4 20 mA and all digital signal shall be via voltage free contacts.

Page 8 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

The Local Control panel shall be pre-wired, PLC based, free standing and shall be suitable for outdoor installation. The compressor and dryer controls including motor starters shall be housed in a single panel. The local control panel enclosure shall be weather proof to NEMA 4X. the enclosure shall be suitable for the hazard area classification stated in data sheet. The panel construction, material, earthling etc. shall be as specified in COMPANY specification. All the alarm circuits shall be grouped into a single group and terminated with dry contacts. The alarms shall be indicated as first-out on the local panel. The height of the panel, including 100 mm plinth, shall be 2200 mm. the width shall nor exceed 2000 mm. the panel shall be designed for bottom entry type. The gland plate shall be removable. Lifting lugs shall be provided on the panel. Load calculations to prove adequacy of such lugs shall be prepared for submission to COMPANY. 3.3.1 Interface The local control panel shall have provision for interfacing with the plants main control system. ESD signal from Plants Main Control System shall initiate the compressor shut down. Each signal shall be hardwired and will be identified in the compressor data sheet. Pre-wired suitability identified terminals shall be located in the local control panel. The terminals shall be clearly labeled for COMPANYs connection to the main plant control system. The control panel shall provide the following interface signals. For Compressor Packages : Common Alarm (potential free contacts). Local / Remote selector (potential free contacts). Status signals for each unit. Air pressure. Run Time (Hrs). Lube Oil Pressure. Lube Oil Temperature. For Dryer Package Unit Shutdown (potential free contacts). Common Alarm (potential free contacts). Unit Tripped (potential free contacts). Dew Point Indication (4-20 mA) input.

Page 9 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

3.3.2

Compressor Control / Sequencing System Each compressor will start in an unloaded condition. Each compressor shall be able to be selected for lead/lag duty without interrupting system operation. All control and monitoring functions shall be from local control panel. The compressor controls shall include the following switches/push buttons and lamps: Push Buttons/Switches Lead/standby mode for each compressor selector switch. Remote/auto/manual selection for compressor sequencing selector switch. Automatic/manual loading of compressor selector switch. Start push button. Emergency stop push button. Acknowledge push button. Reset push button. Lamp Test push button. Indication Lamps Unit running. Unit tripped. Unit ready to start. The compressor controls shall have protection for the following: Inlet filters differential pressure high. Inter/after Cooler outlet temperature high. Differential pressure across the compressor high. The detail list of alarms and trips shall be on the data sheet.

3.3.3

Air Dryer Control The four way valves required for switching from one tower to another and for switching drying to regeneration shall be provided with limit switches shall be used to indicate the tower status i.e. under regeneration or online. The control panel shall have dew point indication. The dryer controls shall have the following protection. Pre filter/After filter differential pressure high. Absorber tower differential pressure high. High dew point at the dryer outlet. Inter/After cooler outlet temperature high (for heated dryer).

Page 10 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

Heater outlet temperature high (for heated dryer).

3.4

Skid Unless otherwise specified on data sheet, all equipment in air compressor/dryer package shall be mounted at separate skid. The skid design shall comply with COMPANY Specification. The base plates shall be stiff enough to resist permanent deformation from bending and twisting due to handling and shall be designed to keep excessive forces and deflections from being transmitted to the equipment. The base plate shall be stiff enough in all directions to ensure that factory set alignments are maintained at all times during design operation. The base plates shall meet the following requirements: No component of the unit (or accessories) may overhang the drained base plate area except the motor conduit box. The base plate shall have a full metal deck complete with provisions for draining to a 1 inch NPT drain located at the base plate edge.

3.5

Balancing and Vibration The power supply shall be 380 V AC, 50 Hz, three phase, 3 wire. The control power shall be 220 V AC, 50 Hz UPS. Further distribution and / or conversion to other voltages shall be done in the local control panel. Instrument / Utility Air connection shall be at single termination point.

3.6

Piping All piping shall be designed in accordance with the latest edition of ASME-B31.3 and COMPANY specification. The extent piping inside package and specific piping requirements will be nominated on the compressor and dryer data sheets. All piping shall be fabricated in accordance with COMPANY specification. Piping and tubing shall be securely fastened to minimize vibration and prevent breakage during shipment and operation. Welded fittings shall be used to maximum extent. Welded tees and reducing weld tees shall be used for branch connections. Screwed piping shall not be used for hydrocarbon service.

Page 11 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

Bolting shall conform to ASME B31.3. Stud bolts shall be ASTM-A-193 Grade B7. Nuts shall be ASTM-A-194 Grade 2H unless the service is classified as low temperature. All drains, including casing drains, shall be piped to skid edge and terminated with a flanged valve. All vents shall have no pocketing, and shall be piped to a single vapor disposal point located at skid edge. 3.7 Painting Each equipment item shall be painted in accordance with COMPANY Specification or as stated on the compressor and dryer data sheets. The surface preparation and painting/coating shall be done only after satisfactory completion of the inspection and testing of the package/equipment. 3.8 Insulation Insulation and cladding shall be as stated on the compressor and dryer data sheet. All insulation shall be in accordance with COMPANY Specification. 3.9 Noise The noise limit for this package shall be as stated on the data sheet, and should be measured at 1 meter from the skid in a free field (open air) environment. Comprehensive noise data on the equipment shall be provided. The overall level specified is the maximum cumulative emission from all noise sources on the package. Noise test reports shall be prepare for submission to COMPANY.

4.0 MATERIAL Any additional specific requirements shall be as stated on the compressor and dryer data sheet.

5.0 MANUFACTURING Any additional specific requirements shall be as stated on the compressor and dryer data sheet.

Page 12 of 13

MULTI PURPOSE REACTOR PLANT BATAM INDONESIA

________________________________

Air Compressor Specification

6.0 INSPECTION AND TESTING Inspection and testing shall be as stated on the compressor and dryer data sheet. Compressor mechanical run and performance test shall be as per API 619. The test program shall be fully detailed and prepared fur submission to COMPANY. Hydro test of compressor casing and pressure parts, pressure vessels and piping shall comply with ASME Codes. Instrument and control functions, loading and unloading, alarms and shutdowns shall be tested. The following dryer tests shall be carried out: Functional / Operational Test. Performance Test. Hydrostatic Test. Noise Test. The Factory Acceptance Test (FAT) procedures shall be fully detailed and prepared for submission to COMPANY. The package functional testing procedure shall be fully detailed and prepared for submission to COMPANY. Witnessed, functional and performance test for each package shall be carried out at the package manufactures work prior to final inspection. The tests shall include compressor performance test and mechanical run test of compressor with motor and auxiliaries. A full performance test of the assembled package at the Manufactures works shall verify compliance with the requirements of the data sheet and the specifications. The following will be verified: The loop testing of all instruments and control circuit has been done. The continuity test of all electrical & earthling circuit has been done.

7.0 PREPARATION FOR SHIPMENT Unless specified otherwise the equipment and accessories will be shipped as one complete installation assembly. Additional requirements shall be stated on the compressor data sheet.

Page 13 of 13

You might also like

- Compressed Air System Design BasisDocument11 pagesCompressed Air System Design Basiskaruna346100% (2)

- Purchase Specification For Screw Type Air Compressor With Air DryerDocument3 pagesPurchase Specification For Screw Type Air Compressor With Air Dryeryash1239No ratings yet

- Plant Air Instrument Air PackageDocument5 pagesPlant Air Instrument Air Packagekumar31052003No ratings yet

- Compressed Air System For Chemical and Industrial PlantsDocument23 pagesCompressed Air System For Chemical and Industrial Plantsjkhan_724384No ratings yet

- Project Standards and Specifications Dryers Systems Rev01Document18 pagesProject Standards and Specifications Dryers Systems Rev01Christian CleofasNo ratings yet

- Compressor SpecificationDocument9 pagesCompressor Specificationcarzante100% (1)

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Document14 pagesA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNo ratings yet

- Heat of Compression Dryer ArticleDocument5 pagesHeat of Compression Dryer ArticleAshwin ChandaranaNo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Air Receivers Volume CalculationDocument98 pagesAir Receivers Volume CalculationBaskar Kannaiah100% (1)

- B 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer PackageDocument12 pagesB 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer PackagepragatheeskNo ratings yet

- Instrument Air - Compressed Air and Gas Drying-2Document21 pagesInstrument Air - Compressed Air and Gas Drying-2brmamor100% (1)

- Nitrogen Generation Unit Datasheet FormatDocument20 pagesNitrogen Generation Unit Datasheet FormatManthan100% (1)

- Air CompressorDocument51 pagesAir CompressorInaam Ur RehmanNo ratings yet

- Specification For Water Softening Plant and Online Self Cleaning FilterDocument16 pagesSpecification For Water Softening Plant and Online Self Cleaning Filterkatepol8264100% (1)

- Tank Specification OGDocument28 pagesTank Specification OGMadhesh RajuNo ratings yet

- Centrifugal Pumps SizingDocument18 pagesCentrifugal Pumps SizingBindu joglekarNo ratings yet

- Chemical Dosing Package - GS140-2 PDFDocument14 pagesChemical Dosing Package - GS140-2 PDFArash Sotoudeh100% (1)

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelNo ratings yet

- Design Features and Operation of Jet EjectorsDocument2 pagesDesign Features and Operation of Jet EjectorsSamiYousifNo ratings yet

- MSN Labs 14 TPH Boiler Bag Filter Technical OfferDocument18 pagesMSN Labs 14 TPH Boiler Bag Filter Technical OfferpavaniNo ratings yet

- Brochure HRFGDocument16 pagesBrochure HRFGjhobanybernalNo ratings yet

- SMPVDocument8 pagesSMPVPrasanta Kumar BeheraNo ratings yet

- Instrument Air Compressor Control PhilosophyDocument2 pagesInstrument Air Compressor Control PhilosophysuhailfarhaanNo ratings yet

- Technical Bid Evaluation Sheet New Oil Transfer Pumps (P-1250)Document2 pagesTechnical Bid Evaluation Sheet New Oil Transfer Pumps (P-1250)Siva baalan100% (1)

- Compressor-Performance Evaluation PDFDocument4 pagesCompressor-Performance Evaluation PDFAlvin Smith100% (1)

- Centrifugal Comp PDFDocument7 pagesCentrifugal Comp PDFmsaroladanNo ratings yet

- Storage Tanks DSDocument18 pagesStorage Tanks DSNatarajan RavisankarNo ratings yet

- Vent Silencer DatasheetDocument2 pagesVent Silencer DatasheetHamid Mansouri100% (1)

- Specification - Air Compressor & DryerDocument54 pagesSpecification - Air Compressor & DryermishtinilNo ratings yet

- Production Pump Sizing P. 0920 A, B, C: CalculationDocument5 pagesProduction Pump Sizing P. 0920 A, B, C: CalculationElias EliasNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- 254624-400-DS-PRO-310, Rev F - Datasheet of VRUDocument18 pages254624-400-DS-PRO-310, Rev F - Datasheet of VRURamesh SharmaNo ratings yet

- Tech Spec For Plate Heat ExchangersDocument37 pagesTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- Specification For LP & HP Dosing System-PC - AUX-BLR - DOS-R00-3Document11 pagesSpecification For LP & HP Dosing System-PC - AUX-BLR - DOS-R00-3Manoj NirgudeNo ratings yet

- 6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferDocument35 pages6.1 Working Principle of Equipment:: 6.2.1 Steady State Heat TransferAthar IqbalNo ratings yet

- Mechanical Specification - Instrument Air CompressorDocument7 pagesMechanical Specification - Instrument Air Compressorsajeesh5113699No ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Chemical DosingDocument24 pagesChemical DosingIskerNo ratings yet

- Air Dryer - Tangguh PJDocument64 pagesAir Dryer - Tangguh PJRanu JanuarNo ratings yet

- Lube Oil PumpsDocument60 pagesLube Oil PumpsReza AgustianNo ratings yet

- DS-TI Tower InternalsDocument10 pagesDS-TI Tower Internalschris100% (1)

- Multi Organics-MEEP-180118-31.12.2018 PDFDocument28 pagesMulti Organics-MEEP-180118-31.12.2018 PDFArjun KrishnakumarNo ratings yet

- Air Compressor SpecificationsDocument5 pagesAir Compressor SpecificationspinkNo ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- Cooling Tower Performance Testing Procedure PDFDocument4 pagesCooling Tower Performance Testing Procedure PDFAnonymous ffje1rpa100% (1)

- Guidelines For Basic Engineering (Incl. Design Calculations)Document55 pagesGuidelines For Basic Engineering (Incl. Design Calculations)Djamel Ait MohamedNo ratings yet

- Constructability Review ChecklistDocument3 pagesConstructability Review ChecklistAnyanele Nnamdi FelixNo ratings yet

- Sizing Air Receiver TankDocument3 pagesSizing Air Receiver TankDennis DanielNo ratings yet

- Nitrogen Generator Manual 20627Document26 pagesNitrogen Generator Manual 20627Inertech ProjectsNo ratings yet

- Intro To TBE For PumpDocument2 pagesIntro To TBE For PumpMuhammad RidhwanNo ratings yet

- Nitrogen BlanketingDocument21 pagesNitrogen Blanketingrvkumar61No ratings yet

- Air Intake Systems: Application and Installation GuideDocument36 pagesAir Intake Systems: Application and Installation Guiderudey18No ratings yet

- LS20-100 Sullair Manual PDFDocument114 pagesLS20-100 Sullair Manual PDFJavier Miramontes100% (1)

- QGS 5 - 7.5 Instruction Manual PDFDocument40 pagesQGS 5 - 7.5 Instruction Manual PDFGustavo GamarraNo ratings yet

- Compresor QGS 10 - 15 Instruction ManualDocument38 pagesCompresor QGS 10 - 15 Instruction ManualosvabribNo ratings yet

- 40-125 HP, Fixed-Speed Oil-Lubricated Rotary, Air-Cooled, Integrated Dryer - tcm45-3526426Document5 pages40-125 HP, Fixed-Speed Oil-Lubricated Rotary, Air-Cooled, Integrated Dryer - tcm45-3526426SantiagoAlpalaNo ratings yet

- Offshore Structures - Analysis and Design by Dr.S.nallayarasuDocument115 pagesOffshore Structures - Analysis and Design by Dr.S.nallayarasumariusz19781103100% (9)

- Company Profile 2009Document16 pagesCompany Profile 2009yoi_123No ratings yet

- Concurrent Design & ICT 1990 - 2000: Perangkat Lunak Drawing Modeling Messing Calculation Simulation - Data BaseDocument1 pageConcurrent Design & ICT 1990 - 2000: Perangkat Lunak Drawing Modeling Messing Calculation Simulation - Data Baseyoi_123No ratings yet

- Typical Activities Sequence OutlineDocument1 pageTypical Activities Sequence Outlineyoi_123No ratings yet

- Ertas & JonesDocument1 pageErtas & Jonesyoi_123No ratings yet

- G NielmenDocument1 pageG Nielmenyoi_123No ratings yet

- Log Book Presentasi RevisiDocument72 pagesLog Book Presentasi Revisiyoi_123No ratings yet

- Blasting and Painting Procedure - 1Document6 pagesBlasting and Painting Procedure - 1Azrul Rais64% (11)

- Engineering Work Brekdown For Typical Process Plant ProjectDocument2 pagesEngineering Work Brekdown For Typical Process Plant Projectyoi_123No ratings yet

- Field+Inspection+Report HydrotestDocument36 pagesField+Inspection+Report Hydrotestyoi_123No ratings yet

- Pressure Drop Calculation Sheet: A4 K D 2.8257 7.149 ReDocument1 pagePressure Drop Calculation Sheet: A4 K D 2.8257 7.149 Reyoi_123No ratings yet

- 900 Spe 5001 Met&systDocument30 pages900 Spe 5001 Met&systyoi_123No ratings yet

- Proses Umum AmoniakDocument22 pagesProses Umum Amoniakyoi_123No ratings yet

- Manual Autodesk Plant 3D English PDFDocument592 pagesManual Autodesk Plant 3D English PDFjlvega18100% (7)

- SPAN Calc.Document48 pagesSPAN Calc.yoi_123No ratings yet

- Intro To Plant Design 2012 Review AnswersDocument42 pagesIntro To Plant Design 2012 Review Answersyoi_123No ratings yet

- Paradise Perkasa F0134 Quo 07 Aug 06 Part 1Document1 pageParadise Perkasa F0134 Quo 07 Aug 06 Part 1yoi_123No ratings yet

- BF V CatalogDocument56 pagesBF V CatalogmaciasrobNo ratings yet

- Ped 5 FTDocument39 pagesPed 5 FTJoy Grace TablanteNo ratings yet

- Detector Demetales Manuel 103Document6 pagesDetector Demetales Manuel 103wilfredoNo ratings yet

- Robit Forepoling Catalogue ENG 03-2015Document36 pagesRobit Forepoling Catalogue ENG 03-2015Purwadi Eko SaputroNo ratings yet

- Industrial ReactorsDocument10 pagesIndustrial ReactorssarahNo ratings yet

- 3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectDocument3 pages3 Tan 8.3 Tan108 Tan 8 - 1 3tan 8.3: Single Choice CorrectShehbaz ThakurNo ratings yet

- Megger-Mjolner-600 Ds enDocument5 pagesMegger-Mjolner-600 Ds enAmit Kumar KandiNo ratings yet

- No 1 Method ValidationDocument2 pagesNo 1 Method ValidationdanaciortanNo ratings yet

- Cloud Computing 101 TutorialDocument203 pagesCloud Computing 101 TutorialYunis Iklil100% (1)

- Winter Student Enrichment PacketDocument9 pagesWinter Student Enrichment PacketshelleyallynNo ratings yet

- Unit B: What Is Customer-Based Brand Equity?Document3 pagesUnit B: What Is Customer-Based Brand Equity?So-Nam Dorji Dr-UKpaNo ratings yet

- ABAP On HANA TopicsDocument23 pagesABAP On HANA Topicsrupesh kumarNo ratings yet

- Etrade Bank-StatementDocument5 pagesEtrade Bank-StatementMark Galanty100% (4)

- Word Formation ListDocument8 pagesWord Formation ListpaticiaNo ratings yet

- Amy CuddyDocument5 pagesAmy CuddygeetaNo ratings yet

- Wartsila O Env Multi Stage Flash EvaporatorsDocument2 pagesWartsila O Env Multi Stage Flash EvaporatorsRichard Periyanayagam0% (1)

- Omnifocus ShortcutsDocument3 pagesOmnifocus ShortcutsLaGouloueNo ratings yet

- Synchronous Motor AC DrivesDocument40 pagesSynchronous Motor AC DrivesHarshal Thakur100% (1)

- A Guide To Become A Succesful Marine EngineerDocument99 pagesA Guide To Become A Succesful Marine EngineerTammam Hassan100% (1)

- San Beda University: Integrated Basic Education DepartmentDocument3 pagesSan Beda University: Integrated Basic Education DepartmentEmil SamaniegoNo ratings yet

- Acr On Clean-Up DriveDocument7 pagesAcr On Clean-Up DriveRichard ToliaoNo ratings yet

- SOM-based Generating of Association RulesDocument5 pagesSOM-based Generating of Association RulesKishor PeddiNo ratings yet

- CC Course IntroDocument11 pagesCC Course IntroSaid TahatNo ratings yet

- Post Covid StrategyDocument12 pagesPost Covid Strategyadei667062No ratings yet

- Wind Tunnel Technique Notes For Aeronautical Engineers TP 2Document6 pagesWind Tunnel Technique Notes For Aeronautical Engineers TP 2Ramji VeerappanNo ratings yet

- Minimum Leak Path For TTJDocument3 pagesMinimum Leak Path For TTJparikshitpadture100% (2)

- Daikin LXE10E-A - Service Manual (TR 01-09B) PDFDocument238 pagesDaikin LXE10E-A - Service Manual (TR 01-09B) PDFmail4ksnNo ratings yet

- Big Data Executive Survey 2019 Findings Updated 010219 1Document16 pagesBig Data Executive Survey 2019 Findings Updated 010219 1satmaniaNo ratings yet

- The 28th Santa Fe Symposium On Jewelry Manufacturing TechnologyDocument6 pagesThe 28th Santa Fe Symposium On Jewelry Manufacturing Technologyชนพัทธ์ คงพ่วงNo ratings yet

- Gerrard 1966Document13 pagesGerrard 1966AnandhuMANo ratings yet