Professional Documents

Culture Documents

(PAPER) - Evaluating Fire Damage To Concrete Structures - tcm45-343618

Uploaded by

mukuld83Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(PAPER) - Evaluating Fire Damage To Concrete Structures - tcm45-343618

Uploaded by

mukuld83Copyright:

Available Formats

Part II of a three-part series on Repair of Fire Damage

Evaluating fire damage to concrete structures

When the structural condition is ambiguous, a reliable diagnosis can assure future safety and may save money in repairs

BY BERNARD ERLIN*, WILLIAM G. HIME*, WILLIAM H. KUENNING *

e ve ral days after a fire, walls and ceilings are cold to both sight and touch. Ash and water or ice lie over everything. Concrete is likely to be spalled, exposing steel that drapes from beams in shallow arcs. Surfaces may be blackened, cracking may be visible and aluminum railings melted. By this time at least a preliminary investigation of the condition of the structure will perhaps have been made. If the first general assessment of the damage has been ambiguous, a reliable evaluation of the condition of the structure by experts becomes necessary. There will be great interest in this evaluation and considerable urgency for completing it because insurance companies will be concerned about the extent of repairs required and owners will want the structure back in service with minimum delay.

Spalling of concrete and melting of aluminum railing from gasoline truck fire below a bridge. Although the complete evaluation will begin with an examination of the condition of various materials that went through the fire, such as ceramics, furniture or metal housings, the information pri m a ri l y needed is the condition of the structural elements that sustain the building loads. Many methods and varieties of test equipment are available for assessing the damage. Some tests can be made at the job site but others require studies of specimens in the laboratory. Although such studies may at times require sophisticated equipment much or all of the information can often be obtained with quite simple equipment or tools.

General survey

Surveys are useful for compiling w h a t e ver information is alre a d y known about the nature of the fire. They begin by drawing on information in fire department records and on re p o rts from witnesses. That i n f o rmation includes the extent and duration of the fire, and the period when failures of members were observed. Information about the type and amount of combustible materials can be used for estimating the prob-

* Erlin, Hime Associates, Materials and Concrete Consultants Northbrook, Illinois ** Consultant, Concrete Technology Lombard, Illinois

TABLE I Estimating Temperatures Attained During Fires (Adapted from Reference 1) Factors for Use in Calculating Wood Load Below Multiply weight of material per unit area by the factor indicated to obtain the equivalent wood load. Material Wood Cellulose Paper Coal Coke or charcoal Lignite Peat Factor 1.0 1.0 0.9 1.8 1.5 0.8 1.3 Material Hay or straw Asphalt Coal tar Petroleum products Factor 0.8 2.1 2.1 2.5 Material Cotton Silk Wool Nitrocellulose Rubber Factor 0.9 1.2 1.2 0.5 2.1

Animal or vegetable oil 2.1 Fats and waxes 2.1 Equivalent fire test period (hours) 1 2 4

Wood load Pounds per square feet 12.5 12.5 - 25 25 - 50 Kilograms per square meter 61 61 - 122 122 - 244

Probable temperature reached in fire atmosphere Degrees F 1,700 1,850 2,000 Degrees C 927 1,010 1,093

TABLE II Conditions of Materials Useful for Estimating Temperature

Attained Within a Structure During a Fire (Adapted from Reference 1) Material Lead Typical Examples Pluming lead; flashing; storage batteries; toys Plumbing fixtures; flashing; galvanized surfaces Small machine parts; brackets; toilet fixtures; cooking utensils Condition Sharp edges rounded or drops formed Drops formed Degrees F 550 - 650 Degrees C 300 - 350

able temperatures reached within the building. If the building had contained, for example, not much other than about 10 pounds of vegetable oil per square foot of floor area, all of which was consumed in the fire, probable tempera t u re s reached within the building can be calculated by using the information in Table 1. The amount of vegetable oil per square foot multiplied by the factor 2.1 (obtained from the top section of the table) gives a value of 21 pounds per square foot, the equivalent wood load to produce the same amount of heat. In the lower part of the table it can be seen that a wood load of 21 pounds per square foot, which falls in the range of 12.5 to 25 pounds, would supply the amount of heat consumed in a 2-hour fire test. If it is assumed that conditions at the actual fire were not significantly different from those in a standard fire test it would mean that the probable temperature reached in the fire atmosphere was 1,850 degrees F (found in the Fahrenheit column).

Zinc

750

400

On-site survey

More reliable information about temperatures can be obtained during on-site surveys. One method is to note the condition of materials exposed to the fire (Table 2). Examinations of rubble might show that window glass had been melted and brass cupboard knobs had become rounded but that copper in electric wires had not been softened. These observations would point to temperatures that had certainly exceeded 1,560 degrees F (indicated by the glass) and had probably been higher than 1,850 degrees F (indicated by the brass) but not as high as the 2,000 degrees F required to melt copper. Those tempera t u re s, howe ve r, might not truly reflect the heat intensity reached in the concrete, which is likely to be less than in the air. Concrete color provides a broad, general guide of tempera t u re s, whether the color represents the original surface or one resulting from spalling. Crazing, cracking,

Aluminum and its alloys

Drops formed Softened or adherent

1,200

650

1,300 - 1,400

700 - 750

Molded glass

Glass block; jars and bottles; tumblers; solid ornaments

Rounded Thoroughly flowed Rounded Thoroughly flowed Sharp edges rounded or drops formed Sharp edges rounded or drops formed Sharp edges rounded or drops formed Sharp edges rounded or drops formed Drops formed

1,400 1,450

750 800

Sheet glass

Window glass; plate glass; reinforced glass

1,450 1,560

800 850

Silver

Jewelry; tableware; coins Door knobs; furniture knobs; locks; lamp fixtures; buckles Window frames; art objects Electric wiring; coins Pipes; radiators; machine pedestals and housings

1,750

950

Brass

1,650 - 1,850

900 - 1,000

Bronze

1,850

1,000

Copper

2,000

1,100

Cast iron

2,000 - 2,200

1,100 - 1,200

Concrete Color Buff

Temperature

Other Possible Physical Effects

950 C, 1,740 F

1,650 F, 900 C

Powdered, light colored, dehydrated paste

1,450 F, 800 C Black Through Gray to Buff 600 C 1,100 F 1,070 F, 575 C 1,000 F, 550 C Pink to Red

Spalling, exposing not more than 25 percent of reinforcing bar surface

Popouts over chert or quartz aggregate particles Deep cracking

300 C, 550 F Normal

550 F, 300 C

Surface crazing

100 F, 40 C

None

Fig. 1 Visual evidence of temperature to which concrete has been heated

(Adapted from References 1 and 2)

popouts caused by quartz or chert aggregate particles, spalling, and d e h yd ration (crumbling and powdering of paste) are general indications of temperatures to which concrete has been exposed, as shown in Figure 1. Concrete temperatures will vary from one enclosed area to another and certainly from room to room. The relationship of temperature and strength loss was discussed in the preceding paper of this series. As indicated there, surface temperatures usually are quite different from temperatures at different depths in the concrete, and thus estimates of strength of the internal c o n c re t e, when based on surface color, are speculative. If precise information on strength is needed other methods that will be discussed are required.

The amount and condition of exposed reinforcing bars or prestressing wires and strands are helpful indications for assessing damage. If the steel is draping or shows embrittled surfaces, serious concrete damage can be anticipated. It does not follow, howe ve r, that unexposed steel has been as seriously affected, if affected at all. The locations and lengths of exposed steel may be useful for reviews and recalculations of design requirements. Distortions and cracking of structural members, as well as their locations, are useful for evaluating the efficacy of building units for sustaining loads. If cracks are located in critical places such as support areas, if deflections are observed anywhere, or if there are misalignments, the support capabilities may have been seriously impaired, whether

support is carried by individual members or integrated members that constitute a support system.

Equipment commonly used at the site

Two very useful tools for examining field concrete are a hammer and chisel. Their resistance to impacts and their resonance when struck can reveal information about hardness, integrity, depth of damage, seriousness of cracking, and the condition of the steel. Other useful tools and test instruments applicable in field studies or in removal of specimens for laboratory studies include: impact hammer, measuring tape, transit or theodolite, level, dial gages, field m i c ro s c o p e, grinders, coring machine, wear test devices, steel hardness tester, soniscope, and load test devices.

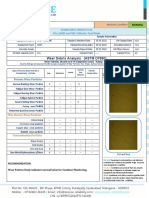

TABLE III Methods for Details Appraisals of Condition of Fire-Damaged Concrete

Condition of Property Actual temperature reached in building Actual temperature reached in concrete Compressive strength Methods Examination of building contents Notes See Tables 1 and 2

Visual examination of concrete, Petrographic, DTA, and metallurgical studies of steel. Tests on cores. Impact hammer studies. Penetration resistance. Soniscope studies.

See Fig. 1

Soundness at highly stressed areas (upper side at center of beam; beam supports; anchorages for reinforcement near support; frame corners) Modulus of elasticity Dehydration of concrete Aggregate performance Spalling Cracking

Hammer and chisel. Visual examination. Soniscope studies.

Tests on cores. Soniscope studies. DTA. Petrographic analysis. Chemical analysis. Visual examination. Petrographic analysis. Visual examination.Petrographic analysis. Visual examination. Soniscope studies. Petrographic analysis. Dorry hardness or other tests Los Angeles abrasion test on concrete chips* Visual examination for spalling, cracking. Color variation in cores. Chipping. Petrographic analysis. Visual examination. Straightedge and scale. Dial gages or theodolite if needed. Visual examination. Checking of dimensions and levels. Visual check of cores for loss of bond to steel. Color change in concrete next to steel.

Surface hardness Abrasion resistance

Depth of damage

See Fig. 1

Deformation of beams,

Gross expansion

Differential thermal movements STEEL CONDITION Reinforcing steel, structural steel or prestressing steel Load carrying capacity

* Of uncertain value for this purpose.

Physical tests. Metallurgical studies. Dimensional changes, displacement and distortion. Load tests on structure

Methods for evaluating materials

By this time a good idea of the condition of the structure will have been achieved, and in a few cases enough information will be available to close the investigation. But often there will be questions that can be resolved only by detailed studies. Methods that can be used to obtain answers to questions regarding any of a number of properties of concrete or the condition of structural members are given in Table 3.

Cores can be used for evaluating strength and modulus of elasticity. Cores should be taken judiciously and from locations where their effect on strength will be minimal though they provide necessary data. Comparisons of these data should be made with data obtained from cores taken from areas that were not exposed to elevated tempera t u re s. These comparisons provide the most reliable information on changes in concrete caused by the temperatures reached. Cores are al-

so useful for giving incidental information about cracking in the interior of a member, the bond to reinforcing steel, and interior t e m p e ra t u res as revealed by color changes. Some of the information that can be obtained is shown in the schematic drawing of Figure 2. The impact hammer is useful for estimating compressive strength, but only when a considerable number of measurements are made and compared to undamaged concrete of the same quality from within the same structure. Determinations of pulse velocities, using a soniscope, provide indications of strength and modulus, and attenuated signals are indications of cracking. The soniscope is singularly the most effective nondes t ru c t i ve instrument for detecting cracks. Cracking can also be studied visually in cores or fragments, but detailed information about cracking usually must be obtained by using p e t ro g raphic methods. Suitably prepared specimens can reveal mic ro c ra c k s, their relationship to aggregate and steel, and their internal orientation. The extent of concrete dehydration can be determined by using p e t ro g raphic methods or by differential thermal analysis (DTA). Specimens for DTA studies should be carefully selected, preferably after the petrographic studies. The petrographic and DTA studies can be extended to assessment of the condition of the aggregate. The hardness and abrasion resistance of surfaces, if they are of interest, can be measured by standard methods and compared to similar data from undamaged concrete in the structure.

Condition of steel

Often a major question in determining what structural repairs will be needed can be answered by determining the condition of steel. In floors and walls, exposed prestressing steel can be measured in place using metallurgical methods. If access to the steel is limited because of

height or structural conformation of the member, short lengths of steel can be removed for laboratory studies. A microhardness test can be used for determining the tensile strength of prestressing steel. This is particularly useful because it is rapid and accurate and requires only a small sample. It correlates well with tensile strength determinations. Tensile and other tests on prestressed or reinforcing steel samples are valuable because they give a direct measurement of the property of greatest interest. Studies of steel mic ro s t ru c t u re are useful for evaluating exposure temperatures and their effect on microstructure, and hence on physical properties.

Load tests

Although a compendium of indirect information about the structural capability of individual elements can be obtained, it may still become necessary, and is indeed frequently d e s i ra b l e, to determine the actual loading capacity of an integrated system of elements. For this an actual load test must be perf o rm e d . That test can be made before reinstatement has been completed, aft e rw a rd, or both. Tests completed prior to reinstatement will establish what repairs, if any, may be required; tests completed after reinstatement will indicate whether corrections have been adequate. Usually, organizations experienced in job-site testing are best qualified for completing the load tests. They are well informed on the various methods that can be used, safety precautions that must be employed, and the interpretation of test data.

Sonic signal being sent through fire-damaged concrete. Sender and receiver are being held tightly against the concrete; signal is recorded on a test instrument at floor or ground level.

Serviceability

Aside from structural considerations, maintenance and safety of structurally noncritical conditions should be evaluated. For example, a concrete member may be structurally adequate, yet careful study of the surface region of the member may reveal incipient spalling or cracking that could result in eventu-

Fig. 2 Much information can be obtained by petrographic methods from cores taken at appropriate intervals. Data can be used to evaluate the extent, type and severity of damage and to estimate the temperatures to which the concrete was subjected.

al dislodgment of concrete sections, small or large. Detailed studies, using petrographic methods, may thus be desirable.

Final evaluation

When all of the data are in and before repairs are undertaken there remain two determinations to be made: (1) what parts of the structure cannot be left in their present condition? and (2) should corrections be made by re p a i r, re p l a c ement, or a combination of the two? These subjects will be discussed in the final paper of this series entitled Reinstating Fi re - Da m a g e d St ru c t u re s.

REFERENCES 1. Green, J. K., Reinstatement of Concrete Structures After Fire, (Part 1), The Architects Journal (England), July 14, 1971, pp. 93-99 2. Smith, Peter, Investigation of Repair of Damage to Concrete Caused by Formwork and Falsework Fire. ACI Journal, Proceedings V. 60, No. 11, November 1963, pp. 1535-1566.

Photomicrograph shows a major crack, approximately parallel to a formed surface, that outlines an incipient spall caused by thermal shock. The intricate network of fine cracks in the mortar was caused by drying. More cracks were seen by direct microscopic viewing. Petrographic evidence showed temperatures had been high enough to dry the concrete but not to decompose components of the paste or aggregates.

Part I of this three-part article on fire damage to concrete structures appeared in CONCRETE CONSTRUCTION in March 1972. Part III will appear in May 1972

Core removed for examination.

PUBLICATION#C720154

Copyright 1972, The Aberdeen Group All rights reserved

You might also like

- Evaluation and Repair of Fire-Damaged BuildingsDocument6 pagesEvaluation and Repair of Fire-Damaged Buildingskatrina_ancheta_2No ratings yet

- Fire Damaged Concrete StructuresDocument11 pagesFire Damaged Concrete StructuresbarouniamineNo ratings yet

- Effects of Fire on Concrete Assessment and RepairDocument5 pagesEffects of Fire on Concrete Assessment and RepairAlejandro Rodríguez100% (1)

- Forensic Engineering of Fire-Damaged Concrete StructuresDocument10 pagesForensic Engineering of Fire-Damaged Concrete Structuresstevecabrera100% (1)

- Chapter 5 MortarDocument6 pagesChapter 5 MortarSabrina AlyaNo ratings yet

- Lecture NotesDocument54 pagesLecture NotesJampani HymavathiNo ratings yet

- 05 - Clay Brick Technical Guide - WebDocument12 pages05 - Clay Brick Technical Guide - WebBrian PierceNo ratings yet

- 2009 - Forensic of Fire StructuresDocument7 pages2009 - Forensic of Fire StructuresivanNo ratings yet

- Petrographic Methods of Examining Hardened Concrete: A Petrographic ManualDocument353 pagesPetrographic Methods of Examining Hardened Concrete: A Petrographic ManualTom RewertsNo ratings yet

- Fire Resistance Study of Concrete in The Application of TunnelDocument9 pagesFire Resistance Study of Concrete in The Application of Tunnelsagar jainNo ratings yet

- Repair of Fire Damage StructureDocument58 pagesRepair of Fire Damage StructureBalan-Nogi Dan57% (7)

- VET Timber Decay CH 7 Ws 9Document5 pagesVET Timber Decay CH 7 Ws 9RoOhi MugHalNo ratings yet

- Mibc Masonry Technical Manual CompleteDocument110 pagesMibc Masonry Technical Manual CompleteWissam AlameddineNo ratings yet

- MASONARYDocument117 pagesMASONARYAhamed A L TNo ratings yet

- Renderoc LAXtraDocument2 pagesRenderoc LAXtrajaga67No ratings yet

- Composite Masonry1Document17 pagesComposite Masonry1Bibek Basnet0% (1)

- Concrete SolutionDocument6 pagesConcrete SolutionMohamed KhanNo ratings yet

- Cracks in Buildings Causes and PreventionDocument35 pagesCracks in Buildings Causes and PreventionAbdul Azeem100% (1)

- Guideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFDocument92 pagesGuideline On Structural Fire Engineering Part I - Fire Scenarios and Calculation of Temperature Under Fire Struct PDFLeung LiangNo ratings yet

- Sealants Just Spaghetti and MeatballsDocument13 pagesSealants Just Spaghetti and MeatballsJosé R. MedinaNo ratings yet

- Heat GuideDocument77 pagesHeat GuideLeonichevNo ratings yet

- Diagnosis of Dampness in Conservation of PDFDocument14 pagesDiagnosis of Dampness in Conservation of PDFoink pihNo ratings yet

- Building Failure - Causes and Case StudiesDocument14 pagesBuilding Failure - Causes and Case Studiesresha bhatiaNo ratings yet

- The Basics of Deteriorating Concrete at Wastwater Plants-Tips On Causes Repair and ResourcesDocument9 pagesThe Basics of Deteriorating Concrete at Wastwater Plants-Tips On Causes Repair and ResourcesPrakash100% (1)

- Evaluation of Concrete Structures Affected by Alkali-Silica ReactionDocument59 pagesEvaluation of Concrete Structures Affected by Alkali-Silica ReactionCarlos Augusto Sánchez RondónNo ratings yet

- IS 3370 Part 2 - 2009Document14 pagesIS 3370 Part 2 - 2009Nagamani Venkataramana100% (1)

- Types of Deformations and Factors Affecting Creep, Shrinkage and Elasticity in Hardened ConcreteDocument33 pagesTypes of Deformations and Factors Affecting Creep, Shrinkage and Elasticity in Hardened ConcreteMia HussainNo ratings yet

- Hot Dip Galvanized Minimum Zinc Weight Standards Comparison ChartDocument1 pageHot Dip Galvanized Minimum Zinc Weight Standards Comparison Chartkh88hmiNo ratings yet

- By David J Hammond S.E. and Paul Decicco P.E.: Nfpa Fire Protection Manual 2003 Sect 12, CH 11Document13 pagesBy David J Hammond S.E. and Paul Decicco P.E.: Nfpa Fire Protection Manual 2003 Sect 12, CH 11fraantoineNo ratings yet

- Failures That Changed Perception of Our Designs-InG IABSE December 14Document22 pagesFailures That Changed Perception of Our Designs-InG IABSE December 14Subramanian NarayananNo ratings yet

- Rakic - Type of Fireproofing Materials PDFDocument3 pagesRakic - Type of Fireproofing Materials PDFbehrouzbehnam100% (1)

- Icri Guidelines On 11-14 Weeks Obstetric Scan July 2020Document19 pagesIcri Guidelines On 11-14 Weeks Obstetric Scan July 2020hasnainpasha100% (2)

- Forensic Engineering of Fire-Damaged StructuresDocument6 pagesForensic Engineering of Fire-Damaged StructuresRYBCZANNo ratings yet

- CARLISLE WATERPROOFING Internationalgeomanual 2002Document91 pagesCARLISLE WATERPROOFING Internationalgeomanual 2002Ajna SalimNo ratings yet

- Passive Fire Protection PDFDocument7 pagesPassive Fire Protection PDFVictor SampaNo ratings yet

- Guide To Chemical Grouting of Joints and Cracks in Concrete MERL-2013-58Document38 pagesGuide To Chemical Grouting of Joints and Cracks in Concrete MERL-2013-58chutton681No ratings yet

- Beyond Failure Forensic Case Studies in Civil EngineeringDocument46 pagesBeyond Failure Forensic Case Studies in Civil EngineeringfaisaltmNo ratings yet

- CSPIF Ground Slab Cracking Report - 2019-SAR-01 - 03Document56 pagesCSPIF Ground Slab Cracking Report - 2019-SAR-01 - 03seii.chenNo ratings yet

- BRE 365 Infiltration CalculationDocument6 pagesBRE 365 Infiltration CalculationRaburgess1No ratings yet

- Historic Mortar Tests NC PTTDocument69 pagesHistoric Mortar Tests NC PTTPutriSusantiNo ratings yet

- Concrete Deterioration: Diagnosis, Repair Methods & MaterialsDocument9 pagesConcrete Deterioration: Diagnosis, Repair Methods & MaterialsVineet KediaNo ratings yet

- Contents-Concrete Repair Manual: Third EditionDocument4 pagesContents-Concrete Repair Manual: Third Editionmy09No ratings yet

- CAUSES AND PREVENTION OF CRACKS IN BUILDINGSDocument35 pagesCAUSES AND PREVENTION OF CRACKS IN BUILDINGSharNo ratings yet

- Fire Protection 5.2 Klemenz Fire ResistanceDocument80 pagesFire Protection 5.2 Klemenz Fire ResistanceaswathiNo ratings yet

- Building Waterproofing RedefinedDocument2 pagesBuilding Waterproofing RedefinedbatteekhNo ratings yet

- Masonry Testing 101 - 2018 04 12Document57 pagesMasonry Testing 101 - 2018 04 12Jeff LongoriaNo ratings yet

- Ac308 - 15 - Concrete Anchor Manufacturers AssociationDocument127 pagesAc308 - 15 - Concrete Anchor Manufacturers AssociationPaulo HenriqueNo ratings yet

- Shrinkage Cracks - Causes - Preventive Measures and Repair MethodsDocument8 pagesShrinkage Cracks - Causes - Preventive Measures and Repair MethodsDaud Hajibhai UnnadpotraNo ratings yet

- CIV575M Lecture No. 4 - Earthquake Risk Reduction by AWC Oreta (DLSU)Document11 pagesCIV575M Lecture No. 4 - Earthquake Risk Reduction by AWC Oreta (DLSU)andyoreta6332100% (1)

- Hot Weather ConcretingDocument26 pagesHot Weather ConcretingSaulat JillaniNo ratings yet

- Technical Note TN 38 Cracks in Concrete PDFDocument4 pagesTechnical Note TN 38 Cracks in Concrete PDFJohnNo ratings yet

- Ross Wood and Timber Condition Assessment Manual CH 4 PDFDocument20 pagesRoss Wood and Timber Condition Assessment Manual CH 4 PDFKen SuNo ratings yet

- Tor Design PDFDocument19 pagesTor Design PDFAlly KhooNo ratings yet

- Evaluating Water-Resistive Barrier (WRB) Coatings Used Under Exterior Insulation and Finish Systems (EIFS) or EIFS With DrainageDocument5 pagesEvaluating Water-Resistive Barrier (WRB) Coatings Used Under Exterior Insulation and Finish Systems (EIFS) or EIFS With DrainageAhmad Zubair RasulyNo ratings yet

- The Effects of Composition and Thermal Path On Hot Ductility of Forging Steels-ConnollyDocument11 pagesThe Effects of Composition and Thermal Path On Hot Ductility of Forging Steels-ConnollyAntonioNo ratings yet

- Selecting Lining MaterialsDocument8 pagesSelecting Lining Materialsluv kanoriaNo ratings yet

- Steel Structure Subjected To Fire and FatigueDocument12 pagesSteel Structure Subjected To Fire and Fatigueakhlaq_hssainkotaNo ratings yet

- Fireproofing For Petrochemical FacilityDocument12 pagesFireproofing For Petrochemical FacilityJames Murray100% (4)

- Abbbdgget 155667Document15 pagesAbbbdgget 155667Wan Ah-LunNo ratings yet

- Maersk Blending On Board (BOB) - OKHHDocument8 pagesMaersk Blending On Board (BOB) - OKHHCalandrasReyCalandrasreyNo ratings yet

- A Knowledge Based System For Material SelectionDocument12 pagesA Knowledge Based System For Material SelectionmnoriegalNo ratings yet

- Advances in Thermal Spray Technology - 2020 - 190Document190 pagesAdvances in Thermal Spray Technology - 2020 - 190Ngo BinhNo ratings yet

- Experimental Investigation On Bituminous Mix Using Coconut CoirDocument8 pagesExperimental Investigation On Bituminous Mix Using Coconut CoirTJPRC PublicationsNo ratings yet

- AASHTODocument6 pagesAASHTOAngelica Fontamillas SuicoNo ratings yet

- Sand Fines Erosion in Gas Pipelines - Experiments and CFD Modeling@NACE-2014-3964Document12 pagesSand Fines Erosion in Gas Pipelines - Experiments and CFD Modeling@NACE-2014-3964Mahfoud AMMOURNo ratings yet

- IS 4151 Product Manual PDFDocument8 pagesIS 4151 Product Manual PDFkrishna singhNo ratings yet

- Refractory Lining of Blast Furnace PDFDocument11 pagesRefractory Lining of Blast Furnace PDFceng el samiuNo ratings yet

- MPZ Operating ManualDocument48 pagesMPZ Operating Manualweslley.luzNo ratings yet

- Inspeccion Visual CamshaftsDocument21 pagesInspeccion Visual CamshaftsJavier Hector CayaNo ratings yet

- VEGA - Indonesia PresentationDocument62 pagesVEGA - Indonesia PresentationSteve WanNo ratings yet

- 99924-2093-03 FR730V FS730V FX730V English eBook-Kawasaki PDFDocument177 pages99924-2093-03 FR730V FS730V FX730V English eBook-Kawasaki PDFRabab Siddiqui100% (2)

- Problem Pumps: A Thing of The Past: OperatingDocument9 pagesProblem Pumps: A Thing of The Past: Operatingkpostulart100% (1)

- Powder Coatings Product Guide - 20-219767Document7 pagesPowder Coatings Product Guide - 20-219767zagNo ratings yet

- Control-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFDocument10 pagesControl-Valve Seat Leakage - Hydrocarbon Processing - August 2011 PDFPiush KumarNo ratings yet

- Mechanical Seminar Topics ListDocument21 pagesMechanical Seminar Topics Listnewlen210% (1)

- F1875 1479757-1Document6 pagesF1875 1479757-1Thaweekarn ChangthongNo ratings yet

- Genuine Rammer Parts and Tool GuideDocument15 pagesGenuine Rammer Parts and Tool GuideFrank HigueraNo ratings yet

- Overland conveyors optimized for cost and performanceDocument17 pagesOverland conveyors optimized for cost and performancematheusNo ratings yet

- Minehaulroaddesignconstructionandmaintenancemanagement 140804110320 Phpapp02 PDFDocument136 pagesMinehaulroaddesignconstructionandmaintenancemanagement 140804110320 Phpapp02 PDFYudhi Tri IndrawanNo ratings yet

- KOYO One-Way Clutches GuideDocument19 pagesKOYO One-Way Clutches GuideZahir KhiraNo ratings yet

- NTU MAE CoursesDocument15 pagesNTU MAE Coursesprofessornath7002No ratings yet

- Isrm SM Hardness and Abrasiveness of Rock - 1978Document9 pagesIsrm SM Hardness and Abrasiveness of Rock - 1978Evandro SantiagoNo ratings yet

- Glossary - Online - Visual TestingDocument22 pagesGlossary - Online - Visual TestingMohamad JunaedyNo ratings yet

- Ceramic Liner Products and FeaturesDocument9 pagesCeramic Liner Products and FeaturesrezandriansyahNo ratings yet

- Sciencedirect: Dry Rotary Swaging With Structured ToolsDocument6 pagesSciencedirect: Dry Rotary Swaging With Structured Toolsehtisham khanNo ratings yet

- Wear Debris Analysis (ASTM D7690) : Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduDocument1 pageWear Debris Analysis (ASTM D7690) : Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaNo ratings yet

- Code Iso Dealer - Pejt5025Document12 pagesCode Iso Dealer - Pejt5025yonathanNo ratings yet

- Subjuct/Module: Level: Lab / Experiment NameDocument8 pagesSubjuct/Module: Level: Lab / Experiment NameTEDDYNo ratings yet

- Bohlerstrip Steel-RulesDocument34 pagesBohlerstrip Steel-RulesAbdul WasayNo ratings yet