Professional Documents

Culture Documents

BP's Proposed Findings - Combined File

Uploaded by

OSDocs20120 ratings0% found this document useful (0 votes)

308 views1,303 pagesBP's Proposed Findings of Fact and Conclusions of Law with Compendium of Exhibits

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBP's Proposed Findings of Fact and Conclusions of Law with Compendium of Exhibits

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

308 views1,303 pagesBP's Proposed Findings - Combined File

Uploaded by

OSDocs2012BP's Proposed Findings of Fact and Conclusions of Law with Compendium of Exhibits

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1303

IN THE UNITED STATES DISTRICT COURT

FOR THE EASTERN DISTRICT OF LOUISIANA

In re: Oil Spill by the Oil Rig Deepwater

Horizon in the Gulf of Mexico,

on April 20, 2010,

This Pleading applies to:

All Cases

*

*

*

*

*

*

*

*

*

*

MDL No. 2179

Section: J

Judge Barbier

Magistrate Judge Shushan

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

BPs PROPOSED FINDINGS OF FACT AND CONCLUSIONS OF LAW

Richard C. Godfrey, P.C.

J. Andrew Langan, P.C.

Matthew T. Regan, P.C.

Hariklia Karis, P.C.

Kirkland & Ellis LLP

300 North LaSalle Street

Chicago, IL 60654

Telephone: 312-862-2000

Facsimile: 312-862-2200

Timothy A. Duffy, P.C.

R. Christopher Heck

James Sollee Buino

Elizabeth R. Sheyn

David R. Freedman

Vanessa Barsanti

Kirkland & Ellis LLP

300 North LaSalle Street

Chicago, IL 60654

Telephone: 312-862-2000

Facsimile: 312-862-2200

Don K. Haycraft (Bar #14361)

R. Keith Jarrett (Bar #16984)

Liskow & Lewis

701 Poydras Street, Suite 5000

New Orleans, LA 70139-5099

Telephone: 504-581-7979

Facsimile: 504-556-4108

Robert C. Mike Brock

Covington & Burling LLP

1201 Pennsylvania Avenue, NW

Washington, DC 20004-2401

Telephone: 202-662-5985

Facsimile: 202-662-6291

Attorneys for BP Exploration & Production I nc., BP America Production Co., and BP p.l.c.

June 21, 2013

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 1 of 705

TABLE OF CONTENTS

INTRODUCTION..........................................................................................................................1

I. THE PARTIES AND THE NATURE OF THE PROCEEDINGS. ..............................1

A. The Parties. .............................................................................................................1

1. The BP Defendants. ...................................................................................1

2. The Transocean Defendants......................................................................3

3. Halliburton. ................................................................................................4

4. Cameron......................................................................................................4

5. M-I, LLC .....................................................................................................4

6. Claimants. ...................................................................................................4

7. State and Federal Governments. ..............................................................5

B. The Nature of the Action. ......................................................................................5

C. The Claims at Issue in MDL 2179. .......................................................................5

1. Economic and Property Damages Cases..................................................5

2. Post-Incident Medical Cases. ....................................................................6

3. Day-of-Incident Personal Injury and Wrongful Death Cases. ..............6

4. Vessels of Opportunity Charter Cases. ....................................................6

5. The Transocean Limitation Action. .........................................................6

6. United States Government Claims. ..........................................................7

7. State and Local Government Claims. ......................................................7

8. Foreign Government Claims. ....................................................................7

9. Claims Between Defendants. .....................................................................8

D. The Phase I Trial. ...................................................................................................8

PROPOSED FINDINGS OF FACT .............................................................................................9

II. BP MANAGED THE DRILLING OF THE MACONDO WELL BY

ASSEMBLING A TEAM OF WORLD-CLASS CONTRACTORS, EACH

OF WHICH HAD DISTINCT ROLES AND RESPONSIBILITIES WITH

REGARD TO THE WELL. ..............................................................................................9

A. Deepwater Drilling in the Gulf of Mexico............................................................9

1. Offshore Drilling Is Extensively Regulated by the United

States. ........................................................................................................10

2. Federal Regulations Reflect the Shared Roles Between

Operators and Contractors in Drilling Deepwater Wells. ...................11

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 2 of 705

ii

B. Consistent with Industry Practice and Federal Regulations, BP Hired

Third-Party Contractors to Drill the Macondo Well. ......................................12

C. BP Contracted with Transocean to Drill the Macondo Well. ..........................13

1. Transocean and Its Rig, the Deepwater Horizon, Had Extensive

Experience and Expertise in Deepwater Drilling. .................................13

2. Transoceans Responsibilities. ................................................................16

a. Transocean Was Responsible for Providing a Drilling

Rig and Equipment Capable of Drilling the Macondo

Well................................................................................................16

b. Transocean Was Responsible for Maintaining the

Deepwater Horizon in Optimal Operating Condition. ..............16

c. Transocean Was Responsible for the Safe Operation of

the Deepwater Horizon. ................................................................18

d. Transocean Was Responsible for the Effective

Operation and Maintenance of the Deepwater Horizon

BOP and for Ensuring Its Compliance with Applicable

Regulations. ..................................................................................19

3. Transoceans Safety Management System Governed

Operations on Board the Deepwater Horizon. .......................................23

4. Transocean Was 100% Responsible for Well Monitoring and

Well Control on the Deepwater Horizon, Including Detecting

and Responding to Kicks and Preventing Blowouts. ........................25

a. Transoceans Well Control Policies. ..........................................26

b. The Transocean Driller Was Responsible for

Continuously Monitoring the Well for Kicks and Other

Anomalies......................................................................................27

c. The Well-Monitoring Information and Equipment

Available to the Transocean Drilling Crew. ..............................30

d. Transocean Was Responsible for Shutting In the Well

in the Event of a Kick. .................................................................33

e. Transocean Was Responsible for Diverting

Hydrocarbons Away from the Vessel in the Event of

Flow to the Rig. ............................................................................36

f. Transocean Was Responsible for Activating the

Emergency Systems on the BOP. ................................................37

5. Transocean Was Aware that Prudent Well Monitoring and

Well Control Responses Exist Precisely to Prevent Kicks,

Something that Occurs in Deepwater Drilling, from Developing

into Blowouts Which Are Extremely Rare Events.............................38

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 3 of 705

iii

a. Kicks Regularly Occur in the Industry. .....................................38

b. Transocean Experienced over 300 Kicks from 2005-

2009................................................................................................40

c. Transocean Was Aware of These Risks from Prior Well

Control Incidents. ........................................................................41

D. BP Contracted with Halliburton to Provide Cementing and Mud

Logging Services...................................................................................................49

1. BP Contracted with Halliburton, Through Its Sperry Division,

for Continuous Well Monitoring in Connection with the

Drilling of the Macondo Well..................................................................49

2. It Was the Mud Loggers Duty to Monitor the Well and

Communicate Effectively with the Drilling Crew. ................................50

3. Mud Logging Equipment on the Deepwater Horizon............................51

4. BP Contracted with Halliburton to Cement the Macondo Well. ........52

a. Halliburton Is a Leading Oil Field Cementing

Company. ......................................................................................52

b. Halliburtons Contractual Responsibilities Relating to

Cementing Services. .....................................................................53

c. BP Relied Upon Halliburton to Provide Cementing

Expertise. ......................................................................................55

d. Halliburton Was Responsible for Designing the Cement

for the Macondo Well. .................................................................55

e. Halliburton Was Responsible for Testing the Cement

for the Macondo Well. .................................................................56

f. Halliburton Was Responsible for Pumping the Cement

for the Macondo Well. .................................................................57

E. Other Entities Involved in Drilling the Macondo Well. ...................................57

1. Cameron....................................................................................................57

2. M-I Swaco. ................................................................................................59

3. Weatherford. ............................................................................................61

4. Dril-Quip. ..................................................................................................62

III. THE DEEPWATER HORI ZON. .....................................................................................63

A. Basic Facts Regarding the Deepwater Horizon. .................................................63

B. Basic Facts Regarding the Deepwater Horizons Safety and

Operational Equipment. ......................................................................................65

1. The Deepwater Horizon BOP. .................................................................65

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 4 of 705

iv

a. Annular Preventers. .....................................................................66

b. Variable Bore Rams (or Pipe Rams). .........................................66

c. Casing Shear Rams and Blind Shear Rams. .............................67

d. ST-Locks. ......................................................................................68

e. The BOP Control System. ...........................................................68

i. BOP Control Pods. ...........................................................68

ii. MUX Cables. ....................................................................69

f. The Deepwater Horizon BOP Emergency Control

Systems. .........................................................................................70

i. The BOP AMF/Deadman System. ..................................70

ii. The Autoshear System. ....................................................70

iii. The Emergency Disconnect System (EDS). ...................70

2. The Riser System......................................................................................71

3. Instrumentation and Indication of Well Status. ...................................72

4. Hydrocarbon Combustible Gas Detection System................................72

5. Overboard Diverters Direct Flow and Gas Away From the Rig

Floor to Reduce the Risk of Ignition. .....................................................74

C. The Roles and Responsibilities of the Transocean Captain and Crew

of the Deepwater Horizon. ....................................................................................75

1. The Responsibilities of the Transocean Crew. ......................................75

2. The Responsibilities of the Rig Captain/Master and OIM...................75

3. The Transocean Personnel Responsible for the Performance of

the Deepwater Horizon at the Macondo Well. .......................................77

D. The Deepwater Horizon Had a Track Record of Safe Operations in

Drilling BP Wells..................................................................................................79

E. Transoceans Safety Assessments of the Deepwater Horizon. ..........................81

1. Transoceans Major Accident Hazard Risk Assessment

(MAHRA) for the Deepwater Horizon. ...................................................81

a. Well Control Procedures and the Training of the Drill

Crew in Well Control...................................................................84

b. Maintenance and Testing of BOPs and Other Subsea

and Well Control Equipment. .....................................................89

F. Transocean Safety Initiatives Applicable to the Deepwater Horizon

Crew. .....................................................................................................................90

G. All Transocean Crew Members Had Stop-Work Authority............................92

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 5 of 705

v

H. All Halliburton Crew Members Also Had Stop-Work Authority. ..................94

IV. HOW THE RISKS OF DEEPWATER DRILLING ARE MANAGED. ....................96

A. The Barriers to a Blowout. ..................................................................................96

1. Cement. .....................................................................................................96

2. Well Integrity Testing. .............................................................................97

a. Seal Assembly Tests. ....................................................................97

b. Positive Pressure Tests. ...............................................................97

c. Negative Pressure Tests. ..............................................................98

3. Well Control. ............................................................................................99

4. The Blowout Preventer. .........................................................................101

V. THE DRILLING OF THE MACONDO WELL. .......................................................103

A. The Design of the Macondo Well. .....................................................................103

1. BPs Macondo Well Engineering and Operations Team. ..................103

2. BPs Pre-Spud Planning. .......................................................................106

B. Consistent With Industry Practice, BP Worked Closely and Shared

Information with Its Contractors to Drill the Macondo Well Safely. ...........110

C. October to November 2009: Drilling by the Transocean Marianas. ............115

D. January to April 2010: Drilling by the Transocean Deepwater

Horizon. ...............................................................................................................116

1. The Drilling Program and Pre-Spud Meeting for the Deepwater

Horizon. ...................................................................................................117

2. Transocean Had Identified Kicks as a Risk in the Operation of

the Deepwater Horizon at the Macondo Well. .....................................118

3. The Deepwater Horizon Commenced Drilling on February 6,

2010..........................................................................................................119

4. Drilling in March 2010. .........................................................................120

a. The March 8 Kick. .....................................................................120

b. BP and Its Contractors Response to the Kick. ........................121

c. BP Investigated the Kick, Developed Lessons Learned,

Shared Those Lessons, and Took Steps to Prevent a

Reoccurrence. .............................................................................122

d. Transocean Never Completed an Investigation into the

March 8 Kick and Never Took any Action in Response

to the Incident. ............................................................................123

5. Drilling Operations from March 16 to April 1, 2010. .........................123

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 6 of 705

vi

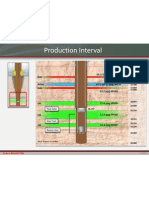

6. Drilling Operations from April 1 to April 9, 2010 - the Final

Interval. ...................................................................................................124

7. April 9, 2010: Total Depth Reached. ...................................................126

a. BP Appropriately Managed Loss Events During the

Drilling of the Macondo Well....................................................127

i. Losses Are Common in Deepwater Wells. ...................127

ii. Operators and Drillers Have Common Practices

to Respond to Losses While Drilling. ...........................127

iii. The Transocean Rig Crew Properly Drilled the

Final Production Interval Consistent With

Industry Standards and Practices. ...............................128

b. BP Complied With Safe Drilling Margin Regulations in

Reaching Total Depth at the Macondo Well. ..........................129

i. BP Met With the MMS in February 2008 and

Discussed the Method for Calculating Drilling

Margin and That Results Would Be Reported in

the IADC. ........................................................................130

ii. Safe Drilling Margin Definitions. .................................132

iii. The Pressure Integrity Test at the 13-5/8 Shoe

Was Valid. .......................................................................132

iv. The Pressure Integrity Test at the 9 7/8 Shoe

Was Valid. .......................................................................134

v. BP Complied with Safe Drilling Margin

Regulations and No Alleged Violation Was

Related to the Incident...................................................135

c. BPs Decision to Use a Long String Production Casing

Was Consistent with Industry Practice, BPs Original

Plan, and Was Approved by the MMS. ...................................137

i. The MMS Has Approved Long String

Production Casing Designs for Deepwater Wells

in the Gulf of Mexico. ....................................................139

ii. BPs Long String Design for the Macondo Well

Was Consistent with Industry Standards. ...................140

iii. The MMS Independently Reviewed and

Approved BPs Long String Design for the

Macondo Well.................................................................140

iv. The Use of a Long String Production Casing

Was Not Related to the Incident. ..................................141

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 7 of 705

vii

d. The MMS Approved BPs Permits, and There Were No

Incidents of Non-Compliance Issued by MMS

Inspectors During the Drilling of the Macondo Well. ............141

E. The Temporary Abandonment Procedure. .....................................................143

1. Development of the Temporary Abandonment Procedure. ...............143

2. The Depth of the Cement Plug. .............................................................146

3. The Displacement Procedure. ...............................................................148

F. A Long String Production Casing Was Run into the Well with Six

Centralizer Subs. ................................................................................................149

1. The Decision to Use Six Centralizers Was Based on Careful

Engineering Judgment and Experience. ..............................................149

2. Halliburton Did Not Indicate that BPs Decision to Use Six

Centralizers Was Unsafe. ......................................................................154

3. The Use of Six Centralizers Was Consistent with Industry

Practice and Appropriate for the Macondo Well. ..............................155

G. The Float Collar Was Converted After Running Casing. ..............................157

1. The Float Collar Served Its Intended Purpose....................................157

2. Nine Attempts Were Made to Establish the Circulation

Necessary to Convert the Float Collar. ................................................161

3. All Parties on the Rig Agreed that the Float Collar Converted. .......162

4. Stress Engineerings Post-Incident Testing Confirmed that the

Float Collar Converted. .........................................................................163

5. The Float Collar Is Not a Well Control Barrier. .................................166

H. A Partial Bottoms Up Circulation Was Performed After

Conversion of the Float Collar and Prior to the Pumping of Cement. .........166

1. A Full Bottoms-Up Was Neither Necessary nor Consistent with

Industry Practice. ...................................................................................166

2. A Partial Bottoms-Up Was Appropriate for the Macondo Well. ......167

3. Not Spotting a Heavy Pill in the Rat Hole Was Consistent With

Industry Practice and Appropriate for the Macondo Well. ..............169

I. Cementing the Final Production Casing. .........................................................170

1. The Execution of the Cement Job.........................................................170

2. Based on the Execution of the Cement Job, a Cement Bond

Log Was Not Used. .................................................................................172

a. The Cement Job Was Executed as Planned and a

Cement Bond Log Was Not Necessary.....................................173

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 8 of 705

viii

b. There Was No Requirement to Run a Cement Bond Log

to Verify Top-of-Cement, Especially Because There

Were No Losses During the Cement Job. ................................173

c. Not Running a Cement Bond Log at Temporary

Abandonment Was Consistent with Industry Practice. .........174

d. BP Used a Reasonable Process in Deciding Not to Run a

Cement Bond Long. ...................................................................175

e. Guide Specifically Asked If Anybody Thought a

Cement Bond Log Was Necessary and Halliburton Did

Not Request One. .......................................................................177

3. The Cement Was Set by the Time of the Negative Pressure

Test. .........................................................................................................177

a. Pre-Incident Compressive Strength Tests Performed on

the Macondo Well Slurry. .........................................................177

b. BP Waited an Appropriate Amount of Time for the

Cement to Set Before the Negative Pressure Test. ..................178

c. The United States Expert Glen Benges Arguments Do

Not Change This Result. ............................................................179

i. OTCs UCA Compressive Strength Test. ....................179

ii. Halliburtons Foam Cube Crush Compressive

Strength Test. .................................................................180

d. BPs Decision for Additional Safety Margin on Pump

Time Did Not Affect Wait-on-Cement Time. ..........................180

4. The Decisions Made by BP with Regard to the Cement Job

Were Confirmed as Appropriate by Halliburtons Post-Job

Report......................................................................................................181

J. The Events of April 20, 2010. ............................................................................183

1. Personnel on the Rig on April 20. .........................................................183

a. BP Personnel...............................................................................183

b. Key Transocean Personnel. .......................................................186

2. Drilling Operations Were Normal for Much of the Day. ...................186

3. The Positive Pressure Test. ...................................................................187

4. The Use of LCM Spacer. .......................................................................188

5. The Negative Pressure Test. ..................................................................188

a. The Negative Pressure Test Procedure Was Discussed

With the Transocean Rig Crew Multiple Times on April

20, 2010 Before it Commenced. ................................................191

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 9 of 705

ix

b. Conducting the Negative Pressure Test. ..................................193

c. The Negative Pressure Test Performed on the Drill

Pipe. .............................................................................................195

d. Transocean Toolpusher Jason Anderson Explained the

Pressure Abnormality as a Bladder Effect. .........................196

e. The Negative Pressure Test Performed on the Kill Line........198

f. The Negative Pressure Test Was Deemed Successful. ............199

g. The Negative Pressure Tests Were Conducted in

Accordance with the April 16 MMS-Approved APM. ...........203

h. Transocean and BP Both Misinterpreted the Results of

the Negative Pressure Test. .......................................................205

i. BP and Transocean Shared Responsibility for

Interpreting the Negative Pressure Test. .....................205

ii. The Misinterpretation of the Negative Pressure

Test Was One of Several Proximate Causes of

the Incident. ....................................................................207

6. Halliburtons Mud Logger Was Able to Continuously Monitor

the Well on April 20, 2010. ....................................................................208

a. Halliburtons Mud Logger Was Aware of the Planned

Rig Operations When He Came on Tour and He Had

No Concerns about His Ability to Monitor the Well. .............208

b. Halliburtons Mud Logger Was Responsible for

Continuously Monitoring the Well and Alerting the Rig

Crew and Company Man of Any Kick Indicators. .................209

c. Halliburtons Mud Logger Was Able to Perform His

Job Fully and Capably on April 20, and Ongoing Rig

Operations Did Not Prevent Halliburton from

Monitoring the Well. ..................................................................210

d. Halliburtons Mud Logger Took a Break Before the

Sheen Test and Did Not Identify Any Anomalies in the

Data When He Returned. ..........................................................212

7. The 20:52 Call. .......................................................................................213

8. The Failure to Detect and Respond to Kick Indications in the

Final Hour Resulted in the Loss of Well Control. ..............................215

a. 20:52-21:08: The Well Began to Flow. ....................................216

b. 21:01-21:08: Flow Went Undetected Despite 100 psi

Pressure Increase. ......................................................................217

c. 21:08-21:14: Flow Continued Undetected Despite a 250

psi Pressure Increase with the Pumps Off. ..............................218

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 10 of 705

x

d. 21:31-21:38: The Pumps Were Shut Off to Diagnose

Anomalies, but Despite a 550 psi Pressure Increase, the

Crew Took No Well Control Actions. ......................................221

e. 21:38-21:49: Hydrocarbons Entered the Riser Prior to

Activation of the Annular Preventer. .......................................224

f. There Was No Attempt to Activate the Blind Shear

Rams Prior to the Explosion. ....................................................227

g. 21:43-21:45: Transocean Diverted Gas onto the Rig by

Directing Flow to the Mud-Gas Separator, Leading to

the Initial Explosion and Fire. ..................................................230

i. Transoceans Well Control Policy Required

Diversion Overboard. ....................................................232

ii. Diversion Overboard Would Have Prevented the

Explosion and Fire on the Deepwater Horizon. ...........233

h. 21:47: The Middle and Upper Variable Bore Rams

Closed and Sealed. .....................................................................234

i. 21:49: Explosions on the Rig. ...................................................236

j. The AMF/Deadman Failed to Activate Because of

Control Pod Deficiencies. ..........................................................237

k. When Attempted After 21:55, the EDS Failed to

Activate. ......................................................................................238

l. The Deepwater Horizon Was Evacuated Shortly After

22:00. ...........................................................................................239

m. The Traveling Block Fell at 22:20 and Buckled the Drill

Pipe. .............................................................................................239

i. The Physical Evidence Indicates the Force from

the Traveling Block Falling Was Transmitted to

the Drill Pipe in the BOP. ..............................................240

ii. The Variable Bore Rams Did Not Have to Resist

the Full Force of The Falling Traveling Block. ...........242

iii. It Is Unlikely that Drill Pipe Segments 39 and 1-

B-1 Separated in a Classic Tensile Failure

Shortly After the Rig Explosions due to Rig

Drift. ................................................................................243

iv. The Ends of the Drill Pipe Segments That Were

Above the Upper Annular Do Not Indicate That

They Separated in a Classic Tensile Failure Due

to Rig Drift. .....................................................................244

v. The Force from the Falling Traveling Block

Would Still Be Transmitted to the Drill Pipe in

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 11 of 705

xi

the BOP if Drill Pipe Above the Upper Annular

Were Separated Before the Block Fell. ........................245

K. The Events of April 21-22, 2010........................................................................246

1. The Autoshear Was Activated Remotely at 07:48. .............................246

2. The Blind Shear Rams Closed but Did Not Seal the Well

Because the Drill Pipe Was Forcibly Held Partially Outside the

Blades. .....................................................................................................247

3. The Deepwater Horizon Sank on April 22, 2010. .................................248

VI. THE FOAM CEMENT DESIGNED, TESTED, AND RECOMMENDED BY

HALLIBURTON FOR THE PRODUCTION CASING FAILED TO SERVE

AS A BARRIER BECAUSE IT WAS UNSTABLE. ..................................................248

A. BP Relied on Halliburton to Provide Suitable Cement. .................................248

1. Jesse Gaglianos Responsibilities. .........................................................248

B. Gagliano Recommended the Slurry For the Macondo Production

Casing. .................................................................................................................249

1. Halliburton Knew of the Specific Properties and Risks of the

Macondo Well.........................................................................................250

2. Gagliano Made Design Proposals to BP With Knowledge of the

Macondo Well Conditions. ....................................................................251

C. Halliburtons Testing Resources. .....................................................................252

D. Halliburton Designed an Unstable Slurry, Improperly Using

Defoamer in a Foam Cement. ...........................................................................252

1. Gagliano Recommended to BP the Foam Cement Design Used

at the Macondo Well. .............................................................................252

2. Foam Cement is Appropriate for Deepwater Wells Such as the

Macondo Well When Designed Appropriately. ..................................254

3. Halliburtons Design of the Foam Cement Used at the

Macondo Well Was Inconsistent with Best Practices and

Halliburtons Manuals...........................................................................256

a. Halliburton Inappropriately Included D-Air 3000, a

Defoamer, to a Foam Slurry Design. ........................................256

b. Halliburton Used Other Inappropriate Additives that

Affected Foam Stability. ............................................................259

c. Gagliano Ignored Halliburton Best Practices and

Internal Protocols.......................................................................260

4. Halliburton Failed to Update the Basis of Design for the

Macondo Well and Subsequently Did Not Identify Risks or

Mitigations Associated With D-Air 3000 or SCR-100. .......................261

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 12 of 705

xii

E. Halliburton Pre-Incident Foam Stability Tests Showed the Slurry

Was Unstable, but Halliburton Failed to Report or Misreported the

Foam Stability Tests in Advance of the Cement Job. .....................................263

1. The February 12 Testing Indicated the Foam Slurry Was

Unstable. .................................................................................................266

2. The February 16 Testing Indicated the Foam Slurry was

Unstable. .................................................................................................268

3. Halliburton Conducted Tests on March 7 Using a Nearly

Identical Blend That Also Showed Instability. ....................................268

4. The March 8 Lab Report Sent to BP Did Not Report the Failed

February 12 and March 7 Foam Tests and Misreported the

February 16 Foam Tests. .......................................................................269

5. The Lab Report Sent to BP on April 1 Also Did Not Report the

Failed February 12 Foam Tests and Misreported the February

16 Foam Tests. ........................................................................................270

6. The April 13 Testing Showed the Foam Slurry Was Unstable. .........271

7. On April 16, Gagliano Cancelled the Only Foam Stability Test

Scheduled for the Slurry Used on the Macondo Well

Production Casing Job. .........................................................................272

8. The April 17 Testing Did Not Show Stability. .....................................272

9. Gagliano Failed to Identify Foam Testing Issues Before

Recommending the Slurry to BP on the Evening of April 18. ...........274

10. Gagliano Failed to Review or Provide BP with the Final Test

Results Before the Cement Job. ............................................................275

F. Halliburton Did Not Fully Test the Cement Slurry Used to Cement

the Macondo Well. .............................................................................................276

1. The Formulation Actually Used to Cement the Macondo Well

Was Never Tested for Foam Stability. .................................................276

2. Halliburton Failed to Run Other Industry Standard Tests on

the Slurry Before the Cement Job. .......................................................278

a. Fluid Loss Test. ..........................................................................278

b. Free Water Test..........................................................................278

c. Static Gel Strength Test.............................................................279

d. Settlement Testing. .....................................................................279

e. Cement Compatibility Testing. .................................................279

G. The Halliburton Cement Failed to Isolate the Reservoir. ..............................280

H. Post-Incident Testing Confirms the Slurry Was Unstable. ............................281

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 13 of 705

xiii

1. CSI Testing on Behalf of BP. ................................................................282

2. Post-Incident Cement Testing by Chevron..........................................284

a. Testing on Lab Stock Is Representative of Testing on

the Rig Blend. .............................................................................287

3. Post-Incident Cement Testing by Oilfield Testing &

Consulting. ..............................................................................................289

4. Post-Incident Testing by Halliburton. .................................................291

a. Halliburton Post-Incident Testing in Duncan. ........................292

b. Halliburton Post-Incident Testing in Broussard. ....................295

i. Foam Stability Testing. ..................................................295

ii. Static Gel Strength Testing. ..........................................296

I. Halliburtons April 18 OptiCem Model Contained Several Inaccurate

Inputs. .................................................................................................................297

J. Halliburtons Unstable Cement Slurry Created a Flow Path for

Hydrocarbons Up the Casing. ......................................................................300

K. The Number of Centralizers Used Did Not Cause the Incident. ...................302

L. The Partial Bottoms-Up Circulation Did Not Cause the Incident. ...............303

M. No Heavy Pill in the Rat Hole Did Not Cause the Incident. ...........................304

N. M57B Was Not a Cause of the Incident. ..........................................................305

1. MMS Regulations Require that the Top-of-Cement Must be

500 Feet Above the Top Hydrocarbon Bearing Zone. ......................305

2. There Is No MMS Definition or Industry Standard Definition

of a Hydrocarbon Bearing Zone. ......................................................306

3. M57B Was an Approximately Two Foot Zone with Uncertain

Petrophysical Properties. ......................................................................306

4. The Determination of a Hydrocarbon Bearing Zone Requires

Engineering Discretion. .........................................................................308

5. The M57B Sands Did Not Flow When Underbalanced During

Well Operations. ....................................................................................309

6. Galina Skripnikova Reviewed All Available Data and Acted

Reasonably in Not Identifying M57B as a Hydrocarbon

Bearing Zone. .........................................................................................309

7. Post-Incident Technical Documents Regarding M57B Do Not

Reflect a Determination as to Whether M57B Was a

Hydrocarbon Bearing Zone. .................................................................310

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 14 of 705

xiv

VII. THE BOP FAILED TO SERVE AS A BARRIER BECAUSE OF

TRANSOCEANS FAILURE TO MAINTAIN THE BOP. ......................................311

A. Transocean Developed the Maintenance Philosophy for the BOP That

It Used Fleet-wide. .............................................................................................311

B. Transocean Represented to BP that the VBRs Complied with API RP

53..........................................................................................................................312

C. Transocean Failed to Maintain the BOP so as to Allow the

AMF/Deadman to Operate During the Incident. ............................................313

1. The AMF/Deadman Sequence Relied on the 27-Volt Battery

and Solenoid 103 to Close the Blind Shear Rams. ..............................313

2. The AMF/Deadman Failed to Activate Because of Deficiencies

in the Yellow and Blue Control Pods. ..................................................315

a. The 27-Volt Battery in the Blue Pod Was Too Depleted

to Operate the AMF/Deadman Function. ................................316

i. Post-Incident Testing Confirmed that the 27-

Volt Battery Was Depleted. ...........................................316

ii. Interlinks Testing Supports the Conclusion that

the Blue Pod Battery Was Too Depleted to

Operate the AMF/Deadman Sequence.........................318

iii. Childs Cycling Theory Is Unsubstantiated and

Inconsistent with the Forensic Evidence. .....................319

iv. Transoceans Internal Battery Testing Is

Unreliable and Irrelevant. .............................................321

v. Transocean Failed to Replace the Blue Pod

Batteries in Compliance With Camerons

Recommendations. .........................................................324

vi. Transocean Could Have Detected the Depleted

27-Volt Battery Before Deploying the BOP at the

Macondo Well.................................................................327

vii. Transocean Was on Notice That It Could Not

Monitor the Blue Pod Batteries Used at the

Macondo Well and That the Batteries Had Not

Been Replaced Since 2007. ............................................328

b. The Reverse-Wired Solenoid Valve Was Not Able to

Operate on April 20, 2010. ........................................................329

i. Proper Wiring Is Crucial to Solenoid 103s

Functionality. ..................................................................330

ii. A Reverse-Wired Solenoid 103Y Could Not Have

Operated on April 20, 2010. ..........................................331

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 15 of 705

xv

(A) Q4000 Testing Established That Solenoid

103Y Could Not Operate the

AMF/Deadman Sequence. .................................332

(B) DNVs PETU and AMF Testing

Established That Solenoid 103Y Could

Not Operate the AMF/Deadman

Sequence..............................................................333

(C) DNVs Bench Testing Established That

Solenoid 103Y Could Not Function the

AMF/Deadman Sequence. .................................336

(D) Camerons Testing Established That a

Reverse-Wired Solenoid Valve Would Not

Have Operated During the

AMF/Deadman Sequence. .................................337

(E) Transoceans Internal Testing Did Not

Establish That a Reverse-Wired Solenoid

Valve Would Have Functioned Under

Actual Conditions...............................................337

iii. Transocean Could Have Detected the Reverse-

Wired Solenoid Valve Before Deploying the BOP

at the Macondo Well. .....................................................338

D. The BOP Would Have Sealed the Well If the AMF/Deadman Had

Worked................................................................................................................339

1. Shearing Conditions Were Favorable at the Time the

AMF/Deadman Conditions Were Met. ................................................340

2. The Force-from-Below Theory Was Unsupported. ........................343

a. The Force-from-Below Theory Did Not Support Drill

Pipe Buckling When the Upper Annular Closed. ...................344

b. The Force-from-Below Theory Did Not Support Drill

Pipe Buckling When the Variable Bore Rams Closed. ...........346

c. The Force-from-Below Theory Did Not Support Drill

Pipe Buckling After the Variable Bore Rams Closed. ............349

3. The Rig Drift Drill Pipe Buckling Theory Is Unsupported................351

E. The Deepwater Horizon BOP Would Have Been Suitable for Subsea

Drilling and Operations at the Macondo Well. ...............................................354

1. The Design and Configuration of the Deepwater Horizon BOP

Was the Result of a Collaborative Process that Involved

Multiple Parties, Including Cameron, Transocean, BP, and

Several Contractors. ..............................................................................354

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 16 of 705

xvi

2. The BOP Configuration Met and Exceeded MMS Regulations

and Was Approved by MMS for the Macondo Well. .........................357

3. The BOP Components Were Adequately Pressure Rated. ................359

4. The BOPs Configuration, Including the Shear Ram

Configuration, Was Consistent with Industry Practice. ....................361

5. The MMS Approved the BOP Configuration for Use at the

Macondo Well and Compliance with MMS regulations [is

considered] the use of BAST [Best Available and Safest

Technology.] 30 C.F.R. 250.107. .....................................................366

6. The BOP Had Sufficient Shearing Capacity. ......................................367

a. The BOP Had Sufficient Shearing Capacity Based on

Camerons Engineering Bulletin EB 702D. .............................369

b. The BOP Had Sufficient Shearing Capacity Based on

the April 11, 2000 Shear Test. ...................................................371

c. The BOP Had Sufficient Shearing Capacity Based on

the August 6, 1999 Shear Test. ..................................................373

d. Additional Validation that the BOP Had Sufficient

Shearing Capacity. .....................................................................374

e. Shear Tests Are the Most Accurate Predictor of

Shearing Pressure. .....................................................................374

f. Transocean Understood that BP Relied on It for

Shearing Calculations. ...............................................................375

g. Maximum Applied Surface Pressure (MASP) Was

Properly Calculated in Accordance with Industry

Practice, and the BOP Was Capable of Shearing the

Drill Pipe under the MASP. ......................................................376

7. The Deepwater Horizons BOPs Operational History Indicated

That It Was Suitable As Configured for the Macondo Well

Deepwater Drilling Operations. ............................................................380

8. Modifications Known to BP Before April 20, 2010, Which

Included the Conversions to a Stripping Annular and Test

Ram, Improved the BOPs Functionality and Were MMS

Approved. ...............................................................................................381

a. The Conversion of the Lower VBR Into a Test Ram

Improved the BOPs Functionality and Was MMS

Approved. ...................................................................................381

b. The conversion of the lower annular to include a

stripping element improved the BOPs functionality

and was MMS approved. ...........................................................384

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 17 of 705

xvii

9. Alternative BOP Features Were Unnecessary to Allow the

Deepwater Horizon BOP to Perform Its Intended Function, to

Comply with MMS Regulations, to Meet Industry Standards,

and Could Have Presented Operational Disadvantages.....................386

a. Two BSRs Were Unnecessary, Not Required By MMS

Regulation and Not Industry Standard. ..................................387

b. DVS Rams Were Unnecessary, Not Required by MMS

Regulation and Were Not Industry Standard. ........................390

c. CDVS Rams Were Unnecessary, Not Required by MMS

Regulation and Not Industry Standard. ..................................393

d. Inclusion of the CSR in the AMF/Deadman Sequence

Was Unnecessary, Consistent with Industry Standards,

And Not Required by MMS Regulation. .................................394

e. Using EDS-2 Instead of EDS-1 as a Default Sequence

Was Unnecessary, Not Required by MMS Regulation

and Not Industry Standard. ......................................................396

f. Tandem Boosters Were Unnecessary, Not Required by

MMS Regulation, Not Industry Standard and Were Not

Practical to Implement. .............................................................398

g. An Acoustic Backup System Was Unnecessary, Not

Required by MMS Regulations, and Not Industry

Standard......................................................................................400

h. Rechargeable Control Pod Batteries, Battery

Monitoring, and a Single Coil Solenoid Were

Unnecessary. ...............................................................................404

i. An Alternate Way to Route MUX Cables Was

Unnecessary, Not Industry Standard, and Was Not

Practical. .....................................................................................409

VIII. BP REASONABLY BELIEVED THAT TRANSOCEAN HAD

MAINTAINED THE DEEPWATER HORI ZON IN A MANNER SUITABLE

TO DRILL THE MACONDO WELL. ........................................................................411

A. The Deepwater Horizon Underwent Several BP Audits Prior to the

Incident. ..............................................................................................................411

1. BP Conducted Audits of the Deepwater Horizon from 2001-

2009..........................................................................................................411

2. BP Conducted an Integrated Acceptance Test of the Deepwater

Horizon in 2001. ......................................................................................414

3. BP Conducted a Technical Rig Audit of the Deepwater Horizon

in 2005. ....................................................................................................415

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 18 of 705

xviii

4. BPs May 2007 Deepwater Horizon Marine Assurance Audit

and DP Proving Trials. ..........................................................................415

5. BP Conducted a Technical Rig Audit of the Deepwater Horizon

in 2008. ....................................................................................................417

6. BP Conducted a Follow-Up Technical and Marine Assurance

Audit of the Deepwater Horizon in 2009. ..............................................418

7. The Deepwater Horizon Did Not Resume Drilling Operations

Until the BP Wells Team, Marine Group, and Transocean

Approved the Resumption of Operations. ...........................................419

8. BP Appropriately Oversaw Transoceans Efforts to Closeout

the Findings from the September 2009 Audit. ....................................420

9. Transocean Represented to BP that Certain Audit Findings

Had Been Successfully Addressed by April 2010. ...............................426

10. On April 20, 2010, No Safety-Critical Audit Findings Were

Outstanding. ...........................................................................................430

B. The Deepwater Horizon Underwent Several Other Maritime Audits,

Inspections, and Certifications Prior to the Incident. ....................................430

1. Transoceans Safety Responsibilities, Including Audit

Responsibilities, under the ISM Code. .................................................431

2. Audits on behalf of the Marshall Islands by Det Norske Veritas

and the American Bureau of Shipping Consistently Found the

Deepwater Horizon in Compliance with the ISM Code. .....................434

3. The Coast Guard Examined the Deepwater Horizon Annually. ........435

4. ModuSpec USA Performed a Rig Condition Assessment of the

Deepwater Horizon in 2005 and April 2010..........................................437

5. The 2010 Lloyds Register Audit. .........................................................443

IX. AS IMPLEMENTED ON THE DEEPWATER HORI ZON, TRANSOCEANS

DUAL COMMAND STRUCTURE WAS ALSO A PROXIMATE CAUSE

OF THE INCIDENT......................................................................................................446

A. The Deepwater Horizon Crew Was Confused with Regard to the

Command Structure. .........................................................................................446

B. The Command Structure Required a Transition of Authority in an

Emergency, Which Increased the Risk of Further Confusion and

Delay in a Critical Situation. .............................................................................449

C. As a Result of Confusion and Delay Caused by Transoceans Dual

Command Structure, the Crew Failed to Activate the EDS in Time to

Save the Deepwater Horizon. .............................................................................451

1. Proper Activation of the EDS Would Have Saved the

Deepwater Horizon. ................................................................................456

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 19 of 705

xix

2. Inadequate Qualifications and Training Contributed to the

Crews Failure to Activate the EDS Before The Explosions. .............457

3. Neither Captain Kuchta nor OIM Jimmy Harrell Was

Properly Qualified or Adequately Trained to be Master of the

Deepwater Horizon. ................................................................................458

X. BP PROMPTLY INVESTIGATED AND ACCURATELY REPORTED ON

THE CAUSES OF THE INCIDENT. ..........................................................................459

A. The Methodology of BPs Internal Investigation. ...........................................459

1. The Structure and Scope of the Investigation. ....................................459

2. The BP Internal Investigation Team Sought but Was Not

Provided Access to Evidence Sufficient to Perform a Complete

Systemic Analysis. ..................................................................................462

B. BPs Investigation Determined the Incident Had Multiple Causes

Involving the Conduct of Multiple Parties. .....................................................463

C. The BP Internal Investigation Report Recommendations and Their

Implementation by BP. ......................................................................................464

D. Other Parties Did Not Conduct Equally Meaningful Investigations. ...........466

1. Halliburton. ............................................................................................466

a. Halliburton Intentionally Hid and Destroyed Evidence

and Misled Investigators. ..........................................................466

i. Tim Proberts Incorrect Testimony to Congress. .......466

ii. Tommy Roths Incorrect Testimony to the NAE. .......467

iii. Halliburtons Destruction of Test Results and Its

Failure to Timely Produce Roths Notes. .....................467

iv. Halliburtons Failure to Timely Produce Rig

Cement Samples. ............................................................469

b. Halliburton Has Refused to Accept any Responsibility

for Its Conduct. ..........................................................................472

2. Transocean..............................................................................................472

a. Transocean Has Admitted It Was Negligent. ..........................473

b. Transoceans Negligence Was Not Limited to the

Matters for Which It Has Admitted Negligence. ....................474

XI. BPS CONDUCT WITH REGARD TO THE MACONDO WELL WAS

CONSISTENT WITH ITS STRONG COMMITMENT TO SAFETY. ...................475

A. In the Years Preceding the Incident, BP Enhanced Its Process Safety

Management System. .........................................................................................475

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 20 of 705

xx

1. BP Developed and Implemented a New Safety Management

System. ....................................................................................................475

2. BPs Leadership Was Committed to and Emphasized Process

Safety. ......................................................................................................477

3. BP Enhanced Its Training on Process Safety Issues. ..........................479

4. BP Increased the Amount and Types of Feedback on Process

Safety Performance Metrics..................................................................481

B. BP Had a Positive and Supportive Safety Culture. ........................................483

1. Safety Was Always the First Priority. ..................................................483

a. BPs Leadership Set the Tone from the Top. ..........................483

b. BPs Leadership in the GoM SPU Engaged Contractors

to Support the Message that Safety Was a Top Priority. .......485

c. BP Emphasized the Importance of Safety in Employee

Performance Evaluations. .........................................................487

d. BP Had Programs and Initiatives to Emphasize Safety

As the Number One Priority in Operations. ...........................488

2. BP Utilized Surveys to Ensure that Its Employees and

Contractors Understood that Safety Was the Number One

Priority. ...................................................................................................489

3. BP Had Procedures In Place to Institutionalize Learning From

Incidents and Near Incidents. ...............................................................491

4. BP Did Not Sacrifice Safety to Decrease Costs or to Save Time. ......492

a. The Initiatives Taken by BP to Improve Process Safety

in the Years Leading Up to the Incident Are Not

Indicative of a Company that Was Cutting Corners to

Save Money. ................................................................................492

5. The Every $ Counts Slogan Was Solely About Increasing

Efficiency. ...............................................................................................493

a. The Removal of the BP Field HSSE Advisor from Rigs

Was Done to Eliminate Duplication and Reduce

Confusion. ...................................................................................494

b. Increases in Production and Decreases in Cash Costs in

the GoM SPU Were Unrelated to Safety. ................................495

c. Safety Was Never Sacrificed at the Macondo Well to

Save Time or Money. .................................................................497

d. No One Ever Rushed Operations at Macondo to Get the

Deepwater Horizon to the Kaskida Well Sooner. .....................499

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 21 of 705

xxi

6. Kevin Lacy, Among Others, Supported and Helped Implement

BPs Safety Initiatives. ...........................................................................500

7. E-mails Between Guide and Sims Do Not Reflect a Poor Safety

Culture or Have Any Causal Effect. ....................................................501

a. The March 2010 E-mails. ..........................................................501

b. The April 2010 E-mails. .............................................................502

C. BP Had Process Safety Policies and Procedures in Place to Identify

and Mitigate Risks Associated With Deepwater Drilling in the Gulf of

Mexico. ................................................................................................................505

1. BP Had Process Safety Systems Governing Deepwater Drilling

in the Gulf of Mexico Before the Adoption of OMS. ..........................505

a. Beyond the Best Common Process. ..........................................505

b. The Drilling and Wells Operations Practice. ..........................507

c. Drilling Engineering Technical Practices. ...............................508

d. The Way We Work. ...................................................................508

2. The GoM SPU Adopted OMS in Late 2008. .......................................509

3. The GoM Drilling & Completions Organization Implemented

OMS in Late 2009. .................................................................................512

4. BP Managed and Monitored Process Safety Risks Associated

With MODUs Owned by Contractors in the Gulf of Mexico. ...........513

a. BP Appropriately Managed the Risks Associated with

Loss of Well Control. .................................................................513

i. Loss of Well Control Was Identified As a Top

Risk for the GoM SPU and Managed By the SPU

Leadership Team, Including the Vice President

of D&C. ...........................................................................513

ii. BP Did Not Need to Conduct A Major Accident

Risk Quantified Assessment on Either the

Deepwater Horizon or the Macondo Well. ...................514

b. Consistent with Industry Standards and Practices, As

Well As BPs OMS, Transoceans Safety Management

System Governed the Operations Onboard the

Deepwater Horizon. ....................................................................515

c. BP Applied its Beyond the Best Common Process to the

Macondo Well.............................................................................517

i. BP Identified, Assessed, and Managed Key Risks

at Each Stage of the Well Planning and Design

Process. ............................................................................517

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 22 of 705

xxii

ii. The Macondo Wells Team Appropriately

Identified Risks in the Macondo Risk Register. ..........518

D. BP Had a Superior and Improving Safety Record in the Gulf of

Mexico. ................................................................................................................519

1. BPs Internal Documents and Communications Demonstrated

the GoM SPUs Outstanding and Improving Safety Record. ............519

2. BP Won the MMS Safety Award For Excellence Award in

2008 and Was a National Finalist in 2008 and 2009. ..........................519

E. Government Data Demonstrates that BP Had a Superior and

Improving Safety Record in the Gulf of Mexico in the Years Leading

Up to the Incident...............................................................................................520

1. BPs Gulf of Mexico Safety Record Improved in the Years

Before the Incident. ................................................................................521

2. BP Had A Superior Safety Record in the Gulf of Mexico in the

Years Before the Incident. .....................................................................522

PROPOSED CONCLUSIONS OF LAW ................................................................................526

XII. INTRODUCTION TO BPs PROPOSED CONCLUSIONS OF LAW. ..................526

XIII. THE COURTS RULINGS ON PRE-TRIAL AND TRIAL MOTIONS. ................528

A. The Courts Jurisdiction. ..................................................................................528

B. BPs Pre-Trial Motions I n Limineand Daubert Motions. .............................528

C. No Adverse Inference Should Be Drawn Against BP Based on

Witnesses Invoking Their Fifth Amendment Rights. .....................................530

D. Sanctions Should Be Imposed on Halliburton for Destruction and

Spoliation of Evidence. ......................................................................................531

XIV. BPXPS LIABILITY UNDER THE OIL POLLUTION ACT OF 1990. .................533

A. BPXP Has Acknowledged Its Responsibilities under OPA. ..........................533

B. BPXP Agreed to Waive the Cap on OPA Damages. .......................................534

C. OPA Liability for the Spill is Divisible. ............................................................535

D. BPXP Has No Liability Under OPA for Injuries Not Proximately

Caused by the Incident. .....................................................................................535

E. BPXP Has No Liability Under OPA to Claimants Who Failed to

Comply with OPAs Presentment Requirement. ............................................536

XV. BPXPS LIABILITY UNDER THE CLEAN WATER ACT. ...................................537

A. The Court Lacks Jurisdiction to Enter Additional Findings

Concerning the Source of the Discharge. .........................................................538

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 23 of 705

xxiii

B. BPXP Is Not Liable for Discharges from the Deepwater Horizon. ................538

1. BPXP Was Not the Owner or Operator of the Deepwater

Horizon. ...................................................................................................538

a. BPXP Did Not Own the Deepwater Horizon. ...........................538

b. BPXP Did Not Demise Charter the Deepwater Horizon. ........538

c. BPXP Did Not Operate the Deepwater Horizon. .................539

2. BPXP Was Not the Person In Charge of the Deepwater

Horizon. ...................................................................................................542

C. BPXP Is Not Liable for Enhanced Penalties Under the Clean Water

Act........................................................................................................................543

1. Negligence. ..............................................................................................544

2. Gross Negligence. ...................................................................................547

a. Objective Element of Gross Negligence. ..................................548

b. Subjective Element of Gross Negligence. .................................549

3. Willful Misconduct.................................................................................552

4. The CWAs Text Confirms that Treble Fines Require Extreme

Misconduct Characterized by a Culpable Mental State. ...................553

5. The Totality of Actions and Omissions Must Be Considered in

Determining Negligence, Gross Negligence, or Willful

Misconduct..............................................................................................556

6. BPs Liability Can Be Based Only on Conduct that Legally

Caused the Incident. ..............................................................................558

7. Agents and Independent Contractors. .................................................560

a. BP Cannot Be Vicariously Liable for the Acts of Its

Contractors. ................................................................................560

b. The Conduct of Agents Cannot Be Considered for

Treble Fines or Punitive Damages............................................564

8. A Court Must Consider Compliance with Government

Regulations and Industry Standards. ..................................................566

D. BPs Conduct Establishes That It Is Not Culpable for Treble Fines

under the CWA. .................................................................................................569

1. BP Exercised Due Care by Implementing Numerous Safety

Steps Designed to Avoid a Blowout. .....................................................569

2. BP Maintained a Strong Safety Culture. .............................................576

3. BPs Well Design Was Safe and Appropriate. ....................................578

4. BP Maintained a Safe Drilling Margin. ...............................................581

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 24 of 705

xxiv

a. BP Fully Complied with the Drilling Margin

Regulation. ..................................................................................581

b. No Alleged Violation of the Safe Drilling Margin

Regulation Could Have Caused the Incident. .........................584

5. The Temporary Abandonment Procedure Satisfied the

Standard of Care and Was Not Causal. ...............................................586

6. BP Is Not Liable for Relying on Halliburton to Conduct the

Cement Job. ............................................................................................588

7. Using Six Centralizers Was Safe, and the Number of

Centralizers Used Had No Relationship to the Incident. ...................589

8. Following Industry Practice in Not Running a Cement Bond

Log Was Safe and Appropriate. ...........................................................591

9. Circulating a Partial Bottoms-Up Was Safe under the

Circumstances. .......................................................................................593

10. No Heavy Pill Was Necessary. ..............................................................595

11. The Float Collar Was Properly Converted. ........................................596

12. Not Disclosing M57B to Halliburton Played No Role in the

Incident. ..................................................................................................596

13. Using LCM Spacer Was Safe and Appropriate. .................................597

14. BP Allowed the Cement to Set Before Conducting the Negative

Pressure Test. .........................................................................................598

15. BPs Negligent Supervision of the Negative Pressure Test Does

Not Constitute Gross Negligence or Willful Misconduct. ..................599

a. The Negative Pressure Test Was Properly Designed..............599

b. BPs Conduct Relating to Interpreting the Negative

Pressure Test Did Not Amount to Gross Negligence or

Willful Misconduct.....................................................................599

c. BPXPs Negligent Supervision Is Only One of Multiple

Proximate Causes of the Incident. ............................................603

16. BP Is Not Liable for Any Failures in Well Monitoring or Well

Control. ...................................................................................................604

17. The Deepwater Horizons BOP Design Was Suitable for the

Macondo Well.........................................................................................604

a. BP Collaborated on the Design and Configuration of

the BOP With Other Parties Including Cameron and

Transocean..................................................................................604

b. The BOPs Configuration Satisfied the Standard of

Care. ............................................................................................605

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 25 of 705

xxv

c. None of the Alleged Alternative Features Were

Necessary or Make the BOP Design Inadequate. ...................607

18. BP Is Not Liable for Transoceans Failure to Properly

Maintain the Deepwater Horizons BOP or Other Equipment. .........608

19. The Guide/Sims E-Mails Do Not Show Negligence and Are

Irrelevant in Any Case...........................................................................609

XVI. BPS LIABILITY UNDER MARITIME LAW. .........................................................609

A. OPA Displaces All Maritime Law Claims Against BP. ..................................610

B. BPs Liability under Maritime Law. ................................................................611

C. Apportionment. ..................................................................................................612

D. BP Is Not Liable for Punitive Damages under Maritime Law. .....................613

XVII. BP P.L.C. IS NOT LIABLE UNDER ANY LAW. .....................................................614

XVIII. TRANSOCEANS LIABILITY. ...................................................................................616

A. Transoceans Liability under Maritime Law. .................................................617

1. Transocean Is Liable for the Deepwater Horizons

Unseaworthiness. ....................................................................................617

a. Maritime Law Imposes an Absolute Duty of

Seaworthiness on Vessel Owners. .............................................617

b. As Implemented on the Deepwater Horizon,

Transoceans Dual Command Structure and

Inadequate Training Caused the Vessel to be

Unseaworthy. ..............................................................................619

i. The Deepwater Horizons Divided Command

Structure Caused Confusion Aboard the Vessel

on April 20, 2010. ...........................................................619

ii. Transocean Failed to Train the Crew Regarding

When to Activate the EDS. ............................................620

iii. The Deepwater Horizon Did Not Have a Properly

Trained Master...............................................................620

c. Transoceans Failure to Properly Maintain the BOP

Caused the Deepwater Horizon to be Unseaworthy. ...............621

2. Transocean Was Negligent. ...................................................................622

a. Transocean Misinterpreted the Negative Pressure Tests. ......622

b. Transocean Failed in Its Responsibility to Monitor the

Well..............................................................................................624

Case 2:10-md-02179-CJB-SS Document 10467 Filed 06/21/13 Page 26 of 705

xxvi

c. Transocean Failed in Its Responsibility to Control the

Well..............................................................................................625

d. Transocean Was Negligent for Implementing a

Confusing Command Structure and Failing to Train

Captain Kuchta. .........................................................................628

e. Transocean Failed to Properly Maintain the BOP,