Professional Documents

Culture Documents

Resin Selection Guide

Uploaded by

haw_shin7039Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Resin Selection Guide

Uploaded by

haw_shin7039Copyright:

Available Formats

Resins and Intermediates Selection Guide

Silicone resins for high-performance decorative and protective coatings

Silicon-based chemistry from the

XIAMETER brand helps you solve tough performance challenges and gain a competitive edge in the coatings marketplace. XIAMETER brand silicone resins and resin intermediates feature resistance to temperature extremes, moisture,corrosion, electrical discharge, and weathering. They are compatible with many organic resins, and many combinations of silicone resins can beformulated for specific applications and film properties.

Product Choice

The XIAMETER brand from Dow Corning offers a diverse line of silicone resins and intermediates for formulating high-performance decorative and protective coatings. Solvent-based, solventless liquid and solid flake options ranging in silicone content from 50 to 100 percent, by weight, are available. This variety allows formulators to fulfill a wide range of performance and regulatory requirements and to achieve the best combination of performance and economy for each application. Tables 2 through 6 provide general guidelines for the selection of appropriate resins and intermediates.

markets has evolved over the decades, allowing formulators to create differentiated, highperformance product offerings. Hybrid resin systems include cold-blended interpenetrating resin networks and copolymerized true resin hybrids. Silicone resins and intermediates found utility in silicone alkyd maintenance paints (1950s), silicone polyester coil coatings (1970s) and most recently, silicone epoxy industrial and marine maintenance coatings (1990s). Gloss and color retention, along with corrosion, moisture, weather, and heat resistance are achieved via the incorporation of silicon-based materials into a wide array of paints, finishes, and coatings. The level of silicone modification is dictated by the severity of the application performance requirements (See Table 1) and can range from a minimum of 15 to 90 percent silicone incorporation into the organic resin. Higher levels of silicone resin (90 to 100 percent of resin binder) provide the highest level of thermal and ultra-violet radiation resistance, but benefit from the inclusion of small portions of organic resins to improve physical properties such as hardness (phenolics and melamines), air dry (acrylics), corrosion resistance (epoxies), and toughness (alkyds).

Temperature and Hardness

Silicone resin choice is heavily influenced by the environmental temperatures to which the end application will be exposed. Film hardness is another important consideration. Optimum coating performance is achieved by balancing these two parameters. Softer, more flexible resins are recommended for coating formulations intended for the highest temperature ranges. Rigid resins with excellent hot hardness are recommended for mid-range temperature applications. See Tables 1, 3, and 4 for temperature and resin hardness information.

Pigments

Innovative Technology

The use of silicones in coatings

When formulating silicone or silicone modified organic binder systems, the performance requirements of the application determine pigment suitability. Standard pigments used with organic binder systems can be employed for those coatings intended for applications exposed to low or moderate temperatures (121 to 204C [250 to 400F]). For higher temperatures, only heat-stable inorganic pigments should be utilized. Consideration should also be given to coatings exposed to weather or chemical attack. Aluminum pastes and metal oxides, in particular iron

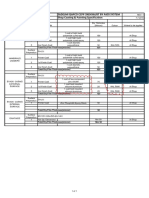

Table 1. Using Resins for Cost-Eective High-Temperature Performance

Performance Temperature Range 1

121C (250F) 121-204C (250-400F) 204-316C (400-600F) 760C (1400F)

Resin Type Silicone-modied organic 2 Silicone-modied organic 2 Organic-modied silicone 3 Organic-modied silicone Silicone Silicone Silicone

3

Pigment All pigments Aluminum Colored Black, aluminum Colored Black, aluminum Ceramic

316-427C (600-800F) 427-538C (800-1000F) 538-760C (1000-1400F)

1

1000 hours, minimum.

15-50 percent silicone.

51-90 percent silicone.

and titanium, are useful. Hydroxyl reactivity on the surface of the pigment allows direct interaction of the pigment with the silicone binder. At elevated temperatures, thermally stable metalo-silicon ceramics are formed. Non-reactive pigments, such as carbon black, or graphite can be used to achieve color shading, but should be minimized in the formulation.

Curing

Corrosion Resistance

Thinners

The resins described in this selection guide can be thinned with aromatic hydrocarbon solvents and hydrocarbon blends. They can also be thinned with most ketones, esters, chlorinated solvents, glycol ethers, and butanol.In selected situations, volatile methylsiloxanes (VMS) can be used as a diluent to reduce viscosity without increasing volatile organic compound (VOC) content. (Note: Exempt status of VMS must be approved by the state in which VMS is used.)

Coatings formulated with siliconebased resins or intermediates generally require a bake or cure at elevated temperatures to achieve optimum film properties. This is especially true if the coating is to be exposed to extreme temperatures or to thermal cycling and shock. With silicone-based coatings, there is a greater danger of under-curing than over-curing. Under-cured films are relatively soft and have poor adhesion.

Curing cycles are primarily determined by the silicone content of the resin vehicle. The typical cure for a coating based on a 100 percent silicone resin is 30 minutes at 232C (450F). A satisfactory cure time for a 50 to 80 percent silicone resin is 15 to 30 minutes at 218C (425F). For blends or copolymers of silicone and organic resins in which silicone is not the primary component, follow the cure recommendation for the primary resin.

Properly cured, XIAMETER silicone resins have good resistance to water and most dilute acids. The degree of corrosion resistance is dependent on several variables such as type of silicone resin, cure conditions, film thickness, pigmentation, if used, and the application environments.

Intercompatibility of Silicone Resins

In general, XIAMETER silicone resins have good intercompatibility. Resins with a phenyl/methyl ratio lower than 1.0/1 tend to be less compatible. Laboratory testing of resin mixtures should be done before commercial use.

Catalysts

The addition of metallic driers such as zinc or cobalt octoate will improve the rate of cure of XIAMETER silicone resins. Suggested amounts are 0.1 to 0.2 percent metal based on the resin solids. Lead catalysts should not be used with these silicone resins. Containers with soldered seams may cause gelation.

XIAMETER Resin Properties

(Bubble Size Denotes Percent Non-Volatile Content)

Organic Compatibility (0 - Low)

3 2.5 2 1.5 1 0.5 0 55 60

RSN0409 RSN0431 RSN0805 RSN0840 RSN0806 RSN0808 RSN0220 RSN0233 RSN0255 RSN6018 RSN0217

RSN0249 RSN-

0804

65 70 Relative Hardness (0 - Soft)

75

80

All products are XIAMETER brand.

Table 2. Characteristics and Typical Properties

Specication Writers: Please contact your local sales ofce before writing specications on this product. Liquid XIAMETER brand Product Characteristics Physical Form Functionality Silicon Dioxide Content Silanol Content 1 Degree of Crosslinking, percent Phenyl/Methyl Ratio Molecular Weight 3 Typical Properties Resin Solids, percent by weight 4 by volume Solvent Specic Gravity VOC 5, g/L (lb/gal) Viscosity (centipoise) Flash Point, closed cup, C (F) 80 74 Xylene 1.12 228 (1.9) 200 27 (81) 80 74 Toluene 1.14 228 (1.9) 800 7 (45) 60 51 Toluene 1.07 431 (3.6) 30 7 (45) 50 42 Xylene 1.01 503 (4.2) 125 27 (81) 50 41 Toluene/Xylene 1.02 515 (4.3) 150 7 (45) 50 42 Xylene 1.01 503 (4.2) 125 27 (81) 60 51 Toluene 1.06 431 (3.6) 20 7 (45)

2 1

RSN-0409 HS Resin RSN-0431 HS Resin

RSN-0804 Resin

RSN-0805 Resin

RSN-0806 Resin

RSN-0808 Resin

RSN-0840 Resin

Solvent solution Silanol 52 1 60 1.1/1 2000 - 7000

Solvent solution Silanol 52 3 66 1.2/1 2000 - 7000

Solvent solution Silanol 64 3 68 0.4/1 2000 - 7000

Solvent solution Silanol 52 1 60 1.1/1 200,000 - 300,000

Solvent solution Silanol 52 1 66 1.2/1 200,000 - 300,000

Solvent solution Silanol 57 1 63 0.7/1 200,000 - 300,000

Solvent solution Silanol 52 3 66 1.2/1 2000 - 7000

Flake Resins XIAMETER brand Product Characteristics Physical Form Functionality Silicon Dioxide Content 1 Silanol Content

1

Resin Intermediates RSN-0249 Flake Resin RSN-0255 Flake Resin RSN-6018 Intermediate RSN-3037 Intermediate RSN-3074 Intermediate RSN-5314 Intermediate

RSN-0217 Flake Resin

RSN-0220 Flake Resin

RSN-0233 Flake Resin

Solid ake Silanol 47 6 75 n/a 1500 - 2500

Solid ake Silanol 52 6 70 2.0/1 2000 - 4000

Solid ake Silanol 52 5 71 1.3/1 2000 - 4000

Solid ake Silanol 63 5 71 0.6/1 2000 - 4000

Solid ake Silanol 62 5

6

Solid ake Silanol 51 6 75 2.7/1

8

Liquid Methoxy 65 15-18 58 0.5/1 800 - 1300

7

Liquid Methoxy 54 15-18 67 1.0/1 1000 - 1500

7

Liquid Methoxy 46 35 7 68 3.3/1 Monomer blend

Degree of Crosslinking, percent 2 Phenyl/Methyl Ratio Molecular Weight 3 Typical Properties Resin Solids, percent by weight 4 by volume Solvent Specic Gravity VOC 5 , g/L (lb/gal) Viscosity (centipoise) Flash Point, closed cup, C (F) Glass Transition Temperature (Tg) C (F)

1 2 3

74 0.84 2500 - 4500

1500 - 2500

99 1.34 138 (280) 65 (149)

99 1.33 138 (280) 49 (120)

99 1.32 138 (280) 47 (117)

99 1.30 138 (280) 41 (106)

>98 1.22 138 (280) 56 (133)

99 1.31 138 (280) -

100 (actives) 1.07 14 138 (280) -

100 (actives) 1.16 120 138 (280) -

100 (actives) 1.04 1.87 28 (83) -

Percent by weight. Silica (SiO2 ) 100% crosslinked; dimethyl silicone uids [(CH3 ) 2 SiO] x 50% crosslinked. Weight average. 4 1.5 g, 3 hr at 135C (275F). 5 Volatile Organic Compound, EPA Reference Method 24. 6 Hydroxyl content. 7 Methoxy content. 8 Propyl.

Table 3. Silicone Liquid Resin Guide

Finished Paint Temperature Performance Range, C (F) To 538 (1000); short term: 650 (1200) Resin System (Solids Content, wt%) Solvent-based (80)

Product Name XIAMETER RSN-0409 HS Resin

Hardness Soft, exible

Typical Applications High-performance coatings; hightemperature applications where low VOC content is required. Used alone or blended with a variety of solvent-based silicone and organic resins. Similar to XIAMETER RSN-0805 Resin except for solids content. Same as XIAMETER RSN-0840 Resin; when reduced VOC content is desired. Maintenance paints, colored baking enamels, decorative nishes. As an additive to improve paint ow-out. Maintenance paints, colored baking enamels, decorative nishes; primarily with metallic pigments. Used alone or blended with XIAMETER RSN-0806 Resin to promote intermediate hardness. Colored baking enamels for space heaters, stoves, etc. Used alone or blended with XIAMETER RSN-0805 Resin to promote intermediate hardness. Similar to XIAMETER RSN-0805 Resin Maintenance paints, colored baking enamels, decorative nishes. Improves heat resistance, weathering of organic resins. As an additive to improve owout of epoxy paints, initial gloss.

High Solids XIAMETER RSN-0431 HS Resin XIAMETER RSN-0804 Resin XIAMETER RSN-0805 Resin

Medium-hard Hard, brittle

To 427 (800) To 315 (600)

Solvent-based (80) Solvent-based (60) Solvent-based (50)

Soft, exible

To 650 (1200)

Standard

XIAMETER RSN-0806 Resin

Medium-hard

To 538 (1000)

Solvent-based (50)

XIAMETER RSN-0808 Resin XIAMETER RSN-0840 Resin

Medium-soft Hard to medium-hard

To 538 (1000); short term: 650 (1200) To 538 (1000)

Solvent-based (50) Solvent-based (60)

Table 4. Silicone Flake Resin Selection Guide

Finished Paint Temperature Performance Range, C (F) To 260 (500) Finished Paint Temperature Performance Range, (F) To 315 C (600) To 260 (500) Resin System (Solids Content, wt%) Solid ake (100) Resin System (SolidsSolid Content, ake wt%) (100) (100)

Product Name Hardness Guide Table 4. Silicone Flake Resin Selection XIAMETER RSN-217 Flake Resin XIAMETER brand Product XIAMETER RSN-0220 Flake Flake Resin Resin RSN-0217

Typical Applications As a powder coating binder and liquid coating binder to improve thermal stability and weatherability. Typical Applications As a powder coating binder or co-binder

Hard, brittle

Hardness Hard Hard, brittle

RSN-0220 Flake Resin

HardT

o 315 (600)

(100) Solid ake (100)

Flake Resins Flake Resins

XIAMETER RSN-0233 Flake Resin

Hard

To 427 (800)

RSN-0233 Flake Resin XIAMETER RSN-0249 Flake Resin

HardT Hard

o 427 (800) To 427 (800)

Solid ake (100) (100)

RSN-0249 Flake Resin XIAMETER RSN-0255 Flake Resin

HardT Hard, rigid

o 427 (800) To 427 (800)

(100) Solid ake (100)

RSN-0255 Flake Resin

Hard, rigid

To 427 (800)

(100)

to heat stability andand weatherAsimprove a powder coating binder liquid ability; for blending with silicone coating binder to impr ove other thermal stability resins to reduce VOC content; in solventand weatherability. based organic coatings to improve lm As a powder binder or co-binder properties; incoating copolymerization with to improve heat stability andmonomers weathercarbinol-functional organic ability; for blending with other silicone or polymers. resins to reduce VOC content; in solventAs a powder coating binder or cobinder to improve heat stability and properties; in copolymerization with weatherability; colored baking enamels, carbinol-functional organic monomers decorativ e nishes; to increase hardness or polymers. of other liquid silicone resins. As a p owder coating binder or co As a powder coating binder to improve binder to improve heat stability and heat stability and weatherability; for weatherability; colored baking enamels, blending with solvent-based silicone resins toliquid reduce VOCs; resins. for blending with of other silicone solvent-based organic resins to improve As a powder binder to improve heat stability coating and weatherability. heat stability and weatherability; for As a coatings binder to improve heat blending with solvent-based silicone stability and weatherability; as a blending resins to reduce VOCs; for blending with resin with solvent-based silicone resins solvent-based organic resins to improve to reduce volatile organic compound heat stability and weatherability. (VOC) content; as a blending resin in As a coatings binder toresins improve heat solvent-based organic to improve stability and weatherability; as a b lending heat stability and weatherability. resin with solvent-based silicone resins to reduce volatile organic compound (VOC) content; as a blending resin in solvent-based organic resins to improve heat stability and weatherability.

Table 5. Silicone Resin Intermediate Selection Guide

Product Name XIAMETER RSN-6018 Intermediate

Physical Form (Solids Content, wt%) Flaked solid (100)

Functionality Silanol

Reactivity Reacts with alkyds, phenolics, epoxies, polyesters and other organic resins containing hydroxyl groups.

Typical Applications Reactive silicone intermediate in colored maintenance and architectural nishes, appliance nishes, coil coatings and high temperature nishes. Blended with other silicone resins to improve hardness. Blended with organic resins to improve weatherability and heat resistance. Reactive silicone intermediate for coil coatings, appliance nishes and other nishes where improved heat or weathering resistance is needed. Typically reacted with saturated polyesters or oil-free alkyds to form a silicone polyester copolymer. Reactive silicone intermediate for coil coatings, appliance nishes and other nishes where improved heat or weathering resistance is needed. Typically reacted with saturated polyesters to form silicone-modied copolymers with 20 to 50 percent silicone content. Reactive silicone intermediate for upgrading the weatherability of acrylic emulsions. Should work equally well with other emulsion systems that are stable at an alkaline pH.

XIAMETER RSN-3037 Intermediate Resin Intermediates

Liquid (90)

Methoxy

Reacts with organic systems containing active hydroxyl groups.

XIAMETER RSN-3074 Intermediate

Liquid (90)

Methoxy

Reacts with organic resins containing active hydroxyl groups.

XIAMETER RSN-5314 Intermediate

Liquid (100, actives)

Methoxy

Reacts with organic resins containing active hydroxyl groups.

Table 6. Compatibility of Selection Silicone Resins with Selected Organic Resins1

XIAMETER brand Product Resin Type Brand

2, 3

RSN-431 HS and RSN-0840 Resins 10% 50% SI I C C C SI C C SI C SI SI

RSN-6018 Intermediate 10% C I C C C I C C SI C C C 50% C I C SI I I C C I C C SI

RSN-0233 Flake Resin 10% C SI C C C SI C C SI C C C 50% C I C C C SI C C I C C SI

Acrylic (Thermoplastic)

Paraloid A-10S Paraloid B-44 Paraloid B-48S Paraloid B-66 Paraloid B-72 Paraloid B-82

C SI C C C C C C SI C C SI

Acrylic (Thermosetting)

Paraloid AT-63 Paraloid AT-400

Alkyd (Long oil) (Medium oil) (Short oil) (Oil-free) C Compatible SI Slightly incompatible I Incompatible

1

Duramac 50-5060 Duramac 204-2768 Duramac 57-5720 Polymac 57-5776

As determined by dry lm on glass slides. This is meant to be representative only. The possible combinations of silicone and organic resins are unlimited. Actual compatibility will depend on formulation variables. NOTE: Paraloid is a registered trademark of The Dow Chemical Company or of its subsidiaries or afliates. NOTE: Duramac and Polymac are trademarks of Resolution Specialty Materials, LLC.

2 3

Selecting a XIAMETER brand Resin

Is the intended coating...

Yes Yes

XIAMETER RSN-0233 Flake Resin

XIAMETER RSN-0255 Flake Resin

Heat >315C?

No No Yes

XIAMETER RSN-6018 Intermediate

Organic Blend?

High Hardness Needed?

No

XIAMETER RSN-0217 Flake Resin XIAMETER RSN-0249 Flake Resin

XIAMETER RSN-0255 Flake Resin

Yes No

Organic Blend?

Yes Yes

XIAMETER RSN-5314 Intermediate

Water-Based?

XIAMETER RSN-3074 Intermediate

Yes

No

Low VOC?

Yes

START

FDA-Regulated Application?

XIAMETER RSN-0431 HS Resin

No

No

Powder Coating?

XIAMETER RSN-6018 Intermediate

Yes

Yes

Organic Blend?

No

Hot Hardness Required?

Yes

XIAMETER RSN-0806 Resin

No

Si-Organic Hybrid?

No

No

XIAMETER RSN-0805 Resin

Important information on storage, handling, and flammability

Storage and Shelf Life

XIAMETER silicone resins should be stored at room temperature in sealed containers away from heat and open flame. XIAMETER solid flake products should be stored below 22C (72F). Refer to the product pages on www.xiameter.com for the shelf life from date of manufacture of the resins and intermediates discussed in this brochure. XIAMETER solid flake resins are electrically nonconductive and, like plastic in particle form, can generate static charges during transfer operations. For this reason, proper precautions should be taken to safely dissipate any charges possibly generated, particularly when solvents or solvent vapors are present. These two important cautions are detailed as follows: 1. The flake itself will generate an electrical potential, and the user should maintain adequate safeguards to properly handle it. The vessel into which the flake is being poured should be grounded along with the platform on which the operator stands. 2. Avoid the presence of ignitable materials during the transfer operation. If possible, have an inert atmosphere in the kettle and keep the solvent vapor content of the surrounding area at safe levels by providing adequate building area ventilation.

Limitations

These products are neither tested nor represented as suitable for medical or pharmaceutical uses.

Flammability

Handling Precautions

XIAMETER silicone resins in organic solvent have a closed cup flash point from 7 to 27C (45 to 80F). The flake resins have a closed cup flash point of approximately 138C (280F).

Product safety information required for safe use is not included. Before handling, read product and safety data sheets and container labels for safe use, physical and health hazard information. The material safety data sheet is available on www.xiameter.com. When working with XIAMETER silicone paint resins formulated with flammable solvents, the following safety precautions should be taken: Keep away from heat and open flame Use only with adequate ventilation Avoid prolonged breathing of vapor Avoid prolonged or repeated skin contact Avoid eye contact

Product Information and Technical Support

Visit www.xiameter.com for: Product technical data sheets Customer service & limited technical support The name of a XIAMETER brand distributor near you

LIMITED WARRANTY INFORMATION - PLEASE READ CAREFULLY The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customers tests to ensure that our products are safe, effective and fully satisfactory for the intended end use. Suggestions of use shall not be taken as inducements to infringe any patent. Dow Cornings sole warranty is that our products will meet the sales specifications in effect at the time of shipment. Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted. DOW CORNING SPECIFICALLY DISCLAIMS ANY OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY. DOW CORNING DISCLAIMS LIABILITY FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES. Dow Corning is a registered trademark of Dow Corning Corporation. XIAMETER is a registered trademark of Dow Corning Corporation. 2012 Dow Corning Corporation. All rights reserved. Form No. 95-1113-01

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Finite Element-Based InvestigationDocument7 pagesA Finite Element-Based InvestigationSteve IpNo ratings yet

- Chapter 1 Why Study Financial Markets and InstitutionsDocument15 pagesChapter 1 Why Study Financial Markets and Institutionshmmms11100% (1)

- HandBook Stuctural SteelDocument267 pagesHandBook Stuctural SteelOnn Lajer100% (9)

- Autodesk Inventor Fusion TutorialDocument251 pagesAutodesk Inventor Fusion Tutorialexperiencia1No ratings yet

- Stress AnalysisDocument6 pagesStress Analysisapi-3836286100% (4)

- Banned by KDN.. The March To PutrajayaDocument375 pagesBanned by KDN.. The March To PutrajayaMohd Samsul Ghazali100% (1)

- Welding Procedures: For FIBERBOND® Fiberglass Piping SystemsDocument15 pagesWelding Procedures: For FIBERBOND® Fiberglass Piping Systemshaw_shin7039No ratings yet

- CAESAR II Quick Reference Guide PDFDocument30 pagesCAESAR II Quick Reference Guide PDFswatantar17No ratings yet

- Derakane Epoxy Vinyl EstersDocument7 pagesDerakane Epoxy Vinyl Estershaw_shin7039100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sigmafast 155YDocument5 pagesSigmafast 155YStephen Francis BothelloNo ratings yet

- Semstone 8084 PDS 7-10Document1 pageSemstone 8084 PDS 7-10vitharvanNo ratings yet

- Estowrap 300H - Estop Japan - Carbon FRP-1Document3 pagesEstowrap 300H - Estop Japan - Carbon FRP-1nugraha pierreNo ratings yet

- Dafen6 1708Document4 pagesDafen6 1708George CobraNo ratings yet

- Stack Painting SpecsDocument1 pageStack Painting SpecsAmer Y KNo ratings yet

- CoalTarEnamelRepairGuide - TM 8540 2017 047 - 11 2017 - 508Document38 pagesCoalTarEnamelRepairGuide - TM 8540 2017 047 - 11 2017 - 508Pablo BenitezNo ratings yet

- 32 Samss 037Document29 pages32 Samss 037Hasan Ahmed100% (1)

- Adhesion Test GuideDocument4 pagesAdhesion Test GuideIsabelo AbaoNo ratings yet

- Hempafloor Self-Level 200Document2 pagesHempafloor Self-Level 200Fadi MagdyNo ratings yet

- Usacereport PDFDocument116 pagesUsacereport PDFProfSatyen RamaniNo ratings yet

- Nitomortar TC2000 Nitomortar TC2000: Constructive SolutionsDocument3 pagesNitomortar TC2000 Nitomortar TC2000: Constructive SolutionsalbertooooooNo ratings yet

- Silane Coupling Agent Guide: Silicones SiliconesDocument12 pagesSilane Coupling Agent Guide: Silicones Siliconescarlos6039No ratings yet

- Ronald Mark Associates v. StonhardDocument21 pagesRonald Mark Associates v. StonhardPriorSmartNo ratings yet

- Tee Bun Pin - Strengthening of Concrete Slab With Opening Using External Fiber Reinforced Polymer (FRP) Strip. 2004Document87 pagesTee Bun Pin - Strengthening of Concrete Slab With Opening Using External Fiber Reinforced Polymer (FRP) Strip. 2004Сергей СерёгинNo ratings yet

- Technical Data Epoxy Tile GroutDocument2 pagesTechnical Data Epoxy Tile GroutMeliany SariNo ratings yet

- Lignin ApplicationsDocument17 pagesLignin Applicationssurapong2005100% (1)

- HexPly F155 Us DataSheet3Document6 pagesHexPly F155 Us DataSheet3ajazNo ratings yet

- Altera Weave Effect An528Document20 pagesAltera Weave Effect An528Tony LuanNo ratings yet

- Causes and Solutions For Cracking in Grouts: Technical BulletinDocument2 pagesCauses and Solutions For Cracking in Grouts: Technical BulletinCarlos AlvaNo ratings yet

- Petchem RD 2nd PartIIDocument274 pagesPetchem RD 2nd PartIIIrfan KhanNo ratings yet

- Mil 24667Document42 pagesMil 24667EstrellaLazoRomero100% (1)

- 840 Series Hygienic Pump: Watson-Marlow PumpsDocument2 pages840 Series Hygienic Pump: Watson-Marlow PumpsCesar Armando Hernandez ViteNo ratings yet

- Paint & Coatings Industry August 2014Document56 pagesPaint & Coatings Industry August 2014Trevor J. Hutley100% (1)

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuNo ratings yet

- Vol I Overall Index Tender DocsDocument7 pagesVol I Overall Index Tender DocsSlobodan VajdicNo ratings yet

- Painting Data SheetsDocument12 pagesPainting Data SheetsRachidNakhil100% (1)

- Sika Crack FixDocument2 pagesSika Crack FixChristian ChetcutiNo ratings yet

- AEROGEL ReviewDocument20 pagesAEROGEL ReviewNarayani RajagopalanNo ratings yet

- Corrosion Testing Report Zinc Rich Primer Vs Stainless SteelDocument2 pagesCorrosion Testing Report Zinc Rich Primer Vs Stainless SteelOscar JiménezNo ratings yet