Professional Documents

Culture Documents

Mf3404 Flexible Manufactuirng Systems

Uploaded by

nkchandruCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mf3404 Flexible Manufactuirng Systems

Uploaded by

nkchandruCopyright:

Available Formats

MF3404 AIM:

FLEXIBLE MANUFACTUIRNG SYSTEMS

LTPC 3003

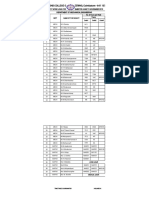

To impart knowledge on group technology, simulation, computer control, automatic manufacturing systems and factory of the future. OBJECTIVE: At the end of this course the student should be able to understand Modern manufacturing systems To understand the concepts and applications of flexible manufacturing systems UNIT I PLANNING, SCHEDULING AND CONTROL OF FLEXIBLE MANUFACTURING SYSTEMS 9 Introduction to FMS - scope types benefits major elements Types of flexibility FMS application and flexibility - optimization Single product, N product, single batch, N Batch scheduling problem Knowledge based scheduling system. UNIT II COMPUTER CONTROL AND SOFTWARE FOR FLEXIBLE MANUFACTURING SYSTEMS 9 Introduction Composition of FMS Hierarchy of computer control Computer control of work center and assembly lines FMS supervising computer control - Types of software specification and selection trends. UNIT III FMS SIMULATION AND DATA BASE 9 Application of simulationmodel of FMSsimulation software limitation manufacturing data systemsdata flowFMS database systemsplanning for FMS database. UNIT IV GROUP TECHNOLOGY AND JUSTIFICATION OF FMS 9 Introduction - matrix formulation Mathematical Programming formulation Graph Formulation Knowledge based system for group technology - Application of possibility distributions in FMS systems justification. UNIT V APPLICATIONS OF FMS AND FACTORY OF THE FUTURE 9 FMS application in aerospace machining sheet metal fabrication, prismatic component production - FMS development towards factories of the future Artificial intelligence and Expert systems in FMS Design Philosophy and Characteristics for Future. TOTAL:45 PERIODS TEXT BOOK : 1. Jha, N.K. Handbook of Flexible Manufacturing Systems ", Academic Press Inc., 1991. REFERENCES : 1. Radhakrishnan P. and Subramanyan S., CAD / CAM / CIM ", Wiley Eastern Ltd., New Age International Ltd., 1994. 2. Raouf, A. and Ben-Daya, M., Editors, Flexible manufacturing systems: recent development, Elsevier Science, 1995. 3. Groover M.P., Automation, Production Systems and Computer Integrated Manufacturing ", Prentice-Hall of India Pvt. Ltd., New Delhi, 1996. 4. Kalpakjian, Manufacturing Engineering and Technology ", Addison-Wesley Publishing Co., 1995. 5. Taiichi Ohno, Toyota, Production System Beyond Large-Scale production ", Productivity Press (India) Pvt. Ltd., 1992.

You might also like

- RitesDocument11 pagesRitesMadmen quillNo ratings yet

- GREAnalyticalWritingSupreme 2024 SAMPLEDocument38 pagesGREAnalyticalWritingSupreme 2024 SAMPLEVibrant PublishersNo ratings yet

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005From EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezNo ratings yet

- Garcia vs. J. Drilon G. R. No. 179267 Case DigestDocument5 pagesGarcia vs. J. Drilon G. R. No. 179267 Case DigestJoannMarieBrenda delaGenteNo ratings yet

- Plant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationFrom EverandPlant Intelligent Automation and Digital Transformation: Volume I: Process and Factory AutomationNo ratings yet

- IRB 1600 Product ManualDocument398 pagesIRB 1600 Product ManualEmanuelNo ratings yet

- Arbitration AgreementsDocument20 pagesArbitration Agreementsmohd suhail siddiqui100% (2)

- Jarratt Davis: How To Trade A Currency FundDocument5 pagesJarratt Davis: How To Trade A Currency FundRui100% (1)

- Flexible Manufacturing Systems: Recent DevelopmentsFrom EverandFlexible Manufacturing Systems: Recent DevelopmentsNo ratings yet

- Soft Computing and Intelligent Systems: Theory and ApplicationsFrom EverandSoft Computing and Intelligent Systems: Theory and ApplicationsNo ratings yet

- Ralph M. McInerny (Auth.) - The Logic of Analogy - An Interpretation of ST Thomas (1971, Springer Netherlands)Document191 pagesRalph M. McInerny (Auth.) - The Logic of Analogy - An Interpretation of ST Thomas (1971, Springer Netherlands)cuba esquivel amadeoNo ratings yet

- Project Excecution and DeliverableDocument7 pagesProject Excecution and DeliverableHari PrashannaNo ratings yet

- Karst RomaniaDocument7 pagesKarst Romaniaproconstruct0% (1)

- CAD CAM II SemDocument13 pagesCAD CAM II SemSayyadh Rahamath BabaNo ratings yet

- 7 ThsemsyllabusDocument8 pages7 ThsemsyllabusDhakshina KNo ratings yet

- Applicable To The Students Admitted From The Academic Year 2010-2011 OnwardsDocument13 pagesApplicable To The Students Admitted From The Academic Year 2010-2011 OnwardsRajaRaman.GNo ratings yet

- Anna University Chennai:: Chennai - 600 025 Affiliated Institutions B.Tech. (8 Semester) Information TechnologyDocument12 pagesAnna University Chennai:: Chennai - 600 025 Affiliated Institutions B.Tech. (8 Semester) Information Technologyammueast9290No ratings yet

- GrooverDocument2 pagesGrooverSaravanan MathiNo ratings yet

- Advanced Manufacturing SystemsDocument23 pagesAdvanced Manufacturing SystemsDhanish KumarNo ratings yet

- CIM SYSTEMS DESIGN MACHINE ELEMENTSDocument6 pagesCIM SYSTEMS DESIGN MACHINE ELEMENTSBala NarayanasamyNo ratings yet

- Tool Engineering Sem 2Document7 pagesTool Engineering Sem 2psg10474383No ratings yet

- Manufacturing and Operations Management CoursesDocument9 pagesManufacturing and Operations Management CoursesSiddharth Narayanan ChidambareswaranNo ratings yet

- 13.804 Compter Integrated Manufacturing (MU)Document2 pages13.804 Compter Integrated Manufacturing (MU)Manjunath NadarajanNo ratings yet

- 4th Year - II Sem - MechDocument10 pages4th Year - II Sem - MechaareachyuthNo ratings yet

- Syll, QB - SEM 5Document130 pagesSyll, QB - SEM 5dce_geethaNo ratings yet

- I.M.Tech - MMT (Full Time) (11-13)Document7 pagesI.M.Tech - MMT (Full Time) (11-13)Balaji PaulrajNo ratings yet

- Sem 4Document12 pagesSem 4RajaRaman.GNo ratings yet

- S8 Industrial Syllabus (2007-2011 Batch)Document5 pagesS8 Industrial Syllabus (2007-2011 Batch)PraveenCETNo ratings yet

- CSEDocument6 pagesCSEstaalinNo ratings yet

- CIM Course OverviewDocument2 pagesCIM Course OverviewbalakaleesNo ratings yet

- FMSDocument2 pagesFMSveerajaniNo ratings yet

- Course Outline CIM 14Document3 pagesCourse Outline CIM 14Bizuayehu TadesseNo ratings yet

- Anna University Tiruchirappalli Tiruchirappalli - 620 024: Regulations 2007 Curriculum M.E. Software EngineeringDocument31 pagesAnna University Tiruchirappalli Tiruchirappalli - 620 024: Regulations 2007 Curriculum M.E. Software EngineeringRevathy GmNo ratings yet

- Me2402 - CimDocument1 pageMe2402 - CimhariccetNo ratings yet

- CS8491 Computer Architecture SyllabusDocument1 pageCS8491 Computer Architecture Syllabussathya priyaNo ratings yet

- Me2402 CimDocument3 pagesMe2402 CimKarthik SubramaniNo ratings yet

- Cse I PDFDocument22 pagesCse I PDFannamyemNo ratings yet

- Code No. Course Title L T P C Theory: Semester VDocument0 pagesCode No. Course Title L T P C Theory: Semester VThyagu RajanNo ratings yet

- 2nd Sem SyllabusDocument6 pages2nd Sem SyllabusAnandi VenougopalNo ratings yet

- 5th SemitDocument11 pages5th SemitMuraliVenkateswaranNemmaraNo ratings yet

- B.E (CSE) - V SemDocument11 pagesB.E (CSE) - V SemAnand KarthikNo ratings yet

- Anna University Chennai:: Chennai 600 025 Affiliated Institutions Curriculum 2008 B.E. Computer Science and EngineeringDocument11 pagesAnna University Chennai:: Chennai 600 025 Affiliated Institutions Curriculum 2008 B.E. Computer Science and EngineeringDaniel MariadassNo ratings yet

- Distributed Systems and Mobile Computing CoursesDocument10 pagesDistributed Systems and Mobile Computing CoursesFemilaGoldyNo ratings yet

- Ec2042 Embedded and Real Time Systems L T P CDocument1 pageEc2042 Embedded and Real Time Systems L T P CBharathi DhasanNo ratings yet

- Ge6151 Computer Programming Complete NotDocument103 pagesGe6151 Computer Programming Complete Notmebratuthimanot9123No ratings yet

- I M.Tech - IT (Full Time) (11-13)Document8 pagesI M.Tech - IT (Full Time) (11-13)Balaji PaulrajNo ratings yet

- M E EmbeddedSystemTechnologiesDocument31 pagesM E EmbeddedSystemTechnologiesRohini BabuNo ratings yet

- M.tech Cse FTDocument33 pagesM.tech Cse FTBalaji SsrNo ratings yet

- Anna University: Coimbatore M.C.A (Master of Computer Applications)Document9 pagesAnna University: Coimbatore M.C.A (Master of Computer Applications)rabin9999No ratings yet

- Cim SyllabusDocument2 pagesCim SyllabusHarish HNo ratings yet

- Parallel Computing Architectures & ProgrammingDocument1 pageParallel Computing Architectures & ProgrammingRohith RajNo ratings yet

- 6th Semester SyllabusDocument12 pages6th Semester SyllabusSathish Kumar RajendiranNo ratings yet

- Course Plan (Amt)Document3 pagesCourse Plan (Amt)Gunabalan SellanNo ratings yet

- Mf5102 Computer Integrated Manufacturing Systems: For Syllabus, Question Papers, Notes & Many MoreDocument2 pagesMf5102 Computer Integrated Manufacturing Systems: For Syllabus, Question Papers, Notes & Many MoreNandha Gopal SenthilnathanNo ratings yet

- Master of Computer Applications Curriculum and SyllabiDocument73 pagesMaster of Computer Applications Curriculum and SyllabiStanly JonesNo ratings yet

- SE9224 Software Metrics and IT9255 Pervasive Computing Project ManagementDocument3 pagesSE9224 Software Metrics and IT9255 Pervasive Computing Project ManagementJai GaneshNo ratings yet

- Anna University Chennai:: Chennai - 600 025 Affiliated Institutions B.Tech. (8 Semester) Information Technology Curriculum - R 2008Document13 pagesAnna University Chennai:: Chennai - 600 025 Affiliated Institutions B.Tech. (8 Semester) Information Technology Curriculum - R 2008Shanmuga SundarNo ratings yet

- Ma 2262 Probability and Queueing Theory 3 1 0 4Document8 pagesMa 2262 Probability and Queueing Theory 3 1 0 4karthickpsvNo ratings yet

- Manufact Engg FDocument31 pagesManufact Engg FtskcbeNo ratings yet

- Cs 41 Design and Analysis of Algorithms 3 1 0 4Document14 pagesCs 41 Design and Analysis of Algorithms 3 1 0 4Ajmal KhanNo ratings yet

- EmbeddedDocument9 pagesEmbeddedNanc Joy100% (1)

- Design Automation of Cyber-Physical SystemsFrom EverandDesign Automation of Cyber-Physical SystemsMohammad Abdullah Al FaruqueNo ratings yet

- Adaptive Intelligent Systems: Proceedings of the BANKAI workshop, Brussels, Belgium, 12-14 October 1992From EverandAdaptive Intelligent Systems: Proceedings of the BANKAI workshop, Brussels, Belgium, 12-14 October 1992Society for Worldwide Society for Worldwide InterbanNo ratings yet

- Expert System: Fundamentals and Applications for Teaching Computers to Think like ExpertsFrom EverandExpert System: Fundamentals and Applications for Teaching Computers to Think like ExpertsNo ratings yet

- Pipelined Processor Farms: Structured Design for Embedded Parallel SystemsFrom EverandPipelined Processor Farms: Structured Design for Embedded Parallel SystemsNo ratings yet

- Next-Gen Mainframe: Mastering Modern Automation Techniques: MainframesFrom EverandNext-Gen Mainframe: Mastering Modern Automation Techniques: MainframesNo ratings yet

- Challenges and Opportunities for Deep Learning Applications in Industry 4.0From EverandChallenges and Opportunities for Deep Learning Applications in Industry 4.0No ratings yet

- 4790 32542 1 PBDocument6 pages4790 32542 1 PBJogi Oscar SinagaNo ratings yet

- SNS College Engineering Answer Key Covers Entrepreneurship DevelopmentDocument5 pagesSNS College Engineering Answer Key Covers Entrepreneurship DevelopmentnkchandruNo ratings yet

- Workload 19-20Document2 pagesWorkload 19-20nkchandruNo ratings yet

- VacationDocument1 pageVacationnkchandruNo ratings yet

- Cotter Joint Design GuideDocument15 pagesCotter Joint Design GuidenkchandruNo ratings yet

- RMD Ac in Dept Eee Index PHPDocument1 pageRMD Ac in Dept Eee Index PHPnkchandruNo ratings yet

- Two Days Workshop For Composite MaterialsDocument2 pagesTwo Days Workshop For Composite MaterialsnkchandruNo ratings yet

- TroubleshootingDocument2 pagesTroubleshootingnkchandruNo ratings yet

- CE6306 STRENGTH OF MATERIALS PART-B TOPICSDocument8 pagesCE6306 STRENGTH OF MATERIALS PART-B TOPICSnkchandruNo ratings yet

- U-4, Topic 7Document2 pagesU-4, Topic 7nkchandruNo ratings yet

- Weekly Workshop Series SathishDocument3 pagesWeekly Workshop Series SathishnkchandruNo ratings yet

- Design and Fabrication of Modified Crop HarvesterDocument13 pagesDesign and Fabrication of Modified Crop HarvesternkchandruNo ratings yet

- RTGS Transfer AcknowledgementDocument1 pageRTGS Transfer AcknowledgementnkchandruNo ratings yet

- DonDocument4 pagesDonnkchandruNo ratings yet

- Deformation and stresses in thin spherical shellsDocument8 pagesDeformation and stresses in thin spherical shellsnkchandruNo ratings yet

- E6311 Set4Document2 pagesE6311 Set4nkchandruNo ratings yet

- Deformation and stresses in thin spherical shellsDocument8 pagesDeformation and stresses in thin spherical shellsnkchandruNo ratings yet

- Npec 032Document6 pagesNpec 032nkchandruNo ratings yet

- Archive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessDocument9 pagesArchive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessnkchandruNo ratings yet

- APDocument10 pagesAPnkchandruNo ratings yet

- Train No. Name From To Departure Arrival Duration Sun Mon TueDocument56 pagesTrain No. Name From To Departure Arrival Duration Sun Mon TuenkchandruNo ratings yet

- Provisional Certificate Letter: Date and SealDocument1 pageProvisional Certificate Letter: Date and SealnkchandruNo ratings yet

- SNS College Internal Assessment Exam ThermodynamicsDocument2 pagesSNS College Internal Assessment Exam ThermodynamicsnkchandruNo ratings yet

- NEDocument59 pagesNEnkchandruNo ratings yet

- Intercooling in Gasturbine Power Plant PDFDocument12 pagesIntercooling in Gasturbine Power Plant PDFnkchandruNo ratings yet

- Archive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessDocument9 pagesArchive of SID: Process Capability Improvement of An Engine Connecting Rod Machining ProcessnkchandruNo ratings yet

- 1.mark The Higher and Lower TemperatursDocument2 pages1.mark The Higher and Lower TemperatursnkchandruNo ratings yet

- ACFrOgAz1tI7u2Z7arXhthcDfA - StuFW8ULNj4idegLIoompNo79Rl Fy2aiiH94DLXw3e1CM49Zfsvpq9tCctKkpuz2obwc oIXRDWvLEACOcGA - ONHYiNgYK OmV4Document1 pageACFrOgAz1tI7u2Z7arXhthcDfA - StuFW8ULNj4idegLIoompNo79Rl Fy2aiiH94DLXw3e1CM49Zfsvpq9tCctKkpuz2obwc oIXRDWvLEACOcGA - ONHYiNgYK OmV4nkchandruNo ratings yet

- Studies of Welded Joints: Archives of Foundry EngineeringDocument6 pagesStudies of Welded Joints: Archives of Foundry EngineeringnkchandruNo ratings yet

- CHAPTER 8 THERMODYNAMICS MCQs YEAR 2012-2009Document68 pagesCHAPTER 8 THERMODYNAMICS MCQs YEAR 2012-2009Kumar SahebNo ratings yet

- Vaclav Havel - From 'Mistake'. SAGEDocument9 pagesVaclav Havel - From 'Mistake'. SAGEADIELruleNo ratings yet

- The Bare Foot Boy 3 Ab 2 ManadoDocument100 pagesThe Bare Foot Boy 3 Ab 2 ManadoKotakuNo ratings yet

- Chara LesDocument5 pagesChara Lesx456456456xNo ratings yet

- Evolution and Diversity of Coleochaete, Charales, and Green PlantsDocument4 pagesEvolution and Diversity of Coleochaete, Charales, and Green PlantsAndrei PusungNo ratings yet

- Project MethodDocument6 pagesProject MethodMtr Jonathan Uribe CarvajalNo ratings yet

- MC Data Dig Graphic Organizer 1Document5 pagesMC Data Dig Graphic Organizer 1api-461486414No ratings yet

- Princes of the Apocalypse Locations IndexDocument2 pagesPrinces of the Apocalypse Locations IndexPedroManzelaDuarteNo ratings yet

- Sic 789 ADocument19 pagesSic 789 AFlorinMacoveiNo ratings yet

- Outlook Business The Boss July 2015Document14 pagesOutlook Business The Boss July 2015Nibedita MahatoNo ratings yet

- Adler Individual-PsychologyDocument3 pagesAdler Individual-PsychologyPORRAS, REJEAN ANN D.No ratings yet

- Brah, Revisting IntersectionalityDocument12 pagesBrah, Revisting IntersectionalityhalimamuslimaNo ratings yet

- Khulasa Al MadadDocument5 pagesKhulasa Al Madadmirwana100% (1)

- GUINNESS F13 Full Year BriefingDocument27 pagesGUINNESS F13 Full Year BriefingImoUstino ImoNo ratings yet

- Apt 2Document12 pagesApt 2Shashank ShekharNo ratings yet

- Swadhin Bangla Betar KendraDocument21 pagesSwadhin Bangla Betar KendraMusfiqur Rahman ApuNo ratings yet

- DTF - Houses of The FallenDocument226 pagesDTF - Houses of The FallenShuang Song100% (1)

- Hbo Group AnalysisDocument5 pagesHbo Group AnalysisAlexa Dei GalinatoNo ratings yet

- Solución: R T β T R (T) = 1000 Ω ΩDocument6 pagesSolución: R T β T R (T) = 1000 Ω ΩDuvan BayonaNo ratings yet

- Progressivism Lesson 3 The PresidentsDocument3 pagesProgressivism Lesson 3 The Presidentsapi-302923213No ratings yet

- RUN ON SENTENCES AND FRAGMENTS GUIDEDocument17 pagesRUN ON SENTENCES AND FRAGMENTS GUIDEWAHEED-UL -ISLAMNo ratings yet

- Fuentes CAED PortfolioDocument32 pagesFuentes CAED PortfoliojsscabatoNo ratings yet