Professional Documents

Culture Documents

JKLakshmi Cement LTD English

Uploaded by

Sanket SatpathyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JKLakshmi Cement LTD English

Uploaded by

Sanket SatpathyCopyright:

Available Formats

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW).

At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

INDEX

S. NO. 1.0 1.1 1.2 1.3 1.4 1.4.1 1.5 1.6 1.7 1.8 2.0 3.0 4.0 5.0 5.1 5.2 5.3 5.4 5.5 6.0 PARTICULAR PROJECT DESCRIPTION INTRODUCTION DETAILS OF THE PROJECT AREA LOCATION MAP RAW MATERIAL REQUIREMENT PAGE NO. 1 1 1 3 4 4 5 6 6 7 4

COMPOSITION OF PPC & PSC PROCESS DESCRIPTION

ANTICIPATED ENVIRONMENTAL IMPACTS

DESCRIPTION OF THE ENVIRONMENT SOCIO ECONOMIC ENVIRONMENT

ENVIRONMENTAL MONITORING PROGRAM ADDITIONAL STUDIES PROJECT BENEFITS ENVIRONMENTAL MANAGEMENT PLAN AIR POLLUTION MANAGEMENT WATER ENVIRONMENT MANAGEMENT NOISE POLLUTION MANAGEMENT SOLID WASTE MANAGEMENT GREEN BELT DEVELOPMENT/PLANTATION CONCLUSION

7 7 7 8 8 8 8 9

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

EXECUTIVE SUMMARY 1.0 1.1 PROJECT DESCRIPTION INTRODUCTION

JK Lakshmi Cement Limited (JKLCL) is a part of JK Organization. With a diverse portfolio ranging from JK Tyres Ltd., JK Sugar Ltd. and JK Agri Genetics Ltd. to Fenner (India) Ltd., JK Paper Ltd. and JK Lakshmi Cement Ltd., JK Organization has touched the lives of millions of individuals. M/s JK Lakshmi Cement Limited (JKLCL) has proposed to set up a Cement Grinding Unit of 1.5 MTPA and DG sets (2X6 MW) at Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa). As per EIA Notification dated 14th September 2006 and as amended on 1st December, 2009, this project falls under Category B, Project or Activity-3 (b) 4, therefore this project requires Environmental Clearance from SEIAA, Orissa.

1.2

DETAILS OF THE PROJECT AREA.

TABLE - 1 SALIENT FEATURES OF THE PROJECT

S. No. A. B. 1. 2. 3. 4. 5. 6. C. 7. 8.

Particulars Nature & Size of the Project

Details Proposed Cement Grinding Unit of 1.5 MTPA and DG sets (2X6 MW)

9.

Location Villages Ghantikhal, Radheyshampur Tehsil Athagarh District Cuttack State Orissa Latitude 20 31'19.62 to 20 32'17.50"N, 85 44'1.06"E to 85 44'31.17"E Longitude Toposheet No. 73 H/10, 73 H/11, 73 H/14, 73 H/15 Environmental Setting of the Study area NH - 42 is approx. 2.3 km in North direction National Highway from the proposed project site. SH-65 is approx. 4 km in NW direction from State Highway the proposed project site. Ghantikhal is approx. 1.0 km in South Nearest Railway Station direction from proposed project site. Rajathagarh is approx. 4.2 km in North direction from proposed project site.

3

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

10. 11. 12.

Nearest Airport Nearest Village Nearest Town Nearest Water bodies

13. Eco sensitive Zone (National Park, Wildlife Sanctuary, Biosphere reserve wildlife corridors etc.) Within 10 km radius of the project site.

Bhubaneswar is approx. 32 km in SSE direction from proposed project site. Radheyshampur is approx. 0.5 km in North direction from proposed project site. Cuttack is approx. 16 km in SE direction from proposed project site Sapua River is approx. 4.0 km in SE direction from proposed project site. Mahanadi River is approx. 4.3 km in SE direction from proposed project site. No Eco sensitive Zone viz. National Park, Wildlife Sanctuary, Biosphere reserve wildlife corridors falling with the 10 km radius of the project site.

14.

15.

16. D. 17. 18. 19. 20.

E. 21. 22. 23.

Kapivas R.F. ( 8.5 Km in NW) Deulia R.F. (~5.0 Km in NW) Ranibania R.F. (~5.7 Km in NW) Gadabola R.F. (~8 Km in NW) Adala R.F. (~7.0 Km in NW) Reserved / Protected Forest Oringa R.F. (2.5 Km in W) within 10 km. radius (Boundary Subasi R.F. ( in W direction) to boundary distance) Sukasana R.F. (7.5 Km in SW) Brahmanbasta R.F. (1.0 Km in E) Sankhaipoi R.F. (~5.2 Km in NE ) Baula R.F.(6.8 Km in E) Baniabandha R.F.(~10 Km in N) Suniamoh R.F. (5.0 Km in E ) Historical & Archeological No Historical & Archeological site falling Important Place within 10 km radius of the project site Major Requirements Land 119 Acres (Proposed). Water Requirement 700 m3/day from Groundwater/Surface Water Manpower Requirement 80 Person Power The proposed grinding unit would require approximately 10.85 MW (say 11 MW) of power. This requirement shall be met from the Orissa Electricity Board / DG sets (for Cost Details Capital cost of the project Rs. 155 crores Capital Cost for EMP Rs. 12 Crores Recurring Cost/annum Rs. 1.10 Crores/annum

Source: Pre-feasibility Report & Site Visit Report

1.3

Location Map

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

1.4 Raw Material Requirement

M/s JK Lakshmi Cement Limited

Figure no. 1.3 Location Map

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

The raw materials required for the proposed grinding unit & productions of PSC (Portland Slag Cement) & PPC (Pozollana Portland Cement) are as mentioned below: Table 2 Source Cement plant, Durg (C.G.) Aarti Steel Ltd. Steel plants of Jajpur, Angul & other steel plants RSMML Rajasthan mines / Visakhapatnam (chemical gypsum) Indian Oil Corporation depot

Raw Material Clinker Fly ash Blast furnace slag

Quantity PPC/PSC(TPD) 3150 for PPC 2250 for PSC 1125 for PPC 2025 for PSC

Distance

Mode of transportation By Road / Railway wagons By Road By Road

650 km Adjacent Nearby industries exist within 100 km 1500 km Rajasthan / 500 km Visakhapatnam Bhubaneswar 50 km

Gypsum

225 for PPC 225 for PSC

By Railway wagons

HSD/ Furnace oil for DG set

2500 KL per annum

By Road

Source: Pre-feasibility Report

1.4.1

S.No. 1. 2. 3. 4.

Composition of PPC & PSC

Raw Material Clinker Fly ash Gypsum Slag Source: Pre Feasibility Report % for PSC 50 Nil 5 45 % for PPC 70-75 20-25 5 Nil

1.5

PROCESS DESCRIPTION

A. Clinker Handling

6

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

Clinker from Durg Cement Plant will be received by railway wagons and will be unloaded by wagon tippler. Clinker will be transported to clinker silo by covered belt conveyor. Then transported to clinker hopper at cement grinding section by covered belt conveyor. B. Fly Ash Handling Transported to the plant by road in closed bulk tankers From the silos to the mill by pneumatic system C. Gypsum storage, handling and crushing Gypsum received by wagon will be unloaded by wagon tippler or manually at the storage yard designated for gypsum storage. Gypsum shall be crushed in the roll crusher and bag filter with adequate capacity will be installed in crusher. Gypsum shall be conveyed to cement mill hopper for feeding to cement mill. D. Cement Production Clinker and gypsum extracted from their respective hoppers, fed to the Roller Press and Cement Mill (closed circuit) Fly Ash and Slag extracted from their respective Silo/hoppers, fed to the Cement Mill directly, Ground to the desired fineness and ground cement is stored in cement silos E. Cement Packing and Dispatch Rotary electronic packing machines will do packing of Cement. Loading of cement in trucks/wagon shall be done by automatic loading machines.

1.6

DESCRIPTION OF THE ENVIRONMENT

Baseline study of the study area (i.e. 10 km radius from the project boundary) was conducted during Summer Season (March, 2011 to May, 2011). Baseline study included ambient air quality, ambient noise level, water quality, soil quality, land use pattern, demography, flora & fauna found separately in the core & buffer zone etc.

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

Ambient Air Quality Monitoring reveals that concentrations of PM2.5 for all the 8 AAQM stations ranged between 14.81 g/m3 to g/m3 28.44. The concentration of PM10 ranged between 35.67 g/m3 to 59.11 g/m3.The maximum & minimum concentrations of SO2 were found to be 6.03 g/m3 & 7.64 g/m3 respectively whereas concentrations of NO2 ranged between 11.27 g/m3 & 16.68 g/m3. The ground water analysis for all the 8 sampling stations shows that pH varies from 7.07 to 7.91, total hardness varies from 54.00 mg/l to 181.80 mg/l & total dissolved solids varies from 93 mg/l to 221 mg/l. Soil Samples indicate pH value ranging from 6.40 to 6.98, which shows that the soil is moderately alkaline in nature. Organic Matter ranges from 1.19 to 1.82 in the soil samples. Nitrogen is found to be in better amount as it ranges from 150.03 kg/ha to 240.75 kg/ha and Phosphorous in medium amount i.e. from 35.46 kg/ha to 77.46 kg/ha, respectively, whereas the Potassium is found to be ranging from 55.39 kg/ha to 167.85 kg/ha.

1.7

SOCIO-ECONOMIC ENVIRONMENT

The population as per 2001 Census records is 80685 (for 10 km radius buffer zone). Scheduled Caste fraction of the population of the study area (10 km) is 16.98% and Scheduled Tribe is 11.01% Literacy rate is 61.88%. Total no. of households is 16695.

1.8

ANTICIPATED ENVIRONMENTAL IMPACTS

The key emissions generated from Plant process are particulate matter. High efficiency bag house will be installed in grinding unit to meet the PM (Particulate Matter) emission level. Fugitive emission shall through controlled by proper covered storage facilities for raw material & product. Installation of bag filters and proper water sprinkling shall be carried out at the material transfer points. No industrial waste water will be generated from grinding unit. Domestic effluent will be generated mainly from office toilets and township, which will be disposed off in soak pits via septic tank. There will be no discharge outside the plant.

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

No Solid waste will be generated from the proposed Cement Grinding Process. During operational phase noise will be generated from compressors, motors, grinding mills in the grinding unit. Ear plugs will be provided to persons working in high noise zone.

2.0

ENVIRONMENTAL MONITORING PROGRAM

Table: 3 Environmental Monitoring Program

S. No. 1. 2. 3. 4. 5.

DESCRIPTION Meteorological Data Ambient Air Quality Stack monitoring Water Quality Noise Level Monitoring

FREQUENCY OF MONITORING Daily Quarterly/ Half Yearly Quarterly/ Half Yearly Quarterly/ Half Yearly Quarterly/ Half Yearly

3.0

ADDITIONAL STUDIES

The Additional Studies conducted as per the additional Terms of References issued vide SEAC letter no. F. No 122/SEAC-212 & Letter dated 1st March, 2011 are Risk Assessment & Rain water Harvesting Plan.

4.0

PROJECT BENEFITS

The companys management will recruit the semi skilled & unskilled workers from the nearby villages, hence rapidly increasing the social status of the villagers. The company will act as a catalyst for accelerating the all-round development process in the surrounding villages of the project site. It will provide services to ensure that the full-benefits of development schemes of the Government and other agencies reach to the villagers. Fly ash and Slag will be used in proposed cement grinding unit which are generated from captive thermal power plant and steel plant as solid waste exist in vicinity of the proposed project site.

5.0

5.1

AIR POLLUTION MANAGEMENT

9

ENVIRONMENTAL MANAGEMENT PLAN

M/s JK Lakshmi Cement Limited

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

The major sources of pollution are particulate matter from grinding unit. Installation of proper pollution control equipment like Bag Houses, Bag filters and better maintenance will help in reducing such emissions. Fly ash, and Finish Product will be stored in silos. Clinker will be stored in silos /covered stock piles and gypsum will be stored in covered shed. Covered conveyors will be utilized for transportation inside the plant. Personal Protective equipments like dust mask will be provided to the workers. Green belt will be developed all along the plant boundary as dust preventive barrier. Regular Ambient Air Quality Monitoring will be done. 5.2 WATER POLLUTION MANAGEMENT There will be no waste water generation from the proposed grinding unit. The domestic effluent generated will be disposed off in soak pits via septic tank. There will be no discharge outside the plant. Rain water harvesting will be done within the plant premises. 5.3 NOISE POLLUTION MANAGEMENT Proper care will be taken by incorporating sound-proof enclosures for equipments and providing earmuffs and earplugs for operators. Proper maintenance, oiling and greasing of machines at regular intervals will be done to reduce generation of noise. Noise attenuating devices like earplugs and earmuffs will be provided to the workers exposed to high noise level. Green belt will be developed all along the plant boundary . Noise level monitoring shall be done on regular basis. 5.4 SOLID WASTE MANAGEMENT

M/s JK Lakshmi Cement Limited

10

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

No solid waste will be generated from the proposed grinding unit. However, material collected by the dust collectors (Bag House/Bag Filters) will automatically be recycled in the process. JKLCL will implement the following measures for solid waste management within the plant premises: Maintenance to prevent spillage and leakage Recycling of the collected spillage JKLCL, to prevent spillage and leakage will implement the following maintenance. The maintenance include inventory for the leakage/ spillage, and to investigate and prevent: Holes in bends etc. caused by the abrasive character of the materials. Deterioration of flexible joints, flaps and seals. 5.5 GREEN BELT DEVELOPMENT/ PLANTATION Approx. 33% of the total project area will be developed under green belt/plantation. Green belt will be developed all along the plant boundary as dust preventive barrier. The trees will be planted at suitable grid spacing to encourage proper growth. Tree plantation will be done every year in the campus to develop dense green belt. Species will be selected as per CPCB guidelines & local forest department. Green belt will be developed all along the plant boundary as dust preventive barrier.

6.0

CONCLUSION

M/s JK Lakshmi Cement Limited

11

Proposed Cement Grinding Unit (1.5 MTPA) and DG Sets (2X6MW). At Villages: Ghantikhal, Radheyshampur, Tehsil: Athagarh, District: Cuttack (Orissa)

Executive Summary of Draft EIA Report

As discussed, it is safe to say that the project is not likely to cause any significant impact on the ecology of the area, as adequate preventive measures will be adopted to control the various pollutants within permissible limits. Green belt development around the area would also be taken up as an effective pollution mitigative technique, as well as to control the pollutants released from the premises of JKLCL. More over this Grinding Unit will help to mitigate the disposal problem of fly ash generated from captive power plants located in the vicinity.

M/s JK Lakshmi Cement Limited

12

You might also like

- Questionnaire - Plastic WasteDocument6 pagesQuestionnaire - Plastic Wastebasu67% (15)

- ZOOMLION CRAWLER CRANE ZCC800HWG Maintenance ManualDocument113 pagesZOOMLION CRAWLER CRANE ZCC800HWG Maintenance Manualmliugong83% (6)

- 800xa 5.1 Ac 800m Controller Data SheetDocument4 pages800xa 5.1 Ac 800m Controller Data Sheetrmsr_7576100% (1)

- Cement Bag Loading SysDocument56 pagesCement Bag Loading SysomercomsatNo ratings yet

- Operating Philosophy - Conveying SystemDocument6 pagesOperating Philosophy - Conveying SystemAmit JainNo ratings yet

- M/s. Gravity Sponge and Power Pvt. LTDDocument52 pagesM/s. Gravity Sponge and Power Pvt. LTDiexNo ratings yet

- Avinash MechwellDocument33 pagesAvinash Mechwell1977julNo ratings yet

- Final TL - CVL ComparativeDocument6 pagesFinal TL - CVL ComparativeRavi ChandarNo ratings yet

- Pellet Plant Presentation-2019Document42 pagesPellet Plant Presentation-2019syed fazlulla hussainNo ratings yet

- VGB Gypsum Analysis SheetDocument45 pagesVGB Gypsum Analysis SheetmsoyoralNo ratings yet

- Coal Feeder-03 Calibration 04 Feb2020Document20 pagesCoal Feeder-03 Calibration 04 Feb2020Muhummad Tanzeel RanaNo ratings yet

- 1.) Introduction: Soham Ferro Manganese Private Limited Nagpur Page 4Document67 pages1.) Introduction: Soham Ferro Manganese Private Limited Nagpur Page 4anand7602No ratings yet

- Bomb CalorimetryDocument11 pagesBomb CalorimetryTomy HaryantoNo ratings yet

- Cement FactoryDocument20 pagesCement FactorySabbir KhanNo ratings yet

- Technical Annexure - PODocument27 pagesTechnical Annexure - POHEMANTNo ratings yet

- Sulphide Sulphur Test of Slag CementDocument10 pagesSulphide Sulphur Test of Slag CementPooja UdupaNo ratings yet

- MW To TPH ConversionDocument1 pageMW To TPH ConversionGM HerbalsNo ratings yet

- 'Wattsup' 9th Issue Environment Protection Technologies SpecialDocument35 pages'Wattsup' 9th Issue Environment Protection Technologies SpecialNaveen ReddyNo ratings yet

- Burner Target Check Procedure - Revised - 220114Document4 pagesBurner Target Check Procedure - Revised - 220114reza212No ratings yet

- Hammer Crusher DesignDocument45 pagesHammer Crusher DesignmubashirNo ratings yet

- Flue Gas Desulfurizer: An Operational Point of View: by Mahendra & Arif SusetyoDocument11 pagesFlue Gas Desulfurizer: An Operational Point of View: by Mahendra & Arif SusetyoArif SusetyoNo ratings yet

- General Specification For Electric Actuators - Integral Motor ControlDocument4 pagesGeneral Specification For Electric Actuators - Integral Motor ControlschgirlNo ratings yet

- Larsen & Toubro Limited-Kansbahal-Foundry PDFDocument16 pagesLarsen & Toubro Limited-Kansbahal-Foundry PDFChristy Austin100% (1)

- Mekelle University: Eit-MDocument31 pagesMekelle University: Eit-MMearegNo ratings yet

- Dry Cleaning & Inspet Esp #1Document16 pagesDry Cleaning & Inspet Esp #1ShahNo ratings yet

- Environmental Infrastructure AT Vatva, AhmedabadDocument14 pagesEnvironmental Infrastructure AT Vatva, Ahmedabadpradips1No ratings yet

- Weighfeeder DetailsDocument4 pagesWeighfeeder DetailsAnonymous p4GdtQpNo ratings yet

- Ash Handling System - Spec - Rev0Document13 pagesAsh Handling System - Spec - Rev0Ramesh-NairNo ratings yet

- ThermalDocument43 pagesThermalSahuManish100% (1)

- CPCB Guidelines For TPPDocument17 pagesCPCB Guidelines For TPPsenthil031277No ratings yet

- FBC Boiler Operation PDFDocument2 pagesFBC Boiler Operation PDFNicholasNo ratings yet

- Waste Heat Recovery Power Plant 2mw 100tpd OrissaDocument84 pagesWaste Heat Recovery Power Plant 2mw 100tpd OrissaEdgardo Chavez BelloNo ratings yet

- Board of Directors: Shree CementDocument5 pagesBoard of Directors: Shree CementChandan AgarwalNo ratings yet

- Coal Beneficiation TechnologyDocument5 pagesCoal Beneficiation TechnologyChandan Das100% (1)

- GS-TS02 Tyre Slip Monitoring System-Operation ManualDocument8 pagesGS-TS02 Tyre Slip Monitoring System-Operation Manualvsrikala68No ratings yet

- BF Dry GCP S-13 PDFDocument2 pagesBF Dry GCP S-13 PDFgautamcool100% (1)

- Organisation Study On SHREE CEMENT BEAWARDocument89 pagesOrganisation Study On SHREE CEMENT BEAWARRajesh YadavNo ratings yet

- Clarifications To NTPC CommentsDocument224 pagesClarifications To NTPC CommentsnishantNo ratings yet

- Coal Mill Gas AnalysisDocument12 pagesCoal Mill Gas AnalysisPaulo VidasNo ratings yet

- Stack HT FGDDocument8 pagesStack HT FGDKiranNo ratings yet

- APTI413 PP Ch9Document56 pagesAPTI413 PP Ch9Stefanos DiamantisNo ratings yet

- Dera Ghazi Khan Cement Industry : (Nishat Group of Industries)Document30 pagesDera Ghazi Khan Cement Industry : (Nishat Group of Industries)Muhammad Hamza RaheelNo ratings yet

- ESP Replacement Parts: Wet & Dry: Air Pollution Control Systems: Parts and Service GuideDocument22 pagesESP Replacement Parts: Wet & Dry: Air Pollution Control Systems: Parts and Service GuideAmogh AbhyankarNo ratings yet

- Cement Industry: Handy ManualDocument54 pagesCement Industry: Handy Manualcostea0028No ratings yet

- Ramachandran - CV Updated Nov17Document3 pagesRamachandran - CV Updated Nov17rk_gprkavi2011No ratings yet

- Control Write Up A388Document57 pagesControl Write Up A388Juhi SinghNo ratings yet

- Annual Solar Report Card JMK Research March 2020 2Document2 pagesAnnual Solar Report Card JMK Research March 2020 2Chandra Shekhar LNo ratings yet

- BHEL ASh Handling Equp QA RequiremntDocument27 pagesBHEL ASh Handling Equp QA Requiremntamol1321100% (2)

- Organic - New - 2019 Product ProfileDocument15 pagesOrganic - New - 2019 Product Profilevaibhav khodakeNo ratings yet

- Combustion Studies of Fuel-Rich PropellantsDocument156 pagesCombustion Studies of Fuel-Rich PropellantsĐăng Khôi TrầnNo ratings yet

- CCI in Oil and Gas PDFDocument8 pagesCCI in Oil and Gas PDFavijitbNo ratings yet

- Lab Manual Chapter IV - Portland CementDocument13 pagesLab Manual Chapter IV - Portland Cementsalil dubeyNo ratings yet

- ACC Lakheri Cement WorksDocument12 pagesACC Lakheri Cement WorksSaji KumarNo ratings yet

- Major Equipment For 6600Tpd JSW Cement Plant NandyalDocument3 pagesMajor Equipment For 6600Tpd JSW Cement Plant NandyalSriram DantuNo ratings yet

- Dharmendra Das PDFDocument4 pagesDharmendra Das PDFdkdas143No ratings yet

- Pre-Feasibility Report: Shree Shyam Sponge & Power LTDDocument32 pagesPre-Feasibility Report: Shree Shyam Sponge & Power LTDفردوس سليمان100% (2)

- Enquiry Specification For BOD PlantDocument94 pagesEnquiry Specification For BOD PlantBanerjee SuvranilNo ratings yet

- Technical Specification For Fly Ash Handling System, R0Document7 pagesTechnical Specification For Fly Ash Handling System, R0SumitskbNo ratings yet

- Emission Regulations Part - 2 PDFDocument24 pagesEmission Regulations Part - 2 PDFAkul SenapatiNo ratings yet

- Design and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaDocument4 pagesDesign and Operating Features of New 27.6 Mva Furnace at Nava Bharat Ventures Limited, PalonchaKvvPrasadNo ratings yet

- Training Report at NFL PanipatDocument22 pagesTraining Report at NFL PanipatKapil AroraNo ratings yet

- EnglishDocument18 pagesEnglishlks.tembosteelsNo ratings yet

- CFT CalculationDocument1 pageCFT CalculationSanket SatpathyNo ratings yet

- Om DCTM 2000knDocument6 pagesOm DCTM 2000knSanket SatpathyNo ratings yet

- BOS ReportsDocument4 pagesBOS ReportsSanket SatpathyNo ratings yet

- ConcreteDocument80 pagesConcreteSanket SatpathyNo ratings yet

- REST DoDocument5 pagesREST DoSanket SatpathyNo ratings yet

- Job Vaccancy: Supreme Ready Mix ConcreteDocument1 pageJob Vaccancy: Supreme Ready Mix ConcreteSanket SatpathyNo ratings yet

- Lab EquipmentsDocument1 pageLab EquipmentsSanket SatpathyNo ratings yet

- Rain Garden How 2 Homeowner Uw ExtensionDocument32 pagesRain Garden How 2 Homeowner Uw ExtensionzionfrancisNo ratings yet

- VendorDocument3 pagesVendorSanket SatpathyNo ratings yet

- ExcavatorDocument1 pageExcavatorSanket SatpathyNo ratings yet

- New BDPA Map - 556 VillagesDocument1 pageNew BDPA Map - 556 VillagesKn Jenamani100% (2)

- Shakti BhawanDocument5 pagesShakti BhawanSanket SatpathyNo ratings yet

- 360 Excavator - Safe OperationDocument21 pages360 Excavator - Safe OperationSanket Satpathy0% (2)

- Workability of Fresh Concrete (Slump Test) : Project Quality Assurance ManualDocument1 pageWorkability of Fresh Concrete (Slump Test) : Project Quality Assurance ManualSanket SatpathyNo ratings yet

- International Metric System...Document2 pagesInternational Metric System...Sanket SatpathyNo ratings yet

- Silt Content in Sand: Project Quality Assurance ManualDocument2 pagesSilt Content in Sand: Project Quality Assurance ManualSanket SatpathyNo ratings yet

- Kennel Club of IndiaDocument5 pagesKennel Club of IndiaSanket SatpathyNo ratings yet

- 360 Degree Process - Planning For ImplementationDocument10 pages360 Degree Process - Planning For ImplementationSanket SatpathyNo ratings yet

- Color CodesDocument2 pagesColor CodesSanket SatpathyNo ratings yet

- 26 Sieve Anal 20mm & 10mmDocument4 pages26 Sieve Anal 20mm & 10mmSanket SatpathyNo ratings yet

- 913 (1) Enlistment RuleDocument71 pages913 (1) Enlistment RuleSubir Kumar BiswasNo ratings yet

- Volume FormulasDocument3 pagesVolume FormulasSanket SatpathyNo ratings yet

- 360 Excavator - Safe OperationDocument21 pages360 Excavator - Safe OperationSanket Satpathy0% (2)

- GGBSDocument7 pagesGGBSChandrashekhar VedantNo ratings yet

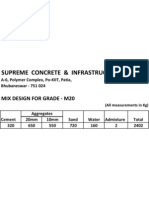

- Mix Design For m20Document1 pageMix Design For m20Sanket SatpathyNo ratings yet

- MaintenanceDocument2 pagesMaintenanceSanket SatpathyNo ratings yet

- 6713d1293784174 L T Technical Interview Question Civil Engineering Students Civil Question L TDocument7 pages6713d1293784174 L T Technical Interview Question Civil Engineering Students Civil Question L TRylie SilverNo ratings yet

- Filters & LubricantsDocument1 pageFilters & LubricantsSanket Satpathy100% (1)

- Concrete Mix DesignDocument36 pagesConcrete Mix Designamitbd80% (5)

- Data Capture Form Environmental ManagementDocument1 pageData Capture Form Environmental ManagementDonavel Nodora JojuicoNo ratings yet

- Resource Recycling For Sustainable Industrial DevelopmentDocument7 pagesResource Recycling For Sustainable Industrial DevelopmentYong JiangNo ratings yet

- Case History On Use of Recycled Aggregates On A6 Alvaston Bypass (Scott Wilson Et Al, 2004)Document10 pagesCase History On Use of Recycled Aggregates On A6 Alvaston Bypass (Scott Wilson Et Al, 2004)sandycastleNo ratings yet

- 34 Gaseous Control Technologies PDFDocument62 pages34 Gaseous Control Technologies PDFenviron13No ratings yet

- Owner'S Manual For Hoist: CXT40410050P35FCD0SDocument92 pagesOwner'S Manual For Hoist: CXT40410050P35FCD0SmanafNo ratings yet

- Maintenance Catalog Reach Stacker Kalmar DRU 450Document266 pagesMaintenance Catalog Reach Stacker Kalmar DRU 450Ridho Ahmad100% (2)

- SLP AccomplishmentDocument32 pagesSLP AccomplishmentRamilNo ratings yet

- Biomedical Waste Management Colour Coding For BeginnersDocument3 pagesBiomedical Waste Management Colour Coding For BeginnersMotherterrasa VocationalNo ratings yet

- Proposal - GROUP 2Document10 pagesProposal - GROUP 2Nash CasunggayNo ratings yet

- City Ordinance 314 Solid Waste MGMTDocument8 pagesCity Ordinance 314 Solid Waste MGMTCharina MiclatNo ratings yet

- Comparative Review of Waste Tyre Pyrolysis 5240E1114021Document6 pagesComparative Review of Waste Tyre Pyrolysis 5240E1114021DHSanjNo ratings yet

- CORE1 CArry Out Minor Vehicle MaintenanceDocument24 pagesCORE1 CArry Out Minor Vehicle MaintenanceFRANCIS EVANGELISTANo ratings yet

- Research Paper Final - CapunoDocument35 pagesResearch Paper Final - CapunojimelenNo ratings yet

- List of ISO 37120 - 2018 Indicators WCCDDocument7 pagesList of ISO 37120 - 2018 Indicators WCCDjiyan_lifeNo ratings yet

- Waste Manifest Attachment III: P A R TDocument1 pageWaste Manifest Attachment III: P A R TSanthoshNo ratings yet

- Minor Projecty Green MarektingDocument19 pagesMinor Projecty Green MarektingAshutosh MishraNo ratings yet

- Design and Fabrication of Pyrolysis UnitDocument3 pagesDesign and Fabrication of Pyrolysis UnitInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Environmental Laws of The PhilippinesDocument13 pagesEnvironmental Laws of The PhilippinesJoselito De Luna BatacNo ratings yet

- Effects of Water PollutionDocument5 pagesEffects of Water PollutionWei ChongNo ratings yet

- Safety Data Sheet: Product Name: MOBILGEAR 600 XP 100Document13 pagesSafety Data Sheet: Product Name: MOBILGEAR 600 XP 100Anonymous tgUmNZkNo ratings yet

- 6.01.str1.14cmg.0.00-Pr.016.ama - Pom.03 enDocument27 pages6.01.str1.14cmg.0.00-Pr.016.ama - Pom.03 eneugengabriel18No ratings yet

- Green Tech. KeTTHADocument44 pagesGreen Tech. KeTTHAShazwanShahNo ratings yet

- Composting & Our Products: EN 13432 CertifiedDocument2 pagesComposting & Our Products: EN 13432 CertifiedJohn Andrae MangloNo ratings yet

- Waste Management SOPDocument30 pagesWaste Management SOPEtta JeneeNo ratings yet

- Achalpur City Waste Management PlanDocument39 pagesAchalpur City Waste Management PlanVishal SinghNo ratings yet

- Jay Bryson H. Ruiz: FactorsDocument9 pagesJay Bryson H. Ruiz: FactorsJay Bryson RuizNo ratings yet

- 2b Recycle PresentationDocument13 pages2b Recycle Presentationapi-307860467No ratings yet

- The Best Practice Guide For Environmental Protection in Construction SiteDocument50 pagesThe Best Practice Guide For Environmental Protection in Construction SiteGary LoNo ratings yet