Professional Documents

Culture Documents

Chapter 17

Uploaded by

Kathrina CastroCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 17

Uploaded by

Kathrina CastroCopyright:

Available Formats

This Accounting Materials are brought to you by www.everything.freelahat.

com

CHAPTER 17

INVENTORY MANAGEMENT

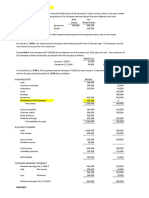

[Problem 1]

Inventory (old)

=

Inventory (new)

=

Decrease in inventory

[P48M/(360 days/8)]

[P48M/(360 days/6)]

Investment income (P266,667 x 15%)

Savings from increased efficiency

Total increase in income

=

=

P1,066,667

800,000

P 266,667

P 40,000

260,000

P300,000

[Problem 2]

1.

EOQ

[(2 x 3,600 x P200) / P25]

2.

No. of orders =

3,600 / 240

15 orders

3.

Average inventory

120 units

4.

Ordering costs (15 x P200)

Carrying costs (120 units x P25)

Total relevant inventory costs

240 / 2

240 units

P3,000

3,000

P6,000

[Problem 3]

1.

EOQ

Order

size

6,400

1,600

400

200

100

No. of

orders

2.5

10

40

80

160

2.

[(2 x 16,000 x P15) / P3]

Ordering costs

=

=

400 units

Carrying costs

Cost

Ordering

per order costs

P 15

P 37.50

15

150.00

15

600.00

15

1,200.00

15

2,400.00

No. of Orders

Average inventory

Average

Carrying

Inventory CCPU cost

TRIC

3,200

P 3 P9,600 P9,637.50

800

3

2,400 2,550.00

200

3

600 1,200.00

100

3

300 1,500.00

50

3

150 2,550.00

Annual demand / Order size

Order size / 2

This Accounting Materials are brought to you by www.everything.freelahat.com

3.

EOQ Graph

[Problem 4]

1.

EPR

[(2 x 40,000 x P40) / P5]

2.

No. of Set-ups =

3.

Ave. inventory

4.

Set-up costs (50 x P40)

Carrying costs (400 x P5)

Total relevant inventory costs

40,000 / 800

=

800 / 2 =

800 units

50

400 units

P2,000

2,000

P4,000

[Problem 5]

1.

EOQ

2.

2,000

[(2x4,000xP2)/CCPU]

(2,000)2

16,000 / CCPU

CCPU

16,000 / 4,000,000

CCPU

P.004

3.

200

=

2

4.

{(2x36,000xP10)/[(P10x10%)+P0.40]}

717 units

[(2x6,000xSUC)/P0.60]

(200) =

12,000 SUC / 0.60

24,000 =

12,000 suc

SUC

24,000 / 12,000

SUC

P2.00

EOQ

[(2x10,000xP25)/(P1x12.5%)]

2,000 units

5.

EOQ (pesos) =

[(2xP36,000xP200)/20%]

P8.485

6.

EOQ (pesos) =

[(2xP60,000xP30)/1%]

P6,000

no. of orders =

P60,000 / P6,000

10

EOQ

[(2x400xP8)/(P5x20%)]

80 units

7.

This Accounting Materials are brought to you by www.everything.freelahat.com

[Problem 6]

1)

1.

2.

3.

2)

Normal usage (10,000 / 250)

Lead time quantity (30 days x 40 units)

Safety stock quantity (40 days x 40 units)

Reorder point

40 units

1,200 units

1,600

2,800 units

c)

Normal Usage (30,000 / 300 days = 100 units)

1.

LTQ (12 days x 100 units)

2.

SSQ (7 days x 100 units)

700 units

(12 days x 100 units) 300 units

3.

ROP

4.

Ave inventory = (6,000/2) + 1,000 units =

Lead time usage

= 10 days x (6,000/300)

d)

ROP

e)

LTQ [20 days x (10,000/250)]

SSQ (20 days x 30 units)

ROP

= 600 units + 300 units

1,200 units

1,000

2,200 units

4,000 units

= 2,000 units

=

900 units

800 units

600

1,400 units

[Problem 7]

a.

b.

LTQ [20 days x (1,200/240)]

SSQ (20 days x 25 units)

ROP

100 units

500

600 units

[Problem 8]

1.

EOQ

[(2x20,000xP40)/P0.10]

4,000 units

2.

EOQ

[(2x20,000xP40)/P0.05]

5,657 units

3.

EOQ

[(2x20,000xP10)/P0.10]

2,000 units

[Problem 9]

1.

EOQ

[(2x50,000xP2.50)/P4]

250 units

2.

EOQ

[(2x50,000xP2.50)/P4]

250 units

This Accounting Materials are brought to you by www.everything.freelahat.com

[Problem 10]

1.

EOQ with variable quantity discount:

Order sizes in units

Purchase Price, net

(4,000 x P20 x net

invoice price)

Ordering Costs

[(4,000/order size)

x P10]

Carrying Costs

[(order size/2)xP2]

Total relevant

inventory costs

/ Total unit order

Average unit cost

2,000

1,000

500

250

125

P74,400

P76,000

P76,800

P77,600

P78,400

20

40

80

160

320

2,000

1,000

500

250

125

76,420

4,000

P 19.10

77,040

4,000

P 19.26

77,380

4,000

P 19.34

78,010

4,000

P 19.50

78,845

4,000

P 19.71

The EOQ level is 2,000 units because it gives the lowest average unit

cost at P19.10.

2.

The presence of variable quantity discount makes the inclusion of the

net purchase price in the computation of the total relevant inventory

costs.

[Problem 11]

1.

EOQ

[(2x67,500xP30)/(50x10%)]

2.

EOQ

(900 units)

Ordering costs [(67,500/900)xP30] P 2,250.00

(4 x P30)

Carrying costs [(900/2)xP5]

2,250.00

[(16,875/2)xP5]

Total relevant inventory costs

P ,500.00

Savings at the EOQ level

P37,807.50

Discount benefit if purchases are made on

a quarterly basis (P50 x 67,500 x 2%)

Incremental cost if purchases are made

quarterly

Net advantages of availing the discount

900 units

Quantity

(16,875 units)

P

120.00

42,187.50

P 42,307.50

P67,500.00

(37,807.50)

P29,692.50

This Accounting Materials are brought to you by www.everything.freelahat.com

[Problem 12]

1.

Optimal order quantity = [(2x100,000xP250)/P0.80] = P7,906 boxes

2.

EOQ

Present System

(7,906 boxes) 20,000 boxes

P 3,162

P 1,250

3,162

P 8.000

P 6,324

P 9.250

P 2,926

Ordering costs [(100,000/7,906)xP250]

[(100,000/20,000)xP250]

Carrying cost [(7,906/2)xP0.80]

[(20,000/2)xP0.80]

Total relevant inventory costs

Savings at the EOQ level

Discount benefit (100,000 boxes x P0.05)

Inventory cost

Net advantage of availing the trade discount

P5,000

2,926

P2,074

[Problem 13]

1.

Ordering cost [(3,000/500)xP380]

Carrying cost [(500/2)xP1]

Total relevant inventory cost

2.

EOQ

[(2x3,000xP380)/P1]

P2,280

250

P2,530

=

1.510 boxes

Ordering costs [(3,000/1,510)xP380]

Carrying costs [(1,510/2)xP1]

Total relevant inventory costs

3.

P 755

755

P1,510

The optimal order size is still 1,510 boxes.

[Problem 14]

Lead time quantity = 5 days x (30,000/300) = 500 units

Number of orders = 30,000 / 3,000

= 10 orders

1.

Optional safety stock = ?

Safety stock

Quantity

0

20

40

60

Carrying costs

( 0 x P10) P 0

[(20/2) x P10] P100

[(40/2) x P10] P200

[(60/2) x P10] P300

Stockout

Total

costs

P 1,160

440

120

0

SSQ Cost

P1,160

540

320

300

The optional safety stock is 60 units with the lowest cost at P300.

This Accounting Materials are brought to you by www.everything.freelahat.com

Computation of stockout costs:

a.

SSQ = 0:

Demand during

lead time

500

520

540

560

Lead time

quantity

500

500

500

500

Excess

demand

0

20

40

60

Probability

130/200 = 65%

20/200 = 10

10/200 = 5

6/200 = 3

Stockout costs = (SOC/unit x net stockout units) x no. of orders x

Probability

(20 x P20 x 10 x 10%)

=

P 400

(40 x P20 x 10 x 5%)

=

400

(60 x P20 x 10 x 3%)

=

360

Total stock out costs

P1,160

b.

c.

d.

SSQ

SSQ

SSQ

= 20:

(20 x P20 x 10 x 5%)

(40 x P20 x 10 x 3%)

Total stock out costs

=

=

P 200

240

P 440

= 40:

Total stockout costs (20 x P20 x 10 x 3%)

P 120

= 60:

Total stockout costs

P 0

2.

Lead time quantity =

Safety quantity

New reorder point

[5 days x (30,000/300)]

500 units

60

560 units

3.

Factors in estimating the stockouts:

a.

Lead time quantity

b.

Variations in lead time usages

c.

Stock out per unit

d.

Number of order (or resources)

e.

Net stockout units (net excess demand - safety stock

quantity)

[Problem 15]

1.

EOQ

[(2x100xP5)/(15%xP55)]

11 units

2.

EOQ

[(2x2,250xP12)/(20%xP3)]

300 units

This Accounting Materials are brought to you by www.everything.freelahat.com

3.

EOQ =

[(2x3,600xP200)/P25)]

240 units

[Problem 16]

1.

Safety stock [10 days x (9,600/240)]

400 units

2.

Reorder point [30 days x (9,600/240)]

1,200 units

[Problem 17]

1.

Safety stock (5 days x 100 units)

500 units

2.

Reorder point (5 days x 600 units)

3,000 units

3.

Normal maximum inventory = (3,500/2) + 500 units = 2,250 units

4.

Absolute maximum inventory = 3,500 + 500 units

= 4,000 units

[Problem 18]

1.

Safety stock (12 days x 80 units)

960 units

2.

Reorder point (12 days x 200 units)

2,400 units

3.

Normal maximum inventory

4.

Absolute maximum inventory =

= (3,000/2) + 960 units = 2,460 units

3,000 + 960

= 3,960 units

[Problem 19]

SSQ level

10

20

40

80

Carrying Costs

(10 x P1) P10

20

40

80

Stock out Costs

(P75 x 5 x 40%) P150

(P75 x 5 x 20%)

75

(P75 x 5 x 8%)

30

(P75 x 5 x 4%)

15

Total

SSQ Costs

P160

95

70

95

The recommended level of safety stock is at 40 units because it

results to the lowest SSQ cost of P70.

[Problem 20]

1.

EOQ

[(2x24,000xP1.20)/(10%xP10)]

240 units

This Accounting Materials are brought to you by www.everything.freelahat.com

2.

Number of Orders

24,000/240

100 times

3.

Ordering Costs (100 x P1.20)

Carrying costs [(240/2) x P1)

4.

Lead time quantity [3 days x (24,000/360)] 200.00 units

Present inventory level

400.00

Excess inventory before the reorder point 200.00

/ Normal usage (24,000/360)

66.67

No. of days before placing an order

3.00 days

5.

Difficulties in applying the EOQ formula:

a. Determination of the cost per order.

b. Determination of the carrying cost ratio or carrying cost per units.

c. Availability of supply.

d. Uncertainty in determining the annual sales.

e. Effects in applying new technology.

P120

120

[Problem 21]

1.

Lead time quantity (10 days x 200 units)

Safety stock quantity

Reorder point

2,000 units

300

2,300 units

2.

Normal maximum inventory =

(4,000/2) + 300

= 2,300 units

3.

Absolute maximum inventory =

4,000 + 300

= 4,300 units

4.

CCPU

4,000

16,000,000

8,000,000 / CCPU

CCPU

8,000 / 16,000,000

[Problem 22]

Optional Safety Stock =

Units of

Safety Stock

10

20

30

40

50

55

[(2x50,000xP80)/CCPU]

=

P0.50

Carrying Cost

(10 x P3) P30

(20 x P3) 60

90

120

150

165

Stockout Costs

(P80 x 5 x 50%) P200

(P80 x 5 x 40%) 160

(P80 x 5 x 30%) 120

(P80 x 5 x 20%)

80

(P80 x 5 x 10%)

40

(P80 x 5 x 3%)

12

Total

SSQ Costs

P230

220

210

200

190

177

This Accounting Materials are brought to you by www.everything.freelahat.com

The optimal safety stock level, is the level one that results to the lowest

total safety stock quantity costs, which in this case is at 55 units.

[Problem 23]

[Problem 24]

You might also like

- Chapter 17Document9 pagesChapter 17Maketh.ManNo ratings yet

- Receivables ManagementDocument5 pagesReceivables ManagementInocencio TiburcioNo ratings yet

- BUSE 3 - Practice ProblemDocument8 pagesBUSE 3 - Practice ProblemPang SiulienNo ratings yet

- Understanding Threats and Safeguards in AccountancyDocument20 pagesUnderstanding Threats and Safeguards in AccountancyKezNo ratings yet

- 9 Trade CreditDocument13 pages9 Trade CreditMohammad DwidarNo ratings yet

- FAR 0-ValixDocument5 pagesFAR 0-ValixKetty De GuzmanNo ratings yet

- Module No. 2 - Special CorporationsDocument8 pagesModule No. 2 - Special CorporationsJohn Russel PacunNo ratings yet

- Chapter 3 Corporate Liquidation and Reorganization-PROFE01Document3 pagesChapter 3 Corporate Liquidation and Reorganization-PROFE01Steffany RoqueNo ratings yet

- ADDITIONAL PROBLEMS Variable and Absorption and ABCDocument2 pagesADDITIONAL PROBLEMS Variable and Absorption and ABCkaizen shinichiNo ratings yet

- Tax On Compensation, Dealings in Properties and CorporationDocument6 pagesTax On Compensation, Dealings in Properties and CorporationOG FAM0% (1)

- Chap. 6 8Document44 pagesChap. 6 82vpsrsmg7jNo ratings yet

- MANAGEMENT ACCOUNTING SOLUTIONS CHAPTER 14 RESPONSIBILITY ACCOUNTINGDocument24 pagesMANAGEMENT ACCOUNTING SOLUTIONS CHAPTER 14 RESPONSIBILITY ACCOUNTINGAang GrandeNo ratings yet

- Philippine Company's Statement of Financial PositionDocument3 pagesPhilippine Company's Statement of Financial PositionKeahlyn BoticarioNo ratings yet

- Gilbert Manufacturing Company Budgets for 2019 and 2020Document69 pagesGilbert Manufacturing Company Budgets for 2019 and 2020lov3m3100% (2)

- Abm QuizDocument5 pagesAbm QuizCastleclash CastleclashNo ratings yet

- RatioDocument13 pagesRatioKaren Joyce Sinsay50% (2)

- Notes PayableDocument4 pagesNotes PayableShilla Mae BalanceNo ratings yet

- Global BusinessDocument2 pagesGlobal BusinessJerica DacanayNo ratings yet

- Week 4 - Lesson 4 Cash and Cash EquivalentsDocument21 pagesWeek 4 - Lesson 4 Cash and Cash EquivalentsRose RaboNo ratings yet

- Fringe Benefits ScenariosDocument2 pagesFringe Benefits ScenariosKatherine BorjaNo ratings yet

- Chapter 14 - Answer PDFDocument18 pagesChapter 14 - Answer PDFAldrin ZlmdNo ratings yet

- TBT CH1Document10 pagesTBT CH1darkNo ratings yet

- CL Cup 2018 (AUD, TAX, RFBT)Document4 pagesCL Cup 2018 (AUD, TAX, RFBT)sophiaNo ratings yet

- AFAR 2 Online Class - Ch. 13Document26 pagesAFAR 2 Online Class - Ch. 13Von Andrei MedinaNo ratings yet

- Consolidated Statement of Financial Position - Date of Acquisition AnalysisDocument2 pagesConsolidated Statement of Financial Position - Date of Acquisition AnalysisKharen Valdez0% (1)

- Acc 211B Job Order Costing - ActivityDocument5 pagesAcc 211B Job Order Costing - Activityjr centenoNo ratings yet

- Problem 14-5: Kayla Cruz & Gabriel TekikoDocument7 pagesProblem 14-5: Kayla Cruz & Gabriel TekikoNURHAM SUMLAYNo ratings yet

- Fin Man - Module 3 ContinuitionDocument6 pagesFin Man - Module 3 ContinuitionFrancine PrietoNo ratings yet

- Tax Chap 14 To 15Document7 pagesTax Chap 14 To 15Jea XeleneNo ratings yet

- PFRS 12 Disclosures of Interest in Other EntitiesDocument32 pagesPFRS 12 Disclosures of Interest in Other EntitiesRenge TañaNo ratings yet

- Consolidation at Acquisition DateDocument29 pagesConsolidation at Acquisition DateLee DokyeomNo ratings yet

- Chapter 7 - Conversion Cycle P4Document26 pagesChapter 7 - Conversion Cycle P4Joana TrinidadNo ratings yet

- Sharing Firm WealthDocument3 pagesSharing Firm WealthJohn Jasper50% (2)

- Bank of The Philippine Islands Balanced Scorecard Group 2Document5 pagesBank of The Philippine Islands Balanced Scorecard Group 2Jasper TabernillaNo ratings yet

- AFAR 2 SyllabusDocument11 pagesAFAR 2 SyllabusLawrence YusiNo ratings yet

- Chapter 4 Accounting Information SystemDocument17 pagesChapter 4 Accounting Information SystemRica de guzmanNo ratings yet

- CH 19 & 20 Practice QuestionsDocument2 pagesCH 19 & 20 Practice QuestionsNCTNo ratings yet

- 2Document13 pages2Ashish BhallaNo ratings yet

- 6a Pred Working Cap MGT 2Document9 pages6a Pred Working Cap MGT 2SamNo ratings yet

- 6 - Pat & Sat Co. - PALACIODocument7 pages6 - Pat & Sat Co. - PALACIOPinky DaisiesNo ratings yet

- May 28, 2015-CH 10-Basic Income Tax Patterns-Valencia & RoxasDocument18 pagesMay 28, 2015-CH 10-Basic Income Tax Patterns-Valencia & RoxasgoerginamarquezNo ratings yet

- Bobadilla Reviewer MASDocument3 pagesBobadilla Reviewer MASMae CruzNo ratings yet

- Fedillaga Case13Document19 pagesFedillaga Case13Luke Ysmael FedillagaNo ratings yet

- Chapter 6Document3 pagesChapter 6Ricky LavillaNo ratings yet

- AE 18 Financial Market Prelim ExamDocument3 pagesAE 18 Financial Market Prelim ExamWenjunNo ratings yet

- Production and Operations Management Case Study Girlfriend Collective by LISA SPENCER Mbamudivc Sem 2Document11 pagesProduction and Operations Management Case Study Girlfriend Collective by LISA SPENCER Mbamudivc Sem 2RADHIKA CHAVDA100% (1)

- Assignment 1 Caro Coleen Sec27Document2 pagesAssignment 1 Caro Coleen Sec27Alyssa TordesillasNo ratings yet

- Evaluating Firm Performance - ReportDocument5 pagesEvaluating Firm Performance - ReportJeane Mae BooNo ratings yet

- Problem 3 Page 41Document8 pagesProblem 3 Page 41MAG MAGNo ratings yet

- Intacc Cash Flow SolutionDocument3 pagesIntacc Cash Flow SolutionMila MercadoNo ratings yet

- DLSU CPA Cash and Cash EquivalentsDocument3 pagesDLSU CPA Cash and Cash EquivalentsEuniceChungNo ratings yet

- Financial Statement Analysis: Select A Tab To Get StartedDocument33 pagesFinancial Statement Analysis: Select A Tab To Get StartedHarold Beltran DramayoNo ratings yet

- What Is Community Tax?: Speaker: Valerie A. OngDocument25 pagesWhat Is Community Tax?: Speaker: Valerie A. Ongmarz busaNo ratings yet

- Specialized Industries Airlines: Name: Jayvan Ponce Subject: Pre 4 Auditing and Assurance: Specialized IndustryDocument10 pagesSpecialized Industries Airlines: Name: Jayvan Ponce Subject: Pre 4 Auditing and Assurance: Specialized IndustryCaptain ObviousNo ratings yet

- How Businesses Manage Resources and Generate ProfitsDocument15 pagesHow Businesses Manage Resources and Generate ProfitsApril MeloNo ratings yet

- Working Capital Solutions - Part 1Document5 pagesWorking Capital Solutions - Part 1Marga DelgadoNo ratings yet

- Accounting Materials Chapter 9 Short-Term Non-Routine DecisionsDocument13 pagesAccounting Materials Chapter 9 Short-Term Non-Routine DecisionsInocencio Tiburcio33% (3)

- Chapter 10Document9 pagesChapter 10teresaypilNo ratings yet

- Cost Accounting Chapter 6Document18 pagesCost Accounting Chapter 6Raffy Roncales70% (10)

- CVPA ANALYSIS AND BEP CALCULATIONSDocument38 pagesCVPA ANALYSIS AND BEP CALCULATIONSLouie De La TorreNo ratings yet

- Test Bank Chapter 1 Managerial AccountingDocument9 pagesTest Bank Chapter 1 Managerial AccountingGelyn CruzNo ratings yet

- Test Bank - Chapter 2 Cost ConceptsDocument36 pagesTest Bank - Chapter 2 Cost ConceptsAiko E. Lara71% (7)

- Process Costing Systems & Equivalent UnitsDocument51 pagesProcess Costing Systems & Equivalent UnitsAiko E. Lara83% (18)

- ABC Costing: Activity Rates & Product CostsDocument44 pagesABC Costing: Activity Rates & Product CostsAiko E. Lara100% (5)

- Test Bank - Chapter18 FS AnalysisDocument87 pagesTest Bank - Chapter18 FS AnalysisAiko E. LaraNo ratings yet

- Relevant Costs for Decision-MakingDocument43 pagesRelevant Costs for Decision-MakingAiko E. Lara93% (14)

- Test Bank - Chapter15 Capital Budgeting2Document29 pagesTest Bank - Chapter15 Capital Budgeting2Aiko E. Lara100% (1)

- Test Bank - Chapter 3 Job Order CostingDocument36 pagesTest Bank - Chapter 3 Job Order CostingAiko E. Lara81% (21)

- Variable Costing Tool for ManagementDocument47 pagesVariable Costing Tool for ManagementAiko E. Lara86% (7)

- Test Bank - Chapter 9 Profit PlanningDocument34 pagesTest Bank - Chapter 9 Profit PlanningAiko E. Lara67% (3)

- Test Bank - Chapter17 Cash FlowsDocument51 pagesTest Bank - Chapter17 Cash FlowsAiko E. Lara100% (4)

- Testbank CoverDocument1 pageTestbank CoverAiko E. LaraNo ratings yet

- Segment Reporting, Profitability Analysis, and Decentralization Ch 12Document32 pagesSegment Reporting, Profitability Analysis, and Decentralization Ch 12Aiko E. LaraNo ratings yet

- Test Bank - Chapter16 ABC ApproachDocument31 pagesTest Bank - Chapter16 ABC ApproachAiko E. Lara50% (2)

- Test Bank - Chapter14 Capital BudgetingDocument35 pagesTest Bank - Chapter14 Capital BudgetingAiko E. Lara100% (8)

- Pre-Lim in Aut PCCDocument6 pagesPre-Lim in Aut PCCAiko E. Lara100% (1)

- Aut 1090Document7 pagesAut 1090Aiko E. LaraNo ratings yet

- Test Bank Chapter 1 Managerial AccountingDocument9 pagesTest Bank Chapter 1 Managerial AccountingGelyn CruzNo ratings yet

- Part 3 Auditing FinalsDocument1 pagePart 3 Auditing FinalsAiko E. LaraNo ratings yet

- CPA Auditing Theory and Practice GuideDocument8 pagesCPA Auditing Theory and Practice GuideAiko E. LaraNo ratings yet

- CPA Auditing Theory and Practice GuideDocument8 pagesCPA Auditing Theory and Practice GuideAiko E. LaraNo ratings yet

- Aut 1089Document22 pagesAut 1089Aiko E. LaraNo ratings yet

- Aut 590Document6 pagesAut 590Aiko E. LaraNo ratings yet

- AUt 1088Document12 pagesAUt 1088Aiko E. LaraNo ratings yet

- Auditing QuizzerDocument32 pagesAuditing QuizzerAiko E. Lara0% (1)

- Auditing Theory ChallengeDocument15 pagesAuditing Theory ChallengeAiko E. LaraNo ratings yet

- Aut 589Document15 pagesAut 589Aiko E. LaraNo ratings yet

- Aut 588Document13 pagesAut 588Aiko E. LaraNo ratings yet

- Audit of Cash and ReceivablesDocument21 pagesAudit of Cash and ReceivablesAiko E. Lara100% (2)

- CPA Review: Code of Ethics for Professional Accountants in the PhilippinesDocument20 pagesCPA Review: Code of Ethics for Professional Accountants in the PhilippinesJedidiah SmithNo ratings yet