Professional Documents

Culture Documents

Characteristic of Defect Signal Using Different Frequency of Eddy Current

Uploaded by

Musim SejukCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Characteristic of Defect Signal Using Different Frequency of Eddy Current

Uploaded by

Musim SejukCopyright:

Available Formats

CHARACTERISTIC OF DEFECT SIGNAL USING DIFFERENT FREQUENCY OF EDDY CURRENT

1.0 INTRODUCTION As a student in a course of Non Destructive Testing at TATIUC, we have to do an assignment in subject Final Project . The assignment about characteristic of defect signal using different frequency of eddy current.We need to use the frequency in range 50 kHz to 100 kHz to find the characteristic of defect signal that appear.

Frequency, Eddy current testing is performed within a frequency range of approximately 50 Hz to 10 MHz, although most applications are performed well within the extremes of that range. As test frequency is increased, sensitivity to surface discontinuities increases, permitting increasingly smaller surface discontinuities to be detected. As frequency is decreased, eddy current penetration into the material increases as in.When fixing a frequency, the initial coil impedance is adjusted. When inspection frequency () is increased, the imaginary part of the impedance is increased.

Defect signal is a signal when scanning of samples with defects. Signal will appear when in the defect area while doing inspection. Appearance defect caused by several factors and the effects that affect the sample. Difference signal also depends on the length and depth of the defect

Signal defect

type of defect

1.1 OBJECTIVE -to investigate the defect signal using different frequency -to determine the type of defect signal

2.0 MATERIAL AND METHOD 2.1 For specimen equipment, the almost equipment that use in this project are eddy current set,calibration block,weld probe.

g

Weld Test Blocks are set to the coating thickness calibration standard with 0.5 mm, 1.0 mm and 2.0mm slots to enable correct calibration.

hhhhhhhh

Weld probes are designed to inspect ferrous welds. They provide a cost effective alternative to magnetic particle inspection, which requires the part to be prepared (cleaned) prior to inspection.

A digital meter as shown in is one whose visual output is shown in discrete step in time. The meter measure input at given moment and the value of the measurement is displayed in numerical from.

2.2 METHOD

Firstly, set the parameter ( mode, frequency, probe, gain) in the eddy current machine. Then, perform calibration on the calibration block. Put white tape on calibration block and weld probe to find the index point. To do index point , mark with pencil or pen when weld probe across 1.0mm slot in positive scan and for the negative scan is same Make sure the signal in eddy current screen is 90 perpendicular.

a) positive scan

b) negative scan

secondly, setup the frequency in range 50 kHz to 100 kHz in eddy current set. When the frequency is decrease to 50 kHz, there have a change in defect signal and when the increase frequency to 60 kHz, there are also have a differences in signal defects. After that, repeat the steps by using to 70 kHz,80 kHz,90 khz,100 kHz. Finally, changes the frequency has a differents signal defect.

4.0 FLOW CHART

start

Set the parameter ( mode, frequency, probe, gain) in the eddy current machine

Scanning with different frequency and see the signal defect

Sketch signal

end

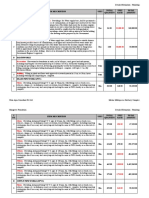

5.0 GANTT CHART

TASK WEEK find the title Meet supervisor then discuss about this project Search for the information about the project Study about this project Find the material and list the budget Learn and start do the step calibration try to scanning on speciment with low frequency try to scanning on specimen with high frequency Troubleshooting Final inspection and presentation

10

11

12

13

14

Figure 5.1 Gantt chart

6.0 EXPECTED RESULT - we will find out the where the phase of defect signal when frequency is change. After that, we can know that the every defect have a different type of signal.

7.0 CONCLUSION

From this project, we able to study new information about the different frequency can effect the characteristic signal defect.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- BloodDocument22 pagesBloodGodd LlikeNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Bidding Process in Infrastructure ProjectsDocument44 pagesBidding Process in Infrastructure ProjectsRajesh Chowdary Chintamaneni100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Surveillance of Healthcare-Associated Infections in Indonesian HospitalsDocument12 pagesSurveillance of Healthcare-Associated Infections in Indonesian HospitalsRidha MardiyaniNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Executive Order No. 786, S. 1982Document5 pagesExecutive Order No. 786, S. 1982Angela Igoy-Inac MoboNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Fuel Supply Agreement - First DraftDocument104 pagesFuel Supply Agreement - First DraftMuhammad Asif ShabbirNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Businesses ProposalDocument2 pagesBusinesses ProposalSophia Marielle MacarineNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- LeasesDocument9 pagesLeasesCris Joy BiabasNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 5th Year PES Mrs - Hamdoud Research Methodology 2Document3 pages5th Year PES Mrs - Hamdoud Research Methodology 2Rami DouakNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Internet Intranet ExtranetDocument28 pagesInternet Intranet ExtranetAmeya Patil100% (1)

- Group Terms&ConditionsDocument5 pagesGroup Terms&Conditionsbelen rodriguezNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Ps 6013 Geometric Dimensioning and Tolerancing Symbology Method, Usage and Definitions 2013-08-01 (G)Document18 pagesPs 6013 Geometric Dimensioning and Tolerancing Symbology Method, Usage and Definitions 2013-08-01 (G)maheshmbelgaviNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Zambia Urban Housing Sector ProfileDocument205 pagesZambia Urban Housing Sector ProfileJosephine ChirwaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CIMICDocument228 pagesCIMICKehinde Olaoluwa100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Geometric Driver Components Serial Copy: Topsolid'WoodDocument22 pagesGeometric Driver Components Serial Copy: Topsolid'Wooddrine100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- ABB FactSheet SYMS - 112018Document2 pagesABB FactSheet SYMS - 112018Muhammad Hassan BalochNo ratings yet

- Novozymes IPRDocument19 pagesNovozymes IPRthereisaneedNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Feasibility Report, Modhumoti, Rev. - April-.2015-1Document19 pagesFeasibility Report, Modhumoti, Rev. - April-.2015-1Jahangir RaselNo ratings yet

- GMDS - Course - FinalDocument282 pagesGMDS - Course - FinalLuisPazPerdomo100% (1)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Good Quality Practices at NTPC KudgiDocument8 pagesGood Quality Practices at NTPC KudgisheelNo ratings yet

- SMB Marketing PlaybookDocument18 pagesSMB Marketing PlaybookpramodharithNo ratings yet

- SignalsVOL 1 SupplementBDocument67 pagesSignalsVOL 1 SupplementBcdettlingerNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design, Analysis &optimization of Crankshaft Using CAEDocument6 pagesDesign, Analysis &optimization of Crankshaft Using CAEInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Buyer Persona TemplateDocument18 pagesBuyer Persona TemplateH ANo ratings yet

- PPR 8001Document1 pagePPR 8001quangga10091986No ratings yet

- PBR ImplementationDocument32 pagesPBR ImplementationBernie C. MagtalasNo ratings yet

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Document52 pages03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendreNo ratings yet

- Accredited Architecture QualificationsDocument3 pagesAccredited Architecture QualificationsAnamika BhandariNo ratings yet

- Radioss For Linear Dynamics 10.0Document79 pagesRadioss For Linear Dynamics 10.0Venkat AnumulaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- IT Quiz QuestionsDocument10 pagesIT Quiz QuestionsbrittosabuNo ratings yet

- Dell PowerEdge M1000e Spec SheetDocument2 pagesDell PowerEdge M1000e Spec SheetRochdi BouzaienNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)