Professional Documents

Culture Documents

High-performance bifurcated axial fans technical guide

Uploaded by

blindjaxxOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High-performance bifurcated axial fans technical guide

Uploaded by

blindjaxxCopyright:

Available Formats

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

BIFURC ATED AXIAL FLOW FA NS

HIGH PERFORMANCE, LOW MAINTENANCE, 'MOTOR OUT OF AIRSTREAM' FOR COMPLETE PEACE OF MIND.

292

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

BENEFITS

HIGH TEMPERATURE PERFORMANCE

The standard bifurcated unit is suitable for temperatures up 90C. High temperature options available up to 230C.

TESTED TO THE HIGHEST STANDARDS

Air performance to BS848 (part 1) 2007 and ISO5801 (part1) 2007 with acoustic performance to AMCA300. All carried out at our own test facilities to ensure the most accurate performance figures and noise data is provided, constantly monitored to give you up to date information you can rely on.

STOCK AVAILABILITY

Stock range available on next day delivery. Standard products available, to give peace of mind when designing those rapid turnaround projects. Contact Nuaire for details.

WIDE RANGE

The widest range of standard bifurcated axials available. A fan to match every application ensures maximum efficiency saving costly energy.

WARRANTY

Bifurcated fans have a 3 year warranty. Ecosmart Bifurcated fans have a 5 year warranty.

COMPREHENSIVE ANCILLARIES LOW MAINTENANCE

Motor out of airstream ensures the unit is not effected by contaminents yet is easily accessible. Including attenuators, frequency inverters, Ecosmart controls and mounting ancillaries all pre-selected for the individual fan to ensure a perfect match and eliminate any on-site fitting problems.

LONG LIFE HEAVY GAUGE GALVANISED STEEL CONSTRUCTION

Ensures strength, durability and protection from damage during installation and will be corrosion resistant.

FAN OPTIONS

Options within the bifurcated axus range, Two speed operation half and full, Flameproof motors to EExd IIBT4 for operation in systems with in duct ambient temp up to 230C.

ANCILLARIES FOR BIFURCATED AXIAL FANS

Mounting Brackets (pair) Typical Code: CMB31 Attenuator (standard, long and podded options). Typical Code: CA31S

Correct method of lifting using a spreader.

Matching Flange (single) Typical Code: CMF31

Guard Typical Code: CGD31

Flexible Connector (Single) Typical Code: CFC31

Inlet Cone Typical Code: CIC31

Anti-Vibration Mounts (for fan only) Codes: See Tables

Backdraught Damper Typical Code: CBD31

Inverters Refer to end of Axial section

Note: individual ancillary code numbers for each fan size are included on page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

293

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

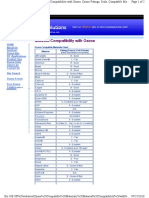

DUTY RANGE - BIFURCATED AXIAL FLOW UNITS

Below is an indication of the overall duty range, a selection of which is covered in this brochure. Please contact Nuaire (029) 20 858 200 for any duty outside the range indicated.

1000

ISO 5801 2007 AMCA 300

Casing

900

Type D Air Density 1.2 kg/m3

800

Code descriptions

700 Fan Static Pressure (Pa)

AXB 100 Z - 4 1 3 A T ES B C |

2 pole

600

|

2

|

3

| | | | | | | |

4 5 6 7 8 9 1011

1

1. 2. 3. 4. 5. 6.

500

400

4 pole

300

200 6 pole

100

Air volume ow rate (m3/s)

Bifurcated AXUS Long cased axial Case diameter in cms Impeller specification reference Motor speed in poles Impeller blade angle reference Electrical supply in Phases 1 = 230V, 50Hz 3 = 400V, 50Hz 7. Impeller material No letter = standard GRP A = Optional aluminium alloy 8. Other options (combinations possible) T = Two speed (full and half) F = Flameproof (EExd 11BT4) 2 = 90oC operation Z = Access door 9. ES = Full Ecosmart controls. BMS interfaces and commissioning controls (as 2 & 3 below) full compatibility with Ecosmart sensors. 10. B = BMS interfaces 0-10V, volt free run and fail indication. Commissioning/speed control built in. Adjustable trickle and boost if required. 11. C = Commissioning/speed control built in. Adjustable trickle and boost if required. All the above control options are preprogrammed with a soft start function. The above control options are provided in a purpose made module mounted remote from the unit. Other controls to be specified separately see selection table.

294

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 315MM 315mm 4 Pole/1440 rpm

90

ISO 5801 2007 AMCA 300

315mm 2 Pole/2800 rpm

350

ISO 5801 2007 AMCA 300

V

80

Type D Air Density 1.2 kg/m3

V

300

Type D Air Density 1.2 kg/m3

70 250 60

200 50

4

40 150

3

30

2 1

100

psF - Static Pressure (Pa)

psF - Static Pressure (Pa)

20

50

10

0 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Angleo RPM Unit A.V. kg Set Motor frame size 1 Phase (230V-50Hz) Motor FLC SC kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

315mm - 4 Pole/1440rpm 1 2 3 AXB31B-41*A 25o AXB31B-42*A 30o 1430 1430 1430 22 22 22 NAV1 71 NAV1 71 NAV1 71 0.37 0.37 0.37 2.9 2.9 2.9 11.6 11.6 11.6 0.37 0.37 0.37 1.06 1.06 1.06 3.5 3.5 3.5 67 71 74 72 76 79 66 69 72 63 67 70 59 62 66 51 55 58 46 50 53 43 46 49

AXB31B-43*A 35o

315mm - 2 Pole/2800rpm 4 5 6 AXB31B-21*A 25o AXB31B-22*A 30o AXB31B-23*A 35o 2810 2810 2810 27 22 22 NAV1 80 NAV1 80 NAV1 80 0.55 0.55 0.55 3.8 3.8 3.8 17.1 17.1 17.1 0.55 0.55 0.55 1.36 1.36 1.36 5.8 5.8 5.8 72 76 79 81 85 88 78 81 84 78 82 85 74 77 81 66 70 73 61 65 68 55 58 61

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

295

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 350MM 350mm 4 Pole/1440 rpm

160

ISO 5801 2007 AMCA 300

350mm 2 Pole/2800 rpm

600

ISO 5801 2007 AMCA 300

V

140

Type D Air Density 1.2 kg/m3

V

Type D Air Density 1.2 kg/m3

500

3

120

100

400

6 7

80

300

5

60

200

40

psF - Static Pressure (Pa)

psF - Static Pressure (Pa)

0 0.05 0.1 0.15 (m3/s) 0.2 0.25 0.3 0.35 0.4 0.45 0.5 0.55 0.6

100

20

0 0 0.2 0.4 0.6 0.8 1.0 1.2

qv - Air volume flow

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Angleo RPM Unit A.V. kg Set Motor frame size 1 Phase (230V-50Hz) Motor FLC SC kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

350mm - 4 Pole/1440rpm 1 2 3 4 AXB35A-41*A 25o AXB35D-41*A 25o 1430 1430 1430 1430 25 25 25 25 NAV2 71 NAV2 71 NAV2 71 NAV2 71 0.37 0.37 0.37 0.37 2.9 2.9 2.9 2.9 11.6 11.6 11.6 11.6 0.37 0.37 0.37 0.37 1.06 1.06 1.06 1.06 3.5 3.5 3.5 3.5 78 74 84 92 67 75 79 75 66 70 74 75 65 71 72 74 61 67 68 69 54 58 60 63 48 50 51 56 43 48 48 48

AXB35D-42*A 30o AXB35M-45*A 35o

350mm - 2 Pole/2800rpm 5 6 7 AXB35A-21*A 25o AXB35D-21*A 25o 2810 2810 2810 25 25 25 NAV2 80 NAV2 80 NAV2 80 0.55 0.55 0.55 3.8 3.8 3.8 17.1 17.1 17.1 0.55 0.55 0.55 1.36 1.36 1.36 5.8 5.8 5.8 80 82 83 80 84 92 83 91 88 85 87 89 80 84 84 73 77 77 68 70 72 60 65 65

AXB35B-22*A 30o

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

296

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 400MM 400mm 4 Pole/1440 rpm

160

ISO 5801 2007 AMCA 300

400mm 2 Pole/2800 rpm

700

ISO 5801 2007 AMCA 300

V

140

Type D Air Density 1.2 kg/m3

V

Type D Air Density 1.2 kg/m3

600

120 500

100 400 80

300 60

200 40

psF - Static Pressure (Pa)

1

20

psF - Static Pressure (Pa)

5

100

0 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

0 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Angleo RPM Unit A.V. kg Set Motor 1 Phase (230V-50Hz) frame Motor FLC SC size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

400mm - 4 Pole/1440rpm 1 2 3 4 AXB40M-41*A 20o AXB40M-42*A 25o AXB40M-43*A 30o AXB40F-43*A 35o 1410 1410 1410 1410 28 28 28 28 NAV2 71 NAV2 71 NAV2 71 NAV2 71 0.37 0.37 0.37 0.37 2.9 2.9 2.9 2.9 11.6 11.6 11.6 11.6 0.37 0.37 0.37 0.37 1.06 1.06 1.06 1.06 3.5 3.5 3.5 3.5 85 85 85 85 79 81 81 83 76 75 77 78 74 75 76 76 68 70 71 71 60 61 64 63 50 52 55 56 53 53 54 55

400mm - 2 Pole/2800rpm 5 6 7 AXB40M-21*A 20o AXB40M-21*A 25o AXB40M-22*A 30o 2700 2700 2700 31 31 31 NAV2 80 NAV2 80 NAV2 80 1.1 1.1 1.1 7.5 7.5 7.5 35 35 35 1.1 1.1 1.1 2.5 2.5 2.5 14 14 14 86 87 90 90 96 95 92 93 94 94 93 94 87 87 88 79 80 81 75 74 75 69 69 69

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

297

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 450MM 450mm 4 Pole/1440 rpm

200

ISO 5801 2007 AMCA 300

450mm 2 Pole/2800 rpm

900

ISO 5801 2007 AMCA 300

V

175

Type D Air Density 1.2 kg/m3

V

800

Type D Air Density 1.2 kg/m3

150

700

600 125 500 100 400

75 300

50 200

5 2

psF - Static Pressure (Pa)

1

25

3 4

0 0 0.25 0.5 0.75 1.0 1.25

psF - Static Pressure (Pa)

100

0 0 0.25 0.5 0.75 1.0 1.25

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit A.V. Angleo RPM kg Set Motor 1 Phase (230V-50Hz) frame Motor FLC size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW SC Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

450mm - 4 Pole/1440rpm 1 2 3 4 AXB45M-41*A AXB45M-42*A AXB45M-43*A AXB45M-45*A 20o 25o 30o 35o 1410 1410 1410 1410 32 32 32 32 NAV2 71 NAV2 71 NAV2 71 NAV2 71 0.37 2.9 0.37 2.9 0.37 2.9 0.37 2.9 11.6 11.6 11.6 11.6 0.37 0.37 0.37 0.37 1.06 1.06 1.06 1.06 3.5 3.5 3.5 3.5 89 87 90 95 82 82 81 83 81 79 80 81 78 78 80 81 71 73 75 75 64 66 69 70 55 58 61 63 57 56 57 60

450mm - 2 Pole/2800rpm 5 6 7 AXB45C-21*A AXB45M-21*A AXB45M-22*A 25o 20o 25o 2700 2700 2800 38 38 38 NAV2 80 NAV2 80 NAV2 90 1.1 1.1 7.5 7.5 35 35 1.1 1.1 1.5 2.5 2.5 3.25 14 14 17.8 86 88 89 97 95 82 90 95 81 93 97 78 87 89 71 80 83 64 74 77 55 69 72 72

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

298

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 500MM 500mm 4 Pole/1440 rpm

200

ISO 5801 2007 AMCA 300

500mm 2 Pole/2800 rpm

900

ISO 5801 2007 AMCA 300

V

175

Type D Air Density 1.2 kg/m3

V

800

Type D Air Density 1.2 kg/m3

700 150

600 125 500 100 400

75

6 1 2

300

3 4

50

psF - Static Pressure (Pa)

25

psF - Static Pressure (Pa)

200

100

0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8

0 0 0.5 1 1.5 2 2.5 3 3.5

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit A.V. Angleo RPM kg Set Motor 1 Phase (230V-50Hz) frame Motor FLC SC size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA3m

8K

500mm - 4 Pole/1440rpm 1 2 3 4 AXB50M-41*A AXB50M-42*A AXB50M-43*A AXB50M-45*A 20o 25o 30o 35o 1350 1350 1350 1350 43 43 43 43 NAV2 80 NAV2 80 NAV2 80 NAV2 80 0.75 0.75 0.75 0.75 5.7 5.7 5.7 5.7 19.8 19.8 19.8 21.5 0.75 0.75 0.75 0.75 2 2 2 2 9 9 9 9 89 84 99 97 81 81 84 88 80 80 82 83 81 81 83 84 76 76 78 79 68 70 71 74 60 62 65 70 57 57 62 62

500mm - 2 Pole/2800rpm 5 6 7 AXB50E-213A AXB50M-213A AXB50M-223A 30o 20o 25o 2857 2857 2857 49 49 49 NAV2 90 NAV2 90 NAV2 90 2.2 2.2 2.2 4.3 4.3 4.3 32 32 32 86 86 89 93 93 96 97 96 98 99 100 100 93 93 92 85 86 86 79 81 82 74 74 75

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

299

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 560MM 560mm 4 Pole/1440 rpm

250

ISO 5801 2007 AMCA 300

560mm 2 Pole/2800 rpm

900

ISO 5801 2007 AMCA 300

V

Type D Air Density 1.2 kg/m3

V

800

Type D Air Density 1.2 kg/m3

200 700

600 150 500

400 100 300

1 2

200

7 8

psF - Static Pressure (Pa)

50

4 3 5

psF - Static Pressure (Pa)

3 3.5

100

0 0 0.5 1 1.5 2 2.5

0 0 0.5 1 1.5 2 2.5 3 3.5 4

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit A.V. Angleo RPM kg Set Motor 1 Phase (230V-50Hz) frame Motor FLC SC size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

560mm - 4 Pole/1440rpm 1 2 3 4 5 AXB56M-41*A AXB56M-42*A AXB56M-43*A AXB56M-45*A AXB56D-45*A 20o 25o 30o 35o 45o 1350 1350 1350 1350 1350 43 43 43 43 43 NAV2 80 NAV2 80 NAV2 80 NAV2 80 NAV2 80 0.75 0.75 0.75 0.75 0.75 5.5 5.5 5.5 5.5 5.8 19.8 19.8 19.8 19.8 19.8 0.75 0.75 0.75 0.75 0.75 2 2 2 2 2 9 9 9 9 9 76 84 79 79 83 79 75 73 77 76 91 85 85 86 87 91 86 87 89 89 83 83 82 83 84 79 80 80 81 81 69 72 74 78 77 66 61 62 63 64

560mm - 2 Pole - 2800rpm 6 7 8 AXB56M-213A AXB56M-223A AXB56H-223A 20o 25o 30o 2880 2880 2890 55 55 55 NAV2 100 NAV2 100 NAV2 112 3 3 4 6.7 6.7 8 50 50 T23 91 86 92 96 94 96 101 106 102 103 114 103 96 102 97 89 98 92 84 95 86 78 87 78

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

300

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 630MM 630mm 4 Pole/1440 rpm

250

ISO 5801 2007 AMCA 300

630mm 2 Pole/2800 rpm

1100

ISO 5801 2007 AMCA 300

V

225

Type D Air Density 1.2 kg/m3

V

1000

Type D Air Density 1.2 kg/m3

200

900

800 175

700

150

600

125 500

5

100

6 1 2 3

400

4 7

300

75

psF - Static Pressure (Pa)

50

psF - Static Pressure (Pa)

0 0.5 1 1.5 2 2.5 3 3.5

200

25

100

0 0 1 2 3 4 5 6

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit A.V. Angleo RPM kg Set Motor 1 Phase (230V-50Hz) frame Motor FLC SC size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

630mm - 4 Pole/1440rpm 1 2 3 4 AXB63M-41*A AXB63M-42*A AXB63M-43*A AXB63M-45*A 20o 25o 30o 35o 1437 1437 1437 1437 80 80 80 80 NAV2 90 NAV2 90 NAV2 90 NAV2 90 1.1 1.1 1.1 1.1 9 9 9 9 30 30 30 30 1.1 1.1 1.1 1.1 2.5 2.5 2.5 2.5 12 12 12 12 86 90 93 95 85 85 85 89 86 86 88 90 87 86 88 89 80 80 81 82 74 76 77 78 65 69 71 73 62 62 64 66

630mm - 2 Pole/2800rpm 5 6 7 AXB63G-213 AXB63M-213 AXB63G-223 25o 20o 30o 2880 2859 2859 100 105 105 NAV5 100 NAV5 112 NAV5 112 3 4 4 6.7 8.4 8.4 50 T24 T24 91 95 91 103 102 103 98 101 100 102 102 104 99 99 100 93 92 94 86 87 88 77 78 79

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). *Insert number for correct phase. 1 = 1 phase, 3 = 3 phase. For ancillaries please refer to page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

301

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 710MM 710mm 6 Pole/960 rpm

250

ISO 5801 2007 AMCA 300

710mm 4 Pole/1440 rpm

500

ISO 5801 2007 AMCA 300

V

Type D Air Density 1.2 kg/m3

V

450

Type D Air Density 1.2 kg/m3

200

400

350

150

300

250

100

200

3 2 1

4 5

150

8 6

10 11

13 12 14

psF - Static Pressure (Pa)

psF - Static Pressure (Pa)

50 Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

100

50

Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit Angleo RPM kg A.V. Set Motor 1 Phase (230V-50Hz) frame Motor FLC SC size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

710mm - 6 Pole/960rpm 1 2 3 4 5 6 7 AXB71LF-611 AXB71LF-623 AXB71LF-633 AXB71LF-643 AXB71LF-653 AXB71LF-663 AXB71LF-673 10o 15o 20o 25o 30o 35o 40o 960 960 960 960 960 960 960 103 107 107 110 110 124 124 NAV5 80 NAV5 90 NAV5 90 NAV5 90 NAV5 90 NAV5 112 NAV5 112 0.37 2.9 11.6 0.75 0.75 1.1 1.1 2.2 2.2 2.4 2.4 4.3 4.3 5.9 5.9 9 9 11.6 11.6 23.6 23.6 73 75 77 80 84 86 88 82 85 89 88 87 89 91 83 84 84 85 87 87 88 84 83 83 83 84 85 86 80 79 79 79 79 80 80 75 75 76 76 75 76 77 66 67 68 68 69 71 72 59 60 61 61 62 63 64

710mm - 4 Pole/1440rpm 8 9 10 11 12 13 14 AXB71LF-413 AXB71LF-423 AXB71LF-433 AXB71LF-443 AXB71LF-453 AXB71LF-463 AXB71LF-473 10o 15o 20o 25o 30o 35o 40o 1420 110 1420 112 1420 112 1420 112 1420 112 1440 153 1440 153 NAV5 90 NAV5 100 NAV5 100 NAV5 112 NAV5 112 NAV3 132 NAV3 132 1.5 2.2 2.2 4 4 5.5 5.5 3.6 4.9 4.9 8.4 8.4 11.3 11.3 18.9 27 27 83 84 86 92 95 98 97 97 98 100 93 93 93 94 96 97 97 93 93 92 93 94 95 95 89 89 88 89 89 89 90 84 85 85 86 86 86 86 75 76 77 78 79 81 82 69 69 70 70 71 72 73

T18.5 89 T18.5 93 T27.1 95 T27.1 98

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). For ancillaries please refer to page 310.

302

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 800MM 800mm 6 Pole/960 rpm

200

ISO 5801 2007 AMCA 300

800mm 4 Pole/1440 rpm

450

ISO 5801 2007 AMCA 300

V

180

Type D Air Density 1.2 kg/m3

V

400

Type D Air Density 1.2 kg/m3

160

350

140

300

120

250

100

200

80

150

60

psF - Static Pressure (Pa)

psF - Static Pressure (Pa)

1

40

4 5

100

6 7

8 Podded attenuator resistance to airflow (Pa) (Unpodded negligible) 9

11 10 12 13 14

20

Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

50

10

12

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit Angleo RPM kg Motor 1 Phase (230V-50Hz) A.V. frame Motor FLC SC Set size kW amps amps 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K 4K Breakout dBA@3m

8K

800mm - 6 Pole/960rpm 1 2 3 4 5 6 7 AXB80LF-611A 10o AXB80LF-623A 15o 960 960 960 960 960 960 960 143 147 147 152 152 193 193 NAV3 80 NAV3 90 NAV3 90 NAV3 112 NAV3 112 NAV4 132 NAV4 132 0.37 2.9 11.6 1.1 1.1 2.2 2.2 3 3 4.3 4.3 5.9 5.9 6.4 6.4 11.6 11.6 23.6 23.6 35.2 35.2 73 75 77 80 84 86 88 82 85 89 88 87 89 91 83 84 84 85 87 87 88 84 83 83 83 84 85 86 80 79 79 79 79 80 80 75 75 76 76 75 76 77 66 67 68 68 69 71 72 63 62 62 63 64 65 66

AXB80LF-633A 20o AXB80LF-643A 25o AXB80LF-653A 30o

AXB80LF-663A 35o AXB80LF-673A 40o

800mm - 4 Pole/1440rpm 8 9 10 11 12 13 14 AXB80LF-413A 10o AXB80LF-423A 15o AXB80LF-433A 20o AXB80LF-443A 25o 1420 1430 1420 1440 1440 1460 1460 147 152 164 193 205 257 257 NAV3 90 NAV3 100 NAV3 112 NAV4 132 NAV4 132 NAV4 160 NAV4 160 1.5 3 4 5.5 7.5 11 11 3.6 6.8 8.4 10.7 14.5 20 20 18.9 42.8 86 86 92 92 92 95 98 100 102 97 97 97 98 98 99 100 96 95 94 95 96 97 98 92 92 91 91 91 93 94 87 88 88 88 88 89 90 80 81 82 83 84 86 89 72 72 71 72 73 74 76

T18.5 87 T25.7 91 T34.8 94 T40.0 100 T40.0 105

AXB80LF-453A 30o AXB80LF-463A 35o

AXB80LF-473A 40o

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). For ancillaries please refer to page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

303

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 900MM 900mm 6 Pole/920 rpm

300

ISO 5801 2007 AMCA 300

900mm 4 Pole/1440 rpm

700

ISO 5801 2007 AMCA 300

V

Type D Air Density 1.2 kg/m3

V

Type D Air Density 1.2 kg/m3

600

250

500

200

400

150

300

100

5

200

6 7

psF - Static Pressure (Pa)

50

Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

3 4

psF - Static Pressure (Pa)

100

Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

10

12

14

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Speed Unit Angleo RPM kg A.V. Set Motor frame size 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K Breakout dBA@3m

4K

8K

900mm - 6 Pole/920rpm 1 2 3 4 AXB90LF-613A AXB90LF-623A AXB90LF-633A AXB90LF-653A 10o 15o 20o 30o 920 945 945 960 200 214 214 255 NAV4 NAV4 NAV4 NAV4 90 112 112 132 1.1 2.2 2.2 4 4.3 5.9 5.9 9 11.6 23.6 T23.6 T16.2 83 86 88 93 90 92 94 96 91 93 96 95 91 92 93 93 86 87 87 86 84 84 85 82 81 81 82 79 67 68 71 70

900mm - 4 Pole/1440rpm 5 6 7 8 AXB90LF-413A AXB90LF-423A AXB90LF-433A AXB90LF-453A 10o 15o 20o 30o 1420 1440 1440 1460 214 243 255 307 NAV4 NAV4 NAV4 NAV6 112 132 132 160 4 5.5 7.5 11 8.4 10.7 14.5 20 T18.5 T25.7 T34.8 T40.0 93 95 97 103 99 102 104 105 100 103 105 104 100 101 103 102 96 96 97 95 94 94 94 92 91 91 91 88 76 78 80 79

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). For ancillaries please refer to page 310.

304

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

PERFORMANCE - BIFURCATED AXIAL FLOW UNITS - 1000MM 1000mm 6 Pole/920 rpm

300

ISO 5801 2007 AMCA 300

1000mm 4 Pole/1440 rpm

600

ISO 5801 2007 AMCA 300

V

Type D Air Density 1.2 kg/m3

V

Type D Air Density 1.2 kg/m3

250

500

200

400

150 Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

300

1

100

2 3 4

7 8

200

10 11

psF - Static Pressure (Pa)

50

psF - Static Pressure (Pa)

14 16

100

Podded attenuator resistance to airflow (Pa) (Unpodded negligible)

10

12

2.5

5.0

7.5

10.0

12.5

15.0

17.5

20.0

22.5

qv - Air volume flow (m3/s)

qv - Air volume flow (m3/s)

ELECTRIC AL & SOUND

Curve Unit No Code Blade Angleo Speed RPM Unit kg A.V. Set Motor frame size 3 Phase (400V-50Hz) In-duct inlet sound power levels dB re 1pW Motor FLC SC Octave band mid frequency Hz kW amps amps 125 250 500 1K 2K Breakout dBA3m

4K

8K

1000mm - 6 Pole/920rpm 1 2 3 4 5 6 AXB100LF-613A AXB100LF-623A AXB100LF-633A AXB100LF-643A AXB100LF-653A AXB100LF-663A 10o 15o 20o 25o 30o 35o 945 950 960 950 970 970 258 287 299 299 371 371 NAV4 NAV6 NAV6 NAV6 112 132 132 132 2.2 3 4 5.5 7.5 7.5 5.9 6.6 9 12.3 16 16 23.6 39.6 85 86 89 92 94 95 95 98 92 92 93 93 94 95 92 90 89 90 91 93 89 87 85 86 87 89 86 84 83 84 85 86 77 75 72 76 79 80 68 67 68 68 69 71

T16.2 87 T21.5 91 T36.8 95 T36.8 102

NAV49 160 NAV49 160

1000mm - 4 Pole/1440rpm 7 8 9 10 11 AXB100LF-413A AXB100LF-423A AXB100LF-433A AXB100LF-443A AXB100LF-453A 10o 15o 20o 25o 30o 1440 1460 1460 1465 1465 299 351 351 371 414 NAV6 132 7.5 11 11 15 18.5 14.5 20 20 27 34 T34.8 94 T40.0 95 T40.0 96 T65.0 100 T71.4 104 98 101 103 104 105 101 101 102 103 103 101 99 98 99 100 98 96 94 95 96 95 94 92 93 94 87 84 81 85 88 77 77 77 78 79

NAV49 160 NAV49 160 NAV49 160 NAV50 180

Notes relating to the table: The electrical and sound information in the table is nominal. Breakout dBA@3m is spherical, free field. Start currents (sc) are DOL other than for motors of 4kW and above which are Star Delta (T). For ancillaries please refer to page 310.

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

305

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

DIMENSIONS - AXUS BIFURCATED AXIAL FAN

C F= No. of G dia holes equi-spaced on H p.c.d.

B Flange

AIRFLOW Unit shown supported on optional mounting brackets and A.V. mounts E ctrs Optional AV mounts J ctrs K foot

DIMENSIONS (mm) & WEIGHTS

Code AXB31 AXB35 AXB40 AXB45 AXB50 AXB56 AXB63 AXB71 AXB80 AXB90 AXB100 A 315 350 400 450 500 560 630 710 800 900 1000 B 400 430 490 540 608 670 740 795 885 1000 1100 C 500 500 530 530 605 605 630 700 950 950 950 D 210 240 270 300 340 370 430 470 540 600 670 E 420 420 450 450 525 525 550 620 870 870 840 F 8 8 8 8 12 12 12 16 16 16 16 G 12 12 12 12 12 12 12 12 12 15 15 H 355 395 450 500 560 620 690 770 860 970 1070 J 220 250 290 330 380 420 500 540 590 670 770 K 270 300 340 380 430 470 550 600 650 750 850 Max. Weight Kg 22 25 31 38 49 55 84 153 257 307 414

306

029 2085 8200

AXIAL FA NS BIFURC ATED TECHNIC AL INFORMATION

CONSULTA NTS SPECIFIC ATION

FAN SPECIFICATION

The ventilation fan Unit shall be configured and arranged as detailed on the drawings and in accordance with the schedule of equipment and shall be of the AXUS Bifurcated (AXB) axial flow fan as manufactured by Nuaire, with motor out of the airstream. The units shall be manufactured from galvanised steel to BS EN10142 1991. Wiring must be direct to the motor terminal box by the contractor. The fan impeller and motor shall be selected to provide the most energy efficient solution conforming to part L regulations and shall be direct drive with IE2 high efficiency motors to BS5000 as standard and shall be foot mounted TEFV type with IP55 enclosures and class F insulation in accordance with BS4999 part 20. They shall have sealed for life ball bearings. Motors shall be prewired to an external electrical terminal box through weatherproof flexible conduit to IP55. The units shall be suitable for operation in airstream temperatures up to 90C. Optional high temperature versions are suitable in airstream temperatures of up to 230C. The impeller blades shall be of special aero-foil section giving excellent performance and low noise characteristic manufactured from cast aluminium alloy. All units shall be suitable for internal and external operation and can be installed any angle. The units will be provided complete with matching flanges, flexible connections, anti vibration mounts and all other necessary components to complete the installation and shall be in accordance with the manufacturers specification. The contractor shall allow for all necessary ductwork transformations to and from the fan unit and any associated components in accordance with the manufacturers recommendations, DW 144 and general good practice. Multiple IDC sockets for interconnection of sensors or fans using pre-plugged 4-core low voltage cable.

ECOSMART SYSTEM OPERATION

The Ecosmart controls will enable the unit to automatically vary its speed as it receives signals from one of the interconnected sensors. When the signal is received the fan shall either increase speed gradually until the required level is achieved or it will work on a trickle and boost principle. This will then move the fan duty point from trickle/background ventilation rate to the required boost ventilation rate. Both the trickle and boost rates are infinitely variable, easy to adjust and remove the need of a main balancing damper.

2. BMS INTERFACES

The fan unit shall be provided with the following integrated BMS interfaces. 0 - 10 volt contacts to provide a full BMS interface. This will enable the following functions:Switch the unit on/off. Switch from low speed to high speed. Full speed control facility. 2 No. Volt free contacts to provide fan run and failure indication to provide system status. An integrated commissioning/speed control to accurately commission the system, with minimum and maximum speeds easily adjusted via a miniature dial, as recommended in Part L. This will enable the unit to be configured to run between set parameters thus saving motor power and limiting noise.

3. COMMISSIONING SET UP

The fan unit shall be provided with an integrated commissioning/speed control to accurately commission the system, as recommended in Part L, minimum and maximum speeds easily adjusted via miniature dial. The commissioning set up facility directly controls the integrated speed control/frequency inverter.

CONTROL SPECIFICATION

The fan unit shall be supplied with one of the following control options (only available for three phase fan units):-

4. STANDARD CONTROLS

The unit shall be provided with a standard speed control or starter in accordance with the manufacturers recommendations. Bifurcated fans have a 3 year warranty. Ecosmart Bifurcated fans have a 5 year warranty. All equipment shall be as manufactured by Nuaire Ltd.

1. ECOSMART CONTROLS

The compact Ecosmart control system complete with all necessary controls to facilitate the operation of the ventilation system. It shall be come complete with an integral factory fitted Ecosmart PCB which will control the fan unit within the desired design parameters and provide the interface between all external control devices and the unit itself. The fan unit shall have the following energy saving components integrally mounted, pre-wired to interface with the purpose made PCB, all components pre-wired, configured and factory fitted by the manufacturer: Integral Frequency inverter/speed controller. Integral maximum and minimum speed adjustment for commissioning. Integral adjustable run on timer. Integral BMS interfaces 0-10V speed adjustment. Integral BMS interfaces Volt free failure and status indication. Integral background ventilation switch (trickle switch).

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

307

AXIAL FA NS ANCILLARIES TECHNIC AL INFORMATION

ANCILLARIES AXUS AXIAL FANS

Ancillary Code (mm) Description Mounting Brackets Mounting brackets supplied as pair. manufactured from heavy gauge steel. Matching Flange Flange supplied as single. Manufactured from galvanised steel. Flexible Connector Circular without flange. Flexible duct material is flameproof and heat resistant up to 132oC. The material is airtight and waterproof. Anti-vibration Mounts Resiliant rubber, for fan only. For further details on AV Mounts please contact Nuaire CFC25 CFC31 CFC35 CFC40 CFC45 CFC50 CFC56 CFC63 CFC71 CFC80 CMC90 CMC100 CMC112 CMC125 CMF25 CMF31 CMF35 CMF40 CMF45 CMF50 CMF56 CMF63 CMF71 CMF80 CMF90 CMF100 CMF112 CMF125 CMB25 CMB31 CMB35 CMB40 CMB45 CMB50 CMB56 CMB63 CMB71 CMB80 CMB90 CMB100 CMB112 CMB125 AX25 250 AX31 315 AX35 350 AX40 400 AX45 450 AX50 500 AX56 560 AX63 630 AX71 710 AX80 800 AX90 900 AX100 1000 AX112 1120 AX125 1250

Acoustic Jacket

Acoustic material laminated with 25mm foam. Complete with straps/buckles for security. For further details on Acoustic Jackets please contact Nuaire

Attenuator

Standard, Long, podded & long podded options.

CA25S CA25L CA25P CA25LP

CA31S CA31L CA31P CA31LP CDG31

CA35S CA35L CA35P CA35LP CDG35

CA40S CA40L CA40P CA40LP CDG40

CA45S CA45L CA45P

CA50S CA50L CA50P

CA56S CA56L CA56P

CA63S CA63L CA63P

CA71S CA71L CA71P

CA80S CA80L CA80P

CA90S CA90L CA90P

CA100S CA112S CA125S CA100L CA112L CA125L CA100P CA112P CA125P

CA45LP CA50LP CA56LP CA63LP CA71LP CA80LP CA90LP CA100LP CA112LP CA125LP CDG45 CDG50 CDG56 CDG63 CDG71 CDG80 CDG90 CDG100 CDG112 CDG125

Guard

Manufactured in heavy gauge galvanised steel with acid zinc plated steel mesh.

CDG25

Inlet Cone

manufactured in heavy gauge galvanised steel with a single bolted flange.

CIC25

CIC31

CIC35

CIC40

CIC45

CIC50

CIC56

CIC63

CIC71

CIC80

CIC90

CIC100

CIC112

CIC125

Backdraft Damper

Gravity operated damper manufactured from heavy gauge galvanised steel with pair of bolted flanges.

CBD25

CBD31

CBD35

CBD40

CBD45

CBD50

CBD56

CBD63

CBD71

CBD80

CBD90

CBD100 CBD112 CBD125

Controls

Choice of Inverter, electronic or transformer speed controls available. For further details on Controls please contact Nuaire

See page 310 for ancillaries

308

029 2085 8200

AXIAL FA NS ANCILLARIES TECHNIC AL INFORMATION

ANCILLARIES BIFURC ATED AXIAL FANS

Ancillary Code (mm) Description Mounting Brackets Mounting brackets supplied as pair. manufactured from heavy gauge steel. Matching Flange Flange supplied as single. Manufactured from galvanised steel. Flexible Connector Circular without flange. Flexible duct material is flameproof and heat resistant up to 132oC. The material is airtight and waterproof. Anti-vibration Mounts Resiliant rubber, for fan only. For further details on AV Mounts please contact Nuaire CFC31 CFC35 CFC40 CFC45 CFC50 CFC56 CFC63 CFC71 CFC80 CFC90 CFC100 CMF31 CMF35 CMF40 CMF45 CMF50 CMF56 CMF63 CMF71 CMF80 CMF90 CMF100 CMB31 CMB35 CMB40 CMB45 CMB50 CMB56 CMB63 CMB71 CMB80 CMB90 CMB100 AXB31 315 AXB35 350 AXB40 400 AXB45 450 AXB50 500 AXB56 560 AXB63 630 AXB71 710 AXB80 800 AXB90 900 AXB100 1000

Attenuator

Standard, Long, podded & long podded options. CA31LP

CA31S CA31L CA31P CA35LP CDG31

CA35S CA35L CA35P CA40LP CDG35

CA40S CA40L CA40P CA45LP CDG40

CA45S CA45L CA45P CA50LP CDG45

CA50S CA50L CA50P CA56LP CDG50

CA56S CA56L CA56P CA63LP CDG56

CA63S CA63L CA63P CA71LP CDG63

CA71S CA71L CA71P CA80LP CDG71

CA80S CA80L CA80P CA90LP CDG80

CA90S CA90L CA90P CA100LP CDG90

CA100S CA100L CA100P

Guard

Manufactured in heavy gauge galvanised steel with acid zinc plated steel mesh.

CDG100

Inlet Cone

manufactured in heavy gauge galvanised steel with a single bolted flange.

CIC31

CIC35

CIC40

CIC45

CIC50

CIC56

CIC63

CIC71

CIC80

CIC90

CIC100

Backdraft Damper

Gravity operated damper manufactured from heavy gauge galvanised steel with pair of bolted flanges.

CBD31

CBD35

CBD40

CBD45

CBD50

CBD56

CBD63

CBD71

CBD80

CBD90

CBD100

Controls

Choice of Inverter. For further details on Controls please contact Nuaire

See page 310 for ancillaries

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

309

AXIAL FA NS ANCILLARIES TECHNIC AL INFORMATION

ANCILLARIES FOR AXIAL FANS - DETAILS

C/L fan

Mounting Brackets

The AXUS mounting brackets are manufactured from heavy gauge galvanised steel and are supplied in pairs. (See table 1 for dimensions). Typical Code: CMB100 (100 = fan diameter in cm).

G H base fixing centres Holes match fan flanges

Matching Flange (Single)

Manufactured from galvanised steel matching flanges are supplied individually. (See table 1 for dimensions and weights). Typical code: CMF100 (100 = fan diameter in cm).

Flexible Connector (Single)

Circular without flanges. Flexible duct material is flameproof and resistant to heat up to 132C/400C, chemicals, ozone, oil and grease. The material is airtight, waterproof and tested to BS476 Part 7. (See table 1 for dimensions and weights). (Supplied complete with fixing straps). Typical Code: CFC100 (100 = fan diameter in cm) - 132C. CFCH100 (100 = fan diameter in cm) - 400C.

To match fan diameter

Guard (Single)

Manufactured from heavy gauge galvanised steel and acid zinc plated steel mesh. (See table 1 for dimensions and weights). Standard Accessory Losses (k). Flat type Finger guard 0.4. Typical Code: CGD100 (100 = fan diameter in cm) Pressure Drop (Pa) = 0.6 x k x Velocity (m/s).

Holes match fan flanges

Inlet Cone (Single)

Manufactured in heavy gauge galvanised steel with a single bolted flange. (See table 1 for dimensions and weights). Standard Accessory Losses (k). Low loss inlet cone 0.38. Typical Code: CIC100 (100 = fan diameter in cm) Pressure Drop (Pa) = 0.6 x k x Velocity (m/s).

Backdraught Damper (Single)

Gravity operated backdraught damper, manufactured from heavy gauge galvanised steel with a pair of bolted flanges. (See table 1 for dimensions and weights). Standard Accessory Losses (k) (Air stream operated) 0.4 Typical Code: CBD100 (100 = fan diameter in cm) - 132C (For horizontal mounting only). Pressure Drop (Pa) = 0.6 x k x Velocity (m/s).

C

310

029 2085 8200

AXIAL FA NS ANCILLARIES TECHNIC AL INFORMATION

ANCILLARIES FOR AXIAL FANS - DETAILS CONT. TABLE 1 DIMENSIONS (mm) & WEIGHTS

Inlet Guard Weight Kg 0.4 0.5 1 1.5 1.7 2.3 2.8 3.2 3.7 4 7 7 8 8 B/draught cone Weight Kg 1.5 2 2 3 4 5 6 9 11 13 20 23 32 40 Damper Weight Kg 6 7.5 9 11 14 16.5 20 22.5 27.5 35 55 66.5 80 88

Fan 250mm 310mm 350mm 400mm 450mm 500mm 560mm 630mm 710mm 800mm 900mm 1000mm 1120mm 1250mm

A 65 65 65 65 65 65 65 65 65 65 65 65 65 65

B 150 150 150 150 150 150 150 150 150 150 150 150 150 150

C 350 350 350 350 350 350 350 350 350 350 350 350 350 350

D 350 350 350 350 350 350 360 400 440 470 520 580 920 985

E 85 85 90 90 90 100 100 130 170 200 220 230 260 300

F 355 405 460 520 580 650 700 830 920 1050 1180 1300 1450 1600

G 170 210 240 270 300 340 370 430 470 540 600 670 750 830

H 150 220 250 290 330 380 420 500 540 590 670 770 870 920

Anti Vibration Mountings

Supplied as a set of 4. To select match isolated assembly weight to max Supporting weight shown on right. Typical code: NAV1 - Resilient Rubber NAV49 - Spring type.

C NAV1-5 Resilient Rubber

DIMENSIONS (mm) & WEIGHTS

Code NAV1 NAV2 NAV3 NAV4 NAV5 NAV6 NAV49 NAV50 NAV51 NAV52 NAV53 NAV54 NAV55 NAV56 NAV57 NAV58 Type Rubber Rubber Rubber Rubber Rubber Rubber Spring Spring Spring Spring Spring Spring Spring Spring Spring Spring B 30 40 40 40 40 50 77 77 77 87 87 87 87 87 87 87 C 50 75 75 75 75 100 76 76 76 127 127 127 127 127 127 127 Max Supporting Weight Kg 20.0 80.0 180.0 260.0 130.0 320.0 400.0 C

NAV6 Resilient Rubber B

480.0 520.0 600.0 700.0 800.0 950.0 1110.0 1270.0 1430.0 C B NAV49-58 Spring

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

311

AXIAL FA NS ANCILLARIES TECHNIC AL INFORMATION

IN-LINE CIRCULAR ATTENUATORS

A 'E' No. of holes tapped 'F' equi-spaced on 'G' P.C.D.

Attenuators and Pods (when fitted) shall be rigidly constructed from galvanised steel, internally lined with sound absorbing material not less than 100mm thick retained by galvanised steel perforated sheet. Attenuator end faces shall be drilled and tapped to match the flange details of the associated fan. Attenuator sound absorbing material shall be chemically inert, noncombustible, non-hydroscopic and vermin resistant. Attenuator shall be tested in accordance with BS4718:1971 ASTME 477. Application: All attenuators shall be suitable for internal and external use at any installed angle. Note: Podded attenuators with higher acoustic performance and other specifications are available. Please contact Nuaire Technical for details.

Standard Un-podded PERFORMANCE, DIMENSIONS (mm) & WEIGHTS

Dynamic Attenuation Octave band mid frequency (Hz) 125 250 500 1K 2K -1 -1 -1 -2 -2 -2 -2 -2 -3 -3 -3 -3 -4 -4 -2 -2 -2 -3 -3 -3 -4 -4 -5 -5 -6 -6 -6 -7 -4 -4 -4 -5 -6 -6 -7 -8 -8 -9 -9 -9 -9 -9 -7 -7 -7 -7 -7 -8 -8 -9 -9 -8 -8 -8 -7 -7 -9 -9 -9 -9 -8 -8 -8 -8 -7 -7 -6 -6 -6 -5 Dimensions & Weights A C D 250 315 355 400 450 500 560 630 710 800 900 1000 1120 1250 450 515 555 600 650 700 760 830 910 1000 1100 1200 1320 1450 250 315 355 400 450 500 560 630 710 800 900 1000 1120 1250

Dia. 250mm 315mm 350mm 400mm 450mm 500mm 560mm 630mm 710mm 800mm 900mm 1000mm 1120mm 1250mm

Unit Code Type CA25S CA31S CA35S CA40S CA45S CA50S CA56S CA63S CA71S CA80S CA90S CA100S CA112S CA125S Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded Standard Un-podded

4K -7 -7 -7 -6 -6 -6 -5 -5 -5 -4 -4 -4 -3 -3

8K -5 -5 -5 -5 -5 -4 -4 -4 -4 -3 -2 -2 -2 -2

E 4 8 8 8 8 12 12 12 16 16 16 16 20 20

F M8 M8 M8 M10 M10 M10 M10 M10 M10 M10 M12 M12 M12 M12

G 300 355 395 450 500 560 620 690 770 860 970 1070 1190 1320

Weight Kg 6.0 8.0 11.0 16.0 20.0 23.0 25.0 30.0 34.0 73.0 92.0 111.0 143.0 188.0

Note: Pressure drop negligible.

Long Un-podded PERFORMANCE, DIMENSIONS (mm) & WEIGHTS

Dynamic Attenuation Octave band mid frequency (Hz) 125 250 500 1K 2K -2 -2 -2 -3 -3 -3 -3 -3 -4 -4 -5 -6 -6 -6 -3 -3 -3 -3 -4 -4 -5 -6 -6 -8 -10 -11 -11 -12 -6 -6 -6 -7 -8 -10 -12 -13 -13 -14 -15 -15 -15 -15 -12 -12 -12 -13 -13 -14 -14 -15 -15 -14 -14 -14 -13 -12 -15 -15 -15 -14 -14 -13 -13 -13 -12 -11 -10 -10 -10 -9 Dimensions & Weights A C D 500 630 710 800 900 1000 1120 1260 1420 1600 1800 2000 2240 2500 450 515 555 600 650 700 760 830 910 1000 1100 1200 1320 1450 250 315 355 400 450 500 560 630 710 800 900 1000 1120 1250

Dia. 250mm 315mm 350mm 400mm 450mm 500mm 560mm 630mm 710mm 800mm 900mm 1000mm 1120mm 1250mm

Unit Code Type CA25L CA31L CA35L CA40L CA45L CA50L CA56L CA63L CA71L CA80L CA90L CA100L CA112L CA125L Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded Long - Un-podded

4K -13 -13 -12 -12 -11 -10 -10 -9 -9 -8 -6 -6 -6 -5

8K -9 -9 -8 -8 -7 -7 -7 -6 -6 -5 -3 -3 -3 -3

E 4 8 8 8 8 12 12 12 16 16 16 16 20 20

F M8 M8 M8 M10 M10 M10 M10 M10 M10 M10 M12 M12 M12 M12

G 300 355 395 450 500 560 620 690 770 860 970 1070 1190 1320

Weight Kg 11.0 15.0 21.0 30.0 38.0 42.0 47.0 56.0 63.0 133.0 166.0 203.0 261.0 343.0

Note: Pressure drop negligible.

312

029 2085 8200

AXIAL FA NS ANCILLARIES TECHNIC AL INFORMATION

CIRCULAR ATTENUATORS

A 'E' No. of holes tapped 'F' equi-spaced on 'G' P.C.D.

Standard Podded PERFORMANCE, DIMENSIONS (mm) & WEIGHTS

Dynamic Attenuation Octave band mid frequency (Hz) 125 250 500 1K 2K -2 -3 -3 -3 -4 -4 -5 -5 -6 -6 -7 -7 -8 -8 -5 -6 -6 -7 -7 -8 -8 -8 -9 -9 -10 -11 -12 -12 -13 -14 -14 -14 -15 -15 -16 -16 -17 -18 -19 -19 -20 -20 -16 -16 -17 -18 -18 -19 -21 -21 -20 -18 -17 -17 -17 -17 -17 -17 -17 -16 -16 -15 -14 -14 -14 -14 -15 -14 -13 -13 Dimensions & Weights C D E 450 515 555 600 650 700 760 830 910 1000 1100 1200 1320 1450 250 315 355 400 450 500 560 630 710 800 900 1000 1120 1250 4 8 8 8 8 12 12 12 16 16 16 16 20 20

Dia. 250mm 315mm 350mm 400mm 450mm 500mm 560mm 630mm 710mm 800mm 900mm 1000mm 1120mm 1250mm

Unit Code CA25SP CA31SP CA35SP CA40SP CA45SP CA50SP CA56SP CA63SP CA71SP CA80SP CA90SP CA100SP CA112SP CA125SP

Type Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded Standard - Podded

4K -11 -11 -11 -11 -11 -11 -11 -11 -11 -11 -11 -11 -11 -11

8K -8 -8 -8 -8 -8 -8 -8 -8 -9 -9 -10 -10 -10 -10

A 250 315 355 400 450 500 560 630 710 800 900 1000 1120 1250

F M8 M8 M8 M10 M10 M10 M10 M10 M10 M10 M12 M12 M12 M12

G 300 355 395 450 500 560 620 690 770 860 970 1070 1190 1320

Weight Kg Z 8.0 12.0 17.0 23.0 30.0 33.0 37.0 44.0 50.0 105.0 132.0 160.0 206.0 269.0 82 26.6 19.7 8.2 6.2 4.0 2.7 1.5 0.9 0.55 0.31 0.22 0.13 0.08

Long Podded PERFORMANCE, DIMENSIONS (mm) & WEIGHTS

Dynamic Attenuation Octave band mid frequency (Hz) 125 250 500 1K 2K -4 -5 -5 -6 -6 -7 -8 -8 -9 -10 -11 -12 -14 -14 -10 -10 -11 -11 -12 -12 -13 -13 -14 -15 -16 -17 -18 -18 -21 -23 -23 -24 -24 -25 -26 -26 -27 -29 -31 -32 -33 -33 -27 -27 -28 -29 -30 -32 -34 -34 -32 -30 -29 -29 -29 -29 -29 -29 -29 -27 -27 -26 -25 -25 -25 -25 -25 -23 -22 -22 Dimensions & Weights C D E 450 515 555 600 650 700 760 830 910 1000 1100 1200 1320 1450 250 315 355 400 450 500 560 630 710 800 900 1000 1120 1250 4 8 8 8 8 12 12 12 16 16 16 16 20 20

Dia. 250mm 315mm 350mm 400mm 450mm 500mm 560mm 630mm 710mm 800mm 900mm 1000mm 1120mm 1250mm

Unit Code CA25LP CA31LP CA35LP CA40LP CA45LP CA50LP CA56LP CA63LP CA71LP CA80LP CA90LP CA100LP CA112LP CA125LP

Type Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded Long - Podded

4K -19 -19 -20 -20 -21 -21 -22 -22 -21 -20 -20 -19 -18 -18

8K -12 -13 -14 -15 -15 -17 -18 -18 -18 -17 -17 -17 -16 -16

A 500 630 710 800 900 1000 1120 1260 1420 1600 1800 2000 2240 2500

F M8 M8 M8 M10 M10 M10 M10 M10 M10 M10 M12 M12 M12 M12

G 300 355 395 450 500 560 620 690 770 860 970 1070 1190 1320

Weight Kg Z 16.0 22.0 31.0 43.0 55.0 61.0 68.0 80.0 91.0 191.0 241.0 291.0 373.0 490.0 82 26.6 19.7 8.2 6.2 4.0 2.7 1.5 0.9 0.55 0.31 0.22 0.13 0.081

Note: Air pressure drop of attenuator (Pa) = Z x Q2 where Z = Factor listed in table above Q = air volume flow rate (m/3s).

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

313

AXIAL FA NS BIFURC ATED UNIT WIRING TECHNIC AL INFORMATION

BIFURCATED WIRING

Single Speed 1 phase

Single Speed 3 phase (below 4kW)

Incoming Single Phase Supply

L N

U2 U1

Motor terminal box

U1 Incoming Three Phase Supply V1 W1

Motor terminal box

230V 1 phase 50Hz supply (Not speed controllable) 400V 3 phase 50HZ supply

3 phase for STAR /DELTA STARTING (4kW and above)

400V 3 phase 50Hz supply

STAR L1 - U1 L2 - V1 L3 - W1 Link W2, U2, V2 DELTA L1 - U1 - W2 L2 - V1 - U2 L3 - W1 - V2

3 phase for DOL STARTING (4kW and above)

400V 3 phase 50Hz supply L1 U1 V1 W1 W2 U2 V2 L2

2 Speed TAP/PAM Wound Motor (D.O.L.starting both speeds)

Note: individual wiring instructions are included with each unit 1U 1V L3 1W 2U 2V 2W Motor terminal box NOTE: LOW SPEED Supply: 1U 1V 1W HIGH SPEED Supply: 2U 2V 2W & link 1U 1V 1W

U1 V1 W1 W2 U2 V2

Note: For D.O.L (Direct On Line Starting) operation or Inverter type Speed Control, wire in DELTA

400V 3 phase 50HZ supply

Matched Nuaire Inverter Speed Control

3 Phase input Connections to motor W V U

L1 L/L2 N/L3 PE/

400V 3 phase 50Hz supply

Motor 3 phase

Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

315

AXIAL FA NS CONTROLS TECHNIC AL INFORMATION

SPEED CONTROLS TABLES

Unit Code 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 AX31X-461 AX31F-441 AX31F-451 AX31B-451 AX35D-411 AX35X-421 AX35F-431 AX35F-441 AX35F-451 AX40D-411 AX40I-411 AX40I-421 AX40I-431 AX40I-441 AX40I-451 AX45S-411 AX45P-411 AX45S-431 AX45S-451 AX45S-471 Electronic Speed Control NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-3A NSC1-6A NSC1-6A NSC1-6A NSC1-3A NSC1-3A NSC1-6A NSC1-6A NSC1-6A 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 Unit Code AX45S-481 AX45P-471 AX45P-481 AX45D-451 AX50C-411 AX50D-411 AX50P-411 AX50P-421 AX50S-45* AX56B-411 AX56F-411 AX56S-42* AX63F-411 AX710-611 AX710-621 AX71P-621 AX71AA-621 AX80O-611 AX80O-621 AX80P-621 Electronic Speed Control NSC1-6A NSC1-6A NSC1-6A NSC1-6A NSC1-3A NSC1-6A NSC1-6A NSC1-6A NSC1-10A NSC1-3A NSC1-6A NSC1-10A NSC1-6A NSC1-6A NSC1-6A NSC1-6A NSC1-6A NSC1-6A NSC1-6A NSC1-6A

* refers to code 1 or 3 phase.

CONTROLS DIMENSIONS (mm) & WEIGHTS

Fan code ES-ISC1.2A ES-ISC2.4A ES-ISC3.3A ES-ISC4.1A ES-ISC5.6A ES-ISC7.3A ES-ISC8.8A ES-ISC12.5A ES-ISC15.6A ES-ISC23.1A ES-ISC38.0A A 230 230 230 230 290 290 290 290 290 290 355 B 325 325 325 325 390 390 390 390 390 390 525 C 410 410 410 410 455 455 455 455 455 455 805 Weight Kg 6 6 6 6 14 14 14 20 20 20 40 Drill D mm 340 340 340 340 470 470 470 470 470 470 710 Pattern E mm 298 298 298 298 373 373 373 373 373 373 510

C

DIMENSIONS

A B

D 2 D

D 2

Code descriptions

ES - ISC 2.4A |

1

|

2

|

3

The Ecosmart Energy Saving Speed Control is designed to control selected Nuaire fans and to match the range of integrated Ecosmart control systems. The control is only available for three phase electrical supply. The case material is of Aluzinc corrosion resistant steel, incorporates a frequency inverter, Ecosmart control board and is directly compatible with the Ecosmart range of user controls, time clocks, stats and sensors. Internal mounting Please note: Select a control by matching the unit full load current with the control code i.e. control code ES-ISC3.3A is suitable for a fan with a maximum full load current of 3.3A. The Inverter overload is pre-set at the rating plate value, if a lower setting is required fit an appropriately sized overload relay or adjust inverter settings. The mains power supply to the controller must be appropriately sized and installed via a local isolation switch (by others).

1. ES = Ecosmart 2. Inverter Speed Control 3. Output Current Rating

The isolator must also accommodate the 230V switched live (if used). The mains supply from the Ecosmart controller to the fan must be appropriately sized, not exceeding 30 metres and must be a screened power cable, earthed at both ends. A four point glanding plate is formed from the base of the control and in order to main EMC compliance, EMC glanding kit is supplied. Not suitable for contra rotating/run and standby axial units. All integrated sensors plug directly into the control panel. Refer to product datasheet No. 671432 for further information.

316

029 2085 8200

AXIAL FA NS CONTROLS TECHNIC AL INFORMATION

CONTROLS CONT.

B A B A

ELECTRONIC SPEED CONTROL (mm)

Dimensions (mm) Unit Code NSC1-3A NSC1-6A NSC1-10A A 83 115 115 B 88 95 95 C 180 195 195 Weight Kg 0.5 0.7 0.7

TRANSFORMER SPEED CONTROL (mm)

Single Phase Unit Code SPCON1.5 SPCON3.5 SPCON7.5 A 115 200 200 B 85 140 140 C 180 280 280 Weight Kg 1.7 3.6 6.0

The electronic speed controllers provide infinitely variable speed control from preset minimum to maximum. All models feature a boost start function, which applies maximum power to the motor for a few seconds to prevent motor stalling before returning to selected speed. Wiring to the motor can be either 2-wires or 3-wires control depending on the motor design. The enclosures for ESC1-3A and ESC1-6A are rated to IP45 with the ESC1-10A rated at IP54. All controllers meet LVD and EMC directives for safety and electromagnetic compatibility.

Autotransformers having class F insulation are used to provide discrete voltage steps. All models are fitted with suitable fuses for short-circuit protection. The controller casing is manufactured from plastic pre-coated steel or impact resistant polycarbonate. All models are suitable for indoor installations only. All controllers meet LVD and EMC directives for safety and electromagnetic compatibility. Transformer speed controls produce a pure sine wave output resulting in quiet motor operation.Transformer controls are therefore preferred for noise sensitive applications.

DIMENSIONS (MM)

Frame size A inverter and Drill Pattern

Front View Side View Drill Pattern

Frame size A inverters codes 3ISC1.2A 3ISC1.6A 3ISC2.1A (image shown) (image shown) (image shown) (image shown) (image shown)

308mm

260mm

3ISC3.0A 3ISC4.0A

Frame size B inverters codes 3ISC5.9A

126mm 230mm Drill Pattern 105mm

3ISC7.7A 3ISC10.2A

Frame size B Drill Pattern

4.8mm 174mm

Frame size C inverters codes 3ISC13.2A 3ISC15.8A 3ISC18.4A 3ISC26.0A

138mm Drill Pattern

Frame size C Drill Pattern

5.5mm 204mm

All inverters are supplied complete with integral class A filters to suppress EMC emissions. Note: Frame size A inverters are pre assembled into metal enclosures.

Code descriptions

3 ISC 1.2A | |

174mm

|

3

1. 3 Phase 2. Inverter Speed Control 3. Output Current Rating Download specification from www.nuaire.co.uk/specifications

nuaire.co.uk

317

You might also like

- The Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)Document69 pagesThe Key To Metal Bumping (Panel Beating, Auto Body Repair Bible)wulfgang2498100% (11)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Deutz 165 MK3 Electrial 1Document100 pagesDeutz 165 MK3 Electrial 1chrideerNo ratings yet

- Erection and Painting of Steel StructureDocument11 pagesErection and Painting of Steel StructureomarcadNo ratings yet

- General Waterstop BrochureDocument8 pagesGeneral Waterstop BrochureMuhammet Kızıl100% (1)

- General Waterstop BrochureDocument8 pagesGeneral Waterstop BrochureMuhammet Kızıl100% (1)

- Pocket Guide To Brick ConstructionsDocument130 pagesPocket Guide To Brick ConstructionsLeontin Leon100% (3)

- VFD DocumentsDocument592 pagesVFD DocumentsLe Anh Dang50% (2)

- Schneider BreakerDocument170 pagesSchneider BreakerJon Lopez50% (2)

- GRP Manholes ChambersDocument20 pagesGRP Manholes ChambersMohamed TahounNo ratings yet

- SADIP CatalogeDocument60 pagesSADIP Catalogejaseer100% (1)

- Viking Johnson AquaGrip BrochureDocument9 pagesViking Johnson AquaGrip BrochureFlorin LixandruNo ratings yet

- Yaesu FT-101ZD Service ManualDocument193 pagesYaesu FT-101ZD Service ManualYayok S. AnggoroNo ratings yet

- Improving Boiler Efficiency by Using Air PreheaterDocument14 pagesImproving Boiler Efficiency by Using Air PreheaterBudiharyatno Arif PangestuNo ratings yet

- Axus Long Cased Axial Fans Technical GuideDocument29 pagesAxus Long Cased Axial Fans Technical GuideNicola Andrei100% (1)

- Hot Water Supply ch.2 PDFDocument55 pagesHot Water Supply ch.2 PDFasmaaasmaaa asmaa100% (1)

- General Materials and Workmanship: Section 1 2 Section 2 7 Section 3 13Document14 pagesGeneral Materials and Workmanship: Section 1 2 Section 2 7 Section 3 13Muhammad EhtshamNo ratings yet

- Adsorption by BhanuDocument20 pagesAdsorption by BhanuHiren vaghaniNo ratings yet

- Guide To Trench ExcavationsDocument43 pagesGuide To Trench ExcavationsmlakkissNo ratings yet

- SikaSwell - Waterproofing SolutionsDocument5 pagesSikaSwell - Waterproofing SolutionsilijarskNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Manual Service - TadiranDocument39 pagesManual Service - TadiranPaul Paulista100% (1)

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Technical Methods For Highways Sampling Methods For Roads Construction MaterialsDocument59 pagesTechnical Methods For Highways Sampling Methods For Roads Construction MaterialsPatrick Bauman100% (1)

- Ese652 - Process Control Ii Chapter 5.2 - Distillation ColumnDocument5 pagesEse652 - Process Control Ii Chapter 5.2 - Distillation ColumnJennifer HughesNo ratings yet

- Hydro Testing ProcedureDocument12 pagesHydro Testing ProcedureGaapchuNo ratings yet

- Hydro Testing ProcedureDocument12 pagesHydro Testing ProcedureGaapchuNo ratings yet

- BurnerDocument33 pagesBurnertoficNo ratings yet

- DATABASE Kawasan Industri PolugadungDocument20 pagesDATABASE Kawasan Industri PolugadungRina Rachman100% (1)

- Bifurcared Axial Flow Fans: High Performance, Low Maintenance, 'Motor Out of Airstream' For Complete Peace of MindDocument11 pagesBifurcared Axial Flow Fans: High Performance, Low Maintenance, 'Motor Out of Airstream' For Complete Peace of MindKhalid SaqallahNo ratings yet

- Panasonic Sa-Ak270 (Eb, Eg)Document120 pagesPanasonic Sa-Ak270 (Eb, Eg)Rafael Hernandez100% (1)

- York Rooftops EngDocument14 pagesYork Rooftops EngBulclimaNo ratings yet

- Biflow SB (Con)Document7 pagesBiflow SB (Con)elaineurbNo ratings yet

- Features Description: FM IF SystemDocument7 pagesFeatures Description: FM IF Systemlu1agpNo ratings yet

- BCI184HDocument8 pagesBCI184H3efooNo ratings yet

- Electrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Document234 pagesElectrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Canea Mihai CaiusNo ratings yet

- HCM434EDocument8 pagesHCM434E3efooNo ratings yet

- 315 - SVP3000 Alphaplus S HART Protokolom PDFDocument12 pages315 - SVP3000 Alphaplus S HART Protokolom PDFJuan Carlos Nodner RiosNo ratings yet

- Quat KrugerDocument52 pagesQuat Krugerruby0808No ratings yet

- CL-kompl EDocument6 pagesCL-kompl EpecqroNo ratings yet

- Ca Dw500uDocument48 pagesCa Dw500uRicardo BerbisNo ratings yet

- UCM224EDocument8 pagesUCM224E3efooNo ratings yet

- Retrofit Masterpact M PlugnplayDocument21 pagesRetrofit Masterpact M Plugnplaynot bookNo ratings yet

- Diktafon Sony BM-575 - 577Document34 pagesDiktafon Sony BM-575 - 577po_guru1No ratings yet

- BCI184FDocument8 pagesBCI184F3efooNo ratings yet

- Aiwa NSX-SZ50Document26 pagesAiwa NSX-SZ50Juan AcostaNo ratings yet

- Aircon MSH Ga50 80 Ob367Document24 pagesAircon MSH Ga50 80 Ob367John KeyNo ratings yet

- Panasonic SA-AK960 Mini ComboDocument121 pagesPanasonic SA-AK960 Mini Comboppstone100% (3)

- CFD 6Document29 pagesCFD 6Guillermo Sandoval OsorioNo ratings yet

- UCM224D - Technical Data SheetDocument8 pagesUCM224D - Technical Data Sheet3efooNo ratings yet

- UCM274EDocument8 pagesUCM274E3efooNo ratings yet

- Transistor de Alta TensãoDocument9 pagesTransistor de Alta TensãoitavolpNo ratings yet

- CA3189EDocument8 pagesCA3189EelektrovodaNo ratings yet

- Multi-Channel Audio Receiver Service ManualDocument15 pagesMulti-Channel Audio Receiver Service ManualBaris YaziciNo ratings yet

- FAHU-1 supply unit specificationsDocument2 pagesFAHU-1 supply unit specificationsDuxToyNo ratings yet

- OnkyoC701A JP SMDocument21 pagesOnkyoC701A JP SMHelder MartinsNo ratings yet

- UCM224CDocument8 pagesUCM224C3efooNo ratings yet

- Ec Axial Fan W3g800gu2501 EngDocument5 pagesEc Axial Fan W3g800gu2501 EngmacmottaNo ratings yet

- TS300SC - SXC-ELzgb Engine Driven WelderDocument1 pageTS300SC - SXC-ELzgb Engine Driven WelderFebianda PrimatamaNo ratings yet

- BCM184H - Technical Data SheetDocument8 pagesBCM184H - Technical Data Sheet3efooNo ratings yet

- GGA - Pressure Independent Terminal UnitsDocument10 pagesGGA - Pressure Independent Terminal UnitsInventor SolidworksNo ratings yet

- HCM434DDocument8 pagesHCM434D3efooNo ratings yet

- Panasonic-SAAK860GCP Audio SysDocument118 pagesPanasonic-SAAK860GCP Audio SysMarcos DAquinoNo ratings yet

- Msc-Ga20 25 35Document24 pagesMsc-Ga20 25 35Andrei GheorghitaNo ratings yet

- bl01 Aa0104 4Document6 pagesbl01 Aa0104 4chris110No ratings yet

- Service Manual: WM-GX400Document30 pagesService Manual: WM-GX400london335No ratings yet

- Transformer Fan DetailsDocument38 pagesTransformer Fan DetailsNeha GuptaNo ratings yet

- A-8017 Stereo AmplifierDocument13 pagesA-8017 Stereo Amplifierapex70100% (1)

- Offers_July_2012_PartsDocument16 pagesOffers_July_2012_PartsMuhammad MaqsoodNo ratings yet

- AHU Standard EcosmartBoxerDocument18 pagesAHU Standard EcosmartBoxerNuaire GroupNo ratings yet

- Sony HCD-H7 - H1500Document54 pagesSony HCD-H7 - H1500aubaisienNo ratings yet

- STR-K760P v1.1Document44 pagesSTR-K760P v1.1danielradu27No ratings yet

- Samsung Ast24a5re Ast18a Sc24ta Sc18zaDocument54 pagesSamsung Ast24a5re Ast18a Sc24ta Sc18zaMarco Lo100% (1)

- 11N95 DGT PH2 DSDocument50 pages11N95 DGT PH2 DSSundar RamasamyNo ratings yet

- PI734EDocument8 pagesPI734E3efooNo ratings yet

- Bu 941Document9 pagesBu 941Uriel HernandezNo ratings yet

- Cq-C1321ne C1311ne C1301neDocument92 pagesCq-C1321ne C1311ne C1301neZoran ProkicNo ratings yet

- All Flanged TeeDocument1 pageAll Flanged TeeblindjaxxNo ratings yet

- Flanged Spigot With Puddle FlangedDocument1 pageFlanged Spigot With Puddle FlangedblindjaxxNo ratings yet

- Flanged TaperDocument1 pageFlanged TaperblindjaxxNo ratings yet

- VFA - FittingsCatalogue DUKERDocument130 pagesVFA - FittingsCatalogue DUKERblindjaxxNo ratings yet

- Di Pipe and Fittings ElectrosteelDocument20 pagesDi Pipe and Fittings ElectrosteelblindjaxxNo ratings yet

- Klamflexproduct BrochureDocument24 pagesKlamflexproduct BrochureblindjaxxNo ratings yet

- SpecifyingDocument4 pagesSpecifyingblindjaxxNo ratings yet

- Next Generation: Ultragrip Reducing CouplingsDocument1 pageNext Generation: Ultragrip Reducing CouplingsblindjaxxNo ratings yet

- Air Test KitDocument2 pagesAir Test KitblindjaxxNo ratings yet

- 00.03 - Document HistoryDocument1 page00.03 - Document HistoryblindjaxxNo ratings yet

- PAM FittingsDocument2 pagesPAM FittingsblindjaxxNo ratings yet

- Viking Johnson MaxiFit BrochureDocument22 pagesViking Johnson MaxiFit BrochureblindjaxxNo ratings yet

- Qatar Construction Specifications 2010 (QCS 2010) IntroductionDocument1 pageQatar Construction Specifications 2010 (QCS 2010) IntroductionblindjaxxNo ratings yet

- Pam Vca02 MF Gate ValveDocument2 pagesPam Vca02 MF Gate ValveblindjaxxNo ratings yet

- 611 Large Orifice Air ValveDocument2 pages611 Large Orifice Air ValveblindjaxxNo ratings yet

- Environmental Safety: Renching and Horing LANDocument26 pagesEnvironmental Safety: Renching and Horing LANblindjaxxNo ratings yet

- 611 Large Orifice Air ValveDocument2 pages611 Large Orifice Air ValveblindjaxxNo ratings yet

- IPPI HDPE Pipe and Fittings Submittal Catalog - Ver 1.4.1 2009Document184 pagesIPPI HDPE Pipe and Fittings Submittal Catalog - Ver 1.4.1 2009Hebert CcahuanaNo ratings yet

- Pam Vca02 MF Gate ValveDocument2 pagesPam Vca02 MF Gate ValveblindjaxxNo ratings yet

- Environmental Safety: Renching and Horing LANDocument26 pagesEnvironmental Safety: Renching and Horing LANblindjaxxNo ratings yet

- FM 200 Properties Uses Storage HandlingDocument16 pagesFM 200 Properties Uses Storage HandlingAfsal NangathanNo ratings yet

- TESA Highlights enDocument36 pagesTESA Highlights enPSINGH02No ratings yet

- OxoneDocument2 pagesOxoneSha Hriyar HNo ratings yet

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaNo ratings yet

- Flexible joints, hoses, expansion joints & vibration isolators catalogDocument18 pagesFlexible joints, hoses, expansion joints & vibration isolators catalogReza TambaNo ratings yet

- Mohammed Et Al. (2022) - Graphene-CelluloseDocument8 pagesMohammed Et Al. (2022) - Graphene-CellulosealhassanNo ratings yet

- MTJ MRJ Series Maintenance and Assembly InstructionsDocument35 pagesMTJ MRJ Series Maintenance and Assembly Instructionsa04205No ratings yet

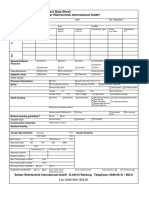

- Agitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDocument1 pageAgitator Data Sheet Stelzer Rührtechnik International GMBH: CompanyDeepikaNo ratings yet

- Air Lift Design Pumps PDFDocument5 pagesAir Lift Design Pumps PDFinggerman100% (1)

- Robotics and Vision SystemDocument64 pagesRobotics and Vision Systemasuras1234No ratings yet

- Renewal Parts - YK Mod F and Later HA-HB-HE-HG - G, H & J Series CompressorsDocument112 pagesRenewal Parts - YK Mod F and Later HA-HB-HE-HG - G, H & J Series CompressorsKannan KrishnamoorthyNo ratings yet

- III. Vacuum Pumps III. Vacuum Pumps: MechanismDocument16 pagesIII. Vacuum Pumps III. Vacuum Pumps: Mechanismnsr2tNo ratings yet

- Housing & CouplingDocument12 pagesHousing & Couplingmajid fardniaNo ratings yet

- QweqDocument2 pagesQweqPraYush RajbhandariNo ratings yet

- Types, Properties and Uses of Bituminous MaterialsDocument8 pagesTypes, Properties and Uses of Bituminous MaterialsOctavian StoichitaNo ratings yet

- ASTM C192 (Group 7)Document38 pagesASTM C192 (Group 7)Raine Fair Haven AiNo ratings yet

- FF8.5GX Universal Compressor R134a 115V 60Hz: GeneralDocument2 pagesFF8.5GX Universal Compressor R134a 115V 60Hz: GeneralWin FloresNo ratings yet

- MIGUA - Migutrans - Catalogue CDocument60 pagesMIGUA - Migutrans - Catalogue CjajayttNo ratings yet