Professional Documents

Culture Documents

Part - 1

Uploaded by

Wagih Abd El-AzizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Part - 1

Uploaded by

Wagih Abd El-AzizCopyright:

Available Formats

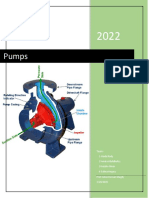

CONSTRUCTION OF CENTRIFUGAL PUMPS

Construction of Centrifugal Pumps

Casing

Casing generally are two types:

I. Volute casings for a higher head. II. Circular casings for low head and high capacity.

Construction of Centrifugal Pumps

Casing

Volute casings:

A volute is a curved funnel increasing in area to the discharge port.

Construction of Centrifugal Pumps

Casing

Volute casings:

Running volute-style pumps at a lower capacity than the manufacturer recommends can put lateral stress on the shaft of the pump, increasing wear-and-tear on the seals and bearings, and on the shaft itself.

Construction of Centrifugal Pumps

Casing

Volute casings:

Double- volute casings are used when the radial thrusts become significant at reduced capacities.

the main purposes of a volute casing is to help balance the hydraulic pressure on the shaft of the pump at the manufacturer's recommended capacity .

Construction of Centrifugal Pumps

Casing

Circular casings:

have stationary diffusion vanes surrounding the impeller periphery that convert velocity energy to pressure energy.

Solid casing is one casting or fabricated piece. Split casing consists of two or more parts are fastened together.

Construction of Centrifugal Pumps

Casing

Circular casings:

Split casing Horizontally split or axially split casing.

Construction of Centrifugal Pumps

Casing

Circular casings:

Split casing

Vertically split or radially split casing.

Construction of Centrifugal Pumps

Casing

Shaft weight

Shaft deflection

Cost

Construction of Centrifugal Pumps

Casing

The ideal design would be one which reduces radial thrust to an acceptable level.

How?

Construction of Centrifugal Pumps

Casing

Some pump casings use a split volute design instead of a double volute.

Construction of Centrifugal Pumps

Casing

Diffuser pump casings:

Some pump casings use a split volute design instead of a double volute.

The liquid leaves the diffuser at a higher pressure than it leaves the impeller, then enters the casing annulus and finally leaves at the discharge branch.

Construction of Centrifugal Pumps

Casing

Diffuser pump casings:

Diffusers are frequently used in multi-stage pumps and are more efficient than volute types of casing.

However, diffuser designs are more costly than volute designs and therefore single-stage diffuser pumps are not used as often as volute types because of the expense.

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

Diffuser

1. Guides the liquid flow from one impeller to the next. 2. acts in a similar manner to a volute by converting velocity energy (kinetic energy) into pressure energy.

Diffuser

Impeller

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

LP HP LP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Multi-stage pumps:

LP

HP

LP

HP

LP

HP

HP

LP

Normal thrust on rotor

Normal thrust on rotor

Construction of Centrifugal Pumps

Casing

Suction and Discharge nozzle:

Construction of Centrifugal Pumps

Casing

Suction and Discharge nozzle:

End suction/Top discharge:

1) Always an overhung type.

2) Typically has lower NPSHR.

Construction of Centrifugal Pumps

Casing

Suction and Discharge nozzle:

Top suction/Top discharge:

1) Always a radially split case pump.

2) It can be either an overhung type or between bearing type..

Construction of Centrifugal Pumps

Casing

Suction and Discharge nozzle:

Side suction/Side discharge:

This pump can have either an axially or radially split case type.

Construction of Centrifugal Pumps

Casing

Seal Chamber and Stuffing Box:

If sealing is by mechanical seal, the chamber is referred to as a Seal Chamber. If sealing is by packing, the chamber is referred to as a Stuffing Box.

They either integral with or separate from the pump case housing that forms the region between the shaft and casing where sealing media are installed.

Construction of Centrifugal Pumps

Casing

Seal Chamber and Stuffing Box:

Construction of Centrifugal Pumps

Casing

Seal Chamber and Stuffing Box:

Internal circulating device

Gland

Throttle bushing

Throat bushing

Construction of Centrifugal Pumps

Bearing housing

You might also like

- 7-Steps Service OperationDocument66 pages7-Steps Service OperationWagih Abd El-Aziz77% (22)

- Pump Installation & MaintenanceDocument116 pagesPump Installation & MaintenanceMohammed El-Shahat100% (8)

- Centrifugal PumpDocument7 pagesCentrifugal PumptanalialayubiNo ratings yet

- Calao Deliquente Diadi River SystemDocument15 pagesCalao Deliquente Diadi River SystemJason MalamugNo ratings yet

- Assignment - 1Document10 pagesAssignment - 1TolphasNo ratings yet

- Pump Construction: ChapterDocument10 pagesPump Construction: ChapterAhmad_Othman3No ratings yet

- Explanation About PumpsDocument36 pagesExplanation About PumpsAnonymous ixIhrPM2No ratings yet

- InducerDocument54 pagesInducerYaswanthNo ratings yet

- 9.marine PumpDocument82 pages9.marine PumpOladokun Sulaiman Olanrewaju80% (5)

- Module 1 Activity No. 1Document5 pagesModule 1 Activity No. 1Benz DyNo ratings yet

- Module 7Document63 pagesModule 7Agilan ChellaramNo ratings yet

- Classification of PumpsDocument23 pagesClassification of PumpsRam Krishna SinghNo ratings yet

- CPump PresentationDocument118 pagesCPump PresentationTalha Ahmad100% (1)

- Cent PumDocument24 pagesCent PumAhmed MostafaNo ratings yet

- Faculty of Engineering Technology and Research: Centrifugal PumpDocument16 pagesFaculty of Engineering Technology and Research: Centrifugal PumpsushantNo ratings yet

- Plunger PumpsDocument7 pagesPlunger PumpsAsad Imran Munawwar100% (1)

- Pumps, Fans and Blowers and CompressorsDocument80 pagesPumps, Fans and Blowers and CompressorsRomart Barosa100% (2)

- Types of Pump Casings (In Centrifugal Pumps & Others) + Pros & ConsDocument10 pagesTypes of Pump Casings (In Centrifugal Pumps & Others) + Pros & ConssarojNo ratings yet

- CF Pump Study 1stageDocument7 pagesCF Pump Study 1stageHa M ZaNo ratings yet

- DR:Ahmed Abdel-Naby PumpsDocument18 pagesDR:Ahmed Abdel-Naby PumpsMostafa Elmaghraby 467No ratings yet

- Pumps: Team:-1-Hoda Nady 2-Amira Abdelhafez 3-Aeisha Omar 4-Salma Hegazy Prof - Yahia Hassan Magdy 2/28/2022Document22 pagesPumps: Team:-1-Hoda Nady 2-Amira Abdelhafez 3-Aeisha Omar 4-Salma Hegazy Prof - Yahia Hassan Magdy 2/28/2022Abdelhameed NadyNo ratings yet

- Basics of Centrifugal PumpsDocument60 pagesBasics of Centrifugal PumpsMajid Sattar100% (1)

- Basic Civil and Mechanical Engineering Unit III Pumps and TurbinesDocument10 pagesBasic Civil and Mechanical Engineering Unit III Pumps and TurbinesA.R. Pradeep Kumar100% (1)

- Assignment: Name Muhammad ArsalanDocument8 pagesAssignment: Name Muhammad ArsalanMuhammad Arsalan TariqNo ratings yet

- Deep Well Turbine and Submersible PumpsDocument92 pagesDeep Well Turbine and Submersible Pumpsahsanul haqueNo ratings yet

- Unit 5Document57 pagesUnit 5mmr315No ratings yet

- Cent Pum-NbDocument27 pagesCent Pum-Nbmass3444No ratings yet

- Basics of PumpDocument7 pagesBasics of PumpMuhammed SulfeekNo ratings yet

- Centrifugal Pump Hand BookDocument150 pagesCentrifugal Pump Hand Bookbarun1977100% (2)

- Centrifugal PumpsDocument27 pagesCentrifugal PumpsHossam SalahNo ratings yet

- Centrifugal Pump DesignsDocument6 pagesCentrifugal Pump DesignsViệt Đặng XuânNo ratings yet

- Design Consideration of Different Volute Casing at Best Efficiency Point PDFDocument5 pagesDesign Consideration of Different Volute Casing at Best Efficiency Point PDFSimon TudorNo ratings yet

- PUMPS 1-NotesDocument16 pagesPUMPS 1-NotesPortifer Harrison Ray Mubanga100% (1)

- Types of Pump Onboard ShipDocument2 pagesTypes of Pump Onboard Shipjemark100% (1)

- Centrifugal PumpsDocument20 pagesCentrifugal PumpsBabylyn AustriaNo ratings yet

- Oil Tanker PipingDocument38 pagesOil Tanker PipingnikhilNo ratings yet

- Centrifugal PumpsDocument27 pagesCentrifugal PumpsNischal LgNo ratings yet

- Centrifugal PumpDocument54 pagesCentrifugal PumpBia Mughal0% (1)

- Applications of Pumps in A Mine: The Mine Pumps Based On Their Operating Principles Can Be Classified As FollowsDocument21 pagesApplications of Pumps in A Mine: The Mine Pumps Based On Their Operating Principles Can Be Classified As FollowsAnshul yadavNo ratings yet

- Cent Pum-NbDocument39 pagesCent Pum-NbDeva RajNo ratings yet

- Centrifugal Pumps: PARAN, John Lloyd MACASAET, Alwin MALABUYOC, Lean ErnestDocument74 pagesCentrifugal Pumps: PARAN, John Lloyd MACASAET, Alwin MALABUYOC, Lean ErnestMeryL Ang100% (1)

- Unit 4 HHM Part 2Document75 pagesUnit 4 HHM Part 2Swati ChaudharyNo ratings yet

- Basic Pump ConstructionDocument90 pagesBasic Pump ConstructionMariaEzzaSyUyNo ratings yet

- Positive-Displacement PumpDocument49 pagesPositive-Displacement PumpSandip KadoliNo ratings yet

- Centrifugal Pump: PrincipleDocument6 pagesCentrifugal Pump: Principle962943415xNo ratings yet

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Document42 pagesBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (1)

- Unit 8 Centrifugal Pumps: Hydraulics and Hydraulic Machines (10CV45)Document10 pagesUnit 8 Centrifugal Pumps: Hydraulics and Hydraulic Machines (10CV45)tonydisojaNo ratings yet

- Industrial Plant EngineeringDocument71 pagesIndustrial Plant EngineeringIan Llapitan0% (2)

- Fundamentals of Centrifugal PumpDocument8 pagesFundamentals of Centrifugal Pumpshashidharbade100% (1)

- Pumps: Pumps and Its TypesDocument34 pagesPumps: Pumps and Its TypesAmir Hamza100% (1)

- PEOP1009 - Pumps-1 PDFDocument17 pagesPEOP1009 - Pumps-1 PDFShazeem HoseinNo ratings yet

- Pump & Types of PumpsDocument33 pagesPump & Types of PumpsAhmad JuttNo ratings yet

- By: Ricky S. Alegre Gabrel C ArsenioDocument19 pagesBy: Ricky S. Alegre Gabrel C ArsenioVictor GuijoNo ratings yet

- Pumps Me14Document30 pagesPumps Me14WIIGEENNo ratings yet

- Basic Civil and Mechanical-unit-3-Pumps and Turbines-SupportDocument10 pagesBasic Civil and Mechanical-unit-3-Pumps and Turbines-SupportVignesh VickyNo ratings yet

- 11.plant Layout PumpsDocument16 pages11.plant Layout Pumpshalder_kalyan9216No ratings yet

- Centrifugal Pump Working and Types - A Complete GuideDocument19 pagesCentrifugal Pump Working and Types - A Complete GuideMohamed AtefNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Pp16aDocument86 pagesPp16aWagih Abd El-AzizNo ratings yet

- Pp12aDocument55 pagesPp12aWagih Abd El-AzizNo ratings yet

- Computer and Network FundamentalsDocument49 pagesComputer and Network FundamentalsWagih Abd El-AzizNo ratings yet

- WKF 100 5Document1 pageWKF 100 5Wagih Abd El-Aziz100% (1)

- Resume 9 OriginalDocument1 pageResume 9 OriginalWagih Abd El-AzizNo ratings yet

- Resume 23 OriginalDocument1 pageResume 23 OriginalWagih Abd El-AzizNo ratings yet

- "C:/Program Files/Skype/Phone/Skype - Exe" /secondaryDocument1 page"C:/Program Files/Skype/Phone/Skype - Exe" /secondaryWagih Abd El-AzizNo ratings yet

- Resume 26 OriginalcccDocument1 pageResume 26 OriginalcccWagih Abd El-AzizNo ratings yet

- Carolyn Green Release FinalDocument3 pagesCarolyn Green Release FinalAlex MilesNo ratings yet

- Tetra Pak Training CatalogueDocument342 pagesTetra Pak Training CatalogueElif UsluNo ratings yet

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocument10 pagesVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorNo ratings yet

- Chi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillDocument32 pagesChi - Square Test: PG Students: DR Amit Gujarathi DR Naresh GillNaresh GillNo ratings yet

- Wilo Water PumpDocument16 pagesWilo Water PumpThit SarNo ratings yet

- Issue of HomosexualityDocument4 pagesIssue of HomosexualityT-2000No ratings yet

- BCA2006 BCA GuideDocument507 pagesBCA2006 BCA GuidePatrick LiaoNo ratings yet

- Energy Optimization of A Large Central Plant Chilled Water SystemDocument24 pagesEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002No ratings yet

- Chapter 03Document35 pagesChapter 03david jenil nabuaNo ratings yet

- Method Statement For Installation of Chilled Water Pump & Condenser Water PumpDocument14 pagesMethod Statement For Installation of Chilled Water Pump & Condenser Water Pump721917114 47No ratings yet

- Cannabis Effects On Driving SkillsDocument15 pagesCannabis Effects On Driving SkillsCharles PetersNo ratings yet

- Vital Statistics: Presented by Mrs - Arockia Mary Associate ProfDocument17 pagesVital Statistics: Presented by Mrs - Arockia Mary Associate ProfraghumscnNo ratings yet

- Index Medicus PDFDocument284 pagesIndex Medicus PDFVania Sitorus100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- (Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)Document4 pages(Cô Vũ Mai Phương) Tài liệu LIVESTREAM - Chuyên đề thi THPT - Câu hỏi giao tiếp xã hội (Buổi 1)nguyen duong trungNo ratings yet

- Amul Amul AmulDocument7 pagesAmul Amul Amulravikumarverma28No ratings yet

- Iso 9227Document13 pagesIso 9227Raj Kumar100% (6)

- Chapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Document44 pagesChapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Tommy RamazzottoNo ratings yet

- Datasheet MEC MPS200 v1 2018Document4 pagesDatasheet MEC MPS200 v1 2018Cepi Sindang KamulanNo ratings yet

- Pyq of KTGDocument8 pagesPyq of KTG18A Kashish PatelNo ratings yet

- Experiment Number 16 Formal ReportDocument4 pagesExperiment Number 16 Formal Reportapi-524547303No ratings yet

- Key ScientificDocument4 pagesKey ScientificGarrettNo ratings yet

- Manual of GardeningDocument812 pagesManual of GardeningPrakash PatelNo ratings yet

- Blood DonationDocument19 pagesBlood DonationsuruthiNo ratings yet

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDocument84 pagesDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyNo ratings yet

- BKM 10e Ch07 Two Security ModelDocument2 pagesBKM 10e Ch07 Two Security ModelJoe IammarinoNo ratings yet

- Chapter 7 Unemployment, Inflation, and Long-Run GrowthDocument21 pagesChapter 7 Unemployment, Inflation, and Long-Run GrowthNataly FarahNo ratings yet

- A.8. Dweck (2007) - The Secret To Raising Smart KidsDocument8 pagesA.8. Dweck (2007) - The Secret To Raising Smart KidsPina AgustinNo ratings yet

- An Energy Saving Guide For Plastic Injection Molding MachinesDocument16 pagesAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoNo ratings yet