Professional Documents

Culture Documents

Dunlop Conveyor Belt Design Manual

Uploaded by

อภิรักษ์ มานะกิจศิริสุทธิCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dunlop Conveyor Belt Design Manual

Uploaded by

อภิรักษ์ มานะกิจศิริสุทธิCopyright:

Available Formats

Dunlop Conveyor Belt Design Manual

Page 1 of 33

DUNLOP Belting

Conveyor Belt Design Manual

INDEX

Introduction Dunlop Conveyor Belting Range Belting Characteristics Additional Features SABS Specifications Conveyor Belt Design Step By Step Example of Belt Tension Calculation Table 1: Table of Symbols Table 2: Material Characteristics Table 2(a): Typical Flowability Determination of Conveyor Capacities Table 3: Capacities of Troughed Belt Conveyors Table 4: Recommended Maximum Belt Speed for Normal Use Table 5: Recommended Idler Spacing Table 6: Friction Factors Table 7: Sag Factor Table 7(a): Recommended Percentage Sag Table 8: Estimated Belt Mass Table 9: Typical Mass of Rotating Parts of Idlers Table 10: Mass of Moving Parts Table 11: Drive Factor Conveyor Belt Selection Table 12: Maximum Recommended Operating Tensions Table 13: Recommended Minimum Pulley Diameters Table 14: Load Support Table 15: Maximum Number of Plies Recommended for Correct Empty Belt Troughing Table 16: Carcass Thickness Table 17: Mass of Belt Carcass Table 18: Mass of Covers per mm of Thickness Rate of Wear Graph Table 19: Minimum Belt Top Cover Gauge Guide Table 20: Belt Modulus Tabulator Calculations Sheet 1: Empty Belt Sheet 2: Fully Loaded Belt Sheet 3: Non-Declines Loaded Sheet 4: Declines Loaded Tension Tabulator Vertical Curves Maximum Incline Angle Graph for Estimating Belt Length/Rolled Belt Diameter Useful Data Conversion Factors Conveyor Belting Design Manual

INTRODUCTION

Dunlop Africa Industrial Products is the leading designer and manufacturer of industrial rubber products in South Africa. In fact our belting systems can be seen on some highly productive plants all around the globe.

What more can you expect, when you consider that our belts have been designed and fabricated by some of the best engineers in the industry and from only the finest raw materials.

Using the most current technology, many components have taken years of refinement to attain such technological precision. And every belt is guaranteed to provide maximum performance and maximum life.

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 2 of 33

And with some 750 000 various specifications available, you can expect to find the right belt for your requirements no matter how specialised.

This manual contains all the elements, formulae and tables you need to specify the exact belt. It has been compiled for your benefit, as a quick reference book for easy selection. If however you have an application not covered in the following pages, please contact Dunlop Africa Industrial Products. A team of experienced and helpful engineers will be pleased to assist you.

Our range of excellent products, competitive pricing and impeccable service, has earned Dunlop Africa Industrial Products the reputation of being the market's first choice.

DUNLOP CONVEYOR BELTING RANGE

Dunlop Africa Industrial Products manufactures the most comprehensive range of conveyor belting in South Africa.

Multi-ply rubber covered conveyor belting

XT textile reinforced conveyor belting with grade N covers

XT textile reinforced conveyor belting with grade M cut resistant covers

Phoenix heat resistant belting

Super Phoenix heat resistant belting

Delta Hete heat resistant belting

Fire resistant belting

Rufftop belting

Riffled concentrator belting

Grey food belting

Salmon pink food belting

Endless belts

Woodmaster

Oil resistant belting

Solid woven PVC belting

Standard solid woven PVC belting

Nitrile covered PVC belting

Steelcord belting

Fire resistant steelcord belting

Steelcord reinforced conveyor belting with cut resistant type M covers

Steelcord reinforced conveyor belting with type N covers

Steelcord reinforced conveyor belting with "Ripstop" protection

Steelcord reinforced conveyor belting with rip detection loops

Flinger belts

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 3 of 33

High speed truly endless belting

BELTING CHARACTERISTICS

XT Rubber Conveyor Belting (conforms to SABS 1173-1977)

From the early days of cotton duck plies, progress has been made in the manufacture of all-synthetic plies offering many advantages.

The range of strengths has been greatly increased, with improvements in the flexible structure. The modern multi-ply belt is manufactured with a synthetic fibre carcass in a wide slab, then slit to width as required for individual orders.

A wide range of belt specifications is available with current belt constructions having versatile applications.

The standard XT belting (Grade N) incorporates covers suitable for the handling of most abrasive materials, having a blend of natural and synthetic rubber.

Cut resistant XT Rubber Belting

Grade M Belts have covers with high natural rubber content recommended for belts operating under extremely arduous conditions where cutting and gouging of covers occurs.

Phoenix Heat Resistant Belting

Phoenix Heat Resistant belting covers are styrene butadiene based and are recommended for belts handling materials with temperatures up to 1200C.

Super Phoenix Heat Resistant Belting

Super Phoenix Heat Resistant belts have chlorobutyl covers and are recommended for belts handling materials with temperatures of up to 1700C.

Delta Hete Heat Resistant Belting

Delta Hete heat resistant belting with EPDM synthetic rubber covers in a formulation developed to allow conveying materials of temperatures up to 2000C.

Fire Resistant Belting (conforms to SABS 971-1980)

Fire Resistant XT belting is manufactured with covers containing neoprene and multi-ply carcass constructions to meet the stringent standards for safety in all underground mining industries and is therefore particularly suited to shaft applications.

Woodmaster

This belt has been especially developed for the Timber Industry. The rubber has been compounded to provide resistance to oil and resin, and is non-staining.

Rufftop Belting

This is a range of rough top package belting, of two or three ply all-synthetic carcass belts with deep impression rubber covers. The range is ideal for the packaging and warehousing industries and baggage handling installations such as airports and railway stations etc.

Riffled Concentrator Belts

Riffled conveyor belting has raised edges, is 1 500 mm wide and available in endless form. These belts are uniquely applied at gold mine concentrators.

Food Quality Belting

Food quality belting is ideal where foodstuffs come into direct contact with the belt surface. This range of belting is manufactured from non-toxic materials and is resistant to oils, fats and staining, and meets the strict hygiene requirements laid down by the food processing industry. The two types available are Grey food belting and Salmon pink belting

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 4 of 33

Endless Belting

The complete XT range can be made available as factory spliced endless belts. These belts are recommended for short conveyor installations. (Suitable for lengths up to 50 in.)

Flinger Belts

Flinger Belts are fitted to flinger conveyors, the primary function of which is to disperse the discharging material over a wide area, thus minimising heap build-up below the main conveyor. The flinging effect is achieved by running the flinger belt at a high speed in a U configuration. Flinger belts are built and cured on a drum to eliminate a spliced join.

Solid Woven (PVC) Belting (conforms to SABS 971-1980)

Commonly known as 'Vinyplast' solid woven PVC. The construction has inherently high fastener holding qualities. The belting is constructed of polyester and nylon with a cotton armouring, is impregnated with PVC and has PVC covers. These belts have been specially developed to resist impact, tear, rot and abrasion and to meet the most stringent flame-resistant standards.

Nitrile Covered (PVC) Belting

The nitrile cover on solid woven PVC belts is specially designed to meet the SABS specifications for use in mines, where a fire hazard exists. In general the nitrile cover has good flame-retardant properties and oil, abrasion and heat resistance.

Steelcord Belting (conforms to SABS 1366-1982)

Steelcord conveyor belting is designed for very long hauls where textile reinforcement would either not achieve the requisite strength or would have too high an elongation at reference load. Resistance to severe shock and exceptional tensile loading is achieved by the wire reinforcement encased between thick top and bottom covers of the highest quality rubber. These belts are designed to conform to or exceed the requirements of stringent standards and offer a long belt life.

Fire Resistant Steelcord Belting (Conforms to SABS 1366. 1982 type F).

Steelcord belting of fire-resistant quality is made with specially compounded rubbers which render it self extinguishing. Fireresistant steelcord belting offers great advantages in maintenance-free operation and long belt life for conveyors situated in fiery mines.

Oil Resistant Belting

Oil resistant belting provides easily cleanable covers of either nitrile or neoprene on all-synthetic fabric plies. Choice of covers gives maximum resistance to mineral and vegetable oils thus permitting the user to convey a wide variety of materials containing mineral and vegetable oils.

ADDITIONAL FEATURES

1.

Rip Protector As an additional feature rip protection can be incorporated into the belt by means of arranging strong nylon fibres transversely or by inclusion of electronic loops. The textile rip protection can be built into the belt in 2-metre lengths at regular intervals or over the full length of the belt.

2.

Shuron Breaker Ply (XT belting) For applications where the lump size of the material carried is large and where adverse loading conditions exist, an open weave breaker ply can be incorporated below the top cover as an extra protection for the carcass.

3.

Chevron Breaker (XT belting) This incorporates steel tyre cord in a 'V shape, as a rip protection, at intervals over the belt length. Particularly recommended for XT belting where arduous conditions are experienced i.e. slag transportation.

4.

Belt Edges Many conveyor belts track off at some stage of their lives, causing edge damage to a greater or lesser extent. Belts can be supplied with either slit or moulded edges. Slit edges: All-synthetic constructed carcasses have good resistance to edge chafing, due to modern fibre construction In addition there is minimal penetration of moisture to the carcass and therefore no problem with carrying out hot vulcanised splices or repairs.

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 5 of 33

Moulded edges: A moulded rubber edge can be provided to protect the carcass from acids, chemicals and oils. In most applications a moulded edge is unnecessary as synthetic fibres will not rot or be degraded by mildew.

SABS SPECIFICATIONS

Dunlop Africa Industrial Products conveyor belting complies with the stringent standards as laid down by the SABS.

1. 2. 3.

SABS 1173-1977 - General purpose textile reinforced conveyor belting. SABS 971-1980 - Fire-resistant textile reinforced conveyor belting. SABS 1366-1 982- Steelcord reinforced conveyor belting.

The above specifications cover the requirements of the various conveyor belts and are classified according to the minimum full thickness breaking strength of the finished belting in kilonewtons per metre width.

Further information regarding SABS specifications will be supplied on request.

CONVEYOR BELT DESIGN

Introduction

A conveyor belt comprises two main components:

1. 2.

Reinforcement or a carcass which provides the tensile strength of the belt, imparts rigidity for load support and provides a means of joining the belt. An elastometric cover which protects the carcass against damage from the material being conveyed and provides a satisfactory surface for transmitting the drive power to the carcass.

In selecting the most suitable belt for a particular application, several factors have to be considered:

1. 2.

The tensile strength of the belt carcass must be adequate to transmit the power required in conveying the material over the distance involved. The belt carcass selected must have the characteristics necessary to: a. b. c. provide load support for the duty. conform to the contour of the troughing idlers when empty, and flex satisfactorily around the pulleys used on the conveyor installation.

3.

The quality and gauge of cover material must be suitable to withstand the physical and chemical effects of the material conveyed.

Belt Tensions

In order to calculate the maximum belt tension and hence the strength of belt that is required, it is first necessary to calculate the effective tension. This is the force required to move the conveyor and the load it is conveying at constant speed. Since the calculation of effective tension is based on a constant speed conveyor, the forces required to move the conveyor and material are only those to overcome frictional resistance and gravitational force.

Mass of Moving Parts

For the sake of simplicity the conveyor is considered to be made up of interconnected unit length components all of equal mass. The mass of each of these units is called the mass of the moving parts and is calculated by adding the total mass of the belting, the rotating mass of all the carrying and return idlers and the rotating mass of all pulleys. This total is divided by the horizontal length of the conveyor to get the mean mass of all the components. At the outset the belt idlers and pulleys have not been selected and hence no mass for these components can be determined. Therefore the mass of the moving parts is selected from the tabulated values to be found in Table 10.

Mass of the load per unit length

As is the case with the components the load that is conveyed is considered to be evenly distributed along the length of the conveyor. Given the peak capacity in ton per hour the mass of the load per unit length is given by:

Q = 0,278

or

Q=

3,600S

The effective tension is made up of 4 components

z z z z

The tension to move the empty belt Tx The tension to move the load horizontally Ty The tension to raise or lower the load Tz The tension to overcome the resistance of accessories Tu

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 6 of 33

The effective tension is the sum of these four components

Te = Tx + Ty + Tz +Tu

Tx = 9,8G x fx x Lc

Tz = 9,8Q x H Various conveyor accessories that add resistance to belt movement are standard on most conveyors. The most common are skirtboards at the loading point and belt scrapers. Other accessories include movable trippers and belt plows.

Tension required to overcome the resistance of skirtboards Tus

Tus =

9,8fs x Q x Ls S x b

Tension to overcome the resistance of scrapers

Tuc = A x x fc

In the case of a belt plow the additional tension required to overcome the resistance of each plow is

Tup = 1,5W Moving trippers require additional pulleys in the system and therefore add tension. If the mass of the additional pulleys has been included in the mass of moving parts then no additional tension is added. However, if a separate calculation of the tension to overcome the resistance of the additional pulleys is required this can be determined for each additional pulley as follows

Tut = 0,01

do x T 1 Dt

Corrected length Lc Short conveyors require relatively more force to overcome frictional resistance than longer conveyors and therefore an adjustment is made to the length of the conveyor used in determining the effective tension. The adjusted length is always greater than the actual horizontal length.

LC = L + 70

The length correction factor is

C=

Lc L

All conveyors require an additional tension in the belt to enable the drive pulley to transmit the effective tension into the belt without slipping. This tension, termed the slack side tension T2, is induced by the take-up system. In the case of a simple horizontal conveyor the maximum belt tension T1 is the sum of the effective tension Te and the slack side tension T2

ie: T1 = Te + T2

T1 is the tight side tension and 12 is the slack side tension For a more complex conveyor profile that is inclined, additional tensions are induced due to the mass of the belt on the slope. This tension is termed the slope tension 'h and increases the total tension.

Thus T1 = Te + T2 + Th

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 7 of 33

The slack side tension is determined by consideration of two conditions that must be met in any conveyor. The first condition is that there must be sufficient tension on the slack side to prevent belt slip on the drive. The second condition is that there must be sufficient tension to prevent excessive sag between the carrying idlers.

Minimum tension to prevent slip Tm

At the point of slipping the relationship between T1 and T2 is

T1 T2

= e

Since T1 = Te + T2

T2 =

1 e - 1

Te

The expression

1 e - 1

is called the drive factor k. and the value of T2 that will just prevent slip is referred to as the minimum to prevent slip Tm and therefore

Tm = k x T e

Minimum tension to limit belt sag Ts The tension required to limit sag is dependent on the combined mass of belt and load, the spacing of the carry idlers and the amount of sag that is permissable.

Ts = 9,8Sf x (B + Q) x ld

The value of the slack side tension must ensure that both conditions are met and therefore T2 must be the larger of Tm or Ts.

Slope tension Th

The slope tension is the product of the belt weight and the vertical lift and has its maximum value at the highest point of the conveyor.

Th = 9,8B x H

Unit tension T

The maximum belt tension T1 has as its reference width the full width of the belt. Usually this is converted to the tension per unit of belt width as this is the reference dimension for belt strengths.

T=

T1 W

Absorbed power

The amount of power required by the conveyor is by definition of power equal to the product of the force applied and the speed at which the conveyor belt travels. The force applied is the effective tension and hence the power required at the shaft of the drive pulley/s is

P = Te x S

STEP BY STEP EXAMPLE OF BELT TENSION CALCULATION

As an example of the application of the formulae the belt tensions for the following conveyor will be determined:

Belt width Conveyor Length Lift

900 mm 250 m 20 m

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 8 of 33

Capacity Belt speed Material conveyed Drive Take-up Idler spacing Idler roll diameter

400 t/hr 1,4 m/s ROM coal 210 degree wrap. Lagged drive pulley. Gravity 1,2 m 127 mm

1. Determine mass of the load per unit length

Q= =

0,278

0,278 x 400 1,4

= 79,4 kg/m 2. Look up the value of the mass of moving parts in Table 10. From the idler roll diameter and the nature of the material conveyed the application is considered as medium duty. For a 900 mm wide belt the mass of moving parts from Table 10 is 55 kg/m 3. Calculate the corrected length and the length correction factor.

LC = L + 70 = 250 + 70 = 320 m C= = LC L 320 250

= 1,28 4. Tension to move the empty belt.

TX = 9,8G x fX x LC = 9,8 x 55 x 0,022 x 320 = 3794 N 5. Tension to move the load horizontally.

TX = 9,8Q x fY x LC = 9,8 x 79,4 x 0,027 x 320 = 6723 N 6. Tension to lift the load.

TZ = 9,8Q x H = 9,8 x 79,4 x 20 = 15562 N 7. No accessories are present and therefore the tension to overcome the resistance of accessories is zero. 8. Effective tension.

Te = T X + T Y + T Z + T U = 3794 + 6723 + 15562 + 0 = 26079 N 9. The absorbed power

P = Te x S = 26079 x 1,4 = 36511W 10. The slack side tension. Slack side tension to prevent slip. The drive factor for 210 degree wrap and lagged pulley with a gravity take-up, as given in Table 11, is 0,38.

Tm = k x T e = 0,38 x 36079 = 9910 N

Slack side tension to limit sag to 2%. The sag factor for 2% sag is 6,3 and the estimated belt mass for a medium load and 900 mm belt width, as given in Table 8, is 11,1kg/m.

TS = 9,8Sf (B + Q) x ld = 9,8 x 6,3 x (11,1 + 79,4) x 1,2

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 9 of 33

= 6705 N

The required slack side tension is the larger of Tm or TS and hence T2 = 9910 N 11. Slope tension using the estimated belt mass found in Table 8 for medium load and 900 mm belt width is:

Th = 9,8B x H = 9,8 x 11,1 x 20 = 2176 N 12. The maximum belt tension

T 1 = Te + T 2 + T h = 26079 + 9910 + 2176 = 38165 N

The maximum belt tension is converted to the unit tension. Effective tension.

T=

T1

W

38165 900

= 42,4 N/mm = 42,4 kN/m

TABLE 1 TABLE OF SYMBOLS

Symbols A B b Bc C D Dt do fc fs fx fy G H ld k L Lc Ls P Q S

Description Contact area of scraper blade Belt mass per unit length Width between skirtplates Edge Distance Length correction coefficient Material Density Diameter of pulley t Diameter of pulley bearings Friction coefficient for scrapers Friction coefficient for skirtboards Friction coefficient for empty belt Friction coefficient for loaded belt Mass of moving parts Change in elevation along conveyor length Idler spacing (carry idlers) Drive factor Horizontal length of conveyor Corrected length of conveyor Length of skirtboard Absorbed power Mass of load per unit length Belt Speed

Unit m2 kg/m m mm

Symbol Sf T T1 T2 Te Sag factor Unit tension

Description

Unit

kN/m N N N N N N N N N N N N mm

Maximum belt tension across full belt width Slack side tension Effective tension Slope tension Minimum tension to prevent slip Minimum tension to limit sag Tension induced in overcoming resistance of accessories Tension to overcome resistance of scrapers Tension to overcome resistance of skirtboards Tension to move the empty belt Tension to move the load horizontally Tension to lift (or lower) the load Belt width Coefficient of friction between belt and drive pulley Angle of wrap on the drive radians Pressure of scraper on the belt Belt capacity expressed in ton per hour Trough angle Material surcharge angle

kg/m3 mm mm

Th Tm Ts Tu Tuc Tus Tx

kg/m m m

Ty Tz W

m m m W kg/m m/s

radians N/m2 t/hr degree degree

TABLE 2 MATERIAL CHARACTERISTICS

Material

Characteristics

Suggested Grade

Bulk Angle of Max. Rec. Density Surcharge Conv. Slope (t/m3) (degrees) (degrees)

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 10 of 33

Acid phosphate Alum Alumina Aluminium sulphate Ammonium chloride Ammonium nitrate Ammonium sulphate, granular Asbestos ore or rock Asbestos shred Ashes, coal, dry Ashes, coal, wet Ashes, fly Ashes, gas producer, wet Asphalt Bagasse Bark, wood, refuse Barley Barytes, powdered Bauxite, ground, dry Bauxite, mine run Bauxite, crushed, 75mm Beans Beet, pulp, dry Beet, pulp, wet Beets, whole Borax Bran Brewers grain, spent, dry Brewers grain, spent, wet Brick Calcium carbide Carbon black, pelletised Carborundum 75mm Cashew nuts Cement, portland Cement, portland, aerated Cement clinker Chalk, lumpy Chalk, 100 mesh and under Charcoal Chrome ore Cinders, blast furnace Cinder, coal Clay, calcined Clay, dry, fines Clay, dry, lumpy Coal, anthracite, 3mm and under Coal, anthracite, sized Coal, bituminous, mined 50 mesh and under Coal, bituminous, mined and sized Coal, bituminous, mined, run of mine Coal, bituminous, mined, slack 12mm and under Coal, lignite Cocoa beans Coke, loose Coke, petroleum, calcined

MA NA MA NA MA MA MA VA MA MA MA MA MA NA NA NA NA MA VA VA VA NA NA NA NA MA NA NA NA VA MA MA VA MA NA NA MA MA MA MA HA/S MA MA MA MA VA NA NA NA NA MA MA MA NA VA VA

N N N N N N N N/M N N N N N N N/PHR N N/GF N N/M N/M N/M N/GF N/GF N/GF N/GF N N/GF N/GF N/GF N/M N N N/M N/GF N/PHR N/PHR N/DHR N N N N N/M N N N N N/PVC N/PVC N/PVC N/PVC N/PVC N/PVC N/PVC N/GF N/M N/M

0,96 0,80 0,90 0,90 0,80 0,70 0,80 1,30 0,37 0,60 0,75 0,70 1,20 1,30 0,13 0,24 0,60 2,10 1,10 1,36 1,30 0,70 0,22 0,60 0,76 0,90 0,30 0,45 0,90 1,76 1,20 0,35 1,60 0,56 1,50 1,06 1,36 1,30 1,10 0,35 2,10 0,90 0,65 1,44 1,76 1,10 0,96 0,90 0,83 0,80 0,90 0,75 0,75 0,56 0,48 0,64

10 25 10 20 10 25 10 20 30 25 25 30 30 30 30 30 10 10 20 20 20 5 30 30 20 20 10 30 30 30 20 5 10 30 25 5 25 10 25 25 10 10 20 25 20 20 20 10 30 20 25 25 25 10 30 20

13 22 12 17 10 23 10 18 30 23 25 23 28 30 30 27 12 15 18 17 20 7 25 25 20 20 12 27 27 27 18 5 15 22 20 10 18 15 28 22 17 18 20 22 22 20 18 16 24 16 18 22 22 12 18 20

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 11 of 33

Coke, breeze, 6mm and under Concrete, 100mm lumps Concrete wet Copper ore Copper sulphate Corn, ear Corn, shelled Cornmeal Cottonseed cake Gullet Dolomite Earth, as dug, dry Earth, wet, with clay Feldspar Flaxseed Flour, wheat Fluorspar Foundry sand, old sand cores etc. Fullers earth, dry Fullers earth, oily Glass batch Grain, distillery, spent dry Granite, broken, 75mm lumps Graphite, flake Gravel, bank run Gravel, dry, sharp Gravel, pebbles Gypsum, dust, not-aerated Gypsum, dust, aerated Gypsum, 12mm screened Gypsum, 75mm lumps Illmenite ore Iron ore, coarse crushed Iron ore, crushed fine Kaolin clay, 75mm and under Lead ores Lead oxide, heavy Lead oxide, light Lignite, air dried Lime, ground, 3mm and under Lime, hydrated Lime, pebble Limestone, agricultural 3mm and under Limestone, crushed Linseed cake Linseed meal Litharge, pulverized (lead oxide) Magnesium chloride Magnesium sulphate Manganese ore

VA VA VA VA VA NA NA NA NA HA/S VA VA MA VA MA NA MA VA MA MA HA/S NA VA NA VA VA VA MA MA MA MA MA VA VA MA MA MA MA MA NA NA MA MA MA NA NA MA MA MA VA

N/M N/M N/M N/M N/M N/GF N/GF N/GF N/GF M N/M N/M N N/M O N/GF N M/PHR N O M N/GF N/M N N/M N/M N/M N N N N N N/M N/M N N N N N N N N N N OR/PVC OR/PVC N N N N/M

0,48 2,10 2,20 2,17 1,30 0,90 0,70 0,65 0,67 1,60 1,60 1,20 1,70 1,44 0,70 0,60 1,70 1,36 0,50 1,00 1,44 0,48 1,44 0,65 1,52 1,52 1,52 1,50 1,04 1,20 1,20 2,40 3,00 3,50 1,00 3,80 2,40 1,20 0,80 1,00 0,60 0,90 1,10 1,40 0,80 0,43 3,60 0,53 1,10 2,15

20 10 24 20 20 25 10 20 20 20 18 20 30 25 10 30 30 25 10 20 10 10 10 10 25 20 10 20 30 25 10 10 20 20 20 10 25 25 10 30 25 10 10 25 20 20 10 30 10 25

22 18 18 20 17 18 10 22 20 20 20 20 23 17 12 21 20 20 15 20 22 15 18 15 20 16 12 20 23 21 15 18 18 18 19 15 20 20 18 23 21 17 20 18 15 20 15 23 15 20

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 12 of 33

Manganese sulphate Marble, crushed 12mm and under Mica, ground Mica, pulverized Mica, flakes Molybdenite, powdered Mortar, wet Nickel-cobalt Oats Peanuts in shells Peanuts, shelled Peas, dried Phosphate, triple super ground fertilizer Phosphate rock, broken, dry Phosphate rock, pulverized Potash ore Pumice, 3 mm and under Pyrites, iron, 50 - 75mm in lumps Pyrites, pellets Quartz Rice Rock, crushed Rubber, pelletised Rubber, reclaim Rye Salt, common dry, coarse Salt, common dry, fine Sand, bank, damp Sand, bank, dry Sand, foundry, prepared Sand, foundry, shakeout Sand, Silica, dry Sand, core Sandstone, broken Sawdust Shale, broken Shale, crushed Sinter Slag, blast furnace, crushed Slag, furnace, granular, dry Slag, furnace, granular, wet Slate Soap, beads or granules Soap, chips Soda ash, briquettes Soda ash, heavy Soda ash, light Sodium nitrate Sodium phosphate Soyabeans, cracked

MA VA MA MA MA MA VA VA NA NA NA NA MA VA VA MA MA VA VA HA/S NA HA/S MA NA NA MA MA VA VA VA VA VA VA VA NA MA MA VA VA VA VA MA NA NA MA MA MA MA MA NA

N N/M N N N N N/M N/M GF/PVC N GF/PVC GF/PVC N/OR/PVC N/M N/M N N N/M N/M N/M GF/PVC N/M N N GF/PVC N/GF/PVC GF/PVC N/M N/M N/M N/M/PHR N/M N/M N/M N/OR/PVC/W N N N/M/PHR M/PHR/DHR M/PHR/DHR N/M N N/PVC N/PVC N N N N N GF/PVC

1,10 1,40 0,22 0,22 0,32 1,70 2,20 1,80 0,42 0,27 0,65 0,75 0,80 2,00 2,10 1,30 0,67 2,25 2,00 1,36 0,65 2,15 0,80 0,45 0,70 0,75 1,20 1,90 1,60 1,36 1,50 1,50 1,04 1,44 0,20 1,50 1,40 1,80 1,36 1,00 1,50 1,36 0,32 0,32 0,80 0,96 0,43 1,20 0,90 0,56

10 10 20 10 5 20 24 10 10 10 10 5 20 20 25 10 30 20 10 10 5 20 20 20 10 10 10 30 20 30 25 10 25 20 25 10 25 10 10 10 30 20 10 10 10 20 25 10 10 20

15 15 23 15 8 25 18 20 10 8 8 8 18 18 18 15 22 17 15 15 8 18 22 18 8 20 11 22 18 24 22 12 26 20 22 18 22 15 10 15 22 18 12 18 7 18 22 11 16 18

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 13 of 33

Soyabeans, whole Starch Steel trimmings Sugar, granulated Sugar, raw, cane Sulphate powdered Talc, powdered Titanium ore Titanium sponge Traprock Triple super phosphate Vermiculite, expanded Vermiculite, ore Walnut shells, crushed Wheat Woodchips Zinc ore, crushed Zinc ore, roasted

NA NA HA/S NA MA MA NA VA MA VA MA MA MA NA NA NA HA/S HA/S

GF/PVC GF M GF N N N N/M N N/M N/OR/PVC N N GF N/GF/PVC OR/W M SPHR/DHR

0,77 0,60 2,40 0,83 0,96 0,90 0,90 2,40 1,04 1,60 0,80 0,25 1,20 0,65 0,77 0,32 2,60 1,76

10 10 20 10 20 10 10 10 30 20 20 20 20 20 10 30 25 25

14 12 18 15 22 21 12 18 25 18 18 23 20 20 12 27 22 25

Characteristics

Key: HA/S - Highly abrasive/sharp MA - Mildly abrasive NA - Non-abrasive VA - Very abrasive

Cover Grade

Code: N - SASS 1173 NH polyisoprine M - Higher natural rubber content SASS 1173 OR - Oil resistant GF - Grey Food PHR - Phoenix Heat Resistant SPHR - Super Phoenix heat resistant W - Wood master DHR - Delta Hete heat resistant PVC - Polyvinylchloride FR - Fire resistant SASS 971

TABLE 2(a) TYPICAL FLOWABILITY

Angle of Angle of Material Characteristics Surcharge Repose 5 10 20 25 30 0 - 19 Uniform Size

20 - 29 Rounded, dry ,medium weight 30 - 34 Granular lumpy (Coal, Clay) 35 - 39 Coal, stone, ores 40 - 45 Irregular (wood chips)

Determination of Conveyor Capacities

The capacity of a troughed belt is a function of:

1. 2. 3.

The cross sectional area of the load which can be carried without spillage. The belt speed. The material density.

The cross sectional area is influenced by many factors including the flowability of the material, the angle of surcharge and the incline angle

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 14 of 33

at the load point of the conveyor. To achieve optimum load area the loading chutes must be designed to ensure the most advantageous initial load shape and this can only be achieved if:

1. 2. 3.

The load is placed centrally on the belt. The material is delivered in the direction of belt travel and at a speed approaching that of the belt. The angle of incline at the load area must be less than 1 ~O,

To ensure that the optimum load shape is maintained along the entire belt length:

1. 2. 3. 4.

The idler pitch should be such as to limit sag to acceptable levels. The belt must be trained properly. The lump size in relation to belt width must be within the recommended limits. The belt must give adequate support to the load.

Under ideal conditions the cross sectional load area is:

At = (Ab + As) / 106

Where

Ab = (0,371W + 6,3 + M x cos) (M x sin)

As =

0,186W + 3,2 + M x cos sin

)2 (

180

sin2 2

M = 0,3145W - 3,2 - Bc W - Belt width (mm) Bc- Edge distance (mm) - Iroughing angle (degree) - Material surcharge angle (degree) At - Cross sectional load area (m2) The belt capacity in ton/hour is Capacity = 3,6At x D x S

Where

D - Material Density (kg/m3) S - Belt speed (m/s)

TABLE 3 CAPACITIES OF TROUGHED BELT CONVEYORS IN TON/HOUR

Recommended Belt Max. Lump Size Trough Area of Load Width Angle Sized Unsized Degrees mm m2 mm mm 600 125 200 20 27 30 35 45 750 150 250 20 27 30 35 45 900 175 300 20 0,033 0,037 0,038 0,040 0,042 0,054 0,060 0,062 0,065 0,068 0,080

Speed m/s 0,5 59 66 69 72 76 97 109 112 117 122 144 0,8 95 106 110 115 121 156 173 179 187 196 230 1,2 142 160 164 173 181 233 259 268 281 294 346 1,6 190 213 218 230 242 311 346 357 375 392 461 2,0 236 266 274 288 303 389 432 446 468 490 576 2,5 297 333 342 360 378 486 540 558 585 612 720 3,0 357 400 410 432 436 583 648 670 702 734 864

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 15 of 33

27 30 35 45 1050 200 350 20 27 30 35 45 1200 250 400 20 27 30 35 45 1350 275 500 20 27 30 35 45 1500 300 600 20 27 30 35 45 1650 350 700 20 27 30 35 45 1800 350 700 20 27 30 35 45 2100 350 700 20 27 30 35 45 2200 350 700 20 27 30 35 45

0,090 0,092 0,096 0,101 0,111 0,124 0,128 0,134 0,140 0,147 0,165 0,170 0,178 0,186 0,189 0,211 0,217 0,227 0,238 0,235 0,263 0,271 0,283 0,296 0,286 0,321 0,330 0,345 0,361 0,343 0,384 0,395 0,413 0,432 0,472 0,528 0,543 0,568 0,594 0,519 0,581 0,598 0,625 0,654

162 166 173 182 200 223 230 241 252 265 297 306 320 335 340 380 391 409 428 423 473 488 509 533 515 578 594 621 650 617 691 711 743 778 850 950 977

259 265 276 291 320 357 369 386 403 423 475 490 513 536 544 608 625 654 685 676 757 780 815 852 824 924 950 994

389 397 415 436 480 536 553 579 605 635 713 734 769 804 816 912 937 981

518 530 553 582 639 714 737 772 806 847 950 979

648 662 691 727 799 839 922 965

810 828 864 909

972 994 1037 1091

1000 1199 1116 1339 1152 1382 1206 1447

1008 1260 1512 1058 1323 1588 1188 1485 1782 1224 1530 1836

1025 1282 1602 1922 1071 1339 1674 2009 1089 1361 1701 2041 1215 1519 1899 2279 1250 1562 1953 2344 1308 1634 2043 2452

1028 1371 1714 2142 2570 1015 1357 1692 2115 2538 1136 1515 1894 2367 2840 1171 1561 1951 2439 2927 1223 1630 2038 2547 3056 1279 1905 2131 2664 3197 1236 1649 2059 2574 3089 1387 1849 2311 2889 3467 1426 1901 2367 2970 3564 1490 1987 2484 3105 3726

1040 1560 2079 2599 3249 3899 988 1482 1976 2470 3087 3704

1106 1659 2212 2765 3456 4147 1138 1706 2275 2844 3555 4266 1189 1784 2379 2976 3717 4460 1244 1866 2488 3110 3888 4666 1359 2039 2719 3398 4248 5098 1521 2281 3041 3802 4752 5702 1564 2346 3128 3910 4887 5864

1022 1636 2454 3272 4090 5112 6134 1069 1711 2566 3421 4277 5346 6415 934 1495 2245 2989 3737 4671 6505

1046 1673 2510 3347 4183 5229 6275 1076 1722 2583 3444 4306 5382 6458 1125 1800 2700 3600 4500 5625 6750 1161 1858 2786 3715 4644 5805 6966

TABLE 4 RECOMMENDED MAXIMUM BELT SPEEDS FOR NORMAL USE (METRES PER SECOND)*

Belt Width (mm) 300 400 500 600 750 900 1050 1200 1350 1500 1800

Grain or Other Run of Mine Hard Ores and Stone Free Flowing Material Coal and Earth + Primary Crushed ++ 2,5 2,5 3,0 3,0 3,6 4,0 4,0 4,6 5,0 5,0 1,5 2,0 2,0 2,5 3,0 3,3 3,6 3,6 3,6 3,6 4,0 1,5 1,8 1,8 2,3 2,8 3,0 3,0 3,3 3,3 3,3 3,8

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 16 of 33

2000 and over

4,0

3,8

* These speeds are intended as guides to general practice and are not absolute. + Moderately abrasive materials. ++ Very abrasive materials.

Note: In the case of belts loaded on inclines of 100 or more it may be necessary to reduce the above speeds in order to achieve maximum capacity.

TABLE 5 RECOMMENDED IDLER SPACING

Troughing Idler - (m) Belt Width (mm) 450 600 750 900 1050 1200 1350 1500 1650 1800 Bulk Density of Material (t/m3) 0,5 0,8 1,2 1,6 2,0 2,5 3,0 1,5 1,5 1,5 1,4 1,2 1,2 1,2 1,2 1,2 1,2 1,5 1,5 1,4 1,4 1,2 1,2 1,0 1,0 1,0 1,0 1,0 1,5 1,5 1,4 1,2 1,0 1,0 1,0 1,0 1,0 1,0 0,9 1,4 1,4 1,2 1,2 1,0 1,0 1,0 1,0 0,9 0,9 0,9 1,4 1,4 1,2 1,0 1,0 1,0 0,9 0,9 0,9 0,9 0,9 1,4 1,2 1,2 1,0 1,0 0,9 0,9 0,9 0,9 0,9 0,8 1,4 1,2 1,0 1,0 0,9 0,9 0,9 0,9 0,9 0,8 0,8 3 3 3 3 3 3 3 3 3 3 3 Return Idlers (m)

2000 and over 1,0

TABLE 6 FRICTION FACTORS

Value of the friction factor Very well aligned Normal operating Normal operating structure with no conditions. conditions. tilted idlers etc. Regenerative Horizontal length Horizontal length Horizontal length conveyor. up to more than more than 250 meters. 250 meters. 500 meters. 0,600 0,650 0,022 0,027 0,600 0,650 0,020 0,022 0,600 0,650 0,020 0,020 0,600 0,650 0,018 0,018

Symbol

Description

fC fS fX fY

Friction coefficient for scrapers Friction coefficient for skirtboards Friction coefficient for empty belt Friction coefficient for loaded belt

TABLE 7 SAG FACTOR

Percentage Sag Factor Sag Sf 3% 2% 1,5% 4,2 6,3 8,4

TABLE 7(a) RECOMMENDED PERCENTAGE SAG

Trough Angle Fine Lumps up to Max Lump Material max lump size (degree) Size 20 35 45 3% 3% 3% 3% 2% 2% 3% 2% 1,5%

TABLE 8 ESTIMATED BELT MASS B

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 17 of 33

Operating Conditions Belt Width Light Duty Medium Duty Heavy Duty (mm) (kg/m) (kg/m) (kg/m) 500 600 750 900 1050 1200 1350 1500 1650 1800 2100 2200 4,1 5,0 6,2 7,4 8,6 9,8 11,0 12,3 13,5 14,7 17,2 18,0 6,2 7,4 9,3 11,1 13,0 14,8 16,7 18,6 20,5 22,3 26,0 27,3 10,3 12,3 15,5 18,5 21,6 24,7 27,8 30,9 33,9 37,0 43,3 45,3

Note:

The values given in the table are estimated values for use in the calculation of maximum belt operating tension necessary to make the correct belt selection. When the belt specification has been determined, the mass should be checked more accurately from Table 17. If the actual mass of the specification differs considerably from the approximate value obtained from the table the tension calculation should be rechecked using the more accurate belt mass.

TABLE 9 TYPICAL MASS OF ROTATING PARTS OF IDLERS (kg/m)

3 Roll Carry Idlers Belt Width 102 450 500 600 750 900 1050 1200 1350 1500 1650 1800 2100 2200 2400 8,0 8,5 9,5 11,0 12,5 14,0 15,5 17,0 18,5 20,0 21,6 24,6 25,6 27,6 Roll Dia 127 10,5 11,1 12,4 14,2 16,1 18,0 19,9 21,8 23,6 25,5 27,4 31,2 32,4 34,9 152 13,1 13,9 15,4 17,6 19,9 22,2 24,4 26,6 28,9 31,2 33,4 37,9 39,4 42,4

Return Idlers Roll Dia 102 127 152 6,0 6,5 7,5 9,0 7,7 8,4 9,6 9,4 10,1 11,6

3 Roll Impact Idlers Roll Dia 133 8,8 9,3 10,4 12,1 13,8 15,4 17,1 18,7 20,3 22,0 23,8 27,1 28,2 30,4 159 11,5 12,2 13,6 15,6 17,7 18,8 21,9 24,0 26,0 28,9 30,1 34,3 35,6 38,4

11,4 13,9

10,6 13,3 16,1 12,1 15,2 18,4 13,6 17,1 20,6 15,1 19,0 22,9 16,6 20,8 25,1 18,1 22,7 27,4 19,6 25,6 29,6 22,6 28,4 34,2 23,6 29,6 35,7 25,7 32,1 38,7

TABLE 10 MASS OF MOVING PARTS G

Mass of Moving Parts (kg/m) Belt Width Light Duty Medium Duty Heavy Duty Extra Heavy Duty (mm) 102mm Idlers 127mm Idlers 152mm Idlers 152mm Idlers Steel Cord Belt Light Belt Moderate Belt Heavy Belt 450 600 750 900 1050 1200 1350 1500 1650 1800 2100 2200 23 29 37 45 52 63 70 25 36 46 55 64 71 82 91 100 33 45 57 70 82 95 107 121 132 144 168 177 49 63 79 94 110 127 143 160 178 205 219

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 18 of 33

TABLE 11 DRIVE FACTOR k

Angle of Belt Wrap at Drive 150 160 170 180 190 200 210 220 230 240 340 360 380 400 420 440 460 480

Type of Drive Plain Plain Plain Plain Snubbed Snubbed Snubbed Snubbed Snubbed Snubbed Dual Dual Dual Dual Dual Dual Dual Dual

Screw Take-up Bare Lagged Pulley Pulley 1,5 1,4 1,3 1,2 1,1 1,0 1,0 0,9 0,9 0,8 0,5 0,5 0,5 0,5 0,4 1,0 0,9 0,9 0,8 0,7 0,7 0,7 0,6 0,6 0,6 0,4 0,4 0,3 0,3 0,3

Gravity or Automatic Winch Take-up Bare Pulley 1,08 0,99 0,91 0,84 0,77 0,72 0,67 0,62 0,58 0,54 0,29 0,26 0,23 0,21 0,19 0,17 0,15 0,14 Lagged Pulley 0,670 0,600 0,550 0,500 0,450 0,420 0,380 0,350 0,320 0,300 0,143 0,125 0,108 0,095 0,084 0,074 0,064 0,056

Notes:

1.

When calculating the driving tension required for dual drive units, the drive factor selected must correspond to the total angle of driving wrap. The drive factors quoted for gravity or automatic take-up systems are minimum values based on the relationship between angle of wrap and coefficient of friction between belt and drum at the point of slip. In the case of screw take-up units, an adjustment has been made to the drive factor to allow for the extra tension which may be induced in the belt either: a. to compensate for the effect of belt elongation when the material is loaded.

2.

b. 3.

due to the difficulty in measuring the amount of tension applied.

In those cases where an electrically or hydraulically loaded winch type take-up is used, where the induced tension can be preset and controlled, the drive factor should be selected to correspond with a gravity take-up system.

CONVEYOR BELT SELECTION

Belt carcass selection criteria In selecting the optimum belt construction for a given application it is necessary to consider the following:

Tensile strength The belt class required is that which has an operating tension greater than or equal to the calculated maximum unit tension T. (Table 12).

Load support Choose the lowest class which meets the tensile strength requirement. Looking at Table 14, determine which load category best describes the load being conveyed i.e. A, B, C, D or E category load. The value obtained at the intersection of the belt specification row and the load category column gives the maximum width at which that belt specification can be used.

Number of plies for troughability The maximum number of plies allowable, in order to ensure that the empty belt will conform to the contour of the troughing idlers, must be checked referring to Table 15. For a particular belt class the value shown at the intersection of the belt width column and troughing angle row, is the maximum number of plies that should be used.

Minimum pulley diameters If the size of the pulleys is already determined, the belt construction provisionally selected from the previous considerations can be checked against the relevant pulley diameters for suitability. For a new installation, the pulley diameters should be equal to or larger than those given in Table 13 (It should be noted that, in this context, the diameters quoted refer to the minimum pulleys around which the particular belt construction will flex satisfactorily. The conveyor designer should also take into account the gearbox ratio and required belt speed when selecting the drive pulley diameter.)

Gauge of covers required The correct gauge of cover necessary to give protection to the belt carcass from material impact and wear must be determined by consideration of the size and density of the material to be handled. (Table 19).

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 19 of 33

Additional Information

Belt modulus Refer to Table 20 for belt modulus.

Belt mass The mass of a particular belt construction can be determined by adding the carcass mass found in Table 17 to the combined mass of covers found in Table 18. This will give the mass per unit area. To calculate the mass per unit length multiply by the belt width in metres.

Belt thickness The belt thickness can be obtained from the information given in Table 16.

TABLE 12 MAXIMUM RECOMMENDED OPERATING TENSIONS

Textile Reinforced Multi-ply and Steelcord Reinforced Conveyor Belting Solid Woven Carcass Conveyor Belting Belt Class 160 200 250 315 400 500 630 800 1000 1250 1600 2000 Max recommended Operating Tension (kN/m) 16,0 20,0 25,0 31,5 40,0 50,0 63,0 80,0 100,0 125,0 160,0 200,0 St 500 St 630 St 800 St 1000 St 1250 St 1600 St 2000 St 2500 St 3150 St 4000 St 5000 St 6300 75,0 94,0 120,0 150,0 187,5 240,0 300,0 375,0 472,0 600,0 750,0 945,0 Belt Class Max recommended Operating Tension (kN/m)

TABLE 13 RECOMMENDED MINIMUM PULLEY DIAMETERS (mm)

Textile Reinforced Rubber Belting Belt Class Pulley Type 2 A 160 B C A 200 B C A 250 B C A 315 B C A 400 B C A 500 B C A 630 B C 315 250 200 315 250 200 315 250 200 315 250 200 400 315 250 500 400 315 500 400 315 400 315 250 400 315 250 500 400 315 500 400 315 630 500 400 630 500 400 630 500 400 630 500 400 630 500 400 800 630 500 400 315 250 400 315 250 500 400 315 500 400 315 No. of Plies 3 4 5 Solid Woven PVC Belting

Steelcord Reinforced Rubber Belting

500 400 315 500 400 315

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 20 of 33

A 800 B C A 1000 B C A 1250 B C A 1600 B C A 2000 B C A 2500 B C A 3150 B C A 4000 B C A 5000 B C A 6300 B C

630 500 400 630 500 400

800 630 500 800 630 500 1000 800 630 1000 800 630

800 630 500 1000 800 630 1000 800 630 1250 1000 800 1250 1000 800

800 630 500 1000 800 630 1250 1000 800 1250 1000 800 1400 1250 1000

500 400 315 630 500 400 800 630 500 1000 800 630 1000 800 630

500 400 315 500 400 315 630 500 400 800 630 500 800 630 500 1000 800 630 1250 1000 800 1250 1000 800 1400 1250 1000 1400 1250 1000

Pulley types A High tension pulleys Wrap exceeding 45 B Low tension pulleys Wrap exceeding 45 or High tension pulleys Wrap up to 45 C Low tension pulleys Wrap up to 45

Examples Head, drive & tripper Tail, take-up, Take-up bend High tension snub or bend pulleys Low tension snub or bend pulleys

TABLE 14 LOAD SUPPORT

Recommended maximum belt width (mm) for correct load support. Multi-ply textile reinforced rubber belting.

Belt Spec

A Light Duty Up to 800 - 25mm Lumps 750 750 900 1050 900 1200 1200 1200 1500 1200 1350 1650 1800 kg/m3

B Light to Medium Duty Up to 1200 - 50mm Lumps 600 600 750 900 900 1050 1050 1050 1500 1200 1200 1500 1800 kg/m3

C Medium Duty Up to 1600 - 100mm Lumps 500 600 750 750 750 1050 1050 1050 1350 1200 1200 1350 1800 kg/m3

D Heavy Duty Up to 2400 - 250mm Lumps 400 4500 600 600 600 750 900 900 900 1050 1050 1200 1500 kg/m3

E Extra Heavy Duty Up to 3000 kg/m3 + 250mm Lumps Not Recommended Not Recommended 500 600 500 600 750 750 750 900 900 900 1350

160/2 200/2 250/2 250/3 315/2 315/3 400/2 400/3 400/4 500/2 500/3 500/4 500/5

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 21 of 33

630/2 630/3 630/4 630/5 800/2 800/3 800/4 800/5 1000/2 1000/3 1000/4 1000/5 1250/3 1250/4 1250/5 1600/3 1600/4 1600/5 2000/4 2000/5

1200 1650 1650 2100 1650 1800 2100 2400 1800 2100 2400 2400 2100 2400 2400 2400 2400 2400 2400 2400

1200 1350 1500 2100 1500 1650 1800 2400 1650 1650 1800 2400 1800 2200 2400 2400 2400 2400 2400 2400

1200 1200 1350 1800 1500 1500 1650 2100 1500 1500 1800 2200 1800 2200 2400 1800 2200 2400 2400 2400

1050 1050 1200 1650 1350 1350 1500 1800 1350 1350 1500 1800 1350 1650 1800 1650 1800 2200 1800 2200

900 1050 1050 1350 1200 1200 1350 1500 1200 1200 1350 1500 1200 1500 1800 1650 1800 1800 1800 2100

TABLE 15 MAXIMUM NUMBER OF PLIES RECOMMENDED FOR CORRECT EMPTY BELT TROUGHING

Belt Width (mm) Belt Troughing Class 350 400 450 500 600 750 900 1050 1200 1350 1500 1650 1800 2100 2200 Angle 160 2 2 2 2 2 2 2 2 3 2 2 2 2 2 2 2 2 3 2 3 3 4 3 4 3 4 2 3 2 2 2 2 2 3 2 3 3 4 3 4 3 4 2 3 2 2 2 2 2 3 3 3 3 4 3 4 3 4 3 4 3 4 2 4 3 3 2 2 2 2 3 3 4 3 4 4 4 4 4 4 4 4 4 3 4 3 4 3 4 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 4 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 4 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 2 2 2 2 3 3 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 5 5 20 35 20 35 20 35 20 35 20 35 20 35 20 35 20 35 20 35 20 35 20 35 20 35

200

250

315

400

500

630

800

1000

1250

1600

2000

TABLE 16 CARCASS THICKNESS (mm)

Belt Class 160 200 250 315

Textile Reinforced Rubber Belting Solid Woven Steelcord Reinforced No. of Plies PVC Belting Rubber Belting 2 3 4 5 2,0 2,6 2,7 2,8 3,2 3,5 4,9

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 22 of 33

400 500 630 800 1000 1250 1600 2000 2500 3150 4000 5000 6300

3,0 4,0 4,3 5,0 5,7

3,8 4,2 5,2 6,0 6,5 8,4 9,5

5,0 5,2 5,8 6,9 7,6 9,6 10,5 12,0 5,9 6,6 7,2 8,5 10,0 11,0 13,0 5,9 6,2 6,9 7,4 8,4 9,9 12,4 3,2 3,2 3,7 3,7 3,7 5,4 5,4 7,0 8,0 9,0 11,0 12,0

Add the thickness of the covers to get the total belt thickness

TABLE 17 MASS OF BELT CARCASS (kg/m2)

Belt Class

Textile Reinforced Rubber Belting No. of Plies 2 3 4 5

Solid Woven PVC Belting Steelcord Reinforced With Nominal Rubber Belting PVC Coating

160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 3150 4000 5000 6300

2,8 3,0 3,1 3,4 3,7 4,3 4,8 5,6 6,5 3,9 4,2 4,4 4,8 5,2 6,4 7,3 8,9 10,7 6,0 6,4 6,8 7,2 8,5 9,7 11,5 14,2 7,5 8,0 8,5 9,0 10,5 12,5 14,9 9,0 9,4 9,7 10,5 11,0 11,7 13,0 15,0 18,0 7,5 7,7 8,2 9,0 9,7 13,4 15,3 18,7 22,4 28,4 35,1 38,7

To obtain total belt mass add the mass of the combined covers from Table 18. The mass per unit length is determined by multiplying the total mass by the belt width in metres.

TABLE 18 MASS OF COVERS PER mm OF THICKNESS (kg/m 2)

Grade of Cover N M OR GF FR

Mass (kg/m2) 1,14 1,10 1,41 1,37 1,27

Grade of Cover PHR SPHR DHR PVC Nitrile

Mass (kg/m2) 1,17 1,21 1,34 1,37 1,32

RATE OF WEAR VS THICKNESS OF COVER

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 23 of 33

The rate at which a belt cover wears is related to the thickness of the cover and to the impact energy imparted by material lumps.

Impact energy can be calculated for any material of known lump mass and vertical velocity.

- x v J - Impact Energy (J) - Mass of lump (kg) v - Verticle velocity (m/s)

TABLE 19 MINIMUM BELT TOP COVER GAUGE GUIDE

Material Class A

Material Class B

Material Class C

Material Class D

Non abrasive material Abrasive material Very abrasive material Very sharp abrasive material such as lime, charcoal, such as salt, anthracite such as slag, copper ore, such as quartz, some ores, Cycle wood chips, bituminous coal, phosphate rock, foundry refuse, glass batch, sinter, coke sand, time iron borings limestone, fullers earth flue dust coal grain s Lump size (mm) Lump size (mm) Lump size (mm) Lump size (mm) dust to 12 12 25 40 60 90 120 180 240+ 2,0 2,0 1,0 1,0 1,0 1,0 1,0 1,0 12 to 50 3,0 2,5 2,5 2,5 2,5 2,5 2,5 2,5 50 to 150 6,0 3,0 3,0 3,0 3,0 3,0 3,0 3,0 150 and over 8,0 5,0 5,0 5,0 5,0 5,0 5,0 5,0 dust to 12 3,0 2,5 2,5 2,5 2,5 2,5 2,5 2,0 12 to 50 6,0 3,0 3,0 3,0 3,0 3,0 3,0 3,0 50 to 150 10,0 6,0 4,0 4,0 4,0 4,0 4,0 4,0 150 and over 10,0 10,0 5,0 5,0 5,0 5,0 5,0 5,0 dust to 12 6,0 3,0 3,0 3,0 3,0 3,0 3,0 3,0 12 to 50 10,0 6,0 3,0 3,0 3,0 3,0 3,0 3,0 50 to 150 10,0 10,0 6,0 5,0 5,0 4,0 4,0 4,0 150 and over 10,0 10,0 10,0 6,0 5,0 5,0 5,0 5,0 dust to 12 8,0 4,0 3,0 3,0 3,0 3,0 3,0 3,0 12 to 50 10,0 8,0 4,0 3,0 3,0 3,0 3,0 3,0 50 to 150 10,0 10,0 8,0 6,0 6,0 5,0 5,0 5,0 150 and over 10,0 10,0 10,0 10,0 6,0 6,0 6,0 6,0

Cycle time - 2L/S

TABLE 20 BELT MODULUS (kN/m)

Belt Class

Multi-ply Steelcord Textile Solid Woven Reinforced Reinforced PVC Belting Rubber Belting Belting 1060 1330 1660 2070 2950 3330 4200 5330 6660 8330 10660 13330 1750 2220 2800 3500 4440 5550 6900 8890 11110 29000 37700 47900 59800 74800 95800 119700 149700 188600 240000

160 200 250 315 400 500 630 800 1000 1250 1600 2000 2500 3150 4000

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 24 of 33

5000 6300

300000 377200

TABULATOR CALCULATIONS

For the purposes of

1. 2.

Calculating vertical curves, or Determining belt tension for conveyors of undulating profile.

It is necessary to calculate the belt tensions at various points on the conveyor. Calculating the tension at any point along the conveyor.

The tabulation method described below is a convenient means of calculating the tensions at any point on the conveyor.

Blank copies of the "Conveyor Tabulation Sheets" are available from Dunlop Africa Industrial Products.

The following method is used to determine the tension at any point along the conveyor:

1. 2. 3. 4. 5. 6. 7.

Calculate the length correction factor. Look up the mass of moving parts in Table 10. Calculate the mass of the load from the design capacity and the belt speed. Calculate the maximum effective tension under constant speed operation. This will always occur when all the non-declined sections of the conveyor are fully loaded and the declined sections empty. Determine the minimum value for the slack side tension under maximum load condition. Commencing from immediately behind the drive, label each pulley, intersection point and loading section. Start and end point of each of the load lengths should also be labelled. Determine the effective tension required to overcome the frictional and gravitational resistances for each of the segments of the conveyor by using formulae on page 4. The value of 12, determined in 5 above, is used to calculate the effective tension to overcome pulley friction. The effective tension at any point on the conveyor is the sum of the effective tensions of all preceeding segments. The total effective tension for the conveyor is the sum of the effective tensions for all segments. The tension at any point 'x' on the conveyor is made up of the effective tension at point 'x' plus the slope tension at point 'x'. Superimposed on this is the tension applied by the take-up system. The tension applied by the take-up is given by the worst case T2 value i.e. the value of T2 which a. b. prevents slip at the highest Te value and, limits sag between carry idlers.

8. 9.

It may be found that the value of T2 obtained when the maximum effective tension has been calculated is different to that used in the calculations. If this is the case the new T2 value is used to calculate tensions at each point.

Steps 7, 8 and 9 should be repeated for four load cases viz empty, fully loaded, non-declined sections loaded and declined sections loaded.

EXAMPLE

Belt width Conveyor length Lift Max capacity Belt speed Skirt length Material conveyed Lump size Bulk density Carry idler diameter Carry idler spacing Return idler diameter Return idler spacing Impact idler diameter Impact idler spacing Drive wrap Drive surface Take-up type

1200 mm 500 m 45 m 4500 t/hr 3,5 m/s 3 m Iron Ore 100 mm 2,4 t/m3 127 mm 1,2 m 127 mm 3,6 m 159 mm 0,45 m 210 degree Rubber lagged Gravity

Step 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 25 of 33

Calculate the length correction factor

C= = =

L + 70 L 570 500 1,14

Step 2

From Table 10 the mass of the moving parts for a 1200 mm wide conveyor of medium duty is 71 kg/m.

Step 3

Calculate the mass of the load

Q= = =

0,278

0,278 x 4500 3,5 357,4 kg/m

Step 4

Calculate the maximum effective tension when the non-declined sections of the conveyor are all carrying load and the declined sections have no load. The total horizontal length of non-declined sections is 20 + 330 = 350 m.

The overall change in elevation on the non-declined sections is 70 in. Note that the actual length of the conveyor is used to calculate Tx and only the loaded length to calculate Ty. The length correction factor is a constant and is used to convert the actual length to a corrected length. The friction factors are determined by the total conveyor length in all cases.

Effective tension to move the empty belt.

Tx = 9,8G x fx C x L = 9,8 x 71 x 0,020 x 1,14 x 500 = 7932N

Effective tension to move the load horizontally.

Ty = 9,8Q x fy C x L = 9,8 x 357,4 x 0,020 x 1,14 x 350 = 30745N

Effective tension to lift the load.

Tz = 9,8Q x H = 9,8 x 357,4 x 70 = 245176N

Effective tension to overcome skirtboard friction The inter-skirtboard width is assumed to be 2/3 of the belt width i.e. 0,8 m.

Tus = =

9,8fs x Q x Ls S x b2 9,8 x 357,4 x 0,020 x 1,14 x 350 3,5 x 0,64

= 3050N

The total effective tension is the sum of the above four.

Te = Tx + Ty + Tz + Tus = 7932 + 30745 + 245176 + 3050 = 286903N

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 26 of 33

Step 5

The minimum slack side tension to prevent slip is:

Tm = k x T e k = 0,38 from Table 11 and hence Tm = 0,38 x 286903 = 109023

The minimum slack side tension to prevent excessive belt sag is:

Ts = 9,8Sf x (B + Q) x Id = 9,8 x 6,3 x (14,8 + 357,4) x 1,2 = 27576N

From Table 8 the estimated belt mass is 14,8 kg/m

Since

Tm > Ts

T2 = Tm

i.e. T2 = 109023N

Step 6

The conveyor is labelled from A to 0 as shown on example sheets 1 to 4.

Step 7

Calculations of the effective tension for each segment (or run) is shown on Sheet 1 for the empty belt, Sheet 2 for the fully loaded belt, Sheet 3 for the case where only non-decline sections are loaded and Sheet 4 where only the decline sections are loaded.

Step 8

The accumulated effective tension column is the sum of the effective tensions of the current segment and all preceeding segments.

Step 9

The total effective tension for each load case is the value in the last row of the column titled 'Accumulated Effective Tension'.

For the empty belt For the fully loaded belt

Te = 7665N Te = 174188N

For all non-declines loaded Te = 283609N For only declines loaded Te = -101755N

The reason for the difference between the effective tension determine step 4 and that on Sheet 3 is the more accurate figures used for mass of the moving parts on the tabulation sheets.

The tension at any point along the conveyor can now be determined, all load cases, by adding the effective tension at the point to the slope tension at the point and then adding the worst case T2 value.

The highest Te value occurs when all non-declines are loaded. i.e. Te = 283609N

Based on this value

Tm = k x T e = = 0,38 x 283609N 107771N

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 27 of 33

Since Ts, calculated in step 5, is less than Tm

T2 = Tm

i.e. T2 = 107771N

Thus, for example, the effective tension at run L - M takes the following values:

1. Empty Belt 2. Fully loaded 4. Declines loaded

4302N - 24577N -26334N

3. Non-declines loaded 6059N

From these it is determined that the tension at point M under the four cases, given by

Te + T2 + Th is

Empty belt

4302 + 107771 + 0 = 112073N

Fully loaded belt

-24577 + 107771 + 0 = 83194N

Non-declines loaded

6059 + 107771 + 0 = 113830N

Declines loaded

-26334 + 107771 + 0 = 81437N

CLIENT NAME

Belt width Conveyor length Lift Max capacity Belt speed Skirt length Material conveyed Lump size Bulk densiy Corrected length Correction factor Lc C Friction Factors Rotating Parts fx Load Friction fy Skirt Friction fs Scraper Friction fc Drive & Take-up Angle of Wrap Drive Surface Take-up Type Drive Factor k Lagged Gravity 0,38 210 Bare Screw 0,020 0,022 0,65 0,60 W L H S Ls 1200 mm 500 m 45 m 4500 t/hr 3,5 m/s 3 m Iron Ore 100 mm 2,4 t/m3 570 m 1,14

CONVEYOR EQUIPMENT NO.

Idler Data Trough Angle Roll Diameter Spacing

Carry Return Impact 35 127 1,2 0 127 3,6 17,1 35 159 0,45 22,9 degree mm m kg/set

Rotating Parts Mass M 19,9

Pulleys Head Drive HT Bend Tail Take-up Take-up Bend LT Bend Tripper

Diameter 630 Head 500 500 500 450 mm mm mm mm mm mm mm mm

Location O O I E D,F B -

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 28 of 33

Length of Run Run (m) Lr A-B B-C C-D D-E E-F F-G G-H H-I I-J J-K K-L L-M M-N N-O 2 98 15 0 0 330 50 20 2 3 17 50 330 100

Idler Mass (kg/m) Mr = M/Id 0 5,7 5,7 0 0 5,7 5,7 5,7 0 50,9 16,5 16,5 16,5 16,5

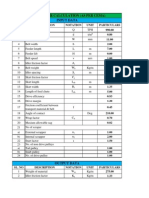

Tension to Overcome Friction (N) Lift Tension to Effective Accumulative Load Absorbed Belt of Overcome Tension Effective Mass Power Pulley Mass Run Gravity for Run Tension Idlers Belt Load (W) (kg/m) (kg/m) 0,01(do/D) (N) (N) (N) (m) 9,8LrCfxMr 9,8LrCfxB 9,8LrCfxQ B Qr T eS T2 9,8QHr Ter Te Hr 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 125 19 0 0 420 64 25 0 34 63 184 1217 369 7 324 50 0 0 1091 165 66 7 10 56 165 1091 331 178 0 178 178 178 0 0 178 0 178 178 178 178 178 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 25 -3 0 0 -67 10 0 0 0 0 -10 70 -25 0 0 0 0 0 0 0 0 0 0 0 0 0 0 185 449 247 178 178 1512 229 270 7 222 297 528 2486 887 185 634 881 1059 1237 2749 2978 3248 3255 3477 3774 4302 6788 7665 647 2218 3082 3706 4330 9621 10422 11367 11390 12168 13208 15055 23757 36829

SHEET 1 - EMPTY BELT

CLIENT NAME

Belt width Conveyor length Lift Max capacity Belt speed Skirt length Material conveyed Lump size Bulk densiy Corrected length Correction factor Lc C Friction Factors Rotating Parts fx Load Friction fy Skirt Friction fs Scraper Friction fc Drive & Take-up Angle of Wrap Drive Surface Take-up Type Drive Factor k Lagged Gravity 0,38 210 Bare Screw 0,020 0,022 0,65 0,60 W L H S Ls 1200 mm 500 m 45 m 4500 t/hr 3,5 m/s 3 m Iron Ore 100 mm 2,4 t/m3 570 m 1,14

CONVEYOR EQUIPMENT NO.

Idler Data Trough Angle Roll Diameter Spacing

Carry Return Impact 35 127 1,2 0 127 3,6 17,1 35 159 0,45 22,9 degree mm m kg/set

Rotating Parts Mass M 19,9

Pulleys Head Drive HT Bend Tail Take-up Take-up Bend LT Bend Tripper

Diameter 630 Head 500 500 500 450 mm mm mm mm mm mm mm mm

Location O O I E D,F B -

Length of Run Run (m) Lr A-B B-C C-D D-E E-F F-G G-H H-I 2 98 15 0 0 330 50 20

Idler Mass (kg/m) Mr = M/Id 0 5,7 5,7 0 0 5,7 5,7 5,7

Tension to Overcome Friction (N) Lift Tension to Effective Accumulative Load Absorbed Belt of Overcome Tension Effective Mass Power Pulley Mass Run Gravity for Run Tension Idlers Belt Load (W) (kg/m) (kg/m) 0,01(do/D) (N) (N) (N) (m) 9,8LrCfxMr 9,8LrCfxB 9,8LrCfxQ B Qr T eS T2 9,8QHr Ter Te Hr 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 0 0 0 0 0 0 0 0 0 125 19 0 0 420 64 25 7 324 50 0 0 1091 165 66 178 0 178 178 178 0 0 178 0 0 0 0 0 0 0 0 0 25 -3 0 0 -67 10 0 0 0 0 0 0 0 0 0 185 449 247 178 178 1512 229 270 185 634 881 1059 1237 2749 2978 3248 647 2218 3082 3706 4330 9621 10422 11367

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 29 of 33

I-J J-K K-L L-M M-N N-O

2 3 17 50 330 100

0 50,9 16,5 16,5 16,5 16,5

14,8 14,8 14,8 14,8 14,8 14,8

0 357,4 357,4 357,4 357,4 357,4

0 34 63 184 1217 369

7 10 56 165 1091 331

0 178 178 178 178 178

0 264 1493 4393 28991 8785

0 0 0 -10 70 -25

0 0 0 -35028 245196 -8750

7 485 1791 -30108 276673 -77908

3255 3740 5531 -24577 252096 174188

11390 13090 19357 -86019 882335 609659

SHEET 2 - FULLY LOADED BELT

CLIENT NAME

Belt width Conveyor length Lift Max capacity Belt speed Skirt length Material conveyed Lump size Bulk densiy Corrected length Correction factor Lc C Friction Factors Rotating Parts fx Load Friction fy Skirt Friction fs Scraper Friction fc Drive & Take-up Angle of Wrap Drive Surface Take-up Type Drive Factor k Lagged Gravity 0,38 210 Bare Screw 0,020 0,022 0,65 0,60 W L H S Ls 1200 mm 500 m 45 m 4500 t/hr 3,5 m/s 3 m Iron Ore 100 mm 2,4 t/m3 570 m 1,14

CONVEYOR EQUIPMENT NO.

Idler Data Trough Angle Roll Diameter Spacing

Carry Return Impact 35 127 1,2 0 127 3,6 17,1 35 159 0,45 22,9 degree mm m kg/set

Rotating Parts Mass M 19,9

Pulleys Head Drive HT Bend Tail Take-up Take-up Bend LT Bend Tripper

Diameter 630 Head 500 500 500 450 mm mm mm mm mm mm mm mm

Location O O I E D,F B -

Length of Run Run (m) Lr A-B B-C C-D D-E E-F F-G G-H H-I I-J J-K K-L L-M M-N N-O 2 98 15 0 0 330 50 20 2 3 17 50 330 100

Idler Mass (kg/m) Mr = M/Id 0 5,7 5,7 0 0 5,7 5,7 5,7 0 50,9 16,5 16,5 16,5 16,5

Lift Tension to Effective Accumulative Tension to Overcome Friction (N) Load Absorbed Belt of Overcome Tension Effective Mass Power Pulley Mass Run Gravity for Run Tension Idlers Belt Load (kg/m) (W) (kg/m) 0,01(do/D) (N) (N) (N) (m) 9,8LrCfxMr 9,8LrCfxB 9,8LrCfxQ B Qr T eS T2 9,8QHr Ter Te Hr 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 0 0 0 0 0 0 0 0 0 357,4 357,4 0 357,4 0 0 125 19 0 0 420 64 25 0 34 63 184 1217 369 7 324 50 0 0 1091 165 66 7 10 56 165 1091 331 178 0 178 178 178 0 0 178 0 178 178 178 178 178 0 0 0 0 0 0 0 0 0 264 1493 0 28991 0 0 25 -3 0 0 -67 10 0 0 0 0 -10 70 -25 0 0 0 0 0 0 0 0 0 0 0 0 245196 0 185 449 247 178 178 1512 229 270 7 485 1791 528 276673 877 185 634 881 1059 1237 2749 2978 3248 3255 3740 5531 6059 282732 283609 647 2218 3082 3706 4330 9621 10422 11367 11390 13090 19357 21205 989559 992631

SHEET 3 - NON-DECLINES LOADED

CLIENT NAME

CONVEYOR EQUIPMENT NO.

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 30 of 33

Belt width Conveyor length Lift Max capacity Belt speed Skirt length Material conveyed Lump size Bulk densiy Corrected length Correction factor

W L H S Ls

1200 mm 500 m 45 m 4500 t/hr 3,5 m/s 3 m Iron Ore 100 mm 2,4 t/m3 Idler Data Trough Angle Roll Diameter Spacing Carry Return Impact 35 127 1,2 0 127 3,6 17,1 35 159 0,45 22,9 degree mm m kg/set

Lc C Friction Factors

570 m 1,14

Rotating Parts Mass M 19,9

Rotating Parts fx Load Friction fy Skirt Friction fs Scraper Friction fc Drive & Take-up Angle of Wrap Drive Surface Take-up Type Drive Factor k Lagged Gravity 0,38 210

0,020 0,022 0,65 0,60 Head Drive

Pulleys

Diameter 630 Head 500 500 500 450 mm mm mm mm mm mm mm mm

Location O O I E D,F B -

HT Bend Tail Take-up Take-up Bend

Bare Screw

LT Bend Tripper

Length of Run Run (m) Lr A-B B-C C-D D-E E-F F-G G-H H-I I-J J-K K-L L-M M-N N-O 2 98 15 0 0 330 50 20 2 3 17 50 330 100

Idler Mass (kg/m) Mr = M/Id 0 5,7 5,7 0 0 5,7 5,7 5,7 0 50,9 16,5 16,5 16,5 16,5

Tension to Overcome Friction (N) Lift Tension to Effective Accumulative Load Absorbed Belt of Overcome Tension Effective Mass Power Pulley Mass Run Gravity for Run Tension Idlers Belt Load (W) (kg/m) (kg/m) 0,01(do/D) (N) (N) (N) (m) 9,8LrCfxMr 9,8LrCfxB 9,8LrCfxQ B Qr T eS 9,8QHr Ter Te Hr T2 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 14,8 0 0 0 0 0 0 0 0 0 0 0 357,4 0 357,4 0 125 19 0 0 420 64 25 0 34 63 184 1217 369 7 324 50 0 0 1091 165 66 7 10 56 165 1091 331 178 0 178 178 178 0 0 178 0 178 178 178 178 178 0 0 0 0 0 0 0 0 0 0 0 4393 0 8785 0 25 -3 0 0 -67 10 0 0 0 0 -10 70 -25 0 0 0 0 0 0 0 0 0 0 0 -35028 0 -87570 185 449 247 178 178 1512 229 270 7 222 297 -30108 2486 -77907 185 634 881 1059 1237 2749 2978 3248 3255 3477 3774 -26334 -23848 -101755 647 2218 3082 3706 4330 9621 10422 11367 11390 12168 13208 -92169 -83467 -356143

SHEET 4 - DECLINES LOADED

CLIENT NAME

Belt width Conveyor length Lift Max capacity Belt speed Skirt length Material conveyed Lump size Bulk densiy Corrected length Correction factor Lc C W L H S Ls _______ mm _______ m _______ m _______ t/hr _______ m/s _______ m _______ _______ mm _______ t/m3 _______ m _______

CONVEYOR EQUIPMENT NO.

Idler Data Trough Angle Roll Diameter Spacing

Carry Return Impact _____ _____ _____ _____ _____ _____ _____ degree _____ mm _____ m _____ kg/set

Rotating Parts Mass M _____ _____

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 31 of 33

Friction Factors Rotating Parts fx Load Friction fy Skirt Friction fs Scraper Friction fc Drive & Take-up Angle of Wrap Drive Surface Take-up Type Drive Factor k _______ Lagged Gravity Bare Screw _______ _______ _______ _______ Head Drive HT Bend Tail Take-up Take-up Bend LT Bend Tripper Pulleys Diameter _______ _______ _______ _______ _______ _______ _______ _______ mm mm mm mm mm mm mm mm Location _______ _______ _______ _______ _______ _______ _______ _______

_______

Length of Run Run (m) Lr

Idler Mass (kg/m) Mr = M/Id

Tension to Overcome Friction (N) Lift Tension to Effective Accumulative Load Absorbed Belt of Overcome Tension Effective Mass Power Pulley Mass Run Gravity for Run Tension Idlers Belt Load (kg/m) (W) (kg/m) 0,01(do/D) (N) (N) (N) (m) 9,8LrCfxMr 9,8LrCfxB 9,8LrCfxQ B Qr T eS T2 9,8QHr Ter Te Hr

TENSION TABULATOR

VERTICAL CURVES

Design of vertical curves

It is necessary to calculate the tension at the point under consideration following the method described in Tabulator Calculations.

Concave curves

The worst condition exists when the belt is loaded to the start of the curve and under these conditions the minimum radius of curvature to prevent the belt lifting off the idlers is

R=

113 Tp B

Where

R = radius of curvature (m) Tp = Belt tension at the point under consideration (kN) B = Belt mass per unit length (kg/m)

Convex curve requirements

The following conditions must be satisfied

1.

Minimum radius to prevent overstress of the belt edges

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 32 of 33

R=

Sin x W x E 4494 (tr - tc)

2.

Minimum radius to prevent buckling

R=

Sin x W x E 8988 (tr - 5,2)

3.

Maximum allowable change of incline per idler to prevent overstress of belt edges

5,1 (tr - tc) x 1000 W x E x Sin

4.

Maximum allowable change of incline per idler to prevent buckling

2,55 (tc - 5) x 1000 W x E x Sin

The curve must be designed with a radius at least large enough to satisfy conditions 1 and 2 and the idler spacing must ensure that conditions 3 and 4 are satisfied.

tr = Rated belt tension (kN/m) R = Radius of curvature (m) = Troughing angle (degrees) W = Belt width (mm) E = Belt modulus (kN/m) tc = Belt tension at the curve (kN/m)

MAXIMUM INCLINE ANGLE

1. 2. 3. 4. 5. 6.

Conventional smooth surface conveyor belts Ruftop package handling belts Chevron top belts Boxes belts with flexible side walls Sandwich type conveyors Elevator belts

GRAPH FOR ESTIMATING BELT LENGTH/ROLLED BELT DIAMETER

Belt length/rolled belt diameter

D = rolled belt diameter (mm) L = belt length (m) t = belt thickness (mm) d = core diameter (mm) N = number of coils on roll

Belt length:

(D + d)N

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Dunlop Conveyor Belt Design Manual

Page 33 of 33

L=

Rolled belt diameter:

or Assuming the length of belt is large and the thickness not abnormally small, then the core diameter can be neglected in approximate calculations. Where d 0,3m for general stock belting and up to 0,5m for heavy rolls of belting, such as steelcord belting or very wide belts.

USEFUL DATA CONVERSION FACTORS

Imperial to metric

To convert from in in ft in2

To

Multiply by

mm 25,4 cm m cm2 2,54 0,3048

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/Dunlop/Belting%20B...

24/05/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

Page 1 of 1

http://www.ckit.co.za/Secure/Conveyor/Troughed/belt_tension/dunlop/belting%20b6.1... 7/06/2004

You might also like

- 07 CB Conveyor Belt Design ManualDocument44 pages07 CB Conveyor Belt Design ManualRavikanth AluriNo ratings yet

- BANDO Eng. CatalogDocument44 pagesBANDO Eng. Catalogatm_o40% (5)

- Dunlop Conveyor Belt Design Manual - HTMLDocument38 pagesDunlop Conveyor Belt Design Manual - HTMLForbes KambaNo ratings yet

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Steel Cord Conveyor Belt 1 PDFDocument16 pagesSteel Cord Conveyor Belt 1 PDFSudarshan deshpandeNo ratings yet

- Pipe Conveyors: Optimal Solutions For Specialised HandlingDocument6 pagesPipe Conveyors: Optimal Solutions For Specialised Handlingneeshakothari31No ratings yet

- Conveyor Chains TsubakiDocument184 pagesConveyor Chains Tsubakitepu msosaNo ratings yet

- ConyevorsDocument9 pagesConyevorsRohan MalkarNo ratings yet

- 243 BUI 1047 BCI Conveyor Belt CatalogDocument19 pages243 BUI 1047 BCI Conveyor Belt CatalogBayu SuprayogiNo ratings yet

- Belt Conveyor Pulley Design - Why The FailuresDocument16 pagesBelt Conveyor Pulley Design - Why The FailuresenrimauryNo ratings yet

- Telescopic ChuteDocument2 pagesTelescopic Chutebiswajit sabuiNo ratings yet

- AUMUND Belt Bucket Elevator Overcomes Coarse Material ChallengesDocument53 pagesAUMUND Belt Bucket Elevator Overcomes Coarse Material Challengesnathaniel villanueva100% (1)

- Sole PlatesDocument12 pagesSole Platesjonodo89No ratings yet

- Installation Handbook - Multiply Conveyor Belts - Rev.4Document36 pagesInstallation Handbook - Multiply Conveyor Belts - Rev.4Guru Raja Ragavendran NagarajanNo ratings yet

- Belt Feeder Properly DesignedDocument2 pagesBelt Feeder Properly DesignedCarlos Ediver Arias Restrepo100% (1)

- 45 TPH DRAG CHAIN CONVEYOR DESIGNDocument7 pages45 TPH DRAG CHAIN CONVEYOR DESIGNImam SampoernoNo ratings yet

- TeleStacker® ConveyorDocument4 pagesTeleStacker® ConveyorSuperior IndustriesNo ratings yet

- Conveyor Belt Design Manual Contitech - EngDocument140 pagesConveyor Belt Design Manual Contitech - Engcanito73100% (12)

- Beltwall: Corrugated Sidewall BeltingDocument8 pagesBeltwall: Corrugated Sidewall Beltingcanito73No ratings yet

- Chute DesignDocument11 pagesChute DesignneilNo ratings yet

- Belt Conveyor Take Up DesignDocument4 pagesBelt Conveyor Take Up DesignKroya HunNo ratings yet

- C 107 - Pulley Catalog - 04 2014Document46 pagesC 107 - Pulley Catalog - 04 2014kawula alit100% (1)

- Dunlop Conveyor Belt Design Manual - P1Document14 pagesDunlop Conveyor Belt Design Manual - P1perdhana2000100% (1)

- Apex Belting Conveyor HandbookDocument102 pagesApex Belting Conveyor Handbooksasha_seferovic1874No ratings yet

- Belt Conveyor Design - Apex FennerDocument94 pagesBelt Conveyor Design - Apex Fennerdhangka100% (12)

- Beumer Belt Bucket Elevator enDocument8 pagesBeumer Belt Bucket Elevator enLev Maravi MandujanoNo ratings yet

- The Evolution of the Pipe-ConveyorDocument9 pagesThe Evolution of the Pipe-ConveyorJohnjun ChenNo ratings yet

- Calc - Vibrating Screen Single Deck NPK1Document5 pagesCalc - Vibrating Screen Single Deck NPK1Waris La Joi WakatobiNo ratings yet

- Bucket Elevator ChainDocument4 pagesBucket Elevator Chainluisreng100% (1)