Professional Documents

Culture Documents

Re 92012

Uploaded by

Ahmed Abd ElhakeemOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Re 92012

Uploaded by

Ahmed Abd ElhakeemCopyright:

Available Formats

RE 92 012/04.

00

RE 92 012/04.00

replaces: 11.94

Variable Displacement Pump A4VTG

for drum drives on mobile concrete mixers for closed circuits Sizes 56...90 Series 3 Nominal pressure 400 bar Peak pressure 450 bar

A4VTG...HW

Index

Features Ordering Code Technical Data Pressure Relief Valve Filtration HW - Hydraulic Control, Mechanical Servo EP - Electrical Control, with Proportional Solenoid Unit Dimensions, Size 71 Unit Dimensions, Size 90 Dimensions for Through Drives Permissible Input and Through Drive Rotation Torques Mechanical Stroke Limiter, M Ports X3 and X4 for Positioning Pressure, T Speed Sensor, G Installation Situation for Coupling Assembly Installation and Commissioning Guidelines 1 2...3 4 5 5 6 6 7 8 9 9 10 10 11 11 12

Features

variable displacement axial piston pump of swashplate design for hydrostatic closed circuit transmissions flow is proportional to drive speed and displacement and is infinitely variable output flow increases with swivel angle from 0 to its maximum value swivelling the pump over centre smoothly changes the direction of flow the pump is equipped with two pressure relief valves on the high pressure ports to protect the hydrostatic transmission (pump and motor) from overloads these valves also function as boost inlet valves an integral auxiliary pump serves as boost and pilot oil pump the maximum boost pressure is limited by a built-in boost pressure relief valve

A4VTG

1/12

RE 92 012/04.00

Ordering Code

Hydraulic fluid Mineral oil (no code) Axial piston unit Variable swashplate design, for drum drives on mobile concrete mixers Operation Pump in closed circuits Size Displacement Vg max in cm3 Control device Hydraulic control, mechanical servo Electrical control with proportional solenoid

A4VT

56 56 12V 24V

71 71

90 90 HW EP1 EP2

Mechanical stroke limiter without mechanical stroke limiter (no code) with mechanical stroke limiter Ports X3, X4 for positioning pressure without ports X3, X4 (no code) with ports X3, X4 Series

3 Index 2 Direction of rotation viewed on shaft end

clockwise anti-clockwise

R L

Seals NBR, shaft seal in FKM (fluor-caoutchouc) Shaft end Splined shaft SAE

without coupling flange with coupling flange 56 71 90

S L

Mounting flange SAE C, 2-hole SAE C, 4-hole Service line connections Ports A/B SAE, (metric fixing screws) at side (same side)

C D

10

= available = in preparation = not available Brueninghaus Hydromatik 2/12 A4VTG

RE 92 012/04.00

A4VT G

Axial piston unit Operation Size Control device Series Index Direction of rotation Seals Shaft end Mounting flange Service line connections

/ 3 2

10

Auxiliary pump and through drive auxiliary pump through drive flange SAE A. 2-Loch SAE B, 2-Loch

hub SAE A SAE B

(N 5/8"-9T 16/32DP) (N 7/8"-13T 16/32DP) 56 71 90

F00 F01 F02

Valves with high pressure relief valve, pilot controlled; with bypass with high pressure relief valve, direct controlled; with bypass Filtration Filtration in the suction line of the auxiliary (boost) pump Speed sensor without speed sensor (no code) with speed sensor

1 5

A4VTG

3/12

Brueninghaus Hydromatik

RE 92 012/04.00

Technical Data

Fluid To review the application of A4VTG pumps with the selected hydraulic fluid, detailed fluid compatibility and application data can be found in data sheets RE 90220 (mineral oil), RE 90221 (environmentally acceptable hydraulic fluids) and RE 90223 (fire resistant fluids, HF). The variable pump A4VTG is not suitable for operation with HFA, HFB and HFC. When using HFD or environmentally acceptable hydraulic fluids limitations for the technical data have to be taken into consideration. If necessary please consult our technical department (please indicate type of the hydraulic fluid used for your application on the order sheet). Operating viscosity range In order to obtain optimum efficiency and service life, we recommend that the operating viscosity (at operating temperature) be selected from within the range: opt = operating viscosity 16...36 mm2/s referred to the circuit temperature (closed circuit). Viscosity limits The limiting values for viscosity are as follows: min = 5 mm2/s short term at a max. permissible temp. of tmax = 115C. Please note that the max. fluid temperature is also not exceeded in certain areas (for instance bearing area). max = 1600 mm2/s short term on cold start ( (n 1000 rpm, tmin = -40C). At temperatures of -25C up to -40C special measures are required. Please contact us for further information. Selection diagram

2500-40 1600 1000 600 400 200 -20 0 20 40 60 80 100 1600

Notes on the selection of the hydraulic fluid In order to select the correct fluid, it is necessary to know the operating temperature in the circuit (closed circuit) in relation to the ambient temperature. The hydraulic fluid should be selected so that within the operating temperature range, the operating viscosity lies within the optimum range (opt) (see shaded section of the selection diagram). We recommend that the highest possible viscosity range should be chosen in each case. Example: At an ambient temperature of XC circuit temperature is 60C. Within the operating viscosity range (opt; shaded area) this corresponds to viscosity ranges VG 46 or VG 68. VG 68 should be selected. Important: The leakage oil (case drain oil) temperature is influenced by pressure and pump speed and is always higher than the circuit temperature. However, at no point in the circuit may the temperature exceed 115C. If it is not possible to comply with the above conditions because of extreme operating parameters or high ambient temperatures please consult us. Temperature range of the radial shaft seal The FKM shaft seal is admissible for a housing temperature range from -25C to +115C. Note: For applications below -25C a NBR shaft seal is necessary (admissible temperature range -40C to +90C). When ordering, please state in clear text: with NBR shaft seal Working pressure range - inlet Auxiliary pump: suction pressure ps min ( 30 mm2/s) ______ 0,8 bar absolute for cold start ________________________ 0,5 bar absolute Working pressure range - outlet Variable pump: Pressure at port A or B nominal pressure pN ______________________________________ 400 bar peak pressure pmax ________________________________________ 450 bar Auxiliary pump: peak pressure pH max ________________________________________ 40 bar (pressure data to DIN 24312)

0 10 G V 68 G V 46 G V 32 G V 2 2

VG

viscosity in mm2/s

100 60 40 20 10

36 opt. 16

Case drain pressure 5 5 Permissible case drain pressure at ports T1 and T2 -40 -25 -10 0 10 30 50 70 90 115 pL _______________________________________ 4 bar abs. temperature t in C short term (at start) __________________________ 6 bar abs. tmin = -40C tmax = +115C fluid temperature range

Brueninghaus Hydromatik

4/12

A4VTG

RE 92 012/04.00

Technical Data

Table of values (theoretical values, without considering mh and v: values rounded) Size Displacement variable pump auxiliary pump (at p = 20 bar) Speed max. speed with Vg max minimum speed Flow at nmax contin. and Vg max Power at nmax contin. p = 400 bar Torque at Vg max p = 400 bar (variable pump without aux. pump) p = 100 bar Moment of inertia (about drive axis) Weight (standard model without through drive) approx.

Vg max Vg H nmax contin. nmin qv max Pmax Tmax T J m

cm3 cm3 rpm rpm L/min kW Nm Nm kgm2 kg

71 71 19,6 3300 500 234 156 451 112,8 0,0072 46

90 90 28,3 3050 500 275 183 572 143 0,0106 48

Pressure Relief Valve

The two high pressure relief valves are protecting the hydrostatic transmission (pump and motor) against overcharge. They are limiting the max. pressure of the respective high pressure line and are serving at the same time for boost valves. The boost pressure is set via boost pressure valve. Standard setups: - boost pressure valve: pSP _________________________________ 22 bar - high pressure valve: pmax ______________________________ 420 bar Note: The valve setups are carried out at n = 1000 rpm and Vg max. At other operating parameters differences in the opening pressures may occur. high pressure relief valve

Filtration

The finer the filtration the better the achieved cleanliness level of the pressure fluid and the longer the life of the axial piston unit. To ensure the functioning of the axial piston unit a minimum cleanliness level of 9 to NAS 1638 18/15 to ISO/DIS 4406 is necessary. At very high temperatures of the hydraulic fluid (90C to max. 115C) at least cleanliness level 8 to NAS 1638 17/14 to ISO/DIS 4406 necessary. If above mentioned grades cannot be maintained please consult supplier. Standard: Filtration in the suction line of the auxiliary pump, S Filter type: ________________________ filter without bypass Recommendation: ____________ with contamination indicator Through flow resistance at filter element: at = 30 mm2/s, n = nmax ___________________________ p 0,1 bar at = 1000 mm2/s, n = nmax ________________________ p 0,3 bar Pressure at port S of the auxiliary pump: at = 30 mm2/s ___________________________ p 0,8 bar at cold start ( = 1600 mm2/s, n 1000 rpm) ______ p 0,5 bar

boost pressure valve

A4VTG

5/12

Brueninghaus Hydromatik

RE 92 012/04.00

HW

Hydraulic Control, Mechanical Servo

EP

Electrical Control, with Proportional Solenoid

The positioning cylinder of the pump and therefore the swivel angle is varied in proportion to the movement of the control lever. The pump control is steplessly variable. Each direction of flow is assigned to one direction of lever movement.

in

In relation to the preselected current, control pressure is applied to the positioning cylinder of the pump via two proportional solenoids on control device EP. The displacement of the pump is thus steplessly variable. One solenoid is assigned to each direction of flow. Operating curve: EP2

800 700 600 500 400 300 200 100 0 1,0 0,8 0,6 0,4 0,2 0 200 300 400 500 600 700 800

40 35 30 25 20 15 10 5 0 1,0 0,8 0,6 0,4 0,2 Vg 50 10 Vg max 15 20 25 30 35 40

I in mA

0,2 0,4 0,6 0,8 1,0 V g

Vg max

Vg Vg max

0,2 0,4 0,6 0,8 1,0 V g

Vg max

in

I in mA

model Swivel angle of control lever: - from 0 to Vg max _______________________________ = 0 to 29 - mech. stop: _________________________________ 40 Torque at control lever - necessary torque for displacement ______ approx. 85 to 210 Ncm - max. torque __________________________ 700 Ncm (7 Nm) Dependant from the operation conditions of the pump (operation pressure, oil temperature) changes of the curve can occur.

control voltage (DC) 12 V 24 V

EP1 EP2

control current I start of control end of control at Vg 0 at Vg max 400 mA 1200 mA 200 mA 600 mA

To control the proportional solenoids the following electronic amplifiers and microcontroller are available: proportional amplifier PVR (RE 95022), chopper amplifier CV (RE 95029) and microcontroller MC with software solutions related to the field of application (RE 95050) (e.g. CSD). Standard: proportional solenoid with manual emergency (without spring return)

MA S

A

MA S

Graph Direction of rotation - Control - Direction of through flow Direction of rotation clockwise anti-clockwise Lever direction (HW) Operated solenoid (EP) a b X2 B to A MA b a X1 A to B MB a b X2 A to B MB b a X1 B to A MA clockwise anticlockwise

MB

anticlockwise

b a

MB X1

S

X1 proportional solenoid a

S

Control pressure

MA X2

A,B

Direction flow Working pressure

clockwise

MA X2

A,B

proportional solenoid b

Brueninghaus Hydromatik

6/12

A4VTG

RE 92 012/04.00

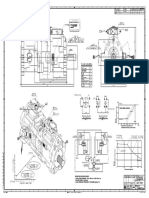

Unit Dimensions, Size 71

Prior to finalising your design, please obtain a certified drawing.

Hydraulic control, mechanical servo HW

(SAE C)

HD-valve boost pressure valve

M12; 17 deep

Connections A,B Service line ports SAE 1" 420 bar (6000 psi) (high pressure series) T1 Case drain or filling port M 26x1,5; 16 deep T2 Case drain M 26x1,5; 16 deep MA Pressure gauge - working pressure A M 12x1,5; 12 deep MB Pressure gauge - working pressure B M 12x1,5; 12 deep R Air bleed M 16x1,5; 12 deep S Boost suction port M 42x2; 18 deep X1, X2 Control pressure ports M 12x1,5; 12 deep (before the orifice) pS Control pressure supply M 14x1,5; 12 deep

Shaft ends detail A-A

Electrical control, with proportional solenoid, EP

L

Splined shaft SAE 13/8" with coupling flange

S

Splined shaft SAE 13/8" pressure angle 30, 21 teeth, 16/32 pitch, flat root side fit, tolerance class 5 ANSI B92.1a-1976

A4VTG

7/12

Brueninghaus Hydromatik

RE 92 012/04.00

Unit Dimensions, Size 90

Hydraulic control, mechanical servo HW

Prior to finalising your design, please obtain a certified drawing.

(SAE C)

HD-valve boost pressure valve

M12; 17 deep

298,9

Connections A,B Service line ports SAE 1" 420 bar (6000 psi) (high pressure series) T1 Case drain or filling port M 26x1,5; T2 Case drain M 26x1,5; Pressure gauge - working pressure A M 12x1,5; MA MB Pressure gauge - working pressure B M 12x1,5; R Air bleed M 16x1,5; S Boost suction port M 42x2; X1, X2 Control pressure ports M 12x1,5; (before the orifice) pS Control pressure supply M 14x1,5;

16 deep 16 deep 12 deep 12 deep 12 deep 18 deep 12 deep 12 deep

Shaft ends

detail A-A

Electrical control, with proportional solenoid, EP

L

Splined shaft SAE 11/2" with coupling flange

S

Splined shaft SAE 11/2" pressure angle 30, 23 teeth, 16/32 pitch, flat root side fit, tolerance class 5 ANSI B92.1a-1976

33,4

Brueninghaus Hydromatik

R2 ,5

8/12

A4VTG

RE 92 012/04.00

Dimensions for Through Drives

Prior to finalising your design, please obtain a certified drawing.

Through drive SAE A (F01) Size 71 splined hub SAE A

N 5/8"-9T 16/32 DP

Size 90 splined hub SAE A

N 5/8"-9T 16/32 DP

M10; 15 deep

A3

A3

Size 71 90

A1 297,6 297,6

A2 9 9

A3 10 8

A4 17

17,5 82,55

suitable for connection of: gear pump G2 (RE 10030) variable pump A10VSO10 (RE 92713) variable pump A10VSO18 (RE 92712)

106,4 A1

A2 A4 A1

A2

(to mounting flange)

(to mounting flange)

Through drive SAE B (F02) Sizes 71, 90 M12; 21 deep splined hub SAE B

N 7/8"-13T 16/32 DP A3

82,55

106,4

Size 71 90

A1 A2 300,6 12,5 313,6 13

A3 9,8 9,8

A4 15,5 19

suitable for connection of: gear pump G3 (RE 10039) gear pump G4 (RE 10042) variable pump A10VG18 (RE 92750) variable pump A10VO28 (RE 92701/ RE 92703)

24

146

A1

A2 A4

(to mounting flange)

Permissible Input and Through Drive Rotation Torques

Size Corner torque (when Vgmax and p = 400 bar) 1) Tmax Nm Max. perm. through drive rotation torque TD perm. Nm Max. permissible input torque 2) TE perm. Nm

1) 2)

101,6

146

71 451 660 970 (W 1 3/8")

90 572 822 1305 (W 1 1/2")

efficiency not taken into consideration drive shaft without side load

Code explanations TD perm. = max. permissible through drive torque in Nm TE perm. = max. permissible input torque at the drive shaft in Nm

A4VTG

9/12

Brueninghaus Hydromatik

RE 92 012/04.00

Mechanical Stroke Limiter, M

Adjustment screws to both Vg max values

86,3

max. 135

28,5

Circuit diagram A4VTG 71HWM

Ports X3 and X4 for Positioning Pressure, T

max. 135

86,3

28,5

X1 X3

X4 X2

X3

113,5

113,5

Circuit diagram A4VTG 71HWT

X4

Brueninghaus Hydromatik

10/12

A4VTG

RE 92 012/04.00

Installation Situation for Coupling Assembly

In order to assure that rotating parts (coupling hub) and fixed parts (housing, circlip) do not contact each other the installation situations are described in this leaflet have to be observed. At design "shaft end L" (SAE splined shaft with mounted coupling flange) Brueninghaus Hydromatik already considered this fact. At design "shaft end S" (SAE splined shaft) it has to be considered when selecting the coupling, that the external diameter of the coupling hub in the area of the shaft collar (size x2 x3) has to be smaller than the internal diameter of the circlip d2.

x2 x1

coupling hub

d4 d3

d2

x3

Size d1 71 90 45 45

d2 min 66,5 66,5

d 3 81 0,1 81 0,1

d 4 127 127

x1 7,0+0,2

d1

x2 12,7-0,5

x3 8 -0,6

+0,9

7,0+0,2 12,7-0,5

Speed Sensor, G

The design "with speed sensor G" is facilitating at electronically piloted drives a speed record of the variable pump A4VTG. In connection with a microcontroller MC (RE 95050) and software CSD an alternating input speed of the pump can thus be picked up and the constant flow qV is resulting. Consequently a constant output speed (mixer drum speed) is generated at the output shaft of the so driven hydromotor.

programming diagnostics speed specification

BB-3

MC + CSD

A1

speed

n = variable

n = constant

qV = constant speed sensor ID

(is supplied as individual item)

The design "with speed sensor G" is including a gears spline at the rotary group of the variable pump and an additional port for the speed record, in which an inductive speed sensor type IDR 18/20-L250 (as to RE 95130) is screwed in. Note: The sensor inclusively necessary mating connector (mating connector for IDR elbow) is supplied as individual item and has to be screwed into the provided port before start-up. To avoid measurment errors, the max. tightening torque of 50 Nm should not be exceeded.

mating connector AMP

(is supplied as individual item)

Size No. of teath A1 A2

71 46 176 170

90 50 176 170

A4VTG

11/12

Brueninghaus Hydromatik

A2

RE 92 012/04.00

Installation and Commissioning Guidelines

General At start-up and during operation the pump housing has imperatively to be filled up with hydraulic fluid (filling of the case chamber). Startup has to be carried out at low speed and without load till the system is completely bleeded. At a longer standstill the case may discharge via operating line. At new start-up a sufficient filling of the housing has to be granted. The leakage oil in the housing has to be discharged to the tank via highest positioned case drain port. The min. suction pressure at port S should not fall below 0,8 bar absolute (cold start 0,5 bar absolute). Installation position Shaft horizontal, further installation positions as to agreement. Installation below tank level Pumps below min. oil level in the tank (standard) Fill up axial piston pump before start-up via highest positioned case drain port Recommendation: Fill up suction lines. Operate pump at low speed (igniton speed) till pump system is completely filled up (Verification: oil is leaking out without bubbles at port pS, discharge oil via gauge pipe into reservoir). Bleed pump at installation position "control device on top" via port R. Bleed closed loop: - variable motor A6VM: via port G - fixed motor A2FM: via operating port A, B - motor with flushing valve: bleeding not necessary Minimal depth of immersion of the suction resp. case drain line in the tank: 200 mm (corresponding to the min. oil level in the tank) Installation on top of tank level Pump on top of min. oil level in the tank Actions as installation below tank level Note: - max. admissible suction height hmax = 800 mm - min. admissible presssure at port S (min. suction pressure)

S T1

R S T1 T2

Brueninghaus Hydromatik GmbH Elchingen Plant Glockeraustrae 2 D89275 Elchingen Phone +49 (0) 73 08 82-0 Telefax +49 (0) 73 08 72 74 Internet: www.rexroth.com/brueninghaushydromatik / E-Mail: info@bru-hyd.com The specified data is for product description purposes only and may not be deemed to be guaranteed unless expressly confirmed in the contract.

All rights reserved Subject to revision

12/12

A4VTG

You might also like

- Axial Piston Compact Unit A10CODocument8 pagesAxial Piston Compact Unit A10COJohn SimmondsNo ratings yet

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- IR Grease Pump Catalouge LM2250E-XX-B3-EnDocument4 pagesIR Grease Pump Catalouge LM2250E-XX-B3-Enankit.jhawarNo ratings yet

- CP CatalogDocument20 pagesCP CatalogCentral Hydraulics100% (1)

- Bomba Denison Serie PremierDocument50 pagesBomba Denison Serie Premiergineslopezruiz100% (1)

- Spare Parts Information-HKN 31021701e 01Document114 pagesSpare Parts Information-HKN 31021701e 01YAKOVNo ratings yet

- AirValves 2013 PDFDocument268 pagesAirValves 2013 PDFSergio Sebastian Ramirez GamiñoNo ratings yet

- L20 Series: Service and Repair ManualDocument28 pagesL20 Series: Service and Repair ManualJoe CorreaNo ratings yet

- Product: Mini Hyd Excavator Model: 304E2 MINI HYD EXCAVATOR ME402271 Configuration: 304E2 Mini Hydraulic Excavator ME400001-UP (MACHINE) POWERED BY C2.4 EngineDocument2 pagesProduct: Mini Hyd Excavator Model: 304E2 MINI HYD EXCAVATOR ME402271 Configuration: 304E2 Mini Hydraulic Excavator ME400001-UP (MACHINE) POWERED BY C2.4 Engineevan100% (1)

- Fan Motor 2 2Document2 pagesFan Motor 2 2Mbahdiro KolenxNo ratings yet

- REXROTH Service Manual PVC PSSFDocument6 pagesREXROTH Service Manual PVC PSSFRaghavendra DeshpandeNo ratings yet

- HMB 100Document12 pagesHMB 100Mohamed ElmakkyNo ratings yet

- Vickers PVB MVB Piston PumpDocument29 pagesVickers PVB MVB Piston Pumppablo cofreNo ratings yet

- Overview Eng CD PDFDocument20 pagesOverview Eng CD PDFRafael Cortes100% (1)

- HNF Lagc Datasheet en PDFDocument16 pagesHNF Lagc Datasheet en PDFMira RedaNo ratings yet

- 2DXL Super Loader Brochure PDFDocument8 pages2DXL Super Loader Brochure PDFSandeep KumarNo ratings yet

- Test Procedure (Margin Pressure and Load Sensing Pressure)Document10 pagesTest Procedure (Margin Pressure and Load Sensing Pressure)Halil KaraNo ratings yet

- Solenoid Control Hk66o102Document40 pagesSolenoid Control Hk66o102seaqu3stNo ratings yet

- Lidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 927940923Document1 pageLidos Lwe Webservice: LTM 1120-1-015 Z23358 Z23358 927940923mohamedNo ratings yet

- VP1 Service ParkerDocument16 pagesVP1 Service ParkerAdrian Alonso Bustos GonzalezNo ratings yet

- Operator Seat AIR 569 - KabseatingDocument20 pagesOperator Seat AIR 569 - KabseatingSolitario AntofaNo ratings yet

- MHV Proportional Directional Control Valve Series MHV... K: FeaturesDocument28 pagesMHV Proportional Directional Control Valve Series MHV... K: FeaturesthijssilderhuisNo ratings yet

- HMC 200Document12 pagesHMC 200Mohamed ElmakkyNo ratings yet

- K3V - DT Kawasaki Hydraulic Pump Parts For For K3V63 / 112 / 140 / 180DTDocument2 pagesK3V - DT Kawasaki Hydraulic Pump Parts For For K3V63 / 112 / 140 / 180DTanon_485665212No ratings yet

- MPV R 01 en PDFDocument35 pagesMPV R 01 en PDFEustahije BrzicNo ratings yet

- 13 - Servo Valve SV 10 - B (Boekwerk)Document36 pages13 - Servo Valve SV 10 - B (Boekwerk)Ivan MaltsevNo ratings yet

- Parts Information: Char-LynnDocument5 pagesParts Information: Char-LynnRidha AbbassiNo ratings yet

- Installation Notes For Axial Piston Units RE 90270/06.91: General PipingDocument12 pagesInstallation Notes For Axial Piston Units RE 90270/06.91: General Pipinghussein_eraki2010No ratings yet

- HMC 080Document12 pagesHMC 080Mohamed ElmakkyNo ratings yet

- Gidronasosy Serii PMV10Document48 pagesGidronasosy Serii PMV10alsief1951No ratings yet

- Rexroth Pump AV8ODocument24 pagesRexroth Pump AV8OvanhoackdNo ratings yet

- Handok Hydraulic - Co: Flow Rate ControlDocument1 pageHandok Hydraulic - Co: Flow Rate Controlanon_485665212No ratings yet

- Table of ContentsDocument27 pagesTable of ContentsEng-Mohammed SalemNo ratings yet

- Bucher Motor ComparisonDocument8 pagesBucher Motor ComparisononurousNo ratings yet

- Radial Piston PumpsDocument135 pagesRadial Piston PumpsTamer Elsebaei EbarhimNo ratings yet

- HY11-3362 Press Control PPCC UKDocument40 pagesHY11-3362 Press Control PPCC UKLucas Cardoso100% (1)

- SAI Hydraulic Motors - Displacement Variation PDFDocument16 pagesSAI Hydraulic Motors - Displacement Variation PDFbrunosamaeianNo ratings yet

- Turolla Hydraulic Gear Pumps Group2 Catalogue en l1016341Document44 pagesTurolla Hydraulic Gear Pumps Group2 Catalogue en l1016341Даниил СторчеусNo ratings yet

- GEH250Document1 pageGEH250JorgeNo ratings yet

- Asdooeidk 33201Document48 pagesAsdooeidk 33201Joze MartinezNo ratings yet

- A10v45 RexrothDocument3 pagesA10v45 RexrothJoaquin ReyesNo ratings yet

- Sauerdanfoss Series s90 Motors CatalogueDocument44 pagesSauerdanfoss Series s90 Motors CatalogueAdrian Alonso Bustos GonzalezNo ratings yet

- Heash Technique B.V. WWW - Heash-Tech - NL Info@heash-Tech - NLDocument50 pagesHeash Technique B.V. WWW - Heash-Tech - NL Info@heash-Tech - NLRidha AbbassiNo ratings yet

- 2011 AC & DC Hydraulic Power Packs CompactDocument97 pages2011 AC & DC Hydraulic Power Packs CompactNicolae MogosNo ratings yet

- Valvula Placa RexrothDocument36 pagesValvula Placa RexrothRafael Koppe100% (1)

- ICVD 01 GB 0319 - WebDocument20 pagesICVD 01 GB 0319 - WebintecelNo ratings yet

- Re92709 2015-12 PDFDocument12 pagesRe92709 2015-12 PDFnedimNo ratings yet

- Tiras de Bronze CatDocument8 pagesTiras de Bronze CatPedro Lorenço JorgeNo ratings yet

- Pvh131 141 Variable Disp Piston Pump 11 Design PLL - 1444Document9 pagesPvh131 141 Variable Disp Piston Pump 11 Design PLL - 1444Agus Yulfizar100% (1)

- Axial Piston Pump 2Document8 pagesAxial Piston Pump 2Eslam MansourNo ratings yet

- Re91401 A2foDocument20 pagesRe91401 A2foTaz Juan GNo ratings yet

- 45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Document56 pages45 Series G Frame 74cc and 90cc Parts Manual (520L0582 REV AA Dec 2007)Sasko Dimitrov100% (2)

- Hydraulic Study MaterialDocument123 pagesHydraulic Study Materialaman kumarNo ratings yet

- Injector Installation 107 EngineDocument5 pagesInjector Installation 107 EnginevalterripNo ratings yet

- Aa2fm Model CodeDocument27 pagesAa2fm Model CodeCristianNo ratings yet

- P1-PD 18cc-140cc Service ManualDocument64 pagesP1-PD 18cc-140cc Service ManualGianna FrolaNo ratings yet

- Rexroth 92500Document48 pagesRexroth 92500EVCY100% (1)

- Axial Variable Duoble PumpDocument40 pagesAxial Variable Duoble Pumpveljeg100% (1)

- Bomba Hidrailica A10VSODocument44 pagesBomba Hidrailica A10VSOkiarabenitezparejaNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Steering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minDocument10 pagesSteering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minAhmed Abd ElhakeemNo ratings yet

- Service Case With Test Unit For Proportional and Servo Valves With Integrated Electronics Type VT-VETSY-1Document12 pagesService Case With Test Unit For Proportional and Servo Valves With Integrated Electronics Type VT-VETSY-1Ahmed Abd ElhakeemNo ratings yet

- Re 29929Document4 pagesRe 29929Ahmed Abd ElhakeemNo ratings yet

- المصطلحات الفنية PDFDocument8 pagesالمصطلحات الفنية PDFAhmed Abd ElhakeemNo ratings yet

- Check Valve, Hydraulically Operated, Type Z2SRK 10Document4 pagesCheck Valve, Hydraulically Operated, Type Z2SRK 10Ahmed Abd ElhakeemNo ratings yet

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocument8 pages4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemNo ratings yet

- Re 29933Document4 pagesRe 29933Ahmed Abd ElhakeemNo ratings yet

- OpenDocument1 pageOpenAhmed Abd ElhakeemNo ratings yet

- Combination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XDocument4 pagesCombination Pumps R4 + G3 Radial Piston Pump Type R4, Series 1X + Gear Pump Type G3, Series 3XAhmed Abd ElhakeemNo ratings yet

- Re 10460Document20 pagesRe 10460Ahmed Abd ElhakeemNo ratings yet

- Re 15190Document24 pagesRe 15190Ahmed Abd ElhakeemNo ratings yet

- Re 00208Document134 pagesRe 00208Ahmed Abd ElhakeemNo ratings yet

- Re 01200Document24 pagesRe 01200Ahmed Abd ElhakeemNo ratings yet

- Re 10039Document10 pagesRe 10039Ahmed Abd ElhakeemNo ratings yet

- Re 08006Document8 pagesRe 08006Ahmed Abd ElhakeemNo ratings yet

- Test Point Card BU 2 Type VT-BU2, Series 3X: Replaces: 10.85Document2 pagesTest Point Card BU 2 Type VT-BU2, Series 3X: Replaces: 10.85Ahmed Abd ElhakeemNo ratings yet

- Re 07700Document2 pagesRe 07700Ahmed Abd ElhakeemNo ratings yet

- RE18136Document4 pagesRE18136Ahmed Abd ElhakeemNo ratings yet

- Re 00208Document134 pagesRe 00208Ahmed Abd ElhakeemNo ratings yet

- Re 15224Document12 pagesRe 15224Ahmed Abd ElhakeemNo ratings yet

- Steering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minDocument10 pagesSteering Unit Type LAGC: Nominal Sizes 50 To 630 Series 1X Nominal Pressure 175 Bar Maximum Flow 63 L/minAhmed Abd ElhakeemNo ratings yet

- Probg3000: Gate SeriesDocument7 pagesProbg3000: Gate SeriesTesteNo ratings yet

- Liebherr LTM 1090-4.1 Mobile Crane - 90t - InformationDocument18 pagesLiebherr LTM 1090-4.1 Mobile Crane - 90t - InformationCallumWoodward100% (2)

- OuktDocument120 pagesOuktKrzysztof Kjb100% (1)

- 651E - 657E Wheel Tractor ScrapersDocument22 pages651E - 657E Wheel Tractor ScrapersAntony Perez GuerraNo ratings yet

- TT 3.2 QuattroDocument41 pagesTT 3.2 Quattromohammad al raeiNo ratings yet

- SIZER 0510 enDocument39 pagesSIZER 0510 enmamijato100% (1)

- Manitou MRT 3255 - MRT-X 3255 (EN)Document4 pagesManitou MRT 3255 - MRT-X 3255 (EN)ManitouNo ratings yet

- Camion 777F Caterpillar.Document36 pagesCamion 777F Caterpillar.Francisco Ferrer100% (1)

- Transmission of Motion & Power3Document67 pagesTransmission of Motion & Power3Vinay GaikwadNo ratings yet

- Downloaded From Manuals Search EngineDocument19 pagesDownloaded From Manuals Search EngineOmarBle100% (2)

- Manual de Servicio 865 DHPDocument606 pagesManual de Servicio 865 DHPMiguelEnriqueCastillo100% (4)

- Barnwell Rotary Shaft SealsDocument28 pagesBarnwell Rotary Shaft SealsZoran JankovNo ratings yet

- PlásticosDocument790 pagesPlásticosZiani Santana100% (1)

- Sym Symphony 125 User Manual (EN)Document24 pagesSym Symphony 125 User Manual (EN)Giulia_067% (3)

- Eaton Fuller RTX 14715Document43 pagesEaton Fuller RTX 14715Mauricio DuranNo ratings yet

- Construction Working and Maintenance of Electro Hydraulic Thruster Drum BrakesDocument26 pagesConstruction Working and Maintenance of Electro Hydraulic Thruster Drum BrakesJoshua GrahitaNo ratings yet

- 4 Chapter 4 2015Document32 pages4 Chapter 4 2015BernadetteNo ratings yet

- 953c PDFDocument20 pages953c PDFLuis Fernando Vasquez RamosNo ratings yet

- TransmisionntDocument11 pagesTransmisionntEdgardo Alfonso Ilabaca Saez100% (3)

- In Planetary Gears: Lo, Adiidistri'Bluti, OnDocument4 pagesIn Planetary Gears: Lo, Adiidistri'Bluti, OnprasannaNo ratings yet

- 115-03 Service Manual (1158075001 EN) 06-2008Document226 pages115-03 Service Manual (1158075001 EN) 06-2008Dale Verseput94% (16)

- G - 2 - AycDocument26 pagesG - 2 - AycRobert Sutton0% (1)

- ClutchesDocument2 pagesClutchesAlonzo Ribera100% (1)

- Worm GearingDocument37 pagesWorm GearingAnonymous Hy5Ir9QXNo ratings yet

- Powershift ValvolineDocument2 pagesPowershift Valvolinerolex21No ratings yet

- Sumitomo - Aerator ApplicationsDocument8 pagesSumitomo - Aerator ApplicationsFabricio Roldan ErazoNo ratings yet

- IECEx OD 020 Ed1.0Document7 pagesIECEx OD 020 Ed1.02Dave2No ratings yet

- Advance Automotive SyllabusDocument2 pagesAdvance Automotive SyllabusAditya DeshpandeNo ratings yet

- Valvoline Service PlusDocument2 pagesValvoline Service PlusVictor ZhicayNo ratings yet

- HH 219 - Maintenance, Operation and Parts ManualDocument54 pagesHH 219 - Maintenance, Operation and Parts ManualCentrifugal Separator100% (1)