Professional Documents

Culture Documents

11ib5896uo A

Uploaded by

pakojidastavimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11ib5896uo A

Uploaded by

pakojidastavimCopyright:

Available Formats

DIRECTIONS FOR USE

NetSure 701, 48 V DC Power Supply System, BMK 447 090 with ACU+

Emerson Network Power Energy Systems AB 2010 All rights reserved

Product code: EN/LZB 135 044/09

11 IB 5896UO, Rev A 2011-01-11 1(36)

DIRECTIONS FOR USE NetSure 701

The contents of this document are subject to revision without notice due to continued progress in methodology, design, and manufacturing.

Emerson Network Power Energy Systems AB

SE 141 82 Stockholm Sweden

Tel. +46 8 721 6000 Fax. +46 8 721 7177 www.emersonenergy.com

11 IB 5896UO, Rev A 2011-01-11 2(36)

DIRECTIONS FOR USE NetSure 701

Contents

1 2 3 4

4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9

Introduction Function Configurations Units in the system

Rectifier Rectifier shelf Control unit ACU+ Supervision module (SM DU) Distribution units Battery connection units AC distribution unit AC connection terminals Interface Board (IB2)

4 4 6 15

15 17 18 18 19 20 22 23 24

5

5.1 5.2 5.3

Technical data

System Cabinet Rectifier

25

25 25 25

6 7 8

8.1 8.2 8.3 8.4

Installation Start-up and installation test Maintenance

Safety Scheduled maintenance Alarms Fault symptoms and trouble shooting

25 25 26

26 26 26 27

9

9.1 9.2 9.3 9.4 9.5

Exchange of units and parts

Exchange of rectifiers Exchange of distribution circuit-breaker Exchange of ACU+ Exchange of IB2 board Exchange of SM DU

31

31 33 34 34 35

10

Abbreviations used in this document

36

11 IB 5896UO, Rev A 2011-01-11 3(36)

DIRECTIONS FOR USE NetSure 701

Introduction

The NetSure 701 48 V DC power system consists of cabinet, two AC distribution unit, maximum 36 rectifiers of 3200 W, battery connection, the battery fuses or the battery CBs, a supervision unit ACU+ and a supervision module SM DU. For extension, cabinets can be connected in parallel.

Function

For the protection of the batteries during a power outage, the load is disconnected at a preset voltage or after a predetermined delay. To prolong the service of some loads at a long power outage, the DC distribution is divided into two branches. One is for normal load and one for priority load, so the disconnection can be made in two steps.

Figure 1.

Example of system topology.

11 IB 5896UO, Rev A 2011-01-11 4(36)

DIRECTIONS FOR USE NetSure 701

Figure 2.

Example of system topology.

11 IB 5896UO, Rev A 2011-01-11 5(36)

DIRECTIONS FOR USE NetSure 701

Configurations

The cabinets can be configured with different numbers of rectifiers, batteryand distribution circuit-breakers/fuses. They can be built for top or bottom cabling. The cabling mode must be stated before ordering.

Positive bar Interconnection bars + and -, for extension cabinet Battery CBs, (2 or 3) x 1500A SM DU AC distribution unit with 16 x 2pole 25A CBs, ACU+ or SM DU in extension cabinet, IB2 board AC distribution unit with 20 x 2pole 25A CBs

Rectifier shelves

Figure 3.

Example of the configuration of top cabling with (2 or 3) x 1500A CBs.

11 IB 5896UO, Rev A 2011-01-11 6(36)

DIRECTIONS FOR USE NetSure 701

Positive bar Interconnection bars + and -, for extension cabinet Battery fuses, (2 or 3) x 1250A SM DU AC distribution unit with 16 x 2pole 25A CBs, ACU+ or SM DU in extension cabinet, IB2 board AC distribution unit with 20 x 2pole 25A CBs

Rectifier shelves

Figure 4.

Example of the configuration of top cabling with (2 or3) x NH4A fuses.

11 IB 5896UO, Rev A 2011-01-11 7(36)

DIRECTIONS FOR USE NetSure 701

Positive bar Interconnection bars + and -, for extension cabinet Battery fuses, 5 x 630A SM DU AC distribution unit with 16 x 2pole 25A CBs, ACU+ or SM DU in extension cabinet, IB2 board AC distribution unit with 20 x 2pole 25A CBs

Rectifier shelves

Figure 5.

Example of the configuration of top cabling with 5 x NH3 fuses.

11 IB 5896UO, Rev A 2011-01-11 8(36)

DIRECTIONS FOR USE NetSure 701

Rectifier shelves

SM DU AC distribution unit with 16 x 2pole 25A CBs, ACU+ or SM DU in extension cabinet, IB2 board AC distribution unit with 20 x 2pole 25A CBs Battery CBs, (2 or 3) x 1500A Interconnection bars + and -, for extension cabinet Positive bar

Figure 6.

Example of the configuration of bottom cabling with 2 or 3 x 1500A CBs.

11 IB 5896UO, Rev A 2011-01-11 9(36)

DIRECTIONS FOR USE NetSure 701

Rectifier shelves

SM DU AC distribution unit with 16 x 2pole 25A CBs, ACU+ or SM DU in extension cabinet, IB2 board AC distribution unit with 20 x 2pole 25A CBs Battery fuses, (2 or 3) x 1250A Interconnection bars + and -, for extension cabinet Positive bar

Figure 7.

Example of the configuration of bottom cabling with 2 or 3 x NH4A fuses.

11 IB 5896UO, Rev A 2011-01-11 10(36)

DIRECTIONS FOR USE NetSure 701

Rectifier shelves

SM DU AC distribution unit with 16 x 2pole 25A CBs, ACU+ or SM DU in extension cabinet, IB2 board AC distribution unit with 20 x 2pole 25A CBs Battery fuses, 5 x 630A Interconnection bars + and -, for extension cabinet

Positive bar

Figure 8.

Example of the configuration of bottom cabling with 5 x NH3 fuses.

11 IB 5896UO, Rev A 2011-01-11 11(36)

DIRECTIONS FOR USE NetSure 701

Positive bar + _ Interconnection bars + and , for extension cabinet Distribution unit 3 x NH4A + _

Distribution unit 6 x NH3

SMDU

Distribution unit 6 x NH3

Figure 9.

Examples of the distribution cabinet top cabling with 6 x NH3 fuses and 3 x NH4A fuses.

11 IB 5896UO, Rev A 2011-01-11 12(36)

DIRECTIONS FOR USE NetSure 701

Distribution unit 6 x NH3

SMDU

Distribution unit 6 x NH3

Distribution unit 3 x NH4A _ _ Interconnection bars + and , for extension cabinet

Positive bar

Figure 10. Examples of the distribution cabinet bottom cabling with 6 x NH3 fuses and 3 x NH4A fuses.

11 IB 5896UO, Rev A 2011-01-11 13(36)

DIRECTIONS FOR USE NetSure 701

Basic configuration:

Note:

Cabinet for overhead cabling or cabinet for under floor cabling Maximum 36 rectifiers 3200 W for main cabinet. Maximum 24 rectifiers 3200 W for extension cabinet. Six rectifier shelves for maximum 6 rectifiers each Multi-function unit with two or three battery CBs max 1500 A, two or three shunts 2000A. Multi-function unit with two or three battery fuses max 1250 A, two or three shunts 2000A. Multi-function unit with five battery fuses max 630 A, a 3000 A shunt. AC distribution unit with 16 x 2pole 25A CBs for 16 rectifiers and an Advanced control unit (ACU+) or Supervision module (SMDU) AC distribution unit with 20 x 2pole 25A CBs for 20 rectifiers. Interconnection between cabinets is made with bars passing the uncovered cabinet sides

The sum of the battery fuses installed must not exceed: - 3150A with 5 x NH3 multifunction unit - 4500A with 3 x NH4 multifunction unit

Distribution cabinet: Cabinet for overhead cabling or cabinet for under floor cabling Distribution unit with six distribution fuses NH3, one shunt 2000A. Distribution unit with three distribution fuses NH4A, three shunts 2000A. Supervision module (SMDU) Interconnection between cabinets is made with bars passing the uncovered cabinet sides

Options: Cables for battery, distribution, earthing and signalling Cabling materials (lugs, tie wraps, markings) Internal AC distribution unit for 10 rectifiers Mains cable Cabinet anchoring material BMY 107 125/1 Temperature sensor (battery, room) KET 103 06/1 (cable 3 m) Temperature sensor (battery, room) KET 103 06/2 (cable 10 m) Maximum six extension cabinets Spare parts

11 IB 5896UO, Rev A 2011-01-11 14(36)

DIRECTIONS FOR USE NetSure 701

4

4.1

Units in the system

Rectifier

The rectifier is voltage regulated of a constant power limitation type (3200 W) and designed to meet the most stringent electrical requirements as well as demands for high power density (fan cooling). It can work independently of the control unit, and can share the load actively and control the system voltage.

LEDs

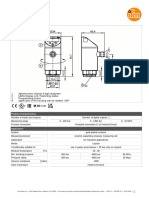

Figure 11. Rectifier 3200e.

4.1.1 LEDs

The front panel has three indicator LEDs. The functions of the LEDs are listed in the table below. LED Power indicator (green) Normal Abnormal ON OFF Flashing ON Flashing Alarm indicator (red) OFF ON Flashing Cause of Abnormality No AC Mains Supply Rectifier is under control by ACU+ AC input over/undervoltage, PFC over/undervoltage and overtemperature Communication with ACU+ failure Output overvoltage Fan Failure

Protection OFF indicator (yellow)

11 IB 5896UO, Rev A 2011-01-11 15(36)

DIRECTIONS FOR USE NetSure 701

4.1.2 Features

Hot swappable. The rectifier is plug-and-play to live inputs and outputs. Active load sharing. The rectifier uses advanced digital active load sharing technology for minimum load difference between units. Power derating by input voltage. The rectifier will go into power derated mode if the input AC voltage is too low or too high. Power derating by output load. The rectifier will limit its output power constant when the load exceeds the nominal output power. Power derating by temperature. For high temperatures the output load will be gradually reduced. See technical data. Current limiting function. The rectifier has a current limiting function. The current limit can be set from an ACU+. Foldback current limiting function. If a short circuit occurs on the rectifier output terminals, the rectifier will keep its output current at a constant value. When the short circuit fault is cleared, the rectifier will automatically restore to normal operation. Adjustable output voltage. The voltage can be set from an ACU+. Current walk-in. The rectifier can be set from an ACU+ to take load gradually in order to reduce the stress on generators, fuses etc. ECO Mode. At low load the rectifier can be shut off due to a high efficiency of the operating rectifiers. Fan control. The fans speed is controlled according to the rectifier internal temperature. The fan is stopped completely at low temperature and at very low or high input voltage.

4.1.3 Digital Signal Processor (DSP)

The rectifier has a built-in advanced DSP that monitors and controls the operation of the rectifier. The DSP also communicates with an ACU+ through a CAN bus. The rectifier can receive commands such as turning on/off, current walk-in on/off signal and high voltage alarm reset signal from an ACU+. An ACU+ can adjust the output voltage, overvoltage alarm point, current walk-in time and the current limit of the rectifier. The rectifier reports its output voltage, output current, temperature, current limit setpoint, overvoltage setpoint, on/off status and alarm information to an SCU/ACU in real time. By querying the DSP, an ACU+ can get the following data from the rectifier: Input voltage, output voltage, output current, current limit setpoint, temperature of rectifier, and overvoltage setpoint. By querying the DSP, an ACU+ can get the following state information from the rectifier: On/off, protect (input protect, inner DC bus voltage protect; overtemperature), fault (HVSD, fan failure), thermal derating, AC derating, AC failure, and unbalance current.

11 IB 5896UO, Rev A 2011-01-11 16(36)

DIRECTIONS FOR USE NetSure 701

An ACU+ can get the following unit information from the rectifier: Address, code, date, SW version and HW version.

4.1.4 Protection functions

Input over/undervoltage protection. The rectifier will shut down and its yellow LED will emit light if the input voltage is outside the range 85 to 290 V AC. An alarm will be sent to the ACU+. Output overvoltage protection. If the rectifier output voltage exceeds a limit that can be set from the ACU+, the rectifier will shut down. If output over voltage occurs two times within 5 minutes, the rectifier can only be restarted manually and its red alarm LED will emit light. An alarm will be sent to the ACU+. Over-temperature protection. The rectifier will limit its power to 50% of rated output power if its internal temperature is higher than 105 C. If the internal temperature reaches 110 C, the rectifier will shut down and its yellow LED will emit light. An alarm will be sent to the ACU+. The alarm will cease and the rectifier will restart when the temperature becomes normal. Communication failure. At communication failure, the rectifier output voltage is reduced to a default value for protection of the battery. The yellow LED will flash and alarm will be sent to the ACU+. Fan alarm. The red LED will flash at a fan fault and the rectifier will stop. Unbalance of Rectifier Output Current. When the output current of the rectifiers in a DC power system is unbalanced, the rectifier that outputs unbalanced current will be identified automatically and its yellow LED will emit light. An alarm will be sent to the ACU+.

4.2

Rectifier shelf

Figure 12. Shelf with six rectifiers. The rectifier shelf has space for six rectifiers. Six shelves can be used in the system.

11 IB 5896UO, Rev A 2011-01-11 17(36)

DIRECTIONS FOR USE NetSure 701

4.3

Control unit ACU+

The control unit is placed in the multifunction unit of the main cabinet. It controls, supervises and communicates with the other units of the power supply system and manages alarm handling, etc. The advanced control unit (ACU+) has an LCD-display, offers internal supervision and alarm handling, sends external alarm signals over relays and communicates externally via Ethernet with external computer-based supervision systems (EEM, for example) that can be implemented for different maintenance activities. It also has an interface to communicate with supervision modules (SM) for supervision of extension cabinets, AC mains and batteries, for example. It has a Web interface for communication with MS Internet Explorer. For detailed information about the ACU+, refer to USERS GUIDE 11 FI 5982 LR.

Figure 13. ACU+.

4.4

Supervision module (SM DU)

The supervision module (SM DU) handles battery current measurement and the alarm management of battery and distribution CBs. It communicates with the ACU+ in the main cabinet via a CAN Bus cable.The SM DU is placed under the distribution unit in the extension cabinets. If optional shunts are included in distribution units in the main cabinet, an SM DU for current measurement can be placed in the battery unit (at bottom configuration) or in the AC unit (at top configuration). For detailed information about the SM DU, refer to USERS GUIDE 11 GP 9816 JB.

11 IB 5896UO, Rev A 2011-01-11 18(36)

DIRECTIONS FOR USE NetSure 701

4.5

Distribution units

There are a number of distribution units with circuit breakers or fuses that can be equipped and configured in different ways.

4.5.1 Positive connection bar

Figure 14. Positive connection bar. The bar has M10 and M12 holes for connection of the battery cables only.

4.5.2 Distribution units

The distribution units are located in the separate distribution cabinet. There are two types of the distribution unit. The distribution units with NH3 fuses or with NH4A fuss. Distribution fuses of maximum 630 A can be used in the distribution fuse holders in the distribution unit BMG 653 75/3 & /5, there is one battery shunt 2000A. Distribution fuses of maximum 1 500 A can be used in the distribution fuse holders in the distribution unit BMG 653 77/2 & /4, there are three battery shunts 2000A.

Figure 15. Distribution unit BMG 653 75/3 with 6 x NH3 fuse holders.

11 IB 5896UO, Rev A 2011-01-11 19(36)

DIRECTIONS FOR USE NetSure 701

Figure 16. Distribution unit BMG 653 77/4 with 3 x NH4A fuses.

4.6

Battery connection units

Battery shunt 3000A

5 x battery fuse holders

Figure 17. Battery fuse unit with 5 x NH3 fuses.

11 IB 5896UO, Rev A 2011-01-11 20(36)

DIRECTIONS FOR USE NetSure 701

2 x battery fuse holders

Figure 18. Battery fuse unit with 2 x NH4A fuse holders.

3 x battery fuse holders

Figure 19. Battery fuse unit with 3 x NH4A fuses.

11 IB 5896UO, Rev A 2011-01-11 21(36)

DIRECTIONS FOR USE NetSure 701

3 x battery CBs

Figure 20. Battery fuse unit with 3 x 1500A CBs. Battery fuses of maximum 630 A can be used in the battery fuse holders in the battery fuse unit BMG 653 79/1 & /2, there is one battery shunt 3000A. Three battery fuses of maximum 1 500 A can be used in the battery fuse holders in the battery fuse unit BMG 653 77/2 & /4, there are three battery shunts 2000A. Two battery fuses of maximum 1 500 A can be used in the battery fuse holders in the battery fuse unit BMG 653 77/7 & /8, there are two battery shunts 2000A. In the battery unit BMG 653 78/2 & /4 are used 1 500 A circuit breakers with three battery shunts 2000A.

4.7

AC distribution unit

Figure 21. AC distribution unit BMG 653 71/ 23.

11 IB 5896UO, Rev A 2011-01-11 22(36)

DIRECTIONS FOR USE NetSure 701

Depending on system configuration and mains voltage, there are two types of AC distribution units available. They are factory mounted in the cabinet. The first one BMG 653 71/23 contains 16 x 2pole 25A 3W+N+PE CBs and control unit ACU+ in main cabinet or in extension cabinet SMDU.

Figure 22. AC distribution unit BMG 653 71/ 6. Depending on system configuration and mains voltage, there are two types of AC distribution units available. They are factory mounted in the cabinet. The second one BMG 653 71/6 contains 20 x 2pole 25A CBs.

4.8

AC connection terminals

If external AC protection fuses/CBs are used, a unit with two terminal blocks on each side walls is delivered. The unit is adapted to the number of rectifier slots included in the cabinet. AC MAINS IN L1 L2 L3 N

Figure 23. Location of the Mains terminals. There are two mains terminals each one AC distribution unit. See, Figure 23 and Figure 24. The cables should be supplied from an external mains distribution unit (optional). There is an option with just L1, L2 and L3 is used when the system is delta connected. The lower ranged of in put voltage Use the low line voltage 230V.

11 IB 5896UO, Rev A 2011-01-11 23(36)

DIRECTIONS FOR USE NetSure 701

AC MAINS IN L1 L2 L3 N N

Customer PE connection

AC MAINS IN L1 L2 L3

Customer PE connection

Figure 24. Mains terminals.

4.9

Interface Board (IB2)

Figure 25. Interface board IB2.

11 IB 5896UO, Rev A 2011-01-11 24(36)

DIRECTIONS FOR USE NetSure 701

5

5.1

Technical data

System

Number of cabinets Nominal DC voltage Maximum output current Operational temperature maximum 2 48 V 4 750 A system with 72 rectifiers 5 to +40 C (with hydraulic magnetic circuit-breakers) 5 to +30 C (with thermal/electro magnetic circuit-breakers) Storage temperature Relative humidity 40 to +70 C 5 to 90%

5.2

Cabinet

Maximum output current Building practice Height (incl. top cover and feet) Footprint (with x depth) Weight 2 375 A cabinet with 36 rectifiers 23 2050 mm 600 x 600 mm maximum 250 kg

5.3

Rectifier

See data sheet EN/LZT 145 230 See data sheet EN/LZT 145 234

Installation

See INSTALLATION INSTRUCTIONS 11GO 4296 KI.

Start-up and installation test

See TEST INSTRUCTIONS 11 NR 7000 MG.

11 IB 5896UO, Rev A 2011-01-11 25(36)

DIRECTIONS FOR USE NetSure 701

8

8.1

Maintenance

Safety

The document SAFETY RULES 11 PA 0267 NH and local safety rules shall be followed when doing maintenance work in the power supply equipment. Measures that require work inside the cabinets or intervention in a unit shall always be carried out by adequately trained personnel with adequate knowledge of the power supply system. When in doubt about an action or how to carry it out, always call for adequately trained personnel. In case it is necessary to work on a live power supply system, the approval for this type of work must be given, based on local regulations governing for example the following areas: General rules for work on live equipment Certification of operatives conducted by certified supervisor Approved tools Customer approval

8.2

Scheduled maintenance

Use a vacuum cleaner to remove dust from the air inlets of the cabinets. Check and test the batteries according to the recommendations of the battery supplier. A scheduled performance test according to the following table shall be performed at least every two years according to item Test of signals and supervision in the document TEST INSTRUCTIONS 11 NR 7000 MG. Settings according to the document TABLE OF SET VALUES, shall be verified in this test. A copy of the test result shall be kept in the logbook of the plant.

8.3

Alarms

The different alarm categories used in the power supply system are Critical, Major, Observation and No Alarm. An alarm of category Critical requires immediate action, whatever the time of day or night. An alarm of category Major requires immediate action if it occurs during working-hours, otherwise as soon as the working-hours commence. An alarm of category Observation is an alarm that indicates a temporary state of operation and does not normally require any action. However, if the alarm persists for more than 20 hours, it must be investigated. If an alarm has category No Alarm it means that the alarm is deactivated and will not be shown in the display of the ACU+.

11 IB 5896UO, Rev A 2011-01-11 26(36)

8.3.1 Alarm categories

DIRECTIONS FOR USE NetSure 701

8.3.2 Procedure in case of alarm

Enter in the logbook of the power supply system all observations made at the moment of failure, such as date, time, system voltage and rectifier load. Enter also what alarm(s) are shown and any external disturbance such as thunderstorm or mains failure. Trace activated alarms by means of the alarm survey of the respective unit and the item, which describes what actions to take on the respective alarm.

8.4

Fault symptoms and trouble shooting

For system alarms, see USERS GUIDE 11 FI 5982 LR for the ACU+.

8.4.1 System alarms

Alarm on the ACU+ display

Cause

Suggestion Check why before manually clearing the alarm from the ACU+ display/ web page. Find out and eliminate the reason for the tripped circuit breaker before resetting it. Check the connectors and cables for the CAN loop. Exchange the rectifier that does not respond. Exchange the ACU+.

Alarm Blocked The outgoing alarms are manually blocked from the ACU+. Fuse Alarm One or more distribution circuit-breakers for the load have tripped. There CAN communication is broken.

CAN Comm Fault

LVD 1 Disconnected

The battery contactor is open because the battery is too deep discharged. The batteries are disconnected at a preset level, in order to protect them from overdischarging. The boost charging current exceeds the set max. value.

If there is a mains failure, check that it is not caused by broken supply fuses. If the rectifiers are working, the problem may be that the system load is higher than the rectifier capacity, causing the batteries to discharge. If this is the reason, install more rectifiers. Check the settings.

Abnorm Bat Curr Contactor Fault Fuse Alarm

An LVD contactor is in a wrong Check the contactor functions. state. Exchange the contactor. Indicates that one or more battery fuses have blown or been removed. If a battery fuse has been removed manually, check with the person that removed it before reinserting it. Ensure that there is no fault before doing that. The battery fuse shall be reinserted by adequately trained personnel. Find out and eliminate the reason for the blown fuse before swapping it.

If the battery fuse is blown. The reason for the failure probably is overload or short circuit. ACU+ fault Manual Mode ACU+ failure. The battery monitoring has been set to Manual mode in the ACU+.

Exchange the ACU+. Check why before resetting it to automatic.

11 IB 5896UO, Rev A 2011-01-11 27(36)

DIRECTIONS FOR USE NetSure 701

Alarm on the ACU+ display Dis Curr Im Cause The currents from two groups of batteries are not equal. Note: There must be two battery shunts in the system to activate this function. The battery test has failed. Check the batteries. Suggestion

Test Failure

Check the float charging level. Check that the load is lower than the capacity of the rectifiers. Check the battery according to the recommendations of the supplier.

Rect Over Volt Rectifier over voltage Mains Failure Multi-rect fail Maintenance Alrm Rectifier Lost All rectifiers have stopped. Two or more rectifiers have stopped. The maintenance timer gives alarm The ACU+ has detected a reduction in the number of running rectifiers. AC input voltage outside the normal range. Rectifier over temperature protection. Rectifier failure

See item 8.4.2 Check if there is a general mains failure. Check that it is not caused by broken supply fuses. See item 8.4.2 Check the settings of the Maintenance Time Delay See item 8.4.2

Rect AC Failure Rect Over Temp Rectifier Failure

See item 8.4.2 See item 8.4.2 See item 8.4.2 See item 8.4.2 See item 8.4.2. If the batteries are being recharged, the alarm will cease by itself when the battery voltage has increased to the charging level. If the system load is higher than the rectifier capacity, the batteries will discharge. If this is the reason, install more rectifiers. If one or more of the rectifiers are out of order, exchange the faulty rectifiers.

Rect Protected Rectifier protection Rect Fan Fail Rectifier fan failure.

Rect Curr limit Rectifier overload. The load is higher than the rectifier capacity.

Under Vol

The distribution voltage has dropped below the preset alarm level, usually initiated because of mains failure.

If there is a mains failure, check if some load could be switched off in order to prolong the operating time of the plant. If there is a rectifier failure, see item 8.4.2. If the system load is too high related to the rectifier capacity, install more rectifiers. If the batteries are being recharged, the alarm will cease by itself when the battery voltage has increased to the charging level.

11 IB 5896UO, Rev A 2011-01-11 28(36)

DIRECTIONS FOR USE NetSure 701

Alarm on the ACU+ display Very Under Vol Cause The distribution voltage has dropped below the preset alarm level, usually initiated because of mains failure. The system voltage exceeds the preset level. Suggestion See DC Volt Low#1/DC Under Voltage

Over Voltage

Check the set float-, battery- and the over-voltage; if the limits are incorrect, find out why they have changed and correct them. Check the temperature.

Low Temp /Low Amb Temp

The temperature on a temperature sensor exceeds the set value.

Check the settings of the ACU+. If the temperature is OK, exchange the temperature sensor. Check the battery temperature.

High Temp

The temperature on a battery temperature sensor exceeds the set value. The temperature on a battery temperature sensor exceeds the set value. The temperature on a room temperature sensor exceeds the set value.

Check the settings of the ACU+. If the temperature is OK, exchange the temperature sensor. See High Temp alarm. Check the room temperature.

Very hi-Temp

High Amb Temp

Check the settings of the ACU+. If the temperature is OK, exchange the temperature sensor. Check the cable and the connector of the temperature sensor. Exchange the temperature sensor.

T Sensor Fault

The temperature sensor has a fault. Planned battery test in progress. Mains failure. Manual battery test in progress. Short battery test in progress. Cyclic boost charge in progress. Automatic boost charge in progress. Manual boost charge in progress. The boost charge function is blocked.

Plan BT AC failure BT Manual BT Short Test Cyclic BC Auto BC Manual BC Charge Prohibit Ab load curr Over Power DI 1 to DI 8

Wait for the test to stop automatically. See Mains Failure alarm. Wait for the test to stop automatically. Wait for the test to stop automatically. Wait for the boost charge to stop automatically. Wait for the boost charge to stop automatically. Wait for the boost charge to stop automatically, or stop it manually. The boost charge will be blocked by abnormal conditions in the system.

The system load is higher than Check the settings. the set level.

Indicate alarms on the digital inputs 1- 8.

Check the equipment connected to the corresponding input.

11 IB 5896UO, Rev A 2011-01-11 29(36)

DIRECTIONS FOR USE NetSure 701

8.4.2 Rectifier

The usual fault symptoms of the rectifier include: power indicator (green) off, protection indicator (yellow) on, protection indicator (yellow) flashing, alarm indicator (red) on, and alarm indicator (red) flashing.

Symptom Power indicator (green) off Cause No input voltage Input fuse/circuit-breaker fault Suggestion Make sure there is input AC voltage Replace the fuse with a new one of the same model or switch on the circuit-breaker.

AC input voltage outside the Check that the AC input voltage is within normal normal range range PFC over voltage Current sharing function is disabled Replace the rectifier Replace the rectifier

Rectifier over temperature protection, which is caused by: Protection indicator Fan blocked Remove the obstacle that block the fan (yellow) on Ventilation blocked: the inlet or outlet blocked Ambient temperature too high or rectifier inlet too close to a heater Rectifier not completely inserted into the slot Protection indicator (yellow) flashing Alarm indicator (red) on Alarm indicator (red) flashing Rectifier communication failure Remove the objects that blocks the inlet or outlet Remove the heater, lower the ambient temperature

Insert the rectifier properly

Exchange the rectifier for a new one.

Rectifier over voltage

Remove the rectifier from the DC power system and then reinsert it. Exchange the rectifier for a new one if the alarm continues.

Fan not running

Replace the fan

When multiple rectifiers are in parallel connection and the unbalance of current sharing among them is higher than 3 %, check if the communication cables are correctly connected. If the current sharing is still unsuccessful after the correction, replace the rectifier of which the current sharing is out of range.

11 IB 5896UO, Rev A 2011-01-11 30(36)

DIRECTIONS FOR USE NetSure 701

9

9.1

Exchange of units and parts

Exchange of rectifiers

1. Push the handle of the faulty rectifier. The handle will pop out and release the locking latch of the rectifier.

Handl e

Figure 26. Rectifier handle. 2. Pull out the rectifier unit and remove it. 3. Make sure the handle of the new rectifier unit is locked in its socket.

Latch

Figure 27. Locking latch. 4. Insert the new rectifier unit. Push it into its slot until the latch blocks the way. The latch is set to block the way with the purpose of prolonging the soft start-up time, as the rectifier may get damaged by a fast start-up. 5. Click the handle. It will pop out, and the latch will withdraw into the rectifier. 6. Continue to push the rectifier into the slot completely. 7. Push the handle into its socket to lock the rectifier. Now the rectifier is fixed to the slot by the latch. The green LED emits light and the fan will start.

11 IB 5896UO, Rev A 2011-01-11 31(36)

DIRECTIONS FOR USE NetSure 701

9.1.1

Rectifier fan replacement

If the fan does not work because it is faulty, exchange it for a new one. 1. Remove the rectifier according to item 9.1.

Figure 28. Fan replacement. 2. Loosen the three screws for the baffle and remove it. 3. Unplug the power cable of the fan and remove the fan. 4. Replace the fan. 5. Plug the fan power cable back into the corresponding socket. 6. Put the fan back (the side with the tag facing inwards). 7. Mount the front baffle and fix it with the three screws.

11 IB 5896UO, Rev A 2011-01-11 32(36)

DIRECTIONS FOR USE NetSure 701

9.2

Exchange of distribution circuit-breaker

1. Open the distribution unit front. 2. Loosen the terminal screws. See Figure 29.

Terminal screws

Lock

Figure 29. Locked circuit-breaker.

Figure 30. Opened circuit-breaker.

3. Pull the lock to unlock the CB from DIN rail. 4. Remove and change the CB. 5. Mount the new CB on the DIN rail. See Figure 31.

Figure 31. Mount the new CB on the DIN rail. 6. Close the lock of the CB and tight the terminal screws.

11 IB 5896UO, Rev A 2011-01-11 33(36)

DIRECTIONS FOR USE NetSure 701

9.3

Exchange of ACU+

fixing screw

Handle with fixing screw

Figure 32. Control unit ACU+.

Note:

If a LVD contactor is in its OFF- position, it will reconnect when the ACU+ is removed from a live system.

1. Loose the fixing screw of handle and pull out the control unit from the subrack. See Figure 32. 2. Insert the new control unit into the subrack, push it in completely and fix it by the fixing screw.

9.4

Exchange of IB2 board

Note:

Be careful not to damage the surface mounted components at the back of the board when pulling it out. 4 x fixing screw

Figure 33. IB2 Board. 1. Loose the fixing screw of the IB2 Board cover above the ACU+, see Figure 32, and pull out the IB2 board

11 IB 5896UO, Rev A 2011-01-11 34(36)

DIRECTIONS FOR USE NetSure 701

2. Disconnect, insulate and mark the signalling cables connected to the terminals of the IB2 board. 3. Remove the fixing screws, and then pull out the IB2 board from the subrack. See Figure 33. 4. Insert the new Ib2 board into the subrack and fix it with the screws. 5. Connect the signalling cables to the terminals of the new board.

9.5

Note: Note:

Exchange of SM DU

The system has no SM DU information during this work. The system is delivered with all software on the enclosed CD.

J1 is the power supply interface. J2 is the I/O interface. J3 is for CAN communication. J4 and J4A are for RS485 communication. J5 is a RJ45 connector and is for the console port. JP1, JP2 and JP3 are jumpers for calibration and software download, and user is not supposed to use them. S1, S2 and S3 are three dip switches. The positions of the connectors are shown in Figure 34. J2

S1 S2 S3 J1

JP1 JP3 LED J5 J4A J4 J3

Figure 34. SM DU without cover. 1. Remove the fixing screw, and then pull out the cover of SM DU. 2. Disconnect J1 cable power off. 3. Disconnect all others signaling cable (J2, J3, J4 and J5). 4. Pull out the SM DU board and change for a new one. Before the change of the new board we must set up the DIP switches and update the configuration by using FAD according to the actual applications of SM DU. 5. Plug in the signaling cables (J2, J3, J4 and J5). 6. Plug in the J1 terminal. 7. Fix the cover with the screws.

11 IB 5896UO, Rev A 2011-01-11 35(36)

DIRECTIONS FOR USE NetSure 701

10

Abbreviations used in this document

AC BC BT BU CAN CB DC DI DIN DSP DU EEM Alternating Current Battery Charge Battery Test Battery connection Unit Controller Area Network Circuit Breaker Direct Current Digital Input Deutsches Institut fr Normung Digital Signal Processor Distribution Unit Emerson EnergyMaster ENERGYMASTER is a registered trademark of Emerson Network Power Energy Systems AB ElectroStatic Discharge High Ohmic Distribution High Voltage Switch Down Hard Ware Liquid Crystal Display Light Emitting Diode Low Ohmic Distribution Low Voltage Disconnect Multi Function Unit Main Earth Terminal Protective Earth Rectifier Standard Control Unit Advanced Control Unit Safety Extra Low Voltage Supervision Module Supervision Module Distribution Unit Supervision Module-Input/Output

ESD HOD HVSD HW LCD LED LOD LVD MFU MET PE R SCU+ ACU+ SELV SM SM DU SM IO

11 IB 5896UO, Rev A 2011-01-11 36(36)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- DSPDocument13 pagesDSPanshujjainNo ratings yet

- Control of Harmonics in 6-Pulse Rectifiers ThesisDocument116 pagesControl of Harmonics in 6-Pulse Rectifiers ThesisAlfredo Lopez CordovaNo ratings yet

- Att.1 QT1-L-G-020-05-00003, KKS Numbering SystemDocument85 pagesAtt.1 QT1-L-G-020-05-00003, KKS Numbering SystemDoan Ngoc DucNo ratings yet

- SkyAir R410A Inv Cooling EDVN281407 PDFDocument532 pagesSkyAir R410A Inv Cooling EDVN281407 PDFThinh Nguyen100% (2)

- Z-TRAUQ Current Transducers GuideDocument2 pagesZ-TRAUQ Current Transducers GuidepakojidastavimNo ratings yet

- 500W48VDC Air-ConDocument1 page500W48VDC Air-ConpakojidastavimNo ratings yet

- Spiral Series Fuse BodyDocument1 pageSpiral Series Fuse BodypakojidastavimNo ratings yet

- Engineering - A Pragmatic Introduction To The Art of Electrical EngineeringDocument140 pagesEngineering - A Pragmatic Introduction To The Art of Electrical EngineeringUfuk DzlNo ratings yet

- R48-2000e Datasheet Rev1.1 20100629Document2 pagesR48-2000e Datasheet Rev1.1 20100629pakojidastavimNo ratings yet

- PowerWizard 2 0 (GB) 1006Document2 pagesPowerWizard 2 0 (GB) 1006pakojidastavimNo ratings yet

- Esure Rectifier R483500eDocument2 pagesEsure Rectifier R483500epakojidastavimNo ratings yet

- 08 0033 1b E HK Kap 11 DCDocument20 pages08 0033 1b E HK Kap 11 DCpakojidastavimNo ratings yet

- RM3048XE 3.0kW 48V DC Modular Rectifiers v1.0Document2 pagesRM3048XE 3.0kW 48V DC Modular Rectifiers v1.0pakojidastavimNo ratings yet

- En PS TL 2CP550 BPS 001 - 0212Document4 pagesEn PS TL 2CP550 BPS 001 - 0212pakojidastavimNo ratings yet

- Mcu2500 GBDocument8 pagesMcu2500 GBpakojidastavimNo ratings yet

- Cordless Tools Battery Technology ComparisonDocument15 pagesCordless Tools Battery Technology ComparisonpakojidastavimNo ratings yet

- Abcde: Connect With ConfidenceDocument2 pagesAbcde: Connect With ConfidencepakojidastavimNo ratings yet

- BUS98Document9 pagesBUS98pakojidastavimNo ratings yet

- DiDocument10 pagesDipakojidastavimNo ratings yet

- 2N-Easy Gate (En)Document2 pages2N-Easy Gate (En)pakojidastavimNo ratings yet

- 10-22 kVA CAL Enclosure (GB) (0908)Document2 pages10-22 kVA CAL Enclosure (GB) (0908)pakojidastavimNo ratings yet

- Tsi Veda 48 230 Data Sheet v03Document2 pagesTsi Veda 48 230 Data Sheet v03pakojidastavimNo ratings yet

- Inverter Pack Solutions DatasheetDocument2 pagesInverter Pack Solutions DatasheetpakojidastavimNo ratings yet

- Terms and Conditions of SaleDocument8 pagesTerms and Conditions of SalepakojidastavimNo ratings yet

- Inverter Pack Solutions DatasheetDocument2 pagesInverter Pack Solutions DatasheetpakojidastavimNo ratings yet

- 04@trainig Cours ENP NetSure 701 UnitsDocument1 page04@trainig Cours ENP NetSure 701 UnitspakojidastavimNo ratings yet

- Emerson - BRAVO Inverter Data SheetDocument2 pagesEmerson - BRAVO Inverter Data SheetOscar ReyesNo ratings yet

- WebSCADA Modbus BrochureDocument2 pagesWebSCADA Modbus BrochurepakojidastavimNo ratings yet

- NOVA Inverter Data SheetDocument2 pagesNOVA Inverter Data SheetpakojidastavimNo ratings yet

- Emerson's Commitment to Workplace Safety and HealthDocument1 pageEmerson's Commitment to Workplace Safety and HealthpakojidastavimNo ratings yet

- ENLZT145294RA BulkSystemsDocument8 pagesENLZT145294RA BulkSystemspakojidastavimNo ratings yet

- IP55 Outdoor EnclosuresDocument8 pagesIP55 Outdoor EnclosuresjaroldskiNo ratings yet

- JSS-296 - NCR-333 - Ton SART20 - Tron 40SDocument401 pagesJSS-296 - NCR-333 - Ton SART20 - Tron 40SBryan MilloNo ratings yet

- Chapter 10 - MLSDocument8 pagesChapter 10 - MLSEl Shazly SaidNo ratings yet

- SJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110Document44 pagesSJ-20200929135033-015-ZXA10 C680&C600&C650&C620 (V1.2.1) Optical Access Aggregation Equipment Routine Maintenance - 996110paulo gadelhaNo ratings yet

- Smart Test Series: 1-Circle The Correct One. (15x1 15)Document3 pagesSmart Test Series: 1-Circle The Correct One. (15x1 15)Zaheer AhmedNo ratings yet

- 3SU11000AB401FA0 Datasheet enDocument4 pages3SU11000AB401FA0 Datasheet enpatrykk11195No ratings yet

- PMIC System HW-Validation EngineerDocument3 pagesPMIC System HW-Validation EngineerSai KrishnaNo ratings yet

- Schematic Circuits: Section C - ElectricsDocument1 pageSchematic Circuits: Section C - ElectricsIonut GrozaNo ratings yet

- Yellampalli S. Wireless Sensor Networks - Design, Deployment..2021Document314 pagesYellampalli S. Wireless Sensor Networks - Design, Deployment..2021Myster SceneNo ratings yet

- 12 Pulse ConverterDocument5 pages12 Pulse ConvertersumitchintuNo ratings yet

- Fixed Gas Detector Instruction Manual SI-1000Document21 pagesFixed Gas Detector Instruction Manual SI-1000Vũ Thiên ÂnNo ratings yet

- EMC quiz questionsDocument1 pageEMC quiz questionsSree MurthyNo ratings yet

- M.tech Lab Manual - PSSDocument33 pagesM.tech Lab Manual - PSSsuresh270No ratings yet

- Toshiba W-528 ManualDocument35 pagesToshiba W-528 Manualgavinj3985No ratings yet

- Phy 102 F2Document29 pagesPhy 102 F2Babalola AyokunuNo ratings yet

- Fusion: User ManualDocument283 pagesFusion: User ManualAndresNo ratings yet

- Motor Test Dynamo MetersDocument9 pagesMotor Test Dynamo MetersDhaneshwar PatilNo ratings yet

- High Frequency Transistor for Amplifier ApplicationsDocument7 pagesHigh Frequency Transistor for Amplifier ApplicationsJose VelasquezNo ratings yet

- Compact Microstrip Feeding Network For Mobile Base Station AntennaDocument5 pagesCompact Microstrip Feeding Network For Mobile Base Station AntennaInnovative Research PublicationsNo ratings yet

- Calibration of Thrmocouples: Assignment # 01Document3 pagesCalibration of Thrmocouples: Assignment # 01ahmadNo ratings yet

- 6 16Document2 pages6 16Indira KarimovaNo ratings yet

- GSM Frequency Bands Table ExplainedDocument2 pagesGSM Frequency Bands Table Explainedamits_aumNo ratings yet

- UNIT 3 Fourier Series Symmetry Properties Questions and Answers - Sanfoundry PDFDocument3 pagesUNIT 3 Fourier Series Symmetry Properties Questions and Answers - Sanfoundry PDFzohaibNo ratings yet

- D 8806 Paper Iii PDFDocument32 pagesD 8806 Paper Iii PDFAryama MandalNo ratings yet

- CH 05Document14 pagesCH 05Abdul Shokor Abd TalibNo ratings yet

- PN7092 Pressure Sensor DisplayDocument5 pagesPN7092 Pressure Sensor DisplayEslam YehiaNo ratings yet

- OLED Specification SheetDocument27 pagesOLED Specification SheetBianca SandorNo ratings yet

- Triple Junction GaAsDocument2 pagesTriple Junction GaAsNezar Gassem ElfadillNo ratings yet