Professional Documents

Culture Documents

Schneider Electric Motion Products

Uploaded by

asritaipOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Schneider Electric Motion Products

Uploaded by

asritaipCopyright:

Available Formats

A Complete Range of Motion Products

For Efficient Machine Control

Your Partner for Motion Control in Machine Automation

Motion controllers, drives, motors and linear motion axes Schneider Electric offers a complete range of motion products and solutions for your specific applications.

Packaging

Material working

Material handling

Printing

Textile

Labelling

Maximum Productivity for Your Machines

Complete Product Range

The complete range of Schneider Electric motion products is made to highest quality standards The products are designed for maximum consistency and interoperability and use a comprehensive platform of common tools and accessories See how a complete range of products

Solution Expertise

solution competency

A global team of experts versed in virtually all industries and applications assist you with their comprehensive solution competency Schneider Electric is able to provide you with highly productive machine solutions to take your know-how to the next level

the power of innovation

Simplicity

global availability

All our motion products are designed for maximum ease over the entire machine lifecycle to reduce costs and make your machine processes even more productive

Openness

energy efficiency specialists make Schneider Electric your partner of choice for cost-effective and energyefficient machine automation

Our products support practically all standardised motion interfaces mechanical, software and communication interfaces This allows you to efficiently design machines which can easily be integrated into your customers automation architectures

Innovation and Standardisation

Schneider Electric has an impeccable reputation as a major innovation driver in the industry To make sure new technologies can be efficiently used, we support international standards and actively participate in standardisation initiatives such as CiA (CAN in Automation), ODVA (Open Device-Net Vendor Association), SERCOS III, PLCopen

Schneider Electric you can rely on us!

Discover Our Solutions for Your Motion Application

This architecture combines a Modicon LMC058 motion controller, Altivar 32 variable speed drives, TeSys U motor starters, distributed I/Os via CANopen and Lexium 32 servo drives via CANmotion. This implementation brings maximum modularity, flexibility and openness to machines due to CANopen, EtherNet/IP and CANmotion.

Horizontal bagging machines

4 2 1 3

Vertical bagging machines

2 5

Application functions

1 Grouping / ungrouping 2 Lateral film position control 3 Digital film tension control Analog film tension control 4 Rotary knives 5 Heating temperature control 6 Flying shear

06 01 14 15

Machine performance Synchronisation of 4 axes in 2 ms or 8 axes in 4 ms with the LMC 058 motion controller Maximum machine productivity due to highly dynamic motor control of the Lexium 32 servo drive Fast machine commissioning Easy integration of Lexium Integrated Drives via CANopen interface Ready-to-use applica- tion function blocks and libraries for easy programming Synergetic use of Lexium 32 servo drives and variable Altivar 32 speed drives with common tools, com- mon software and identical mounting and wiring concepts

02

12

13

08

09

10

03

11 07 04

05

Motion products

01 Controller Modicon LMC058 02 Servo Drive Lexium 32 03 Servo Motor Lexium BMH, BSH 04 Integrated Drive Lexium ILA, ILE, ILS 05 Multi-Axis System Lexium MAX R3

Other Schneider Electric products

06 Graphic terminal Magelis XBT GT 07 Encoder OsiSense XCC 08 Variable speed drive Altivar 32 09 Distributed I/O Advantys OTB 10 Motor starter TeSys U 11 Detectors Osisense XC/XS/XU/XM/XX ... 12 Safety controller Preventa XPS MC 13 Emergency stop Harmony Xalk 14 Pushbuttons & switches Harmony XB4/5 15 Signaling unit Harmony XVM

Discover Our Solutions for Your Motion Application

A CANopen network with Modicon M238 programmable controller, Altivar 312 variable speed drive, Lexium 32 servo drives and Magelis XBT GT display unit brings maximum modularity, flexibility and performance to simple machines.

5

Boxing machines

1

Shrinking machines

2 3 1

Application functions

1 Grouping / ungrouping 2 Lateral film position control 3 Digital film tension control Analog film tension control 4 Heating temperature control 5 Pick & Place

11 07 06 08 12

Machine performance Highly dynamic positioning due to the speed bandwidth of 1.6 kHz of the Lexium 32 servo drive Positioning speeds of up to 8 m/s with Lexium PAS B portal axes Flexibility

01 09 17 03 14 10 04 02 05

13

15

Large choice of fieldbus modules for Lexium 32 (EtherNet IP, CANopen, Profibus DP, DeviceNet) Lexium Linear Motion single-axis and multiaxis systems adapted to individual requirements in terms of length and stroke, precise to the millimetre Excellent price/ performance ratio Economical solution with Modicon M238 logic controller, Lexium 32 Advanced servo drive and Lexium SD3 stepper motor drive

16

Motion products

01 Servo Drive Lexium 32 02 Servo Motor Lexium BMH, BSH 03 Stepper Drive Lexium SD3 04 Stepper Motor Lexium BRS3 05 Multi-Axis System Lexium MAXR3

Other Schneider Electric products

06 Circuit breaker Compact NSX / Multi 9 ... 07 Switch mode Power supply Phaseo ABL 8 ... 08 Logic Controller Modicon M238 ...

09 Safety modules Preventa XPS ... 10 Variable speed drive Altivar ATV 312 11 Display unit Magelis XBT GT 12 Signaling unit Harmony XVM ... 13 Pushbuttons & switches Harmony XB4/5 ... 14 Emergency stop Harmony XALK ... 15 Distributed I/Os IP20 Advantys FTB ... 16 Detectors Osisense XC/XS/XU/XM/XX... 17 Enclosure Spacial 3D ACM & ACP

Controllers for Motion Applications

Flexible Machine Control brings you maximum flexibility and unprecedented levels of optimisation to put you in full control. The controllers handle the standard logic of the machine and control motion.

The Schneider Electric Flexible Machine Control approach provides you with a complete range of controllers from HMI controllers and logic controllers to motion controllers, all with embedded motion functions.

The complete controller range excels with

A single software environment: Simplify machine programming and commissioning with SoMachine Logic and motion programming in a single, fully IEC 1131-compliant environment dramatically reduces programming time and complexity All controllers provide a full set of PLCopen function blocks for the entire motion range

SoMachine

Motion controllers for high-performance machines

One for all: a powerful software solution

Powerful and cost-effective solution for synchronisation of multiple axes Extended motion functions such as Virtual Axis, CAM Profiles, Electronic Gear, interpolation, fast response inputs and outputs Advanced application function blocks such as Flying Shear, Rotary Knife, Grouping/Ungrouping and Clamping

Motion Controllers

Synchronise up to 8 axes on CANmotion

Powerful motion functions

2 D Interpolation Virtual Axis CAM Profiles

HMI controllers Magelis XBTGT/GK All-in-one device, CANopen Embedded motion functions for independent axes

Logic controllers Modicon M238 or M258 Flexible and adaptable, PTO or CANopen Embedded motion functions for independent axes

Motion controllers Modicon LMC058 High performance, CANopen and CANmotion Advanced motion functions for synchronised axes

Lexium Servo Drives & Motors

Lexium 32 is the perfect drive system for applications involving high-precision, dynamic positioning.

The Lexium 32 servo range consists of three high-performance book-size servo drive models Lexium 32 Compact, Lexium 32 Advanced and Lexium 32 Modular and two motor families the versatile medium-inertia Lexium BMH and the dynamic low-inertia Lexium BSH.

Simplicity throughout the entire lifecycle of your machine

Fast engineering with powerful integration and design software (motor sizing, CAD and cabinet drawings, support for PLCopen libraries, commissioning software SoMove) reduce time-to-market Simplified installation with easy access to removable, colour-coded connectors, memory cards and multi-loader Memory cards and standardised FDR function for fast device replacement Safe Torque Off safety function on board

1.6 kHz 4x

speed bandwidth

continuous current = peak current

Openness and modularity

Intelligent, modular product concept responds to all requirements Large selection of fieldbus modules for fast integration into your architecture 3 encoder modules for machine encoder/second motor encoder Safety module for additional safety functions I/O Module with analog and digital I/O

Modularity

3 encoder modules = 8 technologies + 5 fieldbuses + safety module + I/O module

Power and performance

Easy, optimised auto-tuning for different levels of expertise Superior motor control Intelligent vibration and jerk suppression for long machine life

Compactness

Superior power density and sideby-side mounting for extremely small footprint

Top-notch, flange-compatible motor range

Lexium BMH for applications requiring robust load adaptation and plug-and-play motion tuning with maximum ease Lexium BSH for highly dynamic applications

Lexium 32 Compact for communication via +/- 10V or pulse train input

Lexium 32 Advanced for CANopen or CANmotion architectures

Lexium 32 Modular is open for the world of motion with numerous modules

Lexium BMH is extremely versatile

Lexium BSH is highly dynamic

Lexium Integrated Drives

The Lexium Integrated Drives range allows for extremely space-saving decentralised motion solutions.

The Lexium integrated drives range comprises motor, positioning controller, power electronics, fieldbus and Safe Torque Off* safety function in an extremely compact single device. Lexium integrated drives are available with all important motor technologies (servo, brushless DC, stepper). Compact and cost-effective

Decentralised motion Save up to

An unprecedented level of integration for new dimensions in machine planning, design and installation Reduced cabinet size, less air conditioning in cabinet, less wiring and smaller machine footprint all result in reduced complexity and cost The full power and performance of a complete drive with a motor with dimensions as small as 36 x 48 x 52 mm (W x L x H, Lexium ILP/ILT)

50%

of space in the control cabinet. Reduce cabling by up to

Flexible and modular machine concepts

Three motor technologies - servo, brushless DC, stepper - allow you to combine the individual benefits of each technology: dynamics, flexibility, precision 8 fieldbuses for seamless integration into industrial automation environments (RS 485, Profibus DP, CANopen, DeviceNet, Ethernet Powerlink, EtherCAT, Modbus TCP, EtherNet/IP) Versatile connection via PCB connectors or industrial connectors

40% 25%

Cut the installation time by up to

Simple

Easy and reduced wiring Integrated EMC filter* Fast and simple commissioning with user-friendly commissioning software PLCopen application function blocks included* Safe Torque Off safety on board* Stand-alone device with controller inside (Lexium ILP) * Lexium ILA, Lexium ILE, Lexium ILS

350.000

Lexium ILx reliably operating all over the globe, we are the world market leader in the area of compact drives.

With more than

Lexium ILE with brushless DC motor

Lexium ILA with AC synchronous servo motor

Lexium ILS with 3-phase stepper motor

Lexium ILP/ILT with 2-phase stepper motor

Lexium Stepper Drives & Motors

Lexium SDx drives and motors are used for short-distance positioning applications requiring maximum accuracy and high torque.

The Lexium SDx stepper motor drive range consists of two high-precision stepper drive lines the three-phase stepper drives Lexium SD3 and the two-phase stepper drives Lexium SD2. These drive lines are complemented by two perfectly matched stepper motor families Lexium BRS3 three-phase stepper motors and Lexium BRS2 two-phase stepper motors. True simplicity

No encoder systems required Plug & play commissioning without software Safe Torque Off safety function on board* High torque ensures that no gearbox is required in most applications Automatic current reduction

High-precision performance

Superior positioning accuracy The Lexium SDx drives and sinusoidal commutation of the motors enable practically resonance-free operation High power, 5 motor sizes from 0.07 to 16.5 Nm Synchronised motion via CANmotion*

Plug & play commissioning Connect the stepper motor to the drive, set the current and the step resolution ready for use! Maximum accuracy With step angles of

Extreme flexibility and compactness

Control via Pulse/Direction or fieldbus (CANopen, Modbus, Profibus DP) Large choice of power classes, accessories and options Compact drives (45 x 37 x 59 mm, W x H x D, Lexium SD2) and high power density motors

0.1

*Lexium SD3 28

Lexium SD328 3-phase stepper drive CANmotion architectures

Lexium BRS3 3-phase stepper motors

Lexium SD2 2-phase stepper drive

Lexium BRS2 2-phase stepper motors

Lexium Linear Motion

Designed for maximum flexibility, performance and cost-effectiveness, this range offers solutions for all linear movements in the automation industry from single-axis to multi-axis systems.

Lexium Linear Motion is a comprehensive linear motion range comprising Lexium PAS portal axes, Lexium TAS linear tables, Lexium CAS cantilever and telescopic axes and Lexium MAX multi-axis systems.

Solutions for all linear motion tasks

For axis systems below, above and next to the working area, with any combination of arrangements Up to three dimensions with stroke lengths of up to 5,500 mm Any combination of axis types

Modular kit system for consistent, easy mounting and maintenance

Lexium MAX multi-axis concept This innovative system allows for virtually infinite combinations of all single-axis types to create your own unique multi-axis system.

Axes with identical adaptation and motor interfaces Large selection of versions, e.g. for special ambient conditions (corrosion-resistant) Common spare parts Optimised parts logistics

Customised and complete solutions

Single-axis and multi-axis systems adapted to individual requirements in terms of length and stroke, precise to the millimetre Available with mounted motors and/or gearboxes Complete systems available including controllers, drives and motors

Complete mechanical solution

Completely pre-assembled with energy supply chain. minutes for motor replacement due to flexible adaptation

<5

Lexium MAX Multi-axis systems for 2 or 3 dimensional positioning solutions

Lexium CAS Standardised cantilever and telescopic axes

Lexium PAS Portal axes with fixed axis body and moving carriage

Consistency Across the Board

Lexium 32

servo drive

Motion Products Controllers Servo Drives & Motors Stepper Drives & Motors Integrated Drives Linear Motion

Our motion range is part of our complete Motion & Drives offering. Our efforts to make machine design even more effective for you go far beyond, for example, designing products for identical communication protocols.

Benefit from maximum synergies across different product ranges:

Altivar 32

variable speed drive

Drive Products Soft Starters Compact Drives Standard Drives Dedicated Drives Engineered Drives

Benefits

Reduced design and engineering efforts Optimised cabinet size and layout Optimised parts logistics and inventory

Common tools, software and functionality

Multiloader to upload and store configurations with power off Graphic display terminal to read and adjust parameters in many languages Bluetooth for wireless commissioning and maintenance

Identical mounting and wiring concepts

Book size, same heights for side-by-side mounting Removable motor connector Daisy chaining

Common software support

PLCopen libraries Integration files (EPLAN and CAD)

SoMove and SoMove Mobile, SoMachine with identical functionality for both drives, where applicable

Common accessories

Fieldbus modules EMC filters Braking resistors Mains reactors Cables

Common functionality Identical HMI Identical safety design and functionality (STO, SLS, SS1)

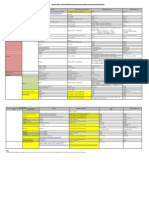

Quick Reference Guide

Product Ranges Controllers Lexium Servo Drives

Description

The Flexible Machine Control approach provides the customer with a complete range of controllers from HMI controllers and logic controllers to motion controllers, all with embedded motion functions.

The Lexium 32 servo range consists of three highperformance book-size servo drive models Lexium 32 Compact, Lexium 32 Advanced and Lexium 32 Modular and two motor families the versatile medium-inertia Lexium BMH and the dynamic low-inertia Lexium BSH.

Application

Flexible Machine Control brings maximum flexibility and unprecedented levels of optimisation to put the customer in full control. The controllers handle the standard logic of the machine and control motion.

Lexium 32 is the perfect drive system for all applications involving high-precision, dynamic positioning.

Technical information

All controllers: Embedded motion functions for independent axes (PLCopen and manufacturer-specific functions blocks) 6 programming languages (IEC 1131-3) Large choice of digital, analogue and expert IO modules Communication interfaces (depending on the controller type): USB, Ethernet, Serial, Profibus DP, CANopen, PTO LMC058 motion controller: 4 synchronised axes in 2 ms with CANmotion (maximum 8 axes) Extended motion functions (Virtual Axis, CAM profiles, Electronic Gear, interpolation) Encoder master input Fast response inputs/outputs embedded (high speed counters, position capture, reflex outputs, etc.) 64 Mbytes of RAM

Power range: 0.15 to 7 kW Voltage range: 115 to 240 VAC, 400 to 480 VAC Speed: up to 8000 rpm Torque: up to 84 Nm Communication interfaces: CANopen, CANmotion, Profibus DP, DeviceNet, EtherNet/IP, EtherCAT

Safety function (STO) on board Enhanced Safety Module (SS1, SS2, SLS, SOS) Encoder module for digital and analog encoders and resolvers I/O Modul with analog and digital I/O

Machines

Packaging machines Material handling machines Material working machines On-the-fly working machines Assembling machines

Packaging machines Material handling machines Material working machines Assembling machines

Lexium Integrated Drives

Lexium Stepper Motor Drives

Lexium Linear Motion

The Lexium ILx Integrated Drives comprise motor, positioning controller, power electronics, fieldbus and Safe Torque Off safety function in an extremely compact single device. Lexium ILx Integrated Drives are available with all important motor technologies (servo, brushless DC, stepper).

The Lexium SDx stepper motor drive range consists of two high-precision stepper drive lines the three-phase stepper drives Lexium SD3 and the two-phase stepper drives Lexium SD2. These drive lines are complemented by two perfectly matched stepper motor families Lexium BRS3 three-phase stepper motors and Lexium BRS2 two-phase stepper motors.

Lexium Linear Motion is a comprehensive linear motion range comprising Lexium PAS portal axes, Lexium TAS linear tables, Lexium CAS cantilever and telescopic axes and Lexium MAX multi-axis systems.

Lexium Integrated Drives allow for extremely space-saving decentralised motion solutions.

Lexium SDx stepper drives and motors are used for short-distance positioning applications requiring maximum accuracy and high torque.

The Lexium Linear Motion products are designed for maximum flexibility, performance and cost-effectiveness. This range offers products for all linear movements in the automation industry from single-axis to multi-axis systems.

Power range: 100 to 370 W Voltage range: 24 to 48 VDC, 115 to 240 VAC Speed: up to 9000 rpm Torque: up to 12 Nm Communication interfaces: RS485, CANopen, Profibus DP, DeviceNet, EtherNet/IP, EtherCAT, Ethernet POWERLINK, Modbus TCP, Pulse/Direction Safety function (STO) on board (Lexium ILA, Lexium ILE, Lexium ILS) Stand-alone device with controller inside (Lexium ILP)

Power range: up to 750 W Voltage range: 24 to 48VDC,115 to 240 VAC Speed: up to 1000 rpm Torque: up to 16.5 Nm Communication interfaces: CANopen, CANmotion, Profibus DP or Pulse/Direction

Single axes: Stroke up to 5.5 m Load up to 150 kg Speed up to 8 m/s Multi axes: Stroke up to 5.5 m Load up to 300 kg Speed up to 8 m/s Available as individual components or completely pre-assembled, customised systems with drives and motors

Safety function (STO) on board (Lexium SD3 28)

Format adjustment Printing machines Material handling machines

Printing machines Labelling machines Screen printing machines

Material handling machines Material working machines On-the-fly working machines Assembling machines

Schneider Electric Industries SAS

DIA7ED1091101EN

Head Office 35, rue Joseph Monier CS 30323 92506 Rueil-Malmaison Cedex France www.schneider-electric.com Due to evolution of standards and equipment, characteristics indicated in texts and images in this document are binding only after confirmation by our departments. Concept, text: Dr. Jan Vester Design: BrainFactory Photos: Schneider Electric Printing:

ART. 837678

Date : 09/2011

You might also like

- General Motion Control: A Complete Range of Motion Products For Efficient Machine AutomationDocument47 pagesGeneral Motion Control: A Complete Range of Motion Products For Efficient Machine AutomationDan PopescuNo ratings yet

- Drive System Rexroth Indradrive: Complete, Intelligent and SafeDocument136 pagesDrive System Rexroth Indradrive: Complete, Intelligent and Safestgpereira100% (1)

- Compact Machine Solutions: Increased Capabilities To Maximize Your Small and Medium Size MachinesDocument50 pagesCompact Machine Solutions: Increased Capabilities To Maximize Your Small and Medium Size MachinesJosé HeinNo ratings yet

- MovidriveDocument20 pagesMovidriveMarlon Ly BellidoNo ratings yet

- Danfoss VLT FC300 VLT Automation Drive DKDPB13C102Document16 pagesDanfoss VLT FC300 VLT Automation Drive DKDPB13C102hoor24332No ratings yet

- CD en 01+Sma+BrochureDocument16 pagesCD en 01+Sma+Brochureamir12345678No ratings yet

- Infineon - Brochure - Motor ControlDocument42 pagesInfineon - Brochure - Motor ControlRyan AngelesNo ratings yet

- Nidec Elevator DriveDocument16 pagesNidec Elevator DriveDarshanNo ratings yet

- Cartision Scalable Mechatronic Solutions 2012 3Document12 pagesCartision Scalable Mechatronic Solutions 2012 3Monark HunyNo ratings yet

- SchneiderDocument64 pagesSchneiderJhon Benites TenorioNo ratings yet

- 71511en1208 PDFDocument122 pages71511en1208 PDFCristopher EntenaNo ratings yet

- KEB Automation Catalog 2019 5Document272 pagesKEB Automation Catalog 2019 5سليم درباشيNo ratings yet

- ACTIA BusCoach 2011 ENDocument16 pagesACTIA BusCoach 2011 ENhackgames1488No ratings yet

- DELTA - IA-Delta - Motion - Control - Solution - Based - On - CODESYS - C - EN - 20201102Document24 pagesDELTA - IA-Delta - Motion - Control - Solution - Based - On - CODESYS - C - EN - 20201102Igor LapkoNo ratings yet

- Servomotors: Totally Drives - The Widest Range of ServomotorsDocument12 pagesServomotors: Totally Drives - The Widest Range of ServomotorsRaj ChavanNo ratings yet

- Ecodrive FinalDocument24 pagesEcodrive FinalChris WrightNo ratings yet

- Rexroth EcoDrive The Complete Servo Drive SolutionDocument23 pagesRexroth EcoDrive The Complete Servo Drive Solutiontomem666No ratings yet

- Motion Controller Modicon LMC058Document10 pagesMotion Controller Modicon LMC058Soon KooiNo ratings yet

- AMC-servo Drive OverviewDocument28 pagesAMC-servo Drive OverviewjoonimNo ratings yet

- Winning: The AssociationDocument4 pagesWinning: The AssociationMostafa EidNo ratings yet

- Catalog PDFDocument448 pagesCatalog PDFykuscuNo ratings yet

- Motores SiemensDocument821 pagesMotores SiemensAngie Romero100% (2)

- Unity ProDocument8 pagesUnity Prodongotchi09No ratings yet

- Drive Solutions: We EngineerDocument8 pagesDrive Solutions: We EngineerDoDuyBacNo ratings yet

- 5939 VM600 Integrated-BrochureDocument8 pages5939 VM600 Integrated-BrochurescribdkhatnNo ratings yet

- Manual VDF SiemensDocument332 pagesManual VDF SiemensMarco Rojas100% (1)

- Mentor MPDocument21 pagesMentor MPiampedrooNo ratings yet

- Bosch Rexroth Innovations 2013Document36 pagesBosch Rexroth Innovations 2013back1949No ratings yet

- Masterdrives Motion ControlDocument16 pagesMasterdrives Motion ControlRaj ChavanNo ratings yet

- Catalogo Completo Servomotores SiemensDocument224 pagesCatalogo Completo Servomotores SiemensFabricioST100% (1)

- Atmel AutomotiveDocument16 pagesAtmel AutomotiveKinga ZiewiecNo ratings yet

- 1769 pp012 - en eDocument2 pages1769 pp012 - en eAkio López HatanakaNo ratings yet

- Sinumerik: Sinumerik 810D The Compact Digital WizardDocument9 pagesSinumerik: Sinumerik 810D The Compact Digital WizardAl ZanoagaNo ratings yet

- Ecodrive Cs The Compact Servo Drive Solution: Universal, Small and EconomicalDocument6 pagesEcodrive Cs The Compact Servo Drive Solution: Universal, Small and EconomicalseregeNo ratings yet

- Modicon Premium 8000BR1063Document8 pagesModicon Premium 8000BR1063Buss BussNo ratings yet

- Universal drive performance and flexibilityDocument10 pagesUniversal drive performance and flexibilityTibor DanielNo ratings yet

- VLT Automation Drive FC 360 PDFDocument16 pagesVLT Automation Drive FC 360 PDFMinh NguyễnNo ratings yet

- Airbag FsDocument2 pagesAirbag FsSanja StošićNo ratings yet

- Motion Sensing and Control ProductsDocument64 pagesMotion Sensing and Control Productsekitani6817No ratings yet

- Alvitar 1Document64 pagesAlvitar 1Nano SalamNo ratings yet

- Motor Control DesignDocument6 pagesMotor Control Designkarthik16eeeNo ratings yet

- Kollmorgen Servo Systems 2011 CatalogDocument80 pagesKollmorgen Servo Systems 2011 CatalogElectromateNo ratings yet

- CNC Controls CNC Controls CNC Controls CNC Controls - SINUMERIK 840D Sinumerik 840D Sinumerik 840D Sinumerik 840DDocument7 pagesCNC Controls CNC Controls CNC Controls CNC Controls - SINUMERIK 840D Sinumerik 840D Sinumerik 840D Sinumerik 840DSam eagle goodNo ratings yet

- Servo Motors: Product DataDocument52 pagesServo Motors: Product DataAnoj Pahathkumbura100% (1)

- FC51Document8 pagesFC51Nguyễn Minh TríNo ratings yet

- Motor Siemenes 1laDocument113 pagesMotor Siemenes 1laenicolas2No ratings yet

- Studi Penerapan Metode Island OperationDocument8 pagesStudi Penerapan Metode Island OperationSyarifah FebriaNo ratings yet

- Compax3Brochure Sept2010Document20 pagesCompax3Brochure Sept2010cartunesNo ratings yet

- MTXDocument24 pagesMTXmmkattaNo ratings yet

- Iasimp Qr028 en eDocument4 pagesIasimp Qr028 en eHvictoria MadridNo ratings yet

- Brochure Simatic-Controller enDocument104 pagesBrochure Simatic-Controller enMiloš PopovićNo ratings yet

- Cat Motor USA WebDocument52 pagesCat Motor USA WebVamshi Kumar Reddy MNo ratings yet

- Woodward MicroNet™ Plus - Product SpecificationDocument4 pagesWoodward MicroNet™ Plus - Product SpecificationMagoroku D. YudhoNo ratings yet

- Practical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11From EverandPractical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11No ratings yet

- Digital Electronics, Computer Architecture and Microprocessor Design PrinciplesFrom EverandDigital Electronics, Computer Architecture and Microprocessor Design PrinciplesNo ratings yet

- Covers Bellows Lift Covers SectionDocument33 pagesCovers Bellows Lift Covers SectionasritaipNo ratings yet

- Ar Rahnu Survey2012Document2 pagesAr Rahnu Survey2012Azar HairussaniNo ratings yet

- CoolTek House Ground Cooling of Air, FINAL VERSION, G. Reimann, H. Boswell and S. Bacon. SB07Document8 pagesCoolTek House Ground Cooling of Air, FINAL VERSION, G. Reimann, H. Boswell and S. Bacon. SB07asritaipNo ratings yet

- Autovation SDN BHDDocument1 pageAutovation SDN BHDasritaipNo ratings yet

- Linear Bearings-HiwinDocument0 pagesLinear Bearings-Hiwinqi_1986No ratings yet

- ZelioDocument31 pagesZelioZaid MahdiNo ratings yet

- Tb6560 Stepping Motor Driver ..Document1 pageTb6560 Stepping Motor Driver ..asritaipNo ratings yet

- Application Form For Credit FacilitiesDocument1 pageApplication Form For Credit FacilitiesasritaipNo ratings yet

- GA 713 BV/NV Configuration Option Progamming Card: Insert This End FirstDocument5 pagesGA 713 BV/NV Configuration Option Progamming Card: Insert This End FirstasritaipNo ratings yet

- PLC Act AnswersDocument2 pagesPLC Act AnswersbsmaldeniyaNo ratings yet

- NTN's Guide to Needle Roller BearingsDocument80 pagesNTN's Guide to Needle Roller Bearingslaurentiucos18100% (1)

- QA NA Ballscrews 101Document260 pagesQA NA Ballscrews 101asritaipNo ratings yet

- NTN Roller Bearing HandbookDocument84 pagesNTN Roller Bearing HandbookKok Toong FattNo ratings yet

- Introduction To Programmable Logic Controllers (PLC'S) : Industrial Control Systems Fall 2006Document47 pagesIntroduction To Programmable Logic Controllers (PLC'S) : Industrial Control Systems Fall 2006Hamidreza MoaddeliNo ratings yet

- V KV Soft ch00 2Document105 pagesV KV Soft ch00 2mgkso706No ratings yet

- 17-Surface Roughness and Machining Symbols FullDocument17 pages17-Surface Roughness and Machining Symbols FullasritaipNo ratings yet

- Ar Rahnu Survey2012Document2 pagesAr Rahnu Survey2012Azar HairussaniNo ratings yet

- GT&DDocument37 pagesGT&DasritaipNo ratings yet

- SKF Bearing Installation and MaintenanceDocument146 pagesSKF Bearing Installation and MaintenanceDefinal ChaniagoNo ratings yet

- 7 Ways To Work SmarterDocument2 pages7 Ways To Work SmarterasritaipNo ratings yet

- Geneva MechanismDocument12 pagesGeneva Mechanismsarodesarang4750No ratings yet

- StepselDocument108 pagesStepselGerman Fjmg GjtdNo ratings yet

- DK4023 CH 8Document13 pagesDK4023 CH 8asritaipNo ratings yet

- DK 4023 FMDocument11 pagesDK 4023 FMasritaipNo ratings yet

- Simp ValvesguideDocument27 pagesSimp ValvesguidevenkateshNo ratings yet

- Schneider Electric - Lexium Stepper Motor & DriveDocument8 pagesSchneider Electric - Lexium Stepper Motor & DriveasritaipNo ratings yet

- Jig & FixtureDocument155 pagesJig & FixtureasritaipNo ratings yet

- Aluminum Roughing & FinishingDocument2 pagesAluminum Roughing & FinishingasritaipNo ratings yet

- Simp ValvesguideDocument27 pagesSimp ValvesguidevenkateshNo ratings yet

- SYSVRF CatalogueDocument39 pagesSYSVRF CatalogueSilas MirandaNo ratings yet

- Royal Enfield and Amal Spares Guide to Checking Bullet ElectricsDocument2 pagesRoyal Enfield and Amal Spares Guide to Checking Bullet Electricsmanri77No ratings yet

- Quiz Questions For DLD LabDocument6 pagesQuiz Questions For DLD LabGerald Carson100% (1)

- 80 Channel System For Various Interior Measurement ScenariosDocument2 pages80 Channel System For Various Interior Measurement ScenariosXVJNo ratings yet

- Step Response Unit ResponseDocument6 pagesStep Response Unit ResponsetirsollantadaNo ratings yet

- TFT LCD Specification for 3.5Document36 pagesTFT LCD Specification for 3.5kumaraswamyhollavNo ratings yet

- W 0700m6 - Gas Mixer PDFDocument5 pagesW 0700m6 - Gas Mixer PDFPopa MihaiNo ratings yet

- Diesel Engine Fire Pump Controller (GPD Model)Document9 pagesDiesel Engine Fire Pump Controller (GPD Model)haryNo ratings yet

- LTE Logical Channels (What Info is TransferredDocument13 pagesLTE Logical Channels (What Info is TransferredAnshul GuptaNo ratings yet

- Inverter 12VDC To 220VAC 100 Watt by Power Transistor 2N3055Document19 pagesInverter 12VDC To 220VAC 100 Watt by Power Transistor 2N3055Bank100% (1)

- 4 (DC Ohmmeter)Document14 pages4 (DC Ohmmeter)Mohd Hafizat Ahmad ZikriNo ratings yet

- MT506TV46 DatasheetDocument2 pagesMT506TV46 DatasheetJederVieiraNo ratings yet

- DC Compound Motor Characteristics and TestingDocument5 pagesDC Compound Motor Characteristics and TestingDionimar DiscionNo ratings yet

- Protection Coordination Back UpDocument35 pagesProtection Coordination Back UpJohn Paul Inovero JavierNo ratings yet

- Civil Engineering - یناتسراش ایرایزادنەئ: One Year Higher Diploma StudyDocument6 pagesCivil Engineering - یناتسراش ایرایزادنەئ: One Year Higher Diploma StudyZhiwar oramariNo ratings yet

- 74738Document12 pages74738sontuyet82No ratings yet

- IM300 Manual EN 1SXF470006M0201 RevCDocument109 pagesIM300 Manual EN 1SXF470006M0201 RevCDaniela NogueiraNo ratings yet

- Est3 Remote Annunciators: 3-Anncpu3, 3-Lcdann, 3-6ann, 3-10ann, 3-Evxxx, 3-4annDocument4 pagesEst3 Remote Annunciators: 3-Anncpu3, 3-Lcdann, 3-6ann, 3-10ann, 3-Evxxx, 3-4annrupali patilNo ratings yet

- PEE, IIEE Fellow, APEC Engr., ACPE: Power System Analysis I (Electrical Transmission Lines)Document27 pagesPEE, IIEE Fellow, APEC Engr., ACPE: Power System Analysis I (Electrical Transmission Lines)Hendrick Brian QuezaNo ratings yet

- Catalgogo de Productos AdiDocument194 pagesCatalgogo de Productos AdiGustavoNo ratings yet

- Pathfinder Manual 2012Document192 pagesPathfinder Manual 2012shawqiNo ratings yet

- Shindengen F072-1847335Document46 pagesShindengen F072-1847335Jm TechNo ratings yet

- Features: ISL95835, ISL95837Document2 pagesFeatures: ISL95835, ISL95837Encluse MaxNo ratings yet

- Ex 6 MicrowaveDocument2 pagesEx 6 Microwavevuthiloan08No ratings yet

- Paper Presentation On Mobile Computing 1Document5 pagesPaper Presentation On Mobile Computing 1arulbenjaminchandru67% (3)

- Ifm Electronic Part Number List & Price List 型号清单和价格表Document85 pagesIfm Electronic Part Number List & Price List 型号清单和价格表Bonnie Comen KimTai0% (1)

- Logic Circuit Design Lab Manual1 - 2 PDFDocument61 pagesLogic Circuit Design Lab Manual1 - 2 PDFAkhil Kumar SNo ratings yet

- Data SheetDocument47 pagesData Sheetestevao_moraesNo ratings yet

- OLTC - Circulating CurrentDocument16 pagesOLTC - Circulating CurrentAsif MominNo ratings yet

- 1-SOP For Operation of LV Panel PDFDocument21 pages1-SOP For Operation of LV Panel PDFFareh Khan100% (1)