Professional Documents

Culture Documents

Dura-Plate UHS Epoxy - JSP PDF

Uploaded by

Nageswara Rao BavisettyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dura-Plate UHS Epoxy - JSP PDF

Uploaded by

Nageswara Rao BavisettyCopyright:

Available Formats

Protective NSF & Certied to Marine NSF/ANSI 61 Coatings

Revised: June 14, 2013

DURA-PLATE UHS

WITH OPTI-CHECK OAP TECHNOLOGY

PART A PART A PART B PART B B62-210 B62W211 B62V210 B62V211 SERIES WHITE OAP (NSF) STANDARD HARDENER (NSF) LOW TEMP HARDENER (NSF)

TRM.35

PRODUCT DESCRIPTION

DURA-PLATE UHS is an ultra high solids epoxy amine engineered specically for immersion service in ballast tanks, oil tanks, and rened fuel storage tanks. The high build, edge-retentive properties of Dura-Plate UHS provide superior protection compared to conventional epoxies. Airless Spray One coat protection Low VOC Low odor High ash point, >200F (93C) Can be used with 1 oz. berglass mat Low Temperature Hardener for applications down to 40F (4.5C). NSF approved to Standard 61 for potable water (tanks of 1000 gallons or greater and pipes of 30" diameter or greater.)

PRODUCT CHARACTERISTICS (CONT'D)

With B62V211 To touch: To handle: To recoat: minimum: maximum: Cure to service: Heat Cure: @ 40F/4.5C 24 hours 48 hours @ 55F/13C 50% RH 5 hours 24 hours @ 77F/25C 3 hours 8 hours

48 hours 24 hours 8 hours 30 days 21 days 14 days 7 days 5 days 3 days 8 hours @ ambient, then 16 hrs @ 140F (60C)*

RECOMMENDED USES

For use over prepared steel or concrete surfaces in industrial and marine exposures such as: Meets MIL-PRF-23236, Type VII, Class 5, 7, 9 and 11, Grade C Ballast tank interiors, Oil storage tank interiors, Rened fuel storage tank and potable water tanks interiors and pipe. NSF approved for one coat application up to 50.0 mils (1250 microns) dft if required Water and waste treatment plants Primary and secondary containment areas Where edge protection lm build properties are required Suitable for use with cathodic protection systems White B62W211 Contains OAP uorescent pigment (NSF Approved)

Material should be at least 50F (10C) for optimal performance. If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent. Sterilize and rinse per AWWA C652. *Not NSF Approved. See Tips Section.

Pot Life*: 20 minutes 20 minutes *Dependent upon temperature and mass Sweat-in-Time: 5 minutes None Shelf Life: Flash Point: Reduction: Clean Up:

10 minutes None

PRODUCT CHARACTERISTICS

Finish Color: Gloss White OAP (NSF), White (NSF), Light Gray (NSF), Light Green (NSF), Black, Haze Gray 98% 2%, mixed 98% 2%, mixed

36 months Store indoors at 40F (4.5C) to 100F (38C). >200F (93C), PMCC, mixed Not recommended MEK, R6K10 or R7K104 Reducer

PERFORMANCE CHARACTERISTICS

Substrate*: Steel Surface Preparation*: SSPC-SP10/NACE 2 System Tested*:

1 ct. Dura-Plate UHS @ 18.0 mils (450 microns) dft with B62GV210 Hardener

*unless otherwise noted below Test Name Test Method Results

Volume Solids: Weight Solids: VOC (EPA Method 24): (with B62-V210 Hardeners) <100 g/L; 0.83 lb/gal, mixed (with B62V211 Hardener) <100 g/L; 0.84 lb/gal, mixed Mix Ratio: 4:1 by volume

Recommended Spreading Rate per coat*:

1 coat system 2 coat system Min. Max. Min. Max. 18.0 450 22.0 550 10.0 250 12.0 300 Wet mils (microns) Dry mils (microns) 18.0 450 22.0 550 10.0 250 12.0 300 18.0 450 22.0 550 20.0 500 24.0 600 Total mils (microns) ~Coverage sq ft/gal (m2/L) 72 1.76 90 2.2 130 3.18 160 3.9 Theoretical coverage sq ft/ 1568 (38.4) gal (m2/L) @ 1 mil/25 micron dft

* See NSF Systems on next page. NOTE: Brush or roll application recommended for stripe coating and repair only. Standard hardener preferred for brush & roll due to pot life.

Abrasion Resistance Adhesion Corrosion Weathering Direct Impact Resistance Dry Heat Resistance Flexibility Immersion (Galvapac/1 ct Dura Plate UHS) Pencil Hardness

ASTM D4060, CS17 wheel, 1000 cycles, 1 kg load ASTM D4541; ASTM D3359 ASTM D5894, 6 cycles, 2016 hours ASTM D2794; ASTM G14 ASTM D2485 ASTM D522, 180 bend, 1/2" mandrel 5 year potable water ASTM D3363

20.8 mg loss 800 psi, minimum (ASTM D4541); 5A (ASTM D3359) Rating 10 per ASTM D610 for rusting and Rating 10 per ASTM D714 for blistering 30 in. lb. (ASTM D2794); 168 in. lb. (ASTM G14) 250F (121C) Passes, 9.7% elongation Rating 10 per ASTM D610 for rusting and Rating 10 per ASTM D714 for blistering 3H

Drying Schedule @ 10.0-22.0 mils wet (250-550 microns):

With B62-V210 To touch: To handle: To recoat: minimum: maximum: Cure to service: Heat Cure: @ 55F/13C 50% RH 12 hours 48 hours @ 77F/25C 5 hours 14 hours @ 100F/38C 3 hours 8 hours

48 hours 14 hours 8 hours 21 days 14 days 14 days 10 days 4 days 24 hours 8 hours @ ambient, then 16 hrs @ 140F (60C)* 20-30 minutes None

*Not NSF Approved. See Tips Section.

Pot Life*: 30-45 minutes 30-45 minutes *Dependent upon temperature and mass Sweat-in-time: 15 minutes None

IMMERSION (Ambient temperature): Ballast Tank mix ......................................... Recommended Crude oil ..................................................... Recommended Diesel fuel .................................................. Recommended Ethanol or Gasohol .................................... Recommended Fresh water/Potable Water......................... Recommended Fuel oil........................................................ Recommended Methanol or methanol blends ..................... Not Recommended MTBE, TAME, ETBE .................................. Recommended Rened petroleum products ....................... Recommended Sea water ................................................... Recommended Hi-Aromatic Gasolines ............................... Recommended

www.sherwin-williams.com/protective

continued on back

Protective NSF & Certied to Marine NSF/ANSI 61 Coatings

RECOMMENDED SYSTEMS

DURA-PLATE UHS

WITH OPTI-CHECK OAP TECHNOLOGY

PART A PART A PART B PART B B62-210 B62W211 B62V210 B62V211 SERIES WHITE OAP (NSF) STANDARD HARDENER (NSF) LOW TEMP HARDENER (NSF)

TRM.35

PRODUCT INFORMATION

SURFACE PREPARATION

Dry Film Thickness / ct. Mils (Microns) Steel, NSF Systems: 1 ct. Dura-Plate UHS Primer 1 ct. Dura-Plate UHS or 1 ct. Dura-Plate UHS or 2 cts. Dura-Plate UHS or 3 cts. Dura-Plate UHS Steel, OAP Fluorescent Pigment System 1 ct. Dura-Plate UHS (B62W211) Steel: 1 ct. 1 ct. or 2 cts. or 1 ct. or 2 cts. Dura-Plate UHS Primer Dura-Plate UHS Dura-Plate UHS Dura-Plate UHS Dura-Plate UHS 4.0-8.0* (100-200) 10.0-12.0* (250-300) 16.0-50.0 8.0-25.0 8.0-16.0 12.0-14.0 4.0-8.0** 10.0-12.0 6.0-7.0 18.0-22.0 10.0-12.0 1.0-1.5** 10.0-12.0 (400-1250) (200-625) (200-400) (300-350) (100-200) (250-300) (150-175) (450-550) (250-300) (25-40) (250-300)

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Refer to product Application Bulletin for detailed surface preparation information. Minimum recommended surface preparation: Iron & Steel: Atmospheric: SSPC-SP6/NACE 3, 2 mil (50 micron) prole or SSPC-SP12/NACE No. 5, WJ-3/NV-2 Immersion: SSPC-SP10/NACE2, 2-3 mil (50-75 micron)prole or SSPC- SP12/NACE No. 5, WJ-2/NV-2 Concrete & Masonry: Atmospheric: SSPC-SP13/NACE 6, or ICRI No. 310.2 CSP 2-3 Immersion: SSPC-SP13/NACE 6-4.3.1 or 4.3.2, or ICRI No. 310.2 CSP 2-3

Surface Preparation Standards

Condition of Surface White Metal Near White Metal Commercial Blast Brush-Off Blast Hand Tool Cleaning Rusted Pitted & Rusted Power Tool Cleaning Rusted Pitted & Rusted ISO 8501-1 BS7079:A1 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

Steel, with hold primer: 1 ct. Copoxy Shop Primer (as required for blast hold primer) 2 cts. Dura-Plate UHS

TINTING

Do not tint Part A. Clear Hardeners B62V210 and B62V211 may be tinted with up to 1 oz. per gallon with Maxitoner Colorant, Phthalo Green or Black (both NSF approved) ONLY.

Steel, Laminate System: 1 ct. Copoxy Shop Primer 1.0-1.5 (25-40) (as required for blast hold primer) or 1 ct. Dura-Plate UHS Primer 4.0-8.0** (100-200) 1 ct. Steel-Seam FT910 as required for lling pits, and transitioning sharp edges, weld seams, etc. 1 ct. Dura-Plate UHS Clear Laminate 40.0-45.0 (1000-1125) Resin with 1 oz. glass mat 1 ct. Dura-Plate UHS 10.0-12.0 (250-300) as required to seal berglass mat Concrete/Masonry: 1 ct. Corobond 100 Epoxy Primer/Sealer (or 1 ct Dura- Plate UHS Primer (as required for NSF) 1 ct. Dura-Plate UHS (as required for NSF) 4.0-6.0 4.0-8.0** 10.0-12.0 (100-150) (100-200) (250-300)

APPLICATION CONDITIONS

Temperature (air, surface): B62-V210 Hardeners B62V211 Hardener 50F (10C) minimum, 110F (43C) maximum 40F (4.5C) minimum, 77F (25C) maximum At least 5F (2.8C) above dew point Material should be 70F (21C) to 85F (29C) or optimal performance. Relative humidity: 85% maximum Refer to product Application Bulletin for detailed application information.

ORDERING INFORMATION

Packaging: Part A: Part B: Weight: 4 gallon (15.1L) container 1 gallon (3.78L) container 10.52 0.2 lb/gal ; 1.26 Kg/L, mixed

* If primer is used, 10 mils (250 microns) dft maximum for primer and 14 mils (350 microns) dft maximum for topcoat. ** When using the B62L210 Primer containing the OAP uorescent pigment, make sure a non-containing OAP uorescent pigment Topcoat is used. Refer to Application Bulletin for treatment of pitted tank bottoms. The systems listed above are representative of the product's use, other systems may be appropriate.

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

www.sherwin-williams.com/protective

Protective NSF & Certied to Marine NSF/ANSI 61 Coatings

Revised: June 14, 2013

DURA-PLATE UHS

WITH OPTI-CHECK OAP TECHNOLOGY

PART A PART A PART B PART B B62-210 B62W211 B62V210 B62V211 SERIES WHITE OAP (NSF) STANDARD HARDENER (NSF) LOW TEMP HARDENER (NSF)

TRM.35

APPLICATION BULLETIN

APPLICATION CONDITIONS

SURFACE PREPARATIONS

Surface must be clean, dry, and in sound condition. Remove all oil, dust, grease, dirt, loose rust, and other foreign material to ensure adequate adhesion. Iron & Steel (atmospheric service) Minimum surface preparation is Commercial Blast Cleaning per SSPC-SP6/NACE 3 or SSPC-SP12/NACE No. 5. For surfaces prepared by SSPC SP6/NACE 3, rst remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. For better performance, use Near White Metal Blast Cleaning per SSPC-SP10/ NACE 2. Blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (2-3 mils / 50-75 microns). For surfaces prepared by SSPC-SP12/NACE No. 5, all surfaces shall be cleaned in accordance with WJ-3/NV2. Pre-existing prole should be approximately 2 mils (50 microns). Prime any bare steel the same day as it is cleaned or before ash rusting occurs. Iron & Steel (immersion service) Remove all oil and grease from surface by Solvent Cleaning per SSPC-SP1. Minimum surface preparation is Near White Metal Blast Cleaning per SSPC-SP10/NACE 2, or SSPC-SP12/NACE No. 5. For SSPC-SP10/NACE 2 blast clean all surfaces using a sharp, angular abrasive for optimum surface prole (2-3 mils / 50-75 microns). For SSPC-SP12/NACE No.5, all surfaces to be coated shall be cleaned in accordance with WJ-2/NV2 standards. Pre-existing prole should be approximately 2 mils (50 microns). Remove all weld spatter. Prime any bare steel the same day as it is cleaned or before ash rusting occurs. Concrete and Masonry For surface preparation, refer to SSPC-SP13/NACE 6, or ICRI No. 310.2, CSP 2-3. Surfaces should be thoroughly clean and dry. Concrete and mortar must be cured at least 28 days @ 75F (24C). Remove all loose mortar and foreign material. Surface must be free of laitance, concrete dust, dirt, form release agents, moisture curing membranes, loose cement and hardeners. Fill bug holes, air pockets and other voids with Steel-Seam FT910. Primer required. Follow the standard methods listed below when applicable: ASTM D4258 Standard Practice for Cleaning Concrete. ASTM D4259 Standard Practice for Abrading Concrete. ASTM D4260 Standard Practice for Etching Concrete. ASTM F1869 Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete. SSPC-SP 13/Nace 6 Surface Preparation of Concrete. ICRI No. 310.2 Concrete Surface Preparation. Concrete, Immersion Service: For surface preparation, refer to SSPC-SP13/NACE 6, Section 4.3.1 or 1.3.2 or ICRI No. 310.2, CSP 2-3.

Temperature (air, surface): B62-V210 Hardeners 50F (10C) minimum, 110F (43C) maximum B62V211 Hardener 40F (4.5C) minimum, 77F (25C) maximum At least 5F (2.8C) above dew point Material should be 70F (21C) to 85F (29C) or optimal performance. Relative humidity: 85% maximum

APPLICATION EQUIPMENT

The following is a guide. Changes in pressures and tip sizes may be needed for proper spray characteristics. Always purge spray equipment before use with listed reducer. Any reduction must be compliant with existing VOC regulations and compatible with the existing environmental and application conditions. Reduction .......................Not recommended Clean Up .......................... MEK, R6K10 or R7K104 Reducer Airless Spray Unit.................................74:1 Pump, minimum Pressure.........................6000 psi minimum Hose...............................3/8" ID Tip ...................................019" - .021" Filter ...............................30 mesh In order to avoid blockage of spray equipment and hose, ush equipment with MEK, R6K10 or R7K104 Reducer at least once every 30 minutes when using the B62V210 Hardener and after each kit when using the Low Temperature Hardener, and before periods of extended downtime. Plural Component Equipment .......................Acceptable Brush ...............................For stripe coating and repair only Brush..............................Nylon/Polyester or Natural Bristle Roller ...............................For stripe coating and repair only Cover .............................3/8" woven with solvent resistant core

Surface Preparation Standards

ISO 8501-1 BS7079:A1 White Metal Sa 3 Near White Metal Sa 2.5 Commercial Blast Sa 2 Brush-Off Blast Sa 1 Rusted St 2 Hand Tool Cleaning Pitted & Rusted C D St 2 C St 3 Power Tool Cleaning Rusted Pitted & Rusted D St 3 Condition of Surface Swedish Std. SIS055900 Sa 3 Sa 2.5 Sa 2 Sa 1 C St 2 D St 2 C St 3 D St 3 SSPC SP 5 SP 10 SP 6 SP 7 SP 2 SP 2 SP 3 SP 3 NACE 1 2 3 4 -

If specic application equipment is not listed above, equivalent equipment may be substituted.

www.sherwin-williams.com/protective

continued on back

Protective NSF & Certied to Marine NSF/ANSI 61 Coatings

APPLICATION PROCEDURES

DURA-PLATE UHS

WITH OPTI-CHECK OAP TECHNOLOGY

PART A PART A PART B PART B B62-210 B62W211 B62V210 B62V211 SERIES WHITE OAP (NSF) STANDARD HARDENER (NSF) LOW TEMP HARDENER (NSF)

TRM.35

APPLICATION BULLETIN

PERFORMANCE TIPS

Surface preparation must be completed as indicated. Mixing Instructions: Mix contents of each component thoroughly using low speed power agitation. Make certain no pigment remains on the bottom or the sides of the can. Then combine four parts by volume of Part A with one part by volume of Part B. Thoroughly agitate the mixture with power agitation. To ensure that no unmixed material remains on the sides or bottom of the cans after mixing, visually observe the container by pouring the material into a separate container. Apply paint at the recommended lm thickness and spreading rate as indicated below:

Recommended Spreading Rate per coat*:

1 coat system 2 coat system Min. Max. Min. Max. 18.0 450 22.0 550 10.0 250 12.0 300 Wet mils (microns) Dry mils (microns) 18.0 450 22.0 550 10.0 250 12.0 300 18.0 450 22.0 550 20.0 500 24.0 600 Total mils (microns) ~Coverage sq ft/gal (m2/L) 72 1.76 90 2.2 130 3.18 160 3.9 Theoretical coverage sq ft/ 1568 (38.4) gal (m2/L) @ 1 mil/25 micron dft

* See NSF Systems on next page. NOTE: Brush or roll application recommended for stripe coating and repair only. Standard hardener preferred for brush & roll due to pot life.

Drying Schedule @ 10.0-22.0 mils wet (250-550 microns):

With B62-V210 To touch: To handle: To recoat: minimum: maximum: Cure to service: Heat Cure: @ 55F/13C 50% RH 12 hours 48 hours @ 77F/25C 5 hours 14 hours @ 100F/38C 3 hours 8 hours

48 hours 14 hours 8 hours 21 days 14 days 14 days 10 days 4 days 24 hours 8 hours @ ambient, then 16 hrs @ 140F (60C)* 20-30 minutes None @ 77F/25C 3 hours 8 hours

*Not NSF Approved. See Tips Section.

Pot Life*: 30-45 minutes 30-45 minutes *Dependent upon temperature and mass Sweat-in-time: 15 minutes None With B62V211 To touch: To handle: To recoat: minimum: maximum: Cure to service: Heat Cure: @ 40F/4.5C 24 hours 48 hours @ 55F/13C 50% RH 5 hours 24 hours

Repair of Pitted Tank Bottoms Extensive, deep pitting: Options: Option 1 ....Apply a full wet coat, by spray application, of Dura-Plate UHS Primer. Follow with rubber squeegee to work material into and ll the pitted areas. After recommended drying time, apply a full coat of Dura-Plate UHS at recommended lm thickness. Option 2 ....Apply Dura-Plate Laminant Resin with 1 oz berglass mat over the pitted areas. After recommended drying time, apply a full coat of Dura-Plate UHS at recommended lm thickness. Option 3 ....Weld new steel plates, or use puddle welds, as required to repair pitted areas. Coat areas as recommended. Shallow pitting, isolated areas: Options: Option 1 ....Same as number 1 above. Option 2 ....Apply Steel-Seam FT910 as required to ll the pitted areas. Coat areas as recommended. When using spray application, use a 50% overlap with each pass of the gun to avoid holidays, bare areas, and pinholes. If necessary, cross-coat spray at a right angle. Spreading rates are calculated on volume solids and do not include an application loss factor due to surface prole, roughness or porosity of the surface, skill and technique of the applicator, method of application, various surface irregularities, material lost during mixing, spillage, overthinning, climatic conditions, and excessive lm build. No reduction of material is recommended as this can affect lm build, appearance, and adhesion. Do not mix previously catalyzed material with new. Do not apply the material beyond recommended pot life. In order to avoid blockage of spray equipment and hose, ush equipment with MEK, R6K10 or R7K104 Reducer at least once every 30 minutes when using the B62V210 Hardener and after each kit when using the Low Temperature Hardener, and before periods of extended downtime. For Immersion Service: (if required) Holiday test in accordance with ASTM D5162 for steel, or ASTM D4787 for concrete. May be applied up to 50.0-60.0 mils (1250-1500 microns) dft in one coat if required. When using the B62L210 Primer containing the OAP uorescent pigment, make sure a non-containing OAP uorescent pigment Topcoat is used. Stripe coat all crevices, welds, and sharp angles to prevent early failure in these areas. Heat curing is not acceptable for NSF approval. Guidance on techniques and required equipment to inspect a coating system incorporating Opti-Check OAP Technology can be found in SSPC-TU 11. Refer to Product Information sheet for additional performance characteristics and properties.

48 hours 24 hours 8 hours 30 days 21 days 14 days 7 days 5 days 3 days 8 hours @ ambient, then 16 hrs @ 140F (60C)*

SAFETY PRECAUTIONS

Refer to the MSDS sheet before use. Published technical data and instructions are subject to change without notice. Contact your Sherwin-Williams representative for additional technical data and instructions.

Material should be at least 50F (10C) for optimal performance. If maximum recoat time is exceeded, abrade surface before recoating. Drying time is temperature, humidity, and lm thickness dependent. Sterilize and rinse per AWWA C652. *Not NSF Approved. See Tips Section.

WARRANTY

The Sherwin-Williams Company warrants our products to be free of manufacturing defects in accord with applicable Sherwin-Williams quality control procedures. Liability for products proven defective, if any, is limited to replacement of the defective product or the refund of the purchase price paid for the defective product as determined by Sherwin-Williams. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY SHERWIN-WILLIAMS, EXPRESSED OR IMPLIED, STATUTORY, BY OPERATION OF LAW OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Pot Life*: 20 minutes 20 minutes 10 minutes *Dependent upon temperature and mass Sweat-in-Time: 5 minutes None None Note: Recommended application procedure direct to steel: Apply a 5.06.0 mil (125-150 micron) coat to the substrate. Allow material to "wet" the surface. Then apply additional material, to bring total lm thickness to the recommended range. Application of coating above maximum or below minimum recommended spreading rate may adversely affect coating performance.

DISCLAIMER

The information and recommendations set forth in this Product Data Sheet are based upon tests conducted by or on behalf of The Sherwin-Williams Company. Such information and recommendations set forth herein are subject to change and pertain to the product offered at the time of publication. Consult your SherwinWilliams representative to obtain the most recent Product Data Information and Application Bulletin.

CLEAN UP INSTRUCTIONS

Clean spills and spatters immediately with MEK, R6K10. Clean tools immediately after use with MEK, R6K10. Follow manufacturer's safety recommendations when using any solvent.

www.sherwin-williams.com/protective

You might also like

- Esoteric Meaning To GoldDocument3 pagesEsoteric Meaning To GoldMohit ChampanerkarNo ratings yet

- Atwood - 1984 - Molten Salt TechnologyDocument536 pagesAtwood - 1984 - Molten Salt TechnologyLanly Romuel100% (1)

- NORSOK Standard Jacket PipesDocument28 pagesNORSOK Standard Jacket PipesvuongNo ratings yet

- Manual GMP and HACCP Guide BookDocument118 pagesManual GMP and HACCP Guide BookMaria Ika Putri SoegiartoNo ratings yet

- Hi - Temp 900Document5 pagesHi - Temp 900bhavesh solankiNo ratings yet

- The Six KingdomsDocument4 pagesThe Six KingdomsBasmanNo ratings yet

- Installation Guide For Buried PipesDocument76 pagesInstallation Guide For Buried PipesMohamed Fawzy Shabana100% (1)

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGerardo Castillo100% (2)

- The Sugars of Honey-A ReviewDocument14 pagesThe Sugars of Honey-A ReviewsedianpoNo ratings yet

- Jews AntiquitiesDocument24 pagesJews AntiquitiesNageswara Rao Bavisetty50% (8)

- Gas Sweetening and Processing Field ManualFrom EverandGas Sweetening and Processing Field ManualRating: 4 out of 5 stars4/5 (7)

- Astm A333Document9 pagesAstm A333Andres Fitria FarrelNo ratings yet

- Maintenance Guideline NTA-855.: OverviewDocument7 pagesMaintenance Guideline NTA-855.: OverviewAmmar BaigNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Hydrogen Peroxide Production StoryDocument22 pagesHydrogen Peroxide Production StorySo Maye100% (1)

- Barrier ZEP HS 环氧富锌底漆 (6KW) (United States - English)Document5 pagesBarrier ZEP HS 环氧富锌底漆 (6KW) (United States - English)longNo ratings yet

- Duraplate Uhs EnglishDocument4 pagesDuraplate Uhs EnglishLuis JaraNo ratings yet

- Dura-Plate Uhs Primer NSF: Protective & Marine CoatingsDocument4 pagesDura-Plate Uhs Primer NSF: Protective & Marine CoatingscerorideNo ratings yet

- Product Data Sheet SP-8888Document7 pagesProduct Data Sheet SP-8888pablo gonzalezNo ratings yet

- Coal Tar PDFDocument4 pagesCoal Tar PDFMohammadreza AsheghNo ratings yet

- Carboguard 891: Selection & Specification DataDocument4 pagesCarboguard 891: Selection & Specification DataPrakashNo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- PDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFDocument3 pagesPDS - SP 8888 - High Temperature Novolac Pipeline Coating - 2017 03 13 PDFMohamed NouzerNo ratings yet

- SP 8888 PDFDocument6 pagesSP 8888 PDFMohammad ShamimNo ratings yet

- SP-9888® Tank Lining: Selection & Specification DataDocument4 pagesSP-9888® Tank Lining: Selection & Specification DataSatees KrishnanNo ratings yet

- Amercoat® 240 / Sigmacover™ 240: Product Data SheetDocument7 pagesAmercoat® 240 / Sigmacover™ 240: Product Data SheetAmila Udara GunasingheNo ratings yet

- Interseal 670 HS EN O-FDocument4 pagesInterseal 670 HS EN O-Fapde06No ratings yet

- ChemflakeDocument5 pagesChemflakeManohar SeetharamNo ratings yet

- Armorite Soft Natural Rubber: Technical Data SheetDocument2 pagesArmorite Soft Natural Rubber: Technical Data SheetSantosh JayasavalNo ratings yet

- Chemflake Special: Technical Data SheetDocument5 pagesChemflake Special: Technical Data SheetSalmanNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

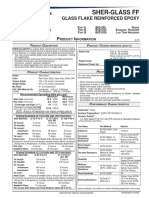

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Tankguard 412Document5 pagesTankguard 412abdulgafoor54No ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carbo Zinc 11 HsDocument2 pagesCarbo Zinc 11 Hstyto_rmzNo ratings yet

- E Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519Document4 pagesE Program Files An ConnectManager SSIS TDS PDF Interline 850 Eng A4 20160519ValentinNo ratings yet

- Nukote XT Plus TdsDocument4 pagesNukote XT Plus TdsAnsar AliNo ratings yet

- ZRC Zero VocDocument2 pagesZRC Zero Vochksn77No ratings yet

- ZRC 3 07Document2 pagesZRC 3 07groelzjNo ratings yet

- Amerlock 400 Sigmacover 400Document6 pagesAmerlock 400 Sigmacover 400Vijay KumarNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Sigmacover 240 Data SheetDocument7 pagesSigmacover 240 Data Sheetantonio larottaNo ratings yet

- Resist 86: Technical Data SheetDocument5 pagesResist 86: Technical Data SheetantonyfmNo ratings yet

- 1040 Stangard (ST) Epoxy MasticDocument5 pages1040 Stangard (ST) Epoxy MasticMayank Gupta50% (2)

- Plastic Steel Putty A v3Document2 pagesPlastic Steel Putty A v3feri.ferdianto02No ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- TDS MarathonDocument5 pagesTDS MarathonSyamsul MaripNo ratings yet

- TDS MarathonDocument5 pagesTDS MarathonSyamsul MaripNo ratings yet

- TDS 2063 Tankguard 412 Euk GBDocument6 pagesTDS 2063 Tankguard 412 Euk GBSrimathi VijayakumarNo ratings yet

- Sigmaprime 700Document7 pagesSigmaprime 700Trịnh Minh KhoaNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Chemflake SpecialDocument5 pagesChemflake SpecialBiju_PottayilNo ratings yet

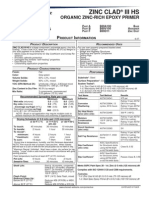

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltNo ratings yet

- Interseal 670 HSDocument4 pagesInterseal 670 HSSyawaluddin Fitri AwangNo ratings yet

- PPG PDS Amercoat 450HDocument6 pagesPPG PDS Amercoat 450HsanguripNo ratings yet

- Amerlock 400Document7 pagesAmerlock 400Satish VishnubhotlaNo ratings yet

- PPG Hi-Temp™ 1027 HDDocument5 pagesPPG Hi-Temp™ 1027 HDMarleo MorenoNo ratings yet

- Tankguard Zinc Jotun PaintDocument5 pagesTankguard Zinc Jotun PaintGurdeep Sungh AroraNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- INTERSEAL 670HS TemperateDocument4 pagesINTERSEAL 670HS TemperatePamungkasNo ratings yet

- Tankguard HB ClassicDocument5 pagesTankguard HB ClassicMuhammad Iqbal Al HaidarNo ratings yet

- Muki Z 2001: Technical Data SheetDocument5 pagesMuki Z 2001: Technical Data SheetIan PerdanaNo ratings yet

- Tankguard 412: Technical Data SheetDocument6 pagesTankguard 412: Technical Data SheetMuneer ahmedNo ratings yet

- Amerlock® 400 Voc: Product Data SheetDocument8 pagesAmerlock® 400 Voc: Product Data SheetCris gomezNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Tankguard Plus: Technical Data SheetDocument5 pagesTankguard Plus: Technical Data SheetKris WilliamsNo ratings yet

- Description Packaging Product Data SheetDocument2 pagesDescription Packaging Product Data SheetRonald Fernandez ManubuluNo ratings yet

- TDS 48342 Jotatemp 1000 Euk GBDocument5 pagesTDS 48342 Jotatemp 1000 Euk GBhenryNo ratings yet

- Barrier SmartpackDocument5 pagesBarrier SmartpackMhd EbalNo ratings yet

- 256 UkDocument4 pages256 UkBùi Văn TấnNo ratings yet

- Pyrogel XT DSDocument2 pagesPyrogel XT DSNageswara Rao BavisettyNo ratings yet

- Durapol Coating For Amines EtcDocument2 pagesDurapol Coating For Amines EtckermadaxNo ratings yet

- Marathon XHBDocument4 pagesMarathon XHBeskim00No ratings yet

- Improving Performance Using Thermal Spray CoatingsDocument5 pagesImproving Performance Using Thermal Spray CoatingsNageswara Rao Bavisetty100% (1)

- Plasguard 7133 PDFDocument11 pagesPlasguard 7133 PDFNageswara Rao BavisettyNo ratings yet

- Plasguard 859 PDFDocument4 pagesPlasguard 859 PDFNageswara Rao BavisettyNo ratings yet

- Plasguard 5308 PDFDocument3 pagesPlasguard 5308 PDFNageswara Rao BavisettyNo ratings yet

- Plasguard 7122 PDFDocument18 pagesPlasguard 7122 PDFNageswara Rao BavisettyNo ratings yet

- Plasguard 5309 PDFDocument3 pagesPlasguard 5309 PDFNageswara Rao BavisettyNo ratings yet

- Plasguard 3070 PDFDocument11 pagesPlasguard 3070 PDFNageswara Rao BavisettyNo ratings yet

- Plasguard 5302 PDFDocument3 pagesPlasguard 5302 PDFNageswara Rao BavisettyNo ratings yet

- Investigation of Corrosion Under Insulation (CUI) and Prevent It by Nano-Composite CoatingDocument5 pagesInvestigation of Corrosion Under Insulation (CUI) and Prevent It by Nano-Composite CoatingNageswara Rao BavisettyNo ratings yet

- Plasguard 5306 PDFDocument3 pagesPlasguard 5306 PDFNageswara Rao BavisettyNo ratings yet

- Pa 3 PDFDocument0 pagesPa 3 PDFNageswara Rao BavisettyNo ratings yet

- Pa 4000 PDFDocument4 pagesPa 4000 PDFNageswara Rao BavisettyNo ratings yet

- Cryogel Z DSDocument4 pagesCryogel Z DSCalo AlcaloNo ratings yet

- Semstone PDFDocument2 pagesSemstone PDFNageswara Rao BavisettyNo ratings yet

- Xuv500 Brochure PDFDocument18 pagesXuv500 Brochure PDFYuva RajNo ratings yet

- CUI - Coating GuideDocument1 pageCUI - Coating GuideNageswara Rao BavisettyNo ratings yet

- Pyrogel XT DSDocument2 pagesPyrogel XT DSNageswara Rao BavisettyNo ratings yet

- Associate Membership Examination Schedule - 2013: Indian Institute of CeramicsDocument3 pagesAssociate Membership Examination Schedule - 2013: Indian Institute of CeramicsNageswara Rao BavisettyNo ratings yet

- 3M Scotchkote DatasheetDocument3 pages3M Scotchkote DatasheetJebranNo ratings yet

- DS PC R95 Rev14 Aug10 PDFDocument2 pagesDS PC R95 Rev14 Aug10 PDFNageswara Rao BavisettyNo ratings yet

- Industrial Coatings:: Reference ProjectDocument1 pageIndustrial Coatings:: Reference ProjectNageswara Rao BavisettyNo ratings yet

- Pyrogel XT DSDocument2 pagesPyrogel XT DSNageswara Rao BavisettyNo ratings yet

- Powercrete R95Document2 pagesPowercrete R95Jimmy CalderonNo ratings yet

- Phase Diagram 2Document6 pagesPhase Diagram 2Mohd AzhamNo ratings yet

- Bateria 12 V 40ah GELDocument2 pagesBateria 12 V 40ah GELelmerNo ratings yet

- 01 1 hd1kv eDocument3 pages01 1 hd1kv eabboali9924No ratings yet

- ME659: Regulations For Health, Safety and Environment PPT Presentation Schedule S.No Date ID Name TopicDocument1 pageME659: Regulations For Health, Safety and Environment PPT Presentation Schedule S.No Date ID Name TopicAmarnath Reddy RagipindiNo ratings yet

- Drinking Water MOHDocument3 pagesDrinking Water MOHNur Amanina OmarNo ratings yet

- Practice Exam 2Document6 pagesPractice Exam 2Erik StyürNo ratings yet

- Unit 8-Thermal Analysis-IIDocument3 pagesUnit 8-Thermal Analysis-IIAli SheikhNo ratings yet

- Sri Lankan Biology Olympiad 2008Document5 pagesSri Lankan Biology Olympiad 2008Science Olympiad BlogNo ratings yet

- Internship Report: Muhammad HAMMAD (Im-138)Document13 pagesInternship Report: Muhammad HAMMAD (Im-138)HammadNo ratings yet

- Gaskets - Kemchan CatologueDocument3 pagesGaskets - Kemchan Catologueselvamech1986No ratings yet

- U.S. National Chemistry Olympiad (Usnco) Coordinator's HandbookDocument19 pagesU.S. National Chemistry Olympiad (Usnco) Coordinator's HandbookJJNo ratings yet

- 01.03.01 Coolant TR0199-99-2091 - enDocument18 pages01.03.01 Coolant TR0199-99-2091 - enEhsanur Rahman100% (1)

- AJC 2010 JC2 H2 Physics Prelim P2 QPDocument19 pagesAJC 2010 JC2 H2 Physics Prelim P2 QPcjcsucksNo ratings yet

- Huang 2018 - Alta Produção de SacccharoDocument12 pagesHuang 2018 - Alta Produção de SacccharoJuan LopesteixeiraNo ratings yet

- A Fabrication Report On AMMCDocument58 pagesA Fabrication Report On AMMCSai RamNo ratings yet

- List of Nse Listed Companies As On 10.12.2010 S.No. Symbol Name of Company Series Isin Number Date of Listing Paid UP Value Market LOT Face ValueDocument44 pagesList of Nse Listed Companies As On 10.12.2010 S.No. Symbol Name of Company Series Isin Number Date of Listing Paid UP Value Market LOT Face ValuergssinghNo ratings yet

- Any Aircraft Showing The Locations of The Composite Part 2. Advantages and Disadvantages of Using A CompositeDocument13 pagesAny Aircraft Showing The Locations of The Composite Part 2. Advantages and Disadvantages of Using A CompositeQueen CryNo ratings yet

- Efka 2526: PropertiesDocument2 pagesEfka 2526: Propertiessriatul2006No ratings yet

- NO Measurement by Griess MethodDocument9 pagesNO Measurement by Griess MethodhardianNo ratings yet

- BT Chuyển hóa HC1Document9 pagesBT Chuyển hóa HC1Nguyễn Khánh LyNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument10 pagesSafety Data Sheet: 1. Identificationkrishnadas kotaNo ratings yet