Professional Documents

Culture Documents

Oncept F IS (AS Nsulated Witchgear) Aintenance AND Xternal Iagnosis

Uploaded by

Yahya Faiez WaqqadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oncept F IS (AS Nsulated Witchgear) Aintenance AND Xternal Iagnosis

Uploaded by

Yahya Faiez WaqqadCopyright:

Available Formats

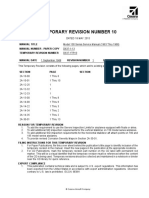

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

Chapter

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

1. CONCEPT OF GIS MAINTENANCE

1.1 Basic Concept of Maintenance and Inspection. In case of GIS, the part covered with gas remains under a good environmental condition without being influenced by water and air pollution in open air, in contrast to the conventional air insulation type equipments. SF6 Gas has been expected to allow longer life of the contacts by high ability of arc extinction and the insulation ability, and nowadays, it is deemed to have succeeded in realizing longer life. In addition, the mechanical coordination has been more developed in every part by means of the structural simplification. On the other hand, it is noted that the GIS overhaul inspection requires some measures; name~ 4ithdrawing of gas, air drawing out for vacuum and air supply, and the efficiency is 5u59eptl3ble to the surrounding air and air dust. The comparative analysis of the faults reveals, as shown in Fig.1 that the rate is about 1 %, which is very low and satisfactory in comparison to the values reported in air insulation equipments. As far as the GCB (Gas Circuit Breaker), which forms the most important part of GIS, is concerned, almost of the faults (about 80 % of the total) ate caused in the operation mechanism such the oil pressure mechanism, air pressure supervisory mechanism, control relays and piping etc. while the internal faults, such as the one in the breaking part is very few in number (several percents). Then the analysis of the fault occurrence shows that the greater part of the faults (about 60 %) took place within one year since the inspections, as is evident in Fig. 2{ from which it is derived that there are many cases in which these faults would be attributed to the inspections themselves, for example neglecting to bolt. It is summarized that:

1.

GIS has been developed for longer life.

Ch. #04

35

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

2. Considering the working property of the overhaul inspection and also the aspects shown when the faults happen, it is desirable to avoid said overhaul inspections as much as possible. Accordingly, it is expected that further effort to avoid the overhaul inspection will allow a smaller number of faults. As mentioned above, the Japanese concept is to intend maintenance without overhaul inspection. For detail of the Japanese maintenance standard of GIS.

36

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

1.2 Concept of External Diagnosis

As explained hereinbefore, maintenance without internal inspection is considered to assure a high reliability in case of GIS, since it is designed for longer life. However, in order to decrease other faults than the ones attributable to the internal inspections, a preventive maintenance is required with adequate understanding of the equipment conditions, and making eventual modifications whenever necessary. For said preventive maintenance, the external diagnosis shall be the ones, capable of meeting the following conditions: 1. To grasp exactly the inside conditions without overhaul. 2. To allow effective diagnosis by a few people 3. To understand as much as possible the equipment conditions during operation In Japan, said external diagnosis has been developed based on the concept described above and it has been adopted partially. The detail of the maintenance and inspection standard as we11 as the external diagnosis are also discussed in next section

2. STANDARD FOR MAINTENANCE AND INSPECTION

This standard is based on the idea that overhaul inspection is not made except the case when it is necessary/for some parts easily affected by open air such as operation mechanism part, in conformity with the concept, as mentioned in 1-1, for nomaintenance and no-inspection. The maintenance inspections are classified as follows: 2.1 Inspection Tour This is made during a tour of inspection to check. externally a presence of abnormal condition in GIS when it's operating:

37

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

Inspection Remark Item General External Items

Inspection Contents

Operation of switch indicator and

switch indicating lamp - Occurrence of abnormal noise and abnormal smell - Presence of overheat discoloration of terminals - Crack or damage of porcelain tubes and its pollution - Rust and damage of earthing case and support structure

-----------------------------------------------------------------------------------------------------------------------------------------Operation - Indication of pressure gage (Air, Oil, gas pressure gage) In operation box and panel, Device and - Indication condition of operation indicator of gas compressor an inspection susceptible of Control Panel an easy front visual checking is required Control Panel -----------------------------------------------------------------------------------------------------------------------------------------Air Leak - Presence. of air leakage noise from air system

-----------------------------------------------------------------------------------------------------------------------------------------Oil Leak - Oil leakage from oil pressure system

Ch. #04

38

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

-----------------------------------------------------------------------------------------------------------------------------------------Drainage - Drainage from air tank and piping

-----------------------------------------------------------------------------------------------------------------------------------------

2.2 Periodic Inspection This should be made every certain period in order to maintain GIS always under a normal condition, so that it can fully accomplish its purpose. 1. Usual Inspection This is made mainly from outside of GIS when stopping operation. Inspection Item Switching Operation Test Detail of Inspection - Switching indication Period Remark

39

Ch. #04

Every 3 If no operation is Years made through one year, it is preferable to - Reading of pressure gauge prior and operate once a year, posterior to operation (air, oil, gas using operation spressure gauge), and checking of air witches to open and leak noise and oil leak. close several times at a time or operation stop. - Operation checking of operation

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

meter

External General Item Operation Device and Control Panel

-Fixing condition of bushing terminal

Every 3 Mechanical Checking years is required

- Checking of humidity, rust and Every 3 Mechanical Checking pollution in operation box and panel years is required - Oil supply and cleaning. -Checking of fixed condition of low voltage circuit wiring

Measuring Test

Measurement resistance

insulation Every 3 For main years conductive part: Equal to or more than 1000 M. - Checking of burn-out heater OHM Every 3 years

of

Other items pertinent to that of inspection tour

(NOTE): This is performed in equipments which structurally allow said test. 2. Precise inspection

This involves an overhaul inspection to be made when it is needed mainly for operation mechanism section while GIS stops operation, as well as Parts-replacement of said section in conformity with this standard.

40

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

Inspection Item

Inspection Contents Period - Repair of rust, deformation damage in spring Remark

Operation -

every 6 - Adjustment of stroke joint section years

Device and - Checking of abnormal condition found in pins of fixing section Control -Oil supply Panel - Inspection and repair of auxiliary switch Adjustment of oil dush pot and oil replacement - Inspection and repair of valves - Checking of air leak in pneumatic operator and oil leak in oil operator

- Parts-replacement according to replacement standard Measuring Test - Switching characteristics test (Measurement of every 6 contact closing time and parting time and three phase years unbalance by voltage and pressure at site). - Measurement or minimum operation pressure

41

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

and voltage. - Trip 'free test - Pressure switch test (Air, oil and gas) - Checking of pressure gauge - Measurement of consume in air, oil and gas operators Other items pertinent to usual insp. 2.3 Temporary Inspection This implies temporary inspection (including overhaul inspection) made for sections where said inspection is regarded as necessary in the following' cases: 1. 2. In case of detecting abnormal conditions In case of attaining the specified switching operation number every 6 years

42

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

Inspection Condition

Inspection Content

Remark

In case of reaching the specified -Overhaul inspection and repair number: (In case that the following items attain the specified operation number. wore parts. - Unloaded operation - Leading and lagging small current operation - Load current operation - Loop current operation - Current similar to the rated breaking current operation. -Inspection and repair and replacement of parts wherever needed of breaking or disconnecting section, and replacement of

In case of discovering abnormal conditions by inspection tour or usual inspection

Ch. #04

43

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

3.

EXTERNAL DIAGNOSIS OF GIS

As mentioned fn the point 1-2, it is required that some appropriate external diagnosis should be applied to GIS for the purpose of fully detecting said faults. In Japan, some external diagnosis has been already put into practical use for said purpose offering the expected results. At this present, another new external diagnosis is in course of development and study with help of other manufacturers, for which we expect to make further study of their effect on the equipments or their application method from now on. 3.1 Types of External Diagnosis Following is the outline of some technique already introduced into practical use and the one under study:

PRACTICALLY USING EXTERNAL DIAGNOSIS

1. Measurement of Operating Time and Operation Number Operating time measurements are performed through digital time meter or' electromagnetic oscillograph. During its operation, said time measurement is carried out by means of auxiliary switch with equalization, while when stopping its operation, a direct measurement is possible in the main circuit using earthing devices. On the other hand, for the measurement of operation number, the available method is to record the obtained number of CO operation using operation number counter, which is a counter usually used. 2. Measuring of SF6 Gas Pressure and Gas Analysis The pressure of SF6 gas is constantly observed by use of temperature-compensatingdensity switch, because of the fluctuating property with the surrounding temperature. When the gas density becomes equal to or lower than the allowed level, the alarm contact is switched on, with close relation to the GIS insulation ability and breaking ability. The gas analysis is helpful for easily finding of abnormality in internal insulation system, allowing the measurement of water content in. gas1 and that of purity as well as the detection of decomposed gas caused when a harmful partial discharge happens internally. In case of a fault with internal arcing, the detection of decomposed gas reveals allocation of this fault. Corresponding devices are portable gas chromatograph with micro-comput9r, gas detector tube, water content meter, gas tester etc. 3. Detection of Metallic Alien Substance located in GIS through Ultrasonic Wave Mike

Ch. #04

There is a case that some materials or forms of metallic substance existent in GIS tank may float in electric field at the operation voltage, causing partial discharge, which greatly

44

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

reduces withstand voltage efficiency of 013. In this case, said metallic substance can be discovered by detecting the ultrasonic wave which originates from the repeated fine collisions of these' substances with tank. The analysis procedure is to attach said ultrasonic wave microphone to the tank surface of GIS for analyzing thus detected ultrasonic-wave through the analyzer. 4. Measuring of partial discharge existent in GIS It is effective to control the internal partial discharge volume for easy discrimination of electric abnormal condition in GIS. Though this measurement of partial discharge is one of the most difficult measuring method, it is possible to confirm the absence of partial discharge in spacers themselves or in their vicinity by means of such a device that allows to detect the electric charge of partial discharge, using both the shield ring on the grounding side of the insulation spacer and the stray capacitance on the high voltage side.

Effective External Diagnosis

The methods considered effective under development are as follows: 1. Internal prospect by X-ray Internal X ray photographing of GIS is considered effective as an available method to discover slacks in bolts, which cause the greater part of the internal fault. For this application, enough attention should be given to - a internal prospect executed during operation, with lower level of X ray irradiation not to do harm to human body nor to the equipments. This has an advantage of, offering vivid images and is practical indeed. 2. Low speed drive method The torques of the switching equipments is minutely changed during the operation when something in GIS is damaged or playing, or when grease is mature. For vivid images of such a minute change in torques, the effective measures are to execute the operation at low speed, for which it is required to add a device driven at low speed when the equipments stopped. 3. Detection method of minute oscillation in tank The electric faults caused in GIS appear as minute oscillation in tank, which is detected through this method. Following Table - l includes the summary of external diagnosis which are effective against some failures assumed concretely based on the above description on the external phenomena resulting from inside conditions, with introduction of the effective detection methods (external diagnosis) corresponding to said phenomena.

Ch. #04

45

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

46

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

47

Ch. #04

CONCEPT OF GIS (GAS INSULATED SWITCHGEAR) MAINTENANCE AND EXTERNAL DIAGNOSIS

3.2 Concept for Application of External Diagnosis There are many kinds of external diagnosis, as listed above; however, none of them are possible to become available for every condition of the equipment, because it is excessively difficult to grasp conditions of equipment completely and exactly. Accordingly, it is indispensable to make an overall judgment by an appropriate combination of various methods according to the purpose and equipment condition. In the following four periods, these methods will be applied to GIS: 1. Factory test 2. Installation test at site 3. During operation (constantly or at the time of inspections). 4. At the time of abnormal condition. 3.3 Technical Subjects for Future External Diagnosis The pertinent standard will b4 established indicating the types' of diagnosis applicable to above four stages and the control value in each case, based on the future study in detail on effect and sensitivity of said methods under development In addition, a diagnosis system by computers will be established, since the analysis based on a constant data accumulation is effective for operation number, gas pressure, temperature rise and partial discharge, for the purpose of continuous and constant supervision, as far as the application form is concerned.

48

Ch. #04

You might also like

- Quoting and Proposals: Carrier Compressor Inspection OfferDocument12 pagesQuoting and Proposals: Carrier Compressor Inspection OfferIwan HusaeniNo ratings yet

- Recommendations For The Inspection of Steam TurbinesDocument20 pagesRecommendations For The Inspection of Steam Turbinesjmsponte100% (2)

- Time Limits / Maintenance Checks A. GeneralDocument6 pagesTime Limits / Maintenance Checks A. GeneralAlexis CabreraNo ratings yet

- Maintenance Inspections: Standby Inspections Running InspectionsDocument35 pagesMaintenance Inspections: Standby Inspections Running Inspectionsrafiee100% (2)

- Maintenance Programs of Gas and Steam TurbinesDocument26 pagesMaintenance Programs of Gas and Steam Turbinesmexx4u2nv100% (1)

- Steam Turbine Inspection BhelDocument26 pagesSteam Turbine Inspection Bheldnageshm4n244100% (5)

- Ger 3620fDocument34 pagesGer 3620ftechnica100% (1)

- CompressorDocument17 pagesCompressorLipika GayenNo ratings yet

- Hydro PlantDocument11 pagesHydro PlantSagar PatilNo ratings yet

- TB43 0151Document10 pagesTB43 0151Glenn SussNo ratings yet

- Pipe LineDocument62 pagesPipe LineBahtiar Anak LaNang100% (1)

- Part A CH 2 Sec 9Document4 pagesPart A CH 2 Sec 9barrysmith77No ratings yet

- Centrifugal Compressor TestingDocument9 pagesCentrifugal Compressor TestingEnergy 2GreenNo ratings yet

- Overall Tech. Cap. 4.1 - Life Extension Hour Technical NoteDocument6 pagesOverall Tech. Cap. 4.1 - Life Extension Hour Technical NoteiJordanScribdNo ratings yet

- Centrifugal Compressor TestingDocument10 pagesCentrifugal Compressor TestingBalasubramanian CNo ratings yet

- Edoc - Pub - Steam Turbine Inspection Bhel PDFDocument26 pagesEdoc - Pub - Steam Turbine Inspection Bhel PDFKarthikeyanNo ratings yet

- Steam Turbine Inspection Bhel PDFDocument26 pagesSteam Turbine Inspection Bhel PDFMohammedBujair100% (4)

- Steam Turbine Inspection Bhel PDFDocument26 pagesSteam Turbine Inspection Bhel PDFReda NariNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim Khalil100% (1)

- Temp Rev 5 - 152 Service ManualDocument200 pagesTemp Rev 5 - 152 Service ManualKamal Jit DhimanNo ratings yet

- Heavy Duty GT: MaintenanceDocument79 pagesHeavy Duty GT: Maintenanceprasad5034100% (5)

- Centrifugal Gas Compressor TestingDocument12 pagesCentrifugal Gas Compressor Testingjohn100% (2)

- 05 00 00 inDocument4 pages05 00 00 inMarco Antonio PrietoNo ratings yet

- Plant Inspection Guideline ManualDocument36 pagesPlant Inspection Guideline ManualAcid Burns100% (1)

- API 510 VesselsDocument11 pagesAPI 510 Vesselsmoonstar_dmeNo ratings yet

- TB Maintenance ConceptDocument16 pagesTB Maintenance ConceptNur Farahatan100% (1)

- T&CDocument11 pagesT&Cccy199No ratings yet

- SAIC-A-2015 Rev 2Document9 pagesSAIC-A-2015 Rev 2ரமேஷ் பாலக்காடுNo ratings yet

- Analisis de Valvula Anti Surge y Fast StopDocument17 pagesAnalisis de Valvula Anti Surge y Fast Stopmcs21187No ratings yet

- Maint IPENDocument13 pagesMaint IPENosmaidaNo ratings yet

- Unit Iv Classification of Jet Engine ComponentsDocument81 pagesUnit Iv Classification of Jet Engine Componentsraj6062No ratings yet

- Amm 05-10-00 Time Limits and Maintenance ChecksDocument21 pagesAmm 05-10-00 Time Limits and Maintenance ChecksLUCIENE ORECCHIO VIEIRANo ratings yet

- Ssid Doc For 180Document60 pagesSsid Doc For 180Pankaj SharmaNo ratings yet

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument11 pagesCondition Monitoring of Steam Turbines by Performance AnalysisSikander Girgoukar100% (1)

- Overview of AGA 7 Revision: On Gu Id El in EsDocument5 pagesOverview of AGA 7 Revision: On Gu Id El in EsTriHendrawanNo ratings yet

- Maintenance DetialsDocument9 pagesMaintenance DetialsAdura OgunnuNo ratings yet

- Pump Inspection HandbookDocument16 pagesPump Inspection Handbookyoonchankim0911100% (2)

- Turbines Paper Ray BeebeDocument9 pagesTurbines Paper Ray Beebealiscribd46No ratings yet

- Pneumatic TestDocument6 pagesPneumatic TestShrichand G. BathvNo ratings yet

- Ni 2916Document13 pagesNi 2916nandafontenelleNo ratings yet

- 23 05 93 Testing Adjusting and BalancingDocument7 pages23 05 93 Testing Adjusting and BalancingLangzkie NalipaNo ratings yet

- AICIP ExamDocument8 pagesAICIP Examcybercreed2002_11486100% (1)

- A319 00 SurcicingDocument4 pagesA319 00 Surcicingsan2inNo ratings yet

- Blanik l13 - Gfa Ad-369Document11 pagesBlanik l13 - Gfa Ad-369mersoigNo ratings yet

- Inspection Operation 18: Item Code Number Task Zone Mech IN-SP RemarksDocument1 pageInspection Operation 18: Item Code Number Task Zone Mech IN-SP RemarksBrian NolascoNo ratings yet

- HVAC Testing-Adjusting-Balancing For Small SystemsDocument17 pagesHVAC Testing-Adjusting-Balancing For Small SystemsgabrielNo ratings yet

- Static Equipment and Typical Maintenance JobsDocument46 pagesStatic Equipment and Typical Maintenance JobsDedy WindiyantoNo ratings yet

- Appendix-3.0 Scope of Chiller Maintenance WorksDocument3 pagesAppendix-3.0 Scope of Chiller Maintenance Worksnoormuddassirkhan100% (1)

- ML C Ser c206hmm15Document3 pagesML C Ser c206hmm15Juan TapiaNo ratings yet

- Gdflo 497Document9 pagesGdflo 497raritylimNo ratings yet

- SAIC-A-2015 Rev 7Document8 pagesSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- Operational Inspection and Nonroutine Inspection NotesDocument1 pageOperational Inspection and Nonroutine Inspection NotesJennifer AjeroNo ratings yet

- QA AssesmentDocument6 pagesQA AssesmentBanglar Song -বাংলার গানNo ratings yet

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDocument37 pagesRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaNo ratings yet

- Maintenance Plan: Maintenenance Engineering (Me-403)Document22 pagesMaintenance Plan: Maintenenance Engineering (Me-403)moe100% (1)

- Civil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithDocument6 pagesCivil Aviation Requirements Section 2 - Airworthiness Series I' Part I Issue Ii, 15Th March, 1976 Effective: ForthwithManish MishraNo ratings yet

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Gas Turbine Off-Line Compressor Washing Operation: Functional DescriptionDocument2 pagesGas Turbine Off-Line Compressor Washing Operation: Functional DescriptionYahya Faiez WaqqadNo ratings yet

- CH 4Document22 pagesCH 4Yahya Faiez WaqqadNo ratings yet

- Gas Turbine MaintenanceDocument80 pagesGas Turbine MaintenanceYahya Faiez WaqqadNo ratings yet

- Metallurgical Failure Analysis: by DR - Yahya WaqadDocument130 pagesMetallurgical Failure Analysis: by DR - Yahya WaqadYahya Faiez WaqqadNo ratings yet

- Duct Leakage Testing - SUPPLY SYSTEM: TroubleshootingDocument3 pagesDuct Leakage Testing - SUPPLY SYSTEM: TroubleshootingYahya Faiez WaqqadNo ratings yet

- Advantages of Using HamiltonDocument3 pagesAdvantages of Using HamiltonYahya Faiez WaqqadNo ratings yet

- Application of The Calculus of Variation and Lagrange EquationsDocument4 pagesApplication of The Calculus of Variation and Lagrange EquationsYahya Faiez Waqqad100% (1)

- Equipment Earthing: 1. GeneralDocument16 pagesEquipment Earthing: 1. GeneralYahya Faiez WaqqadNo ratings yet

- E DX Xe X e DX D X Xe Xe e DX X e DX X E: Because Now We Will Start With A New Guess For The Second Term I.EDocument1 pageE DX Xe X e DX D X Xe Xe e DX X e DX X E: Because Now We Will Start With A New Guess For The Second Term I.EYahya Faiez WaqqadNo ratings yet

- Additional Examples: SolutionDocument4 pagesAdditional Examples: SolutionYahya Faiez WaqqadNo ratings yet

- Even NDocument1 pageEven NYahya Faiez WaqqadNo ratings yet

- Specifications of Typical Substation Earthing SystemDocument5 pagesSpecifications of Typical Substation Earthing SystemYahya Faiez WaqqadNo ratings yet

- Earthing OF Impulse Voltage StationsDocument6 pagesEarthing OF Impulse Voltage StationsYahya Faiez WaqqadNo ratings yet

- CHPT 4Document54 pagesCHPT 4Yahya Faiez Waqqad0% (1)

- General Operation & Maintenance Instructions For Earthing DevicesDocument5 pagesGeneral Operation & Maintenance Instructions For Earthing DevicesYahya Faiez WaqqadNo ratings yet

- Cha 1Document40 pagesCha 1Yahya Faiez WaqqadNo ratings yet

- Electric Power System "Distribution System Installations To Be Grounded"Document11 pagesElectric Power System "Distribution System Installations To Be Grounded"Yahya Faiez WaqqadNo ratings yet

- CHPT 3 PDFDocument8 pagesCHPT 3 PDFYahya Faiez WaqqadNo ratings yet

- Chemical Plant TroubelshootingDocument100 pagesChemical Plant TroubelshootingYahya Faiez WaqqadNo ratings yet

- Electric Power System "Distribution System Installations"Document11 pagesElectric Power System "Distribution System Installations"Yahya Faiez WaqqadNo ratings yet

- Paper MT Ii PDFDocument1 pagePaper MT Ii PDFiscristin26No ratings yet

- THE TITLE OF EXPERIMENT Ion ExchangeDocument18 pagesTHE TITLE OF EXPERIMENT Ion Exchangeputri wildanaNo ratings yet

- 2018 Year 9 Science ProgramDocument16 pages2018 Year 9 Science Programapi-364379734No ratings yet

- 12 Types of Bearing DefectsDocument5 pages12 Types of Bearing Defectsjameel babooramNo ratings yet

- 0901 B 803808 e 4479Document7 pages0901 B 803808 e 4479SiddharthapachisiaNo ratings yet

- Influence of Acerola Pulp Concentration On Mead Production by Saccharomyces Cerevisiae AWRI 796Document8 pagesInfluence of Acerola Pulp Concentration On Mead Production by Saccharomyces Cerevisiae AWRI 796mashelyNo ratings yet

- Standard Book Material - Thermodynamics - Arjuna JEE AIR 2024 (Physical Chemistry)Document5 pagesStandard Book Material - Thermodynamics - Arjuna JEE AIR 2024 (Physical Chemistry)PULKIT ARORANo ratings yet

- HW3 QM2 Fall2014Document1 pageHW3 QM2 Fall2014Mena Awan100% (1)

- Limnologica: Wojciech Ejankowski, Tomasz LenardDocument8 pagesLimnologica: Wojciech Ejankowski, Tomasz LenardMoltimer Folchart CrawNo ratings yet

- Assignment 4Document2 pagesAssignment 4challamjNo ratings yet

- Silver Clusters in Zeolites: Structure, Stability and PhotoactivityDocument1 pageSilver Clusters in Zeolites: Structure, Stability and PhotoactivityJan HermannNo ratings yet

- Sedimentation 1Document25 pagesSedimentation 1JatskinesisNo ratings yet

- 14 List of Products For Cert of Fitness (1) DNVDocument23 pages14 List of Products For Cert of Fitness (1) DNVCrywul Suitswitt FazhNo ratings yet

- A Sustainable Bioplastic Obtained From Rice StrawDocument12 pagesA Sustainable Bioplastic Obtained From Rice StrawNovrynda Eko SatriawanNo ratings yet

- Remote Sensing PresentationDocument18 pagesRemote Sensing PresentationShoaibNo ratings yet

- Chapter 2 Pharmaceutical Aids and NecessitiesDocument11 pagesChapter 2 Pharmaceutical Aids and NecessitiesZarah Pauline Jimenez100% (2)

- W1 L5 - Laboratory ApparatusDocument23 pagesW1 L5 - Laboratory ApparatusSaba OsamahNo ratings yet

- BTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Document8 pagesBTech (Mechanical With Specialization in Energy Engineering) Curriculum For AY2012-13Akshat GargNo ratings yet

- Basic Ecology Principle and ConceptDocument96 pagesBasic Ecology Principle and ConceptRhoxie RoxasNo ratings yet

- Polymer SyllabusDocument6 pagesPolymer SyllabusJOSEPH HERBERT MABELNo ratings yet

- Biology Unit PlanDocument10 pagesBiology Unit Planapi-246097943No ratings yet

- Model Paper Engg - Chemistry 1 1 r16Document1 pageModel Paper Engg - Chemistry 1 1 r16vrkoradaNo ratings yet

- Science 7 ExamDocument5 pagesScience 7 Examangge21No ratings yet

- Ur m60Document3 pagesUr m60Goran JurisicNo ratings yet

- Standard SpecificationsDocument5 pagesStandard SpecificationsIan54321No ratings yet

- 99ebook Com Msg00388 PDFDocument15 pages99ebook Com Msg00388 PDFM Sarmad KhanNo ratings yet

- SPE-10489-PA PVT y Scal PDFDocument9 pagesSPE-10489-PA PVT y Scal PDF'Andres TorregrosaNo ratings yet

- Is 439 1989Document11 pagesIs 439 1989rajpd28No ratings yet

- Maharashtra HSC Chemistry Paper 2-Target PublicationDocument45 pagesMaharashtra HSC Chemistry Paper 2-Target PublicationKhanAbdullah100% (1)

- WEDECO LBXSeriesDocument8 pagesWEDECO LBXSeriesÁrpád VassNo ratings yet