Professional Documents

Culture Documents

06 - Dosing Pump Clearance - 04

Uploaded by

Lakshmanan VenkateswaranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06 - Dosing Pump Clearance - 04

Uploaded by

Lakshmanan VenkateswaranCopyright:

Available Formats

REF:- IEI/RAB/4322090027/06 DATE:- 4

th

February 2011

TO,

The AGM.

M/S MADHUCON PROJECTS LIMITED,

Madhucon house,Plot no.1129/A,

Road No:-36, Hitec city road,

Jubilee hills, Hyderabad 500 016

Kind Attn:- Mr. L Vekateswaran

Ref:- TPL inspection report No. HYD09MPL115/CHEMRI2901111KSP

Sub:- Action on non-conformance mention in the report & MDCC for the pumps.

Dear Sir,

With respect to subjected matter TPL has given following non conformance for the Ferric chloride

dosing Pump TAG No. DP2-A/B.

NON CONFORMANCE

1. Max. Discharge Pressure as per data sheet is 16 kg/cm2 where as actual is 10 kg/cm2.

ACTION BY ION EXCHANGE

We are here confirming that maximum pressure at discharge of dosing pump is 2 kg/cm2 as per our design

so 10 kg/cm2 is acceptable for the pump.

We request you to give the dispatch clearance of the pumps against report of TPL & this letter for the 18 No.

so that we will dispatch the same to site.

Assuring our best service at all the time.

Enclosure :- TPL inspection report for dosing pumps

Thanking you!!!!!

Yours faithfully,

Monish shah

Project Division.

I

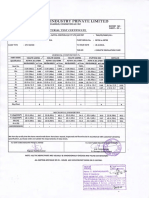

SIMHAPURI ENERGY PRIVATE LIMITED

TPL - Third Party

Inspection Agency

CHP CLEARANCE I INTERIM INSPECTION REPORT

Manufacturer/Sub-Vendor;

Ion Exchange India LTD/Milton Roy

Place: Chennai

Qty. offered Quantity Items

for accepted Rejected / Remarks

Inspection

I

QHafaRtifle

1

during visit with

Identification

20 Nos. 18 Nos. 2Nos. Tag

Nos. DP2

AlB

FORSEPL USE

,pjJ(

Disposal Code

r1

r

I Name & Sign of Inspecting Official & Seal

K. _wr_

SENIOR SURVEYOR

._a '.""'TS LIMITED

CHENNA!

Spec./Drg.

Reference

Refer

Supplier

Annexure

I/CNo.

!SEPL I

Contract Name & Project : lx135MW Thermal Power Plant, Nellore

Contract No. / PO No. : LPL/lon Exchange/WfPI08-09-{)06 Dt 06-D6-2009 &

2010-2011/006/N/00207/4322090027

Date of Inspection / Review : 29-01-2011

TPL Inspection Report No. :HYD09MPL115/CHEMRI2901111KSP

SI.No Plan

of Material/Ref.

Test

I

HP-02/Rev

Refer Supplier Annexure 1 Dt.

21.10.10

Sign of /

y'

tJ\}.- ): r'V

__ r. C.Jr:;, X \"""

Sign of Contractor

Format:21/11/2009

G

Annexure-I to CHP Clearance-Interim Inspection Report

TATA

NO.HYD09MPL115/CHEMR12901111KSP DATE: 29-01-2011

I. Customer &lor Supplier Documents Used for This Surveillance:

. ApJlfOVal

Status

2010

HP-02/ Dt. 21.10.10

Refer Supplier Annexure

II. Non-conformances/Issues:

o

1

Purchase Order from Iron Exchange India

Manufacturing Quality Plan

GA & Part Drawings

Data sheets

Approved by SEPL

Approved by IEIL

Approved by IEIL

Item No. Description of Description of Non-conformance Responsibility for

Component Corrective Action

10 Ferric Chloride Dosing

Pump-Tag Nos. DP2

Max. Discharge Pressure as per Data Sheet is

16Kg/cm

2

, where as the actual is 10KG/cm

2

Ion Exchange

AlB

III. Summary of Quality Surveillance Activities Performed

Format: 20/03/2010

Page 1 of 3

G

Annexure-I to CHP Clearance-Interim Inspection Report

TATA

No.HYD09MPL115/CHEMR12901111KSP DATE: 29-01-2011

Refer the Supplier Annexure 16 Nos 14Nos 2Nos- Tag.

Nos. DP2-A1B

maximum rated

Pressure

deviation

requires client's

approval

Detail of Activities Carried out

1. Visual inspection carried out on all the Dosing Pumps for General work man ship and Finish- Satisfactory

2. Material certificates reviewed as per MOP and found meeting the requirements

3. Dimensional checks carried out as per GA Drawing and found meeting the drawing requirements

4. Performance Testing witnessed at Working Pressure for 100%.75%.50% & 25% of stroke and the Capacity

found within the acceptable limits (Witnessed 51 No. 1453,-MRA 34,51. No 1774- B145-1A & 51. No. 412- PHL

70A)

5. Repeatability, Linearity and Steady state accuracy verified and found satisfactory

6. Hydrostatic Pressure test witnessed for 10 Mts. As per approved OAP and found No leak and Pressure Drop-

Acceptable

7. PRV-Set Pressure verified for B145-1A at3.5KG/CM' and found opens at that same Pressure

8. Tag No Marking and Name plate details verified and found in order except Tag Nos. DP2- A1B( Refer Clause II)

9. Accessories verified and found as per the P.O

10. Calibration status of the Pressure Gauges verified and found in order (Gauge Nos. PG/21/03 & PG/7/02)

IV. Identification: All items stamped TPU112 on Name plate

V. Conclusion: 14 Items are accepted and 2 Nos require vendor's clarification/ Clients approval for Non

Conformance (Refer Clause'lI)

VI. Inspection Status:

VII. Progress Photographs:

Fonno!: 2010312010

Page 2 of 3

G

Annexure-) to CHP Clearance-Interim Inspection Report

TATA

No.HYD09MPL115/CHEMR12901111KSP DATE: 29-01-2011

-

.

-

_.

-> ",'

-.-

.

VIII. Surveyor/Report Submission Details:

Dale- J2 Pf

Name K_SIVAPRAKASAM

Day-Alpha Month-Year 29 January 2011

C ta I D I -I Cell:09445269051

Localion Chennai

on c e al S Email: sivaprakasamk@lalaprojects_com

Format: 20/03/2010

Page 3 of 3

-

I

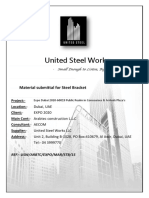

== MILTON ROY

INDIA

P.O

DESCRIPTION MODEL

S.NO

1 ACID DOSING PUMP MRA-34

2 SBS DOSING PUMP MRA-34

3

ANTISCALENT DOSING

MRA-34

PUMP

10

FERRIC CHLORIDE

PHL-70 A

DOSING PUMP

11

PE DEWATERING

B145-1A

DOSING PUMP

4

PULSATION DAMPNER

B145-1A

FOR PE DEWATERING

5

PULSATION DAMPNER

MRA-34

FOR ANTISCALENT

6

PULSATION DAMPNER

MRA-34

FOR SBS DOSING

7

PULSATION DAMPNER

MRA-34

FOR ACID DOSING

8

PULSATION DAMPNER

PHL-70 A

FOR FEBatC CHLORIDE

"

''' .

"

'., ' ,I.

(/

SUPPLIER ANNEXURE

I

HEAD

PP

SS

SS

PP

SS

SS

SS

SS

PP

PP

PUMP

S.NO

1452,1453

1448,1449

1446,1447

411,412

1773,1774

-

-

-

-

-

QUANTITY

2

2

2

2

2

2

2

2

2

2

DRAWING NO

1611 SP-GA-MRA-PP-001,

REVB

1611 SP-GA-MRA-SS-001.

REVA

1611 SP-GA-MRA-SS-001,

REVA

1611

REVA

1611 SP-GA-B145-SS-001,

REV A

PDA-1 OLT-SS-001,

REVB

1611 SP-PDA-5LT-SS-001,

REVB

1611 SP-PDA-5LT-SS-001,

REVB

1611 SP-PDA-5LT-PVC-001,

1611SP-PDA-1 OLT-PVC-001,

REV A

TAG NO

DP4 AlB

DP6-AlB

DP-5 AlB

DP-2 AlB

DP3-AlB

DP3-AlB

DP-5 AlB

DP6-AlB

DP4NB

DP-2 AlB

- .. - ... -- -

DATASHEET NO

A4-4322090027 -12-38,

REV-O

A4-4322090027-12-40,

REV-O

A4-4322090027-12-36,

REV-O

-12-28,

.

REV-O

A4-4322090027-12-34,

REV-O

A4-4322090027-12-34,

REV-O

A4-4322090027-12-36,

REV-O

A4-4322090027-12-40,

REV-O

A4-4322090027-12-38.

REV-O

A4-4322090027-12-28,

REV-O

I

-=

=

-===

'="

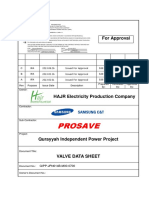

MILTON ROY INDIA (P) LTD

Suhsidiary-Hamiltoo Sandstr&nd Cocpn.., USA. A Unitrd Technologies Company

t

.... Un-"

..

I CONTENT SHEET I

CLIENT : MIS ION EXCHANGE (I) LTO

P.O NO : 2010-20111006/NJ00207

FINAL QUANTiTY FOR DOSING PUMPS

\ MILTON ROY . ,

SL.NO: SERVICE

I

MOC

!MAKE MODEL If

UMP

SL.Nu j

I

r

y

"

,

66.8 .. 7 1 1452

I

DP4A [ACID DOSING I pp I 1 5.5

I

-

..

- !

7 2 MRA-34 1453 UP4-8 ACro DOSING 60.8 pp I 1 i I

I_

I

I

IL\

-

) \tRA-J4 DP6,\ 7 SBSDOSING SS I 1 60.8 ..

I

r

I "RA). \ 1449 ! DP6.0 i SOS DOSING I SS I 1 ..,. .. 7 5.5

I I I I

i ' ,

i MRA.). i '446 I DP5.,I

AN

TlSCALENT' I I ., s 7 5.5

: I DOSING j SS I. 60.8

[ I

i

, \] MRA-J4 1447 1 DP.58 1,\.".;TISCALEl'iT! 55 ( 608

...

I

I

. I ! !

40 7

j

II ( I B1451A 177) DPJ.'\ I

I

ss I I 133

".

I I I

I i

: I

I

8 I BJ451A I DPJ." DE\\'ATERINGI

"3

i :' I DOSING

-I

i

-

SS I

10

C I

I PHL-9CJ A 411 I' DP2A I FERRI pp I '000 '000

I . C}{WRI DE i

, ,---!-'

C

Ie

I PHl.9Q A 4D DP1-& FERRI pp I 11)00 I 1000

- -.

-r----:

; CHLORIDt; I

i ! I

I I ' ' ' I I

L":' TO]'!. Hi, I'

I i

'.-. \', '.. ::

, - _ r->. .. P 11'

.d

You might also like

- Daily Drilling Report No.28 Pozo La Colpa 2XDDocument6 pagesDaily Drilling Report No.28 Pozo La Colpa 2XDJuan Pablo Sanchez MelgarejoNo ratings yet

- Test CertificateDocument7 pagesTest CertificateVinay YadavNo ratings yet

- Mps SDM 2014 Tp042Document37 pagesMps SDM 2014 Tp042Janardhan Surya100% (1)

- D04Document7 pagesD04Ahmed SoomroNo ratings yet

- 25 - (AL-SOLC-HSE-025) AL-SOLC Hydrotesting PDFDocument5 pages25 - (AL-SOLC-HSE-025) AL-SOLC Hydrotesting PDFahmed08839494No ratings yet

- Datasheet For Restriction OrificeDocument42 pagesDatasheet For Restriction OrificeSujith Sekar50% (2)

- Hy25-3001 UsDocument16 pagesHy25-3001 Usfrancis_15inNo ratings yet

- Job Piping Material SpecificationDocument36 pagesJob Piping Material SpecificationSanjay KumarNo ratings yet

- Sa-Dar-Cv-W O74-004Document6 pagesSa-Dar-Cv-W O74-004Divakar PanigrahiNo ratings yet

- ECE R110-ReceptaclesDocument29 pagesECE R110-ReceptaclessleonNo ratings yet

- PQRDocument2 pagesPQRnaseema1100% (1)

- Hydro Test Procedure: ItemDocument6 pagesHydro Test Procedure: Itemtulasirao.nammiNo ratings yet

- S-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Document10 pagesS-900-1670-581 - 1 - (Inspection and Test Plan For Rotating Machinery (Pumps and Air Compressors) )Alif Rahmat Febrianto100% (3)

- Fw-Pump TbeDocument43 pagesFw-Pump TbeTeguh Setiono100% (1)

- Mu-00-S08 Urs For Cooling Water Circulation PumpsDocument13 pagesMu-00-S08 Urs For Cooling Water Circulation Pumpsdhanu_lagwankarNo ratings yet

- ( cAMERON: Certification of ComplianceDocument4 pages( cAMERON: Certification of ComplianceOSDocs2012No ratings yet

- Sharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportDocument2 pagesSharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportAmol KhatateNo ratings yet

- P-90913 Vibration ReportDocument9 pagesP-90913 Vibration ReportPetroen100% (1)

- Bus Coupler D130 Function Test: 1. General Data and InformationDocument7 pagesBus Coupler D130 Function Test: 1. General Data and InformationMushtaque Ahmed SoomroNo ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- 110-KA-701B Maint ReportDocument15 pages110-KA-701B Maint ReportDIPANKAR LALANo ratings yet

- Post HydrotestingDocument7 pagesPost HydrotestingVineet SinghNo ratings yet

- Site Acceptance Test Procedure Last Rev1Document11 pagesSite Acceptance Test Procedure Last Rev1Heber Manurung50% (6)

- HIC & SSC Test ProcedureDocument32 pagesHIC & SSC Test ProcedureMohamed FarisNo ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- National: TechnicalDocument3 pagesNational: TechnicalRähûl Prätäp SïnghNo ratings yet

- How To Start Combined Cycle Power PlantDocument37 pagesHow To Start Combined Cycle Power PlantBv Rao100% (1)

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Transmittal Joseph Thomas: D F Power Systems Pvt. LTDDocument58 pagesTransmittal Joseph Thomas: D F Power Systems Pvt. LTDVinod MahajanNo ratings yet

- Function Test For 132KV GIS LCCDocument8 pagesFunction Test For 132KV GIS LCCAhmed Soomro0% (1)

- 3119-Gear Box Data Sheet Rev.01Document4 pages3119-Gear Box Data Sheet Rev.01SAHTEESHKUMARNo ratings yet

- Pressure Test For Piping According To Asme B31.4Document13 pagesPressure Test For Piping According To Asme B31.4ahmed088394940% (1)

- GRE GeneralDocument3 pagesGRE GeneralBoopathi Mothees BNo ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- HODs Meet Presentation Model-InstDocument35 pagesHODs Meet Presentation Model-InstDhilip AnNo ratings yet

- P2 Series InstallationlManualDocument6 pagesP2 Series InstallationlManualGianna FrolaNo ratings yet

- Hydro Test ReportDocument2 pagesHydro Test ReportAnonymous a8oga83No ratings yet

- Narmada Hydrotest Procedure (Rigid) - Rev 1Document37 pagesNarmada Hydrotest Procedure (Rigid) - Rev 1api-2622018486% (7)

- LR Series III Wiring RecallDocument13 pagesLR Series III Wiring RecallStephen Cooke100% (1)

- SRV Detaisl Awa Salawas PDFDocument222 pagesSRV Detaisl Awa Salawas PDFdiwakarngm100% (1)

- Evening Drilling ReportsDocument2 pagesEvening Drilling ReportsSneha AmmuNo ratings yet

- FQP For Civil WorkDocument15 pagesFQP For Civil WorkManoj ShahNo ratings yet

- Gas ValveDocument9 pagesGas ValveJJNo ratings yet

- 14 LPS@150 MDocument1 page14 LPS@150 MGokul KrishnanNo ratings yet

- Usw Arbtc Expo Mar STB 15 Rev00 PDFDocument89 pagesUsw Arbtc Expo Mar STB 15 Rev00 PDFnoufalNo ratings yet

- 0.0 TRP-5111 A 660/760 TM SET-UP 1.0 Purpose: SECTION: Hot Tap Services Revision # - 1Document4 pages0.0 TRP-5111 A 660/760 TM SET-UP 1.0 Purpose: SECTION: Hot Tap Services Revision # - 1vuongNo ratings yet

- Bhije:. T: Phase - I) Chandwa, JharkhandDocument4 pagesBhije:. T: Phase - I) Chandwa, Jharkhandsuleman247No ratings yet

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiNo ratings yet

- Session 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Document31 pagesSession 208-Mike Lam-20 (Hydraulic-Workover Units-LW Completions)Ruslan ZakirovNo ratings yet

- 2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDocument22 pages2037-PL-PL-0058-IR-T-015 Dated 17.12.19-IRN IR PDFDadaso Baburao JamdarNo ratings yet

- Repair Procedure ANNEXUREDocument16 pagesRepair Procedure ANNEXUREShaikh AdilNo ratings yet

- 5 - A9a SpecificationDocument4 pages5 - A9a SpecificationPrasanta Kumar BeheraNo ratings yet

- Vacuum Breaker Valve Data SheetDocument4 pagesVacuum Breaker Valve Data SheetMathivanan AnbazhaganNo ratings yet

- Standard Operating Procedure (SOP) PDFDocument13 pagesStandard Operating Procedure (SOP) PDFArup Ranjan SahooNo ratings yet

- MR For Gate Valve Cast 301015Document43 pagesMR For Gate Valve Cast 301015AHMEDMALAHYNo ratings yet

- Inspection and Test Plan: On-Shore Pipeline CertificationDocument2 pagesInspection and Test Plan: On-Shore Pipeline CertificationKayra Riri Chirul100% (1)

- Revise Insp Report - 1 PDFDocument4 pagesRevise Insp Report - 1 PDFShankar RajNo ratings yet

- Mac LS 0 002 0Document4 pagesMac LS 0 002 0arifayee-1No ratings yet

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Ga DRG of Pile Dss Sys-R2Document1 pageGa DRG of Pile Dss Sys-R2venka07No ratings yet

- Single Roll CrusherDocument2 pagesSingle Roll CrusherLakshmanan VenkateswaranNo ratings yet

- Errata No - 01 To Bidding DocumentsDocument12 pagesErrata No - 01 To Bidding DocumentsLakshmanan VenkateswaranNo ratings yet

- Coal Washeries May-10Document112 pagesCoal Washeries May-10Micheal AhmadNo ratings yet

- Nit - BopDocument12 pagesNit - BopLakshmanan VenkateswaranNo ratings yet

- Bomb CalorimetryDocument11 pagesBomb CalorimetryTomy HaryantoNo ratings yet

- LOAD Cell NotesDocument15 pagesLOAD Cell NotesLakshmanan VenkateswaranNo ratings yet

- 31.5.10 Hydraulically Operated ValveDocument14 pages31.5.10 Hydraulically Operated ValveLakshmanan VenkateswaranNo ratings yet

- P & IdDocument13 pagesP & IdLakshmanan Venkateswaran100% (1)

- P 143 MPR Apx IDocument28 pagesP 143 MPR Apx ILakshmanan VenkateswaranNo ratings yet

- Ms. Patel Energy LTD EIA Part IIDocument99 pagesMs. Patel Energy LTD EIA Part IILakshmanan Venkateswaran100% (1)

- Reporting Format Total Piping 11Document2 pagesReporting Format Total Piping 11Lakshmanan VenkateswaranNo ratings yet

- The Sounds of Telugu: 1. Articulatory ConfigurationsDocument11 pagesThe Sounds of Telugu: 1. Articulatory ConfigurationsEmilynoellel LangstonNo ratings yet

- 10 AI Summer Vacation HWDocument2 pages10 AI Summer Vacation HWAyushi SinghNo ratings yet

- Chapter Two: Describing DataDocument20 pagesChapter Two: Describing DataJames Alex HabaradasNo ratings yet

- Appendix in Research PaperDocument6 pagesAppendix in Research Papergvzfmq91100% (1)

- ARCO ANDI Wayne PIB Installation and Start Up GuideDocument39 pagesARCO ANDI Wayne PIB Installation and Start Up GuidejotazunigaNo ratings yet

- Accenture United Nations Global Compact IndexDocument4 pagesAccenture United Nations Global Compact IndexBlasNo ratings yet

- Technical Seminar Report CV94Document62 pagesTechnical Seminar Report CV941MS19CV053 KARTHIK B SNo ratings yet

- Removal Processes and Machine Tools: Indian Institute of Technology DelhiDocument28 pagesRemoval Processes and Machine Tools: Indian Institute of Technology DelhiEthan HuntNo ratings yet

- Risk Management Q1Document8 pagesRisk Management Q1Parth MuniNo ratings yet

- Carnot Cycle and EngineDocument18 pagesCarnot Cycle and EngineXYZNo ratings yet

- Unit 2-Translation Practice MarkDocument3 pagesUnit 2-Translation Practice MarkHương ThảoNo ratings yet

- Simulation and Analysis of 10 Gbps APD Receiver With Dispersion CompensationDocument5 pagesSimulation and Analysis of 10 Gbps APD Receiver With Dispersion CompensationMohd NafishNo ratings yet

- Mazada Consortium LimitedDocument3 pagesMazada Consortium Limitedjowila5377No ratings yet

- AWS Lecture NotesDocument4 pagesAWS Lecture NotesAsad Bin Ala Qatari0% (1)

- The Ultimate Guide To The Gemba WalkDocument9 pagesThe Ultimate Guide To The Gemba WalkĐan VũNo ratings yet

- Excavation and Trenching Implementation PlanDocument29 pagesExcavation and Trenching Implementation Planracing.phreakNo ratings yet

- B737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysDocument6 pagesB737 SRM 51 - 40 - 08 Rep - Fiberglass OverlaysAlex CanizalezNo ratings yet

- SAP TestingDocument7 pagesSAP Testingpvpreddy67No ratings yet

- Principal's Corner: School ProfileDocument7 pagesPrincipal's Corner: School ProfileAngel Mae LabadorNo ratings yet

- Thermal Stress AnalysisDocument11 pagesThermal Stress AnalysisFahad KhanNo ratings yet

- Las-Shs Gen - Chem Melc 1 q2 Week-1Document11 pagesLas-Shs Gen - Chem Melc 1 q2 Week-1Carl Baytola RatesNo ratings yet

- Mathematics 10 Performance Task #1 Write The Activities in A Short Bond Paper Activities Activity 1: Go Investigate!Document2 pagesMathematics 10 Performance Task #1 Write The Activities in A Short Bond Paper Activities Activity 1: Go Investigate!Angel Grace Diego Corpuz100% (2)

- 0404 eDocument80 pages0404 eFrancisco MisleNo ratings yet

- Instructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Document6 pagesInstructional Module: IM No.: IM-NSTP 1-1STSEM-2021-2022Princess DumlaoNo ratings yet

- Soft-Starter: Programming ManualDocument162 pagesSoft-Starter: Programming ManualThaylo PiresNo ratings yet

- Hatton National Bank PLC: Instance Type and TransmissionDocument2 pagesHatton National Bank PLC: Instance Type and TransmissiontaraNo ratings yet

- Spectatorship Affect and Liveness in Contemporary British Performance PDFDocument358 pagesSpectatorship Affect and Liveness in Contemporary British Performance PDFShivansh Tuli100% (1)

- Respons 910 Analyzer: Operator's ManualDocument246 pagesRespons 910 Analyzer: Operator's ManualUmashankar LoganathanNo ratings yet

- Existing VendorsDocument1 pageExisting VendorsSuperintending EngineerNo ratings yet

- (Type The Documen T Title) : (Year)Document18 pages(Type The Documen T Title) : (Year)goodluck788No ratings yet

- Close Up b1 AnswersDocument6 pagesClose Up b1 Answersmega dragos100% (1)