Professional Documents

Culture Documents

Nullifying gravitational force with high-speed rotational water nozzles

Uploaded by

avalosheOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nullifying gravitational force with high-speed rotational water nozzles

Uploaded by

avalosheCopyright:

Available Formats

Europisches Patentamt

(19)

European Patent Office Office europen des brevets

*EP001526073A1*

(11)

EP 1 526 073 A1

(12) (43) Date of publication:

EUROPEAN PATENT APPLICATION

27.04.2005 Bulletin 2005/17

(51) Int Cl.7:

B64G 1/40, F03H 5/00

(21) Application number: 04000643.9 (22) Date of filing: 14.01.2004 (84) Designated Contracting States:

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IT LI LU MC NL PT RO SE SI SK TR Designated Extension States: AL LT LV MK

(72) Inventor: FUKAI, Kiyotatsu

Utsuomiyashi, 321-0138 (JP)

(74) Representative: Meissner, Bolte & Partner

Anwaltssoziett GbR Postfach 86 06 24 81633 Mnchen (DE)

(30) Priority: 20.10.2003 JP 2003393088 (71) Applicant: FUKAI, Kiyotatsu

Utsuomiyashi, 321-0138 (JP)

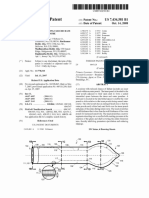

(54)

Equipment to nullify gravitational force

inate gravitational force due to a reaction force created by expelled water from high-speed rotational, downward-directed nozzles (6) at a high speed, and to prevent most of the floating power, obtained from the reaction force, from being eliminated through the use of structural advantages of the equipment, i.e. by utilizing the force of synthetic vector (8) direction, gained from high-speed water fromdownward-directed nozzles (6).

(57) Having the dream of a vehicle nullifying gravitation and flying in the air, the human race considered rockets that would fly with the reaction force of a giant pillar of flames. The human race thus consumed several trillions of dollars and overcame the tragedy of burning scores of people to death due to failure. [Constitution] This invention represents gravitation-nullifying equipment, which is designed to obtain floating power to elim-

EP 1 526 073 A1

Printed by Jouve, 75001 PARIS (FR)

1 Description [Detailed Explanation of the Invention] [Technological Field to Which Invention Belongs]

EP 1 526 073 A1

tion is quite an epoch-making technological achievement based on the development of equipment to nullify gravitation founded on the aforementioned reference material, which has to date not been used.

5

[Conventional Technology] [0001] This invention belongs to the field of hydraulic rotating machinery, and it relates to a unique, so-far nonexistent system, to nullify gravitation. Accordingly, to understand this invention, it is necessary to remember, in connection with Fig. 1, publicly known basic phenomena of hydraulics, which are quoted in hydraulic textbooks for graduate schools of universities. [0002] When a robust box V, shown within the oblique view diagram in Fig. 1, is completely filled with water, and when nozzles 4' and 6' are revolved at a speed of V in the direction of arrow 3', with fixed point 2' as the center of rotation, when the nozzles 4' and 6' in the diagram are closed, and when the gravitational acceleration of water head H, based on normal acceleration, is g near the tips of nozzles 4' and 6', the formula1 H = V2/ 2g, can be established. The method of verifying this is omitted as it is publicly known. Next, while water is supplied from around point 2' into box 1' to a degree that the full water level within the box is maintained, when stoppers are removed from nozzle 4' and nozzle 6', whose opening diameters were equalized, and when water is expelled from their tips, water is spurted into the directions of 5' and 7', respectively. The speed of both water jets is publicly known as V = 2gH, and the expelling of water continues. On this occasion, the speed of water expelled from nozzle 4' is of course V. If p is set at the specific mass of water, and if Q is set at the water volume to be expelled during a unit time, it is well known that the reaction force pushing rotationally toward the revolving direction 3' will be F = QV. To reconfirm, this force F continually causes the rotation toward arrow 3' at a speed of V. Here, expelled water 5' from nozzle 4' continues to provide energy; i.e. Driving Force Speed = F V = pQV2, to box 1' in the counter clockwise direction 3' in the unit time. On the other hand, the energy required in expelling the water from nozzles 4' and 6' at a speed of V, to bring the speed from 0 at the fixed point 2', the center of revolution, to the level of V and to feed water volume Q in the unit time will be 1/2QV2 2 (for 2-nozzles or per pair). This is equal to the energy given in the unit time in expelling water from nozzle 4' to arrow 5', as already explained; i.e. F V = QV2, and it will be offset within the equipment as a whole, so that it will not emerge out of the equipment. Accordingly, for the continual revolution of box 1' toward the rotation direction 3', it is necessary to provide energy corresponding to the machinery loss portion, which is equivalent to the wind loss and bearing loss, from outside, because the equipment is not a perpetual motion machine. [0003] The above is an explanation summary, quoted from the hydraulics textbook of a graduate school, which has a high reference value for this invention. This inven[0004] For man to fly into the air nullifying gravitation, there have been no other ways but to use rockets or jet engines, which expel pillars of flames from their ends while carrying much fuel, and to fly based on the reaction of the process. As such, such huge expenses as adversely affecting a national budget have been openly used in the embellished name of national defense, and when an explosion occurs as a result of failure, a tragedy in which many people are burned to death was forcibly endured. Accordingly, the equipment to nullify gravitational force, based on this invention, will bring about an economic, industrial, and military revolution of the largest scale in the history of human beings. It will bring about a great renovation to the conventional technology for man, who has so far known only the method of reaching space due to a reaction from jetting gas. [Actual Form of Invention] [0005] In this invention, the reaction force F = pQV will arise, as already explained, in connection with nozzle 4' in connection with Fig. I, when nozzles 4 and 6 spurt "expelled water arrows" 5 and 7, during the revolution of the hollow disk in the direction of arrow 3 at the speed of V, as shown in the partial plan of the hollow disk within Fig. 4. Naturally, the same reaction force F = pQV will also be generated for nozzle 6'. It is self evident that the similar reaction force F = pQV will also arise in nozzles 4 and 6 in Fig. 4. As in Fig. 1, the reaction force working on nozzle 4 in Fig. 4 in the equipment of this invention will revolve the hollow disk 1 in the direction of arrow 3, while the force working on nozzle 6 will serve as the power to nullify gravitation, propelling the entire equipment into the air. Arrow 7, showing the downward expelled water from the place of nozzle 6' in the front view drawing concerning the composite speed vector within Fig. 2, and arrow 3', showing the revolving direction, mutually have a relationship of 90 degrees at the speed of V, while their composite vector 8' will have a relationship of 45 degrees with the downward expelled water shown as arrow 7'. This verifies the fact that the downward expelled water arrow 7 in Fig. 4 cannot ram onto a flat bottom face near the water-conveyance panel 16 vertically mounted in the frame/tank 12. The expelled water arrow 7, from nozzle 6, will drop at an angle of 45 degrees, even if it falls on the flat bottom of the frame/tank 12, so that its shock and the reducing force, will be in accordance with the formula: F'= QV sin 45 = QV about 0.7. Even in this case, pQV about 0.3 will serve as a upward propelling force from each nozzle 6, for the equipment as a whole. This is a benefit created by

10

15

20

25

30

35

40

45

50

55

EP 1 526 073 A1

chance due to the design of the invention. For a realistic trial calculation, it is assumed that 1 unit of equipment has 4 nozzle 6s, with 1 unit for right rotation and 1 unit for leftward rotation combined as 1 set to offset the torques, and calculation is made as to the intensity of the force for propelling upward. In this case, it is assumed that the diameter of expelled water 7 from nozzle 6 is 0.05m, that its cross-sectional area A is 0.002m2, with the total number of the nozzle 6 in the 2 units being 8. It is also assumed that the rotational diameter of nozzle 6 is 1m, that its speed is 100m/S; i.e. 1,909.85 rpm, and that is 102kg, S2/m4. Because Q = AV in the case of this equipment, the outcome of the following formula: QV 0.3 x 8 = AV 0.3 8 = 102 0.002 1002 about 0.3 8 (units) = 4,896 (kg), will be the force to propel the equipment upwards. If most of the equipment is manufactured of reinforced plastic, spindle 2 can be relatively thin, and can be such an object, whose durability can be calculated by multiplying the resistance factor, capable of enduring the machinery loss and the loss related to water-pumping devices 13 and 20, by some safety ratio. Accordingly, the total weight may be 2,000 kg at maximum. Therefore, room for loading 2,896 kg (4,896 - 2,000) will arise as a result. Since this is not a perpetual movement machine, the equipment will stop if the power source for the motor 18 in Fig. 5 is turned off. The enforcement equipment of this invention may contribute to the occurrence of an epoch-making event, in which about 2 persons will be sent from Japan to the Moon or Mars. Because this invention is equipment logically and inevitably composed based on the combination of various kinds of phenomena quantitatively backed by authoritative textbooks of graduate schools for universities, there will be no possibility of failure, if design and manufacture are immediately undertaken. In addition, for reference, because the hollow disk 1 is revolving toward arrow 3 at a speed of V, the expelled water arrow 5 from nozzle 4 in Fig. 4 is spurted in the contrary direction toward arrow 5 at a speed of V, its speed in relation to the earth will be zero, so when the expelled water leaves nozzle 4 at each location, the expelled water will descend strictly downward. The water is expected to look as if it is a water curtain, with a round shape. Meanwhile, water that falls straight downward as shown by arrow 7 from nozzle 6, progresses naturally toward the synthetic vector arrow 8', due to the effect of the direction toward arrow 3, at the same V speed, as explained regarding Fig. 2. On this occasion, as with the case of arrow 8 shown in Fig. 3, the standstill-time water surface 11 will be guided by high-speed arrow 8, becoming a paraboloid of revolution 10. The water whose periphery is rising and which is rotating at a high speed will ram into the side of the frame/tank 12, while the water itself at the side will also become a. force, accelerated by centrifugal power, to press against the side wall of the frame/tank 12, because of the revolving movement at a speed close to V. Therefore, the movement energy of the arrow 8 water is consumed. For this reason, the

10

15

20

25

30

35

40

45

50

55

source for shock onto the bottom face of the frame/tank 12 in Fig. 3 will almost disappear. It is accordingly clear that there is virtually no force reducing the reaction force F = pQV, which was applied by expelled arrow 7 from nozzle 6 in Fig. 4. Accordingly, most of the already explained 4,896 kg force from 8 nozzle 6's to propel the entire equipment upwards will remain. What should be noted here is that the enforcement equipment for this invention will be operated at a temperature of about minus 30 C, which is similar to the temperature at an altitude of 5,000 m. Therefore, a liquid that doesn't freeze at that temperature must be used for most of the liquid. Also, specific mass p of water, frequently used in this patent specification, represents, at an assumed temperature of 0 , 102.03kg, S2/m4, while flow volume every second Q = m3/S, and speed V = m/S, all in MKS units. At the enforcement equipment of this invention, a powerful horizontal component force will be generated, if the rotational spindle 2 is slightly inclined forward or backward, so that its forward/backward movement can be freely implemented. [0006] Through the use of the attached diagram, the entire structure of the equipment for this invention will be explained. As shown in the diagram of a partial longitudinal section when the entire equipment is composed - in Fig. 5 - the cylindrical frame/tank 12 and its lid 23 will be manufactured with metal or reinforced plastic. A small-output vertically oriented motor 18, powered using batteries or some other power source, is fitted at the center of lid 23. The bearing for spindle 2 of the motor 18 is fixed to lid 23, and to its spindle 2, the hollow disk 1 and its upper lid 17 are fixed. The hollow disk 1 will naturally revolve together with spindle 2. Around the hollow disk 1, nozzle 4, whose expelled water 5 will spurt in the contrary direction to arrow 3, and nozzle 6, whose expelled water will be directed directly downward, are fixed as 1 set of nozzles, and multiple such units will be installed at equal distances around the hollow disk. On the bottom surface of the hollow disk 1, multiple diaphragms 22 will be set radially, and further fitted with lid 23. On the bottom of the frame/tank 12 to which the bearing 19 of the lower portion of spindle 2 is to be fitted, several water-conveyance panels 16 will be set in a radial manner, to control the high-speed rotation of water so that water will be prone to flow into multiple holes 14' of cylinder 20 for pumping-upwards, which will also be fixed to the bottom surface. The height of cylinder 20 for pumping-upwards will be arranged so as not to reach a water channel hole 21 at the lower center of the hollow disk 1. Because of the pumping-upwards work done by the spiral-shaped thin, long panel 13, which is fixed to spindle 2 in the partial cross-sectional diagram showing the pumping-upwards mechanism of the hollow disk 1 in Fig. 6, water will progress from hole 14' to arrow 14, due to the high-speed rotation of spindle 2. After passing through the water channel hole 21 at the lower, central part of the hollow disk 1, water will be sucked through internally by the centrifugal force. The water surface 11

EP 1 526 073 A1

at a standstill in time is shown in Fig. 3 and Fig. 5, but the water level is not necessarily meant to be one; it is only shown as a reference value. The object 15, shown in the partial cross-sectional diagram when the whole of Fig. 5 is composed, is a water ascent prevention metal bracket composed by fixing a metal circle, with a semicircular cross-section as a halved round tube, to the inner wall of the frame/tank 1, and this will perform particularly significant work when the equipment is inclined. [Effects of Invention] [0007] This use of this invention's equipment is expected to abolish helicopters throughout the world within 10 years, and to enable passenger aircraft to take off or land with quite a short runway. All vehicles and trains will be transferred to using this invention's equipment. Huge man-made structures will be carried from the earth to the Moon and Mars, and the rocket-based space travel will become a matter of a funny story in the past. Thus, the greatest economic and industrial reformation in the history of the human race will occur. Great changes will also take place in military situations. A new, great civilization of the 21st century is expected to blossom as a result. From the a foregoing, it is obvious that the present invention concerns not only an apparatus but also a method for nullifying gravitational force. Further, the invention is also referring to a model for explaining an idea to nullity gravitational force. [Simple Explanation of the Diagrams] [0008] [Fig. 1] Oblique View Regarding the Basic Phenomenon, [Fig. 2] Front View of the Synthetic Vector of Speed, [Fig. 3] Diagram Showing Linear/Three Dimensional Synthetic Vector Relationships, [Fig. 4] Partial Front View of the Hollow Disk, [Fig. 5] Partial Cross-Sectional View When Assembled, [Fig. 6] Partial CrossSectional Diagram Showing the Pumping-upwards related Mechanism of the Hollow Disk [Explanations of Symbols] [0009] 1' Box, 2' Fixed point, 3' Arrow showing the rotation direction, 4' Nozzle, 5' Arrow showing the direction of expelled water, 6' Nozzle, 7' Arrow showing the direction of expelled water, 8' Arrow showing the synthetic vector of speed, 1 The partial front view of the hollowed disk, 2. Spindle, 3. Arrow showing the rotation direction, 4. Nozzle, 5. Arrow showing the direction of expelled water, 6. Nozzle, 7. Arrow showing the direction of expelled water, 8. Arrow showing the direction of the synthetic vector of speed, 10 Sketch of paraboloid of revolution shown three dimensionally and linearly, 11 Linearly shown water surface at a standstill in time, 12 Frame/ water tank, 13 Side view of the spiral, thin panel, 14' Cylinder hole for entry by water pumped-upwards, 14 Arrow showing the channel of water pumped-upwards,

15 Ring-shaped, water ascent prevention metal bracket with a semi-circular cross-section, 16 Water-conveyance panel, 17 Upper lid over the hollow disk, 18 Motor, 19 Bearing, 20 cylinder for pumping water upwards, 21 Water channel hole at the lower center portion of the hollow disk, 22 Diaphragm, 23 Lid over the frame/tank.

Claims

10

1.

15

20

25

30

35

A system designed to nullify gravitational force, based on the following arrangements: a small-output vertically oriented motor, which is powered using batteries or another power source, is fixed to the upper center of a cylindrical frame and built in tank, while within a hollow disk that has a spindle connected to the shaft of the motor through a bearing and, being fixed to the spindle, can freely rotate, multiple, radially fixed diaphragms are attached; around the hollow disk, a nozzle expelling water in the reverse direction to the rotational direction of the hollow disk is fitted and another nozzle expelling water in a downward direction is fitted at a place suitably far enough apart from the first nozzle, with these nozzles being a pair; and multiple pairs of such nozzles are fixed at equal distances; while a cylinder with many water outlet holes in its lower portion and of a height not reaching or contacting the central hole of the hollow disk is set centrally on the frame/tank bottom near the bearing at the lower portion of the frame/tank, and around this cylinder, multiple, radially arranged water-conveyance panels are fitted; and thin plates, which are fixed to the spindle within the cylinder, which is fitted to the bottom face of the frame/tank, and which are revolved in close proximity to one another, to perform the work of pumping water up to the hollow disk, are set spirally.

40

45

50

55

EP 1 526 073 A1

EP 1 526 073 A1

EP 1 526 073 A1

You might also like

- IMPACT OF A JET ReportDocument11 pagesIMPACT OF A JET ReportKyra Claire Zaharr100% (6)

- The Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisFrom EverandThe Mechanics of Water-Wheels - A Guide to the Physics at Work in Water-Wheels with a Horizontal AxisNo ratings yet

- Impact of JetDocument12 pagesImpact of JetShafizNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Impact of Jet: Technical Engineering CollageDocument6 pagesImpact of Jet: Technical Engineering CollageDhurghAm M AlmosaoyNo ratings yet

- The Energy Evolution – Harnessing Free Energy from Nature: Volume 4 of Renowned Environmentalist Viktor Schauberger's Eco-Technology SeriesFrom EverandThe Energy Evolution – Harnessing Free Energy from Nature: Volume 4 of Renowned Environmentalist Viktor Schauberger's Eco-Technology SeriesNo ratings yet

- Experiment 5 - Group 2Document16 pagesExperiment 5 - Group 2Arrianna PeterNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Defense Technical Information Center Compilation Part NoticeDocument41 pagesDefense Technical Information Center Compilation Part NoticeIgnacio TabuadaNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- Supercavitating Propellers PDFDocument41 pagesSupercavitating Propellers PDFAlex FatecNo ratings yet

- TEPZZ 6798 A - T: European Patent ApplicationDocument28 pagesTEPZZ 6798 A - T: European Patent ApplicationVictor Von DoomNo ratings yet

- Impact of Jet PDFDocument4 pagesImpact of Jet PDFKrm LeoNo ratings yet

- New Microsoft Office Word DocumentDocument10 pagesNew Microsoft Office Word DocumentSivaKumarNo ratings yet

- MF Lab2Document13 pagesMF Lab2RafiHunJian100% (1)

- Fluids Lab - Experiment 3 - Center of Pressure On A Submerged Plane SurfaceDocument9 pagesFluids Lab - Experiment 3 - Center of Pressure On A Submerged Plane SurfaceJordan Hines72% (25)

- Fluids Lab - Experiment 4 - Impact of A Jet of WaterDocument9 pagesFluids Lab - Experiment 4 - Impact of A Jet of WaterJordan Hines50% (2)

- Experiment (9) Impact of A Water Jet: Page Lab. Supervisor: Eng. Walaa AraydahDocument9 pagesExperiment (9) Impact of A Water Jet: Page Lab. Supervisor: Eng. Walaa AraydahMarNo ratings yet

- ObjectDocument8 pagesObjectYousef SailiniNo ratings yet

- Impact of Water JetsDocument11 pagesImpact of Water JetsDek RasalaNo ratings yet

- PNA Vol 2 Chapter VI Section 4 PDFDocument7 pagesPNA Vol 2 Chapter VI Section 4 PDFCesar Augusto Carneiro SilvaNo ratings yet

- Vertical water jet suspends plate; jet force on stationary plateDocument14 pagesVertical water jet suspends plate; jet force on stationary plateMd RoknuzzamanNo ratings yet

- UTM CHEMICAL ENGINEERING LAB REPORTDocument39 pagesUTM CHEMICAL ENGINEERING LAB REPORTSo Lah Musa75% (8)

- SAILING YACHT PERFORMANCE: EFFECTS OF HEEL AND LEEWAY ON RESISTANCE AND SIDEFORCEDocument10 pagesSAILING YACHT PERFORMANCE: EFFECTS OF HEEL AND LEEWAY ON RESISTANCE AND SIDEFORCEklzsailingNo ratings yet

- Jordan University of Science and Technology Faculty of Engineering Civil Engineering DepartmentDocument16 pagesJordan University of Science and Technology Faculty of Engineering Civil Engineering DepartmentOmar H DarabsehNo ratings yet

- Free Force VortexDocument25 pagesFree Force Vortexamirul84% (19)

- QJKDocument18 pagesQJKPallavi ChaudhuryNo ratings yet

- Impact of A JetDocument13 pagesImpact of A JetMohammad KhidirNo ratings yet

- Laboratory Expirements: Submitted By: Alipaspas, Jill Anne Sumitted To: Eng. Clark Jason AmoresDocument16 pagesLaboratory Expirements: Submitted By: Alipaspas, Jill Anne Sumitted To: Eng. Clark Jason AmoresJudd CortezNo ratings yet

- Hydrostatic Pressure Center of PressureDocument10 pagesHydrostatic Pressure Center of PressureAhmad Abdullah0% (1)

- Tesla Patent 1,061,142Document4 pagesTesla Patent 1,061,142jmunjaNo ratings yet

- Turbine - 1Document80 pagesTurbine - 1Vineet Gupta100% (1)

- LAPORAN PRAKTIKUM EKSPERIMEN ALIRAN CAIRANDocument9 pagesLAPORAN PRAKTIKUM EKSPERIMEN ALIRAN CAIRANKia FajarNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanNo ratings yet

- Jiang Etal 2019Document34 pagesJiang Etal 2019Quién SabeNo ratings yet

- Impact of A Water JetDocument5 pagesImpact of A Water JetAnirban SardarNo ratings yet

- 1 MomentumDocument20 pages1 MomentumPatrick YuNo ratings yet

- Wind Turbine Propulsion of ShipsDocument10 pagesWind Turbine Propulsion of ShipsBoris SitorusNo ratings yet

- Niraj Kumar: Study of Sloshing Effects in A Cylindrical Tank With and Without Baffles Under Linear AccelerationDocument31 pagesNiraj Kumar: Study of Sloshing Effects in A Cylindrical Tank With and Without Baffles Under Linear AccelerationSaurabh Suman100% (1)

- Laboratory Experiment Sheet: Universiti Kuala Lumpur Malaysia France Institute Mechanical Engineering SectionDocument9 pagesLaboratory Experiment Sheet: Universiti Kuala Lumpur Malaysia France Institute Mechanical Engineering SectionluqmanmazelanNo ratings yet

- Lab Section - Impact On Jet PDFDocument12 pagesLab Section - Impact On Jet PDFYan TrindadeNo ratings yet

- Using The Surface Panel Method To Predict The Steady Performance of Ducted PropellersDocument6 pagesUsing The Surface Panel Method To Predict The Steady Performance of Ducted PropellersmohammadfarsiNo ratings yet

- Lab VortexDocument13 pagesLab VortexDaniel RazakNo ratings yet

- Orifice & Free Jet FlowDocument6 pagesOrifice & Free Jet FlowMohamedElkikiNo ratings yet

- Corrected Experiment Impulse Turbine PDFDocument12 pagesCorrected Experiment Impulse Turbine PDFAlvi RahmanNo ratings yet

- Tutorial and Practice ProblemsDocument3 pagesTutorial and Practice ProblemsPranshul SesmaNo ratings yet

- Prof TVKB Propeller TheoryDocument26 pagesProf TVKB Propeller TheorytvkbhanuprakashNo ratings yet

- GW Flow to Wells Chapter AnalysisDocument7 pagesGW Flow to Wells Chapter Analysismaribo2005No ratings yet

- Experiment Title: Study of Free and Forced VorticesDocument9 pagesExperiment Title: Study of Free and Forced VorticesSakib RafeeNo ratings yet

- European Patent Application: Floating Hydroelectric Power Generation PlantDocument10 pagesEuropean Patent Application: Floating Hydroelectric Power Generation PlantMisha JovicNo ratings yet

- Experiment 3 Hydraulics LabDocument12 pagesExperiment 3 Hydraulics LabMatt NashrudinNo ratings yet

- Impact of A JetDocument13 pagesImpact of A Jethazheer183% (6)

- Measuring Wave, Viscous and Breaking Wave Resistance ComponentsDocument14 pagesMeasuring Wave, Viscous and Breaking Wave Resistance Componentsvivekt510No ratings yet

- Swinburne University of Technology: School of Engineering (Sarawak Campus)Document19 pagesSwinburne University of Technology: School of Engineering (Sarawak Campus)Mahfuzah MustaphaNo ratings yet

- Maneuverability of Frigates in Waves SimulationDocument10 pagesManeuverability of Frigates in Waves SimulationjdmorapNo ratings yet

- FM42 - ManualDocument11 pagesFM42 - ManualAmy FarhanaNo ratings yet

- Artificial Supercavitation Physics and CalculationDocument34 pagesArtificial Supercavitation Physics and Calculationmohsen123No ratings yet

- Mubarak.. Impact of Jet Lab ReportDocument11 pagesMubarak.. Impact of Jet Lab Reportscwanhker50% (4)

- US20210147837A1Document144 pagesUS20210147837A1avalosheNo ratings yet

- AU2016202220B2Document271 pagesAU2016202220B2avalosheNo ratings yet

- US7434581Document14 pagesUS7434581avalosheNo ratings yet

- United States Patent (19) : Jan. 8, 1991 11 Patent Number: 45 Date of PatentDocument14 pagesUnited States Patent (19) : Jan. 8, 1991 11 Patent Number: 45 Date of PatentavalosheNo ratings yet

- European Patent Specification: Anti-Angptl8 Antibodies and Uses ThereofDocument174 pagesEuropean Patent Specification: Anti-Angptl8 Antibodies and Uses ThereofavalosheNo ratings yet

- Color and Shape Discrimination in The Stingless Bee Scaptotrigona Mexicana Guérin (Hymenoptera, Apidae)Document7 pagesColor and Shape Discrimination in The Stingless Bee Scaptotrigona Mexicana Guérin (Hymenoptera, Apidae)avalosheNo ratings yet

- European Patent Specification: Anti-Hla-B 27 Antibodies and Uses ThereofDocument149 pagesEuropean Patent Specification: Anti-Hla-B 27 Antibodies and Uses ThereofavalosheNo ratings yet

- European Patent Specification: Anti-Il-33 Antibodies and Uses ThereofDocument129 pagesEuropean Patent Specification: Anti-Il-33 Antibodies and Uses ThereofavalosheNo ratings yet

- Two-Component Developer with Cyan Toner CharacteristicsDocument50 pagesTwo-Component Developer with Cyan Toner CharacteristicsavalosheNo ratings yet

- Measuring Rigidity and Erection of the PenisDocument14 pagesMeasuring Rigidity and Erection of the PenisavalosheNo ratings yet

- United States Patent (10) Patent No.: US 8,002,692 B2Document15 pagesUnited States Patent (10) Patent No.: US 8,002,692 B2avalosheNo ratings yet

- United States Patent (10) Patent No.: US 8.403,825 B2Document13 pagesUnited States Patent (10) Patent No.: US 8.403,825 B2avalosheNo ratings yet

- Carcassonne New VersionDocument334 pagesCarcassonne New Versionavaloshe100% (2)

- Elaboracion de Una Tisana - A - Partir - de - Hojas - de - AguacateDocument20 pagesElaboracion de Una Tisana - A - Partir - de - Hojas - de - AguacateLessley AVNo ratings yet

- Ielts Writing Lesson Plan 1 1Document10 pagesIelts Writing Lesson Plan 1 1avalosheNo ratings yet

- Wind Tunnel 2Document26 pagesWind Tunnel 2avalosheNo ratings yet

- Ielts App FormDocument8 pagesIelts App FormavalosheNo ratings yet

- Induction Type Wind Tunnel with Water InjectionDocument2 pagesInduction Type Wind Tunnel with Water InjectionavalosheNo ratings yet

- Arduino InternalsDocument392 pagesArduino InternalsPanagiotisVourtzoumisNo ratings yet

- Funtoo Complete ManDocument62 pagesFuntoo Complete ManavalosheNo ratings yet

- Signpost WordsDocument1 pageSignpost Wordsavaloshe100% (1)

- Gentoo Minimal Amd64Document124 pagesGentoo Minimal Amd64avalosheNo ratings yet

- United States Patent: Clemm (45) Date of Patent: Dec. 10, 2013Document16 pagesUnited States Patent: Clemm (45) Date of Patent: Dec. 10, 2013avalosheNo ratings yet

- Build A Wind TunnelDocument6 pagesBuild A Wind TunnelJajap TanudjajaNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,584,803 B2Document14 pagesUlllted States Patent (10) Patent N0.: US 8,584,803 B2avalosheNo ratings yet

- Ulllted States Patent (10) Patent N0.: US 8,601,433 B2Document29 pagesUlllted States Patent (10) Patent N0.: US 8,601,433 B2avalosheNo ratings yet

- Build Your Own Inexpensive Wind Tunnel: Feature ArticleDocument11 pagesBuild Your Own Inexpensive Wind Tunnel: Feature ArticleavalosheNo ratings yet

- United States Patent: Baek (10) Patent N0.: (45) Date of PatentDocument17 pagesUnited States Patent: Baek (10) Patent N0.: (45) Date of PatentavalosheNo ratings yet

- United States Patent: Gandolph Et A) - Dec. 10, 2013Document15 pagesUnited States Patent: Gandolph Et A) - Dec. 10, 2013avalosheNo ratings yet

- Estimate Software Modification Effort with Scale DistributionDocument13 pagesEstimate Software Modification Effort with Scale DistributionavalosheNo ratings yet

- I.C. Engines Jet Engines GuideDocument12 pagesI.C. Engines Jet Engines GuidePotluri NagasaitejNo ratings yet

- Hydraulics Plate 1&2Document2 pagesHydraulics Plate 1&2Cyrus R. Flores0% (1)

- ChapterDocument39 pagesChapterIsmail ibrahimNo ratings yet

- Aircraft Performance and DesignDocument10 pagesAircraft Performance and DesignluciopatricioNo ratings yet

- F Division Aerospace Prototype Space Vehicles As of Dec 1 2023Document11 pagesF Division Aerospace Prototype Space Vehicles As of Dec 1 2023bronsonNo ratings yet

- TM AssignmentDocument2 pagesTM Assignmentsanjay kushwahNo ratings yet

- PHD Thesis Catalogue Year Student Thesis Title at 20/08/2012Document8 pagesPHD Thesis Catalogue Year Student Thesis Title at 20/08/2012Deepak AnandanNo ratings yet

- HM Series Brochure Eng 2014Document12 pagesHM Series Brochure Eng 2014Nico LomibaoNo ratings yet

- Uck 421 EnglishDocument121 pagesUck 421 EnglishSafa Eren PEPEÇNo ratings yet

- ASPHALT PLANT MOBILE VARIANT: MDM 25 (20-30 tphDocument10 pagesASPHALT PLANT MOBILE VARIANT: MDM 25 (20-30 tphNisarg SutharNo ratings yet

- Jet Nozzle New CatalogueDocument3 pagesJet Nozzle New Cataloguedikran33No ratings yet

- Air-Jet WeavingDocument3 pagesAir-Jet Weavinga.owais0% (2)

- Jet 1Document20 pagesJet 1Karim El ShamashergyNo ratings yet

- Gas Turbine Engine 1 of 2021Document16 pagesGas Turbine Engine 1 of 2021lintoNo ratings yet

- Ijpret - Mech 127 PDFDocument5 pagesIjpret - Mech 127 PDFsk sanketNo ratings yet

- Valve Noise ReductionDocument7 pagesValve Noise Reductionchemsac2No ratings yet

- Model Question PaperDocument2 pagesModel Question PaperpvjotaniyaNo ratings yet

- Commercial Aircraft Propulsion and Energy Systems Research - Reducing Global Carbon Emissions PDFDocument123 pagesCommercial Aircraft Propulsion and Energy Systems Research - Reducing Global Carbon Emissions PDFTutu TuNo ratings yet

- Ventilare Si Desfumare Parcaje - ModelDocument220 pagesVentilare Si Desfumare Parcaje - ModelalanatoraNo ratings yet

- MJP Designers Guide Nov11Document15 pagesMJP Designers Guide Nov11Thiha BoBoNo ratings yet

- Pelton Wheel Turbine .MechDocument19 pagesPelton Wheel Turbine .MechkalamNo ratings yet

- Tech Gen 1Document58 pagesTech Gen 1Tanishk Kumar SinghNo ratings yet

- Jet Force on Vanes ApparatusDocument3 pagesJet Force on Vanes ApparatusAbhi JindalNo ratings yet

- V2500 Line and Base Maintenance Oil: For Training Purposes Only For Training Purposes OnlyDocument64 pagesV2500 Line and Base Maintenance Oil: For Training Purposes Only For Training Purposes OnlyHENIGUEDRINo ratings yet

- Hydraulics - Series 1 (Fundamentals of Fluid Flow) - Sample Problems PDFDocument2 pagesHydraulics - Series 1 (Fundamentals of Fluid Flow) - Sample Problems PDFNica Remollo100% (3)

- Assignment 1Document6 pagesAssignment 1kaushalshah28598No ratings yet

- Aft MPM 04 CompactDocument2 pagesAft MPM 04 CompactForum Pompierii0% (1)

- Fluid Mechanics-II Lab Manual: University College of Engineering and TechnologyDocument27 pagesFluid Mechanics-II Lab Manual: University College of Engineering and Technologyzia malikNo ratings yet

- Jet Interaction Effect on PGMM PrecisionDocument7 pagesJet Interaction Effect on PGMM Precisionscorpion_l_81No ratings yet

- Package Familiarization LM2500 - 50 HZDocument560 pagesPackage Familiarization LM2500 - 50 HZFreddie Asiedu Larbi100% (9)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- The Way Home: Tales from a life without technologyFrom EverandThe Way Home: Tales from a life without technologyRating: 4 out of 5 stars4/5 (45)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)