Professional Documents

Culture Documents

Develop Diesel Fuel Additives

Uploaded by

idownloadbooksforstuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Develop Diesel Fuel Additives

Uploaded by

idownloadbooksforstuCopyright:

Available Formats

Petroleum & Coal ISSN 1337-7027 Available online at www.vurup.

sk/pc Petroleum & Coal 51(3) 167-175, 2009

DEVELOPMENT OF DEPOSIT CONTROL ADDITIVES FOR DIESEL FUEL

M. Bublik1, . Beck2, J. Baladincz3, J. Hancsk2,

1

MOL Hungarian Oil and Gas Plc., P.O. Box 1., H-2443, Szzhalombatta, Hungary; 2University of Veszprm, H-8201, Veszprm, P.O. Box 158, Hungary, 3Slovnaft a.s.., Vlcie Hrdlo, Bratislava, Slovakia

Received April 1, 2009, accepted July 15, 2009

Abstract During the research activity a new, raw material and energy-saving technology has been developed for the preparation of polyisobutylene(PIB)-succinimide type diesel fuel additives. PIB-succinicanhydride type intermediers having new structure were obtained as the products of radical initiation-based synthesis. The intermediers were used to acylate polyethylene polyamines to produce the final product. The synthesised final products have shown better analytical and performance properties such as improved deposit control efficiency. In the second part of the paper, the incorporation of fatty acid methyl ester into the molecular structure of PIB-succinicanhydride has been studied to widen the functions and enhance the performance of the succinimide type additive family. During the product-improvement the advantageous reaction parameters have been determined. It was concluded, that the synthesized fuel additives can dissolve in diesel fuel perfectly, had excellent corrosion inhibiting- and lubricity improving effects and the DD efficiency of traditional succinimides could be achieved moreover in some cases exceeded. Based on the IR, GPC, 13C and 1H NMR analytical tests original molecular structures of both additive types were confirmed.

Keywords: Diesel fuel; fuel additives; polyisobutylene-succinic anhydride; synthesis with radical initiation; fatty acid methyl ester; PIB-succinimide; deposit control additives.

1. Introduction Engine fuels are comprised of green, high quality blending components and highly efficient additives. Nowadays, application of high performance additives is essential to meet the required fuel properties and to protect the engine and the environment [1, 2]. Out of the numerous additive types, Deposit Control Additives (DCAs) are applied in the highest amount. Deposits may form in the fuel injector system of the engine. These deposits influence the emission, fuel economy, cold start behaviour, driveability and performance, too. DCAs are generally long chain hydrocarbons attached to a polar head group. Deposit precursors are attracted to the deposit control molecule, and become bounded into the dispersant micelles. At normal operating temperatures the DCA is a liquid that forms a thin film on the surface of the inlet system. The thin film is driven forward by air and fuel vapour flow, but forms a first line barrier to deposit precursors as well as a dispersant/neutraliser of the precursors protecting the metal surface. In the case of deposits on the metal surface, the liquid film slowly removes them by a detergent action [1,2]. Diesel fuel detergents are predominantly based on ashless polymeric products. Among these polyisobutylene-based different alkene-, alkyl-, polyalkene-, polyalkyl-succinic anhydrides derivatives are applied in highest amount. The derivatives of succinic anhydrides are usually produced in two steps: the first step is the preparation of polyisobutylene-succinic anhydrid (PIBSA) by ene-reacton between polyisobutylene and maleic anhydride. In case of fuel detergents, the main reaction type are the thermally iniciated and catalytic reactions. In the second step, the intermediates synthesized through the first step are used to acylate amines, amino alcohols, alcohols etc.

168

Possibilities for the next reactions and the properties of the final products significantly depend on the structure and purity of the resultant intermediate as well as the conversion of MA- and olefin. The main research ways targeting the improvement of the reaction parameters are the thermal or radical initiation, catalytic synthesis or their combinations[3]. Fatty acid methyl esters (FAME) and/or their derivatives are able to substitute diesel fuels and/or their additives. The use of FAMEs can reduce the import dependence of crude oil and its products. The application of esters based on vegetable oils in premium quality diesel fuels ensures environmental advantages (lower CO2-emission, biodegradability, non-toxic, etc.). Many vegetable oils can be used as a source of methyl ester production; however, the application of the rapeseed- and the sunflower-oils is the most wide-spread because their properties are the most similar to those of diesel fuel. Their advantage is the good lubricity and the smaller emission of particulate matter [4]. A more and more significant utilization option of vegetable oils resulting in substantial value addition is the production of additives that are useful for various industrial purposes. This utilization option is not only motivated by their renewable nature and their superior biodegradability compared to synthetic products, but also by their applicability in various chemical reactions or structural modifications due to the unique distribution of their unsaturated bonds and their reactive functional groups [5]. 2. Experimental The aim of our research work was the development of polyisobutylene-based, ash-free detergent dispersant additives of diesel fuel. Our main purpose was the elimination of the disadvantages of the thermic PIBSA-synthesis (high energy demand and reaction time, not too bright color etc.) and the demand of distinguishable product (new productstructure). Beside these, the other objective of our work was the development of a multifunctional fuel additive containing bio-component as molecular-constituent. With the incorporation of fatty acid methyl ester into the molecular structure we wished to widen the functions and enhance the performance (lubricity improving and corrosion inhibiting effect) of the succinic imide type additive family and also to increase its biodegradability. 2.1 Materials For the synthesis of PIBSA commercially available polyisobutylenes (PIBs) were selected, their main properties are summarized in Table 1. Beside PIBs, maleic anhydride (MA, produced by MOL), aromatic solvent, and radical initiator and in the second part of this research work rapeseed oil methyl ester (RME, prepared by us), were used in the first step. Polyethylene polyamines and base oil (as solvent oil, SN-150) was applied for the preparation of final products. Table 1 The main properties of polyisobuthylenes Properties Appearance Molecular weight, M n Polydispersity vinyledene content, % KV at 100C, mm2/s Flashpoint (COC), C Iodine-bromine number, gI/100 g PIB R-PIB HR-PIB Clear and bright 910 1030 1050 1.60 1.82 1.52 <80 84.7 88 223.6 190.0 192 214 190 204 47.8 49.1 35.6

PIB: polyisobutylene, R-PIB: reactive polyisobutylene, HR-PIB: highly reactive polyisobutylene

2.2 Experimental methods The analytical and performance tests of the intermediates and the final products were carried out according to international and local standards and proprietary methods (Tab 2).

169

Table 2 Analytical and performance tests Properties Kinematic viscosity (KV) Total Base Number (TBN) Nitrogen content Active material content Total Acid Number (TAN) Saponification Number (SN) Maleic anhydride content Molecular weight and its distribution Molecular structure Methods EN ISO 3104 ISO 3771 modified Kjeldahl local standard (column chromatography) proprietary (titrimetric) ISO 6293 proprietary (titrimetic) proprietary (GPC) IR spectroscopy NMR spectroscopy Steel drift test ASTM D 665 Copper strip test Potential DD Efficiency (PDDE) Performance tests Methods proprietary (paper chromatography and centrifugation)

Peugeot XUD9A/L engine test Lubricity

CEC F-23-A-00 EN ISO 12156-1 ASTM D 4172 ISO 2160:2000

2.3. Experimental design The polyisobutylene-succinic anhydrides were prepared in a four-neck flask equipped with a stirrer, a reflux cooler, a thermometer and a raw-materials feeder. The reaction was carried out at atmospheric pressure and different temperatures (max 150C) in aromatic solvent (< 30%), with radical initiation (<15%) and various molar ratios of the reactants (MA/PIB:1,0:1,0 1,0:2,0 and PIB/RME/MA 1,0:0,8:0,8-1,0:1,3:1,4). The solvent and the unreacted materials were removed at 200 C by vacuum distillation. Selected intermediates were used to acylate polyethylene polyamines. The additives were prepared under inert N2 atmosphere in a five-neck flask equipped with a stirrer, a reflux cooler, a thermometer and a N2 feeder. Polyethylene polyamines were added to the intermediate containing base oil (SN-150) by continuous stirring. The acylating reactions were carried out at 165-185 C under mild vacuum with a reaction time of 4-6 hours (according to well known methods in the synthesis of polyalkylene succinimides). Unreacted polyamines were removed at 200C by vacuum distillation. 3. Results and Discussion 3.1. Production and laboratory investigation of the polyisobutylene-succinic anhydride derivatives prepared by radical initiation The properties of some typical intermediate products, synthesised from different PIBs by thermally initiated (TI) and by radically initiated (RI) processes, are shown in Table 3. It can be seen that the synthesis of intermediate products from low reactivity PIB ( vinyledene content <80%) were carried out by low conversion and thus with low active material content. The coupling ratio was lower than it was expected at this molecular weight. To reach the 1:1 SA/PIB coupling ratio it was possible only at 2:1 MA/PIB feedstock molar ratio. A significantly higher conversion was achieved in case of the other two PIBs where the coupling ratios were also higher. There was a lower difference between the high reactivity (HR-PIB) and the reactive (R-PIB) PIBs. The conversions were about 80% in case of intermedier produced from R-PIB while it was ~90% in case of the PIBSA synthesised from HR-PIB. From the additive production point of view the most advantageous reaction parameters and molar ratio of the components were determined by laboratory and pilot plant experiments. By applying accurate amount of components, temperature and reaction time intermediate products (polyisobutylene succinic anhydride = PIBSA) could be synthesized from PIB having M n ~1000.Using these parameters, intermedier products having different MA/PIB connection ratio can be produced.

170

It has been determined that in case of PIBDISA (MAPIB molar ratio 2:1) production the reaction time of the second MA ring connecting to the PIB chain is much longer, therefore the longer time of the synthesis is preferred to produce this intermedier, meanwhile decreasing the unreacted MA results in less PIBDISA type molecules. Table 3 Properties of some typical synthesized PIBSAs Properies PIB MA/PIB molar ratio Type of process Temperature, C Solvent Active material, % m/m KV at 100C, mm2/s TAN mg KOH/g Conversion*, % MA/PIB coupling ratio PIBSA PIB 1.0 RI max 150 aromatic 33.0 819 43.0 53.4 0.5 R-PIBSA R-PIB 1.0 RI max 150 aromatic 822.3 82.8 77.0 0.82 HR-PIBSA HR-PIB 1.0 RI max 150 aromatic 76.3 891 98.4 89.2 0.96 Commercial** HR-PIB 1.1 TI above 210 80.0 64.0 -

* based on theoretical TAN; ** containing 50% base oil

By using IR, GPC, 13C and 1H NMR techniques, the molecular structure of the PIBSAs were investigated. The results of the IR spectroscopy (Tab 4.) showed that the reaction between the MA and PIBs was carried out. Based on the results of the 1H and 13C NMR tests [6] the difference of the molecular structure between the PIBSA produced by radically initiated method and thermal way has been determined. The PIBSA synthesised by thermal way mainly contains molecules having 1:1 PIB-SA connection ratio. The PIBSA produced by radical initiated method consist of in addition of the above mentioned molecule succinic anhydride substituted with two PIB molecules, which ensures the dispersant effect, and there are some polyisobutene molecules connected with two or more succinic anhydride rings, which can improve the detergent effect due to the formation of more polar molecules. Based on the structure investigation, some possible structures of the intermediate are demonstrated on Figure 1. Table 4 Typical absorption maximums of PIBSAs and succinimides Typical absorption maximums, cm-1 1870-1700 1770-1700 1080 1485-1445 750-700 1395-1365 3000-2800 990-890 990-890 3300-3150 Vibration type C=O C=O sz C-O(H) s CH2 CH2 C3 C2, C2 C=C C=C NH Chemical groups Anhydrides with five carbon atoms Imides Primer OH bonds Saturated bonds of polyisobutenes Saturated bonds of polyisobutenes Saturated bonds of polyisobutenes Saturated bonds of polyisobutenes Olefinic bonds of polyisobutenes Olefinic bonds of polyisobutenes Amide-V PIBSA Succinimide PIBSA PIBSA, Succinimide PIBSA, Succinimide PIBSA, Succinimide PIBSA, Succinimide PIBSA PIBSA PIBSA Sample

There were mono-(PIBMSI) and bis-succinimides(PIBBSI) synthesized from the previously shown intermediate products, their properties are listed in Table 5. It was concluded, that the values of the TBN and nitrogen content changed according to the active material content of the intermedier products. The properties of the low reactivity PIBs were significantly lower than the usual values. Besides, their detergent-dispersant efficiencies

171

(PDDE) were relatively good. PDDE values of the succimides synthesized from higher reactivity PIBs reached the level of the commercially available succimidies. Based on IR analysis (Tab. 4), the formation of PIB-succimides structure was determined.

R1 O O

O R O R1 O

O O

O O O

1 R R2

O O O

O

R

R21 O

R2

O O

PIBMBAI PIBMSAI

R R

(DIPIB)BAI (DIPIB)SAI

O O O

R2MSA ( R1MSA )n PIBPBAI PIBPSAI

O R

R2 O

R2

O O

PIBDISAI PIBDIBAI

O O

DI(PIBBA)I DI(PIBSA)I

R2

O O O

P(PIBBA)n I P(PIBSA) nI

n n

R and R2= polyisubutylene group with 30-80 C-number; R1= alkyl group with 2-5 C-number; PIBMSAI: PIB mono-succinic anhydride prepared by radical initiation PIBDISAI: PIB di-succinic anhydride prepared by radical initiation (DIPIB)SAI: (di-PIB) succinic anhydride prepared by radical initiation DI(PIBSA)I: di-(PIB succinic anhydride) prepared by radical initiation P(PIBSA)nI: poly (PIB succinic anhydride) prepared by radical initiation Figure 1 The possible structures of the intermediates Table 5 Properties of some typical synthesized polyisobutylene succinimides (PIBSI)

Properties KV at 100C, mm2/s Oil content, % TBN, mg KOH/g N-content, % Detergent Index (DI), % Washing efficiency (W), mm (max 125) PDDE, % (max 100) * commercial PIBMSI 172.1 50 3.33 0.34 100 64 73 PIBBSI 159.5 50 0.71 0.19 100 24 55 RPIBMSI 92.8 50 97 85 81 RPIBBSI 90.4 50 100 82 81 HR-PIBMSI 150.3 50 60.5 2.5 100 94 86 115* 50 90 3.25 100 87 83 HR-PIBBSI 90.3 50 25.0 1.35 100 93 86 70* 50 21.6 1.03 100 95 86

172

3.2. Synthesis and laboratory analysis of polyisobutylene-succinic anhydrides containing fatty acid methyl ester The synthesis of the additives containing fatty acid methyl ester (FAME) components as it was described in details in our previous works [7; 8] was carried out by the same process as mentioned above. In the first step, the effect of temperature, the change of molar ratio of the raw materials, the amount of the solvent and the initiator on the properties of the polyisobutylene-succinic anhydrides containing fatty acid methyl ester (ASA) was investigated. Main properties of some typical intermediates were given in Table 6. In accordance with the active material content, the polyisobutene-conversion varied between 60 and 70%, and the conversion of maleic anhydride was between 70 and 85% calculated from the acid number. Based on the results of experiments the optimal parameters of the synthesis of polyisobutylene-succinic anhydrides containing fatty acid methyl ester were determined; amount of the solvent: <30% (based on the amount of reaction mixture), amount of initiator: <15% (based on MA), reaction temperature: <180C, reaction time: 4-7 h. Table 6. Main properties of some typical intermediates containing FAME as molecularconstituent Properties Appearance Active material, % Kinematic viscosity at 100 C, mm2/s TAN, mg KOH/g MA content mg/g SN, mg KOH/g SN-TAN, mg KOH/g MA conversion, % PIBSAF-1 Bright 63.3 136.6 67.9 2.32 68.8 0.9 79.2 PIBSAF-2 Bright 63 181.9 71.3 2.1 89.7 18.4 76.5 PIBSAF-3 Bright 69.3 186.3 76 1.6 91.7 15.7 86.0 PIBSAF-4 Cloudy 59,6 195,84 80,4 3,64 126,6 46,2 76.0

The IR spectra of the intermediates were measured to determine the molecular structure of the polyisobutylene-succinic anhydrides containing fatty acid methyl ester. In the spectra the s and as CH2 and the s CH3 vibrations were observed in the range of 3000-2800 cm-1, 1485-1445 cm-1 and 1365-1400 cm-1. The absorption maximums of the symmetric and asymmetric C-O-C- bonds in the range of 1300-1150 cm-1 refers to esteric character as well as the characteristic intensive carbonyl vibration of C=O groups in the range of 1800-1730 cm-1 that are also typical for esters. The presence of succinic anhydride is indicated by the C=O carbonyl vibrations of anhydrides with five carbon atoms in the wave number range of 1800-1730 cm-1. The GPC analysis showed that the number average molecular weight of intermediates was 1550 300 and the average of the polydipersity was 1,70. It suggests that the molecular weight of the intermediers is equal with the sum of molecular weight of raw materials, the polyisobutylene and also the FAME compounds linked into the molecular structure (Fig 2). This was also confirmed by the homogeneous and clear appearance of the intermediates. The range of molecular weight was between 12300 and 500, so beside of the main component, the intermedier contained unreacted PIB and fatty acid methyl ester substituted succinic anhydride.

O CH3 H CH2 C

n

H3C

O C

CH CH

CH3

CH3

C C C H2 H CH2 2 O

Fig. 2 The structure of the polyisobutylene-succinic anhydride containing fatty acid methyl ester

173

Based on these results and the 1H and 13C NMR tests [9] it was found, that the fatty acid methyl ester can be built into the PIB-succinic anhydride structure, thus producing a novel compound having original structure. The preferred intermediates were used to produce final product. The polyisobutylenesuccinic anhydrides containing fatty acid methyl ester were diluted with base oil (SN-150) to reduce their viscosity, and different polyethylene polyamines (PEPA) were acylated with it at various PEPA/PIBSAF molar ratio. Main properties of some typical succinic derivatives (PIBFSI) were given in Tab 7. The synthesized additives were dissolved in SN-150 base oil in 3% concentration for the DD efficiency tests. The detergent index of all products was 100%. The results of their washing effect and potential DD effect showed that efficiency of traditional succinics could be achieved (Tab 7.). Based on the copper strip corrosion test, it was found, that the additives had excellent corrosion inhibiting properties, as well. The result of cooper strip test made with unadditized gas oil was 1B, so the strip was mild orange. The additives applied in 10-30 ppm concentration range inhibited the corrosion completely, so the classification of the strip after the test was 1A. The results of stricter rust prevention in ferrous parts confirmed the previous effects in copper strip test. The lubricity improving efficiency of the additives was investigated in the range of 50400 ppm in gas oil. The wear scar of the unadditized gas oil used as a reference was 530 m. The results of the performance test showed that the additives based on vegetable oil had significant lubricity improving effect and by the application of 100 ppm additive, the limit of the standard could be reached (Fig. 3). Table 7 Main properties of the final products Properties PIBFSI-1 Intermediate PIBSAF-1 Acylating agent TEPA Kinematic viscosity at 100 C, 402,7 mm2/s 3% additive in base oil Kinematic viscosity at 40 C, 35,8 mm2/s Kinematic viscosity at 100 C, 6,08 mm2/s Extended viscosity index 116 Detergent Index, % 100 Washing Efficiency, mm 83 PDDE, % 82 Corrosion properties (10-30 ppm additive in gas oil) Copper strip corrosion 1A Steel drift corrosion 0 Lubricity tests (200 ppm additive in gas oil) HFRR wear scar, m 333 713 Fourball wear scar, m [5] PIBFSI-2 PIBSAF-2 DETA 374,8 37 6,07 110 100 72 76 1A 0 345 730 PIBFSI-3 PIBSAF-3 PEHA 351,8 36,8 6,09 111 100 80 80 1A 0 343 726

TEPA: tetraethylene pentaamine; DETA: diethylene triamine; PEHA: pentaethylene hexaamine

The IR spectra and GPC of the final products were measured to determine the molecular structure of the additives. The number average molecular weight of the final product was 2200 400, the average polydipersity was 1.70; the average range of molecular weight was 12700-900. These mean that there were mono- and bissuccinimides containing bio-components as molecular-constituent synthesised from the previously shown intermediate products. The characteristic vibrations of CH2 and CH3- and the adsorption maximums of the olefinic bonds, as well as characteristic symmetric and asymmetric C-O-C- vibration of esters remained in the IR spectra of final products . Instead of the C=O vibrations of anhydrides with five carbon atoms, the adsorption band of the imide can be observed in the range of 1700-1770 cm-1. The low intensity adsorption bands related to amides can be seen in the range of 1670-1630 cm-1. The results of the IR spectroscopy showed that

174

the fatty acid methyl esters are present in the synthesized additives as a building block of the molecule. Standard limit according to EN590

600 500

Wear scar, m

400 300 200 100 0 0 50 100 150 200 250 300 350 400

Additive concentration, mg/kg

Figure 3 The lubricity properties of the selected PIBFSI-1 additives 3.3. Peugeot XUD-9 engine tests of the synthesized additives It is a common experience that the results of laboratory and field tests method may be different; therefore the Peugeot XUD-9 tests (CEC F-23-A-01) of the chosen sample at both additive types were carried out. During the tests the concentration of the synthesized and reference additives was 90 vppm. Commercial additive package (Com. AP) containing succinic type deposit control additive was the reference. As it is shown on Figure 4 PIB-succinimid produced by radically initiated method had the highest nitrogen content and the best detergent property. The additives containing bio-components as molecular-constituent had better DD efficiency than the traditional succinimide, although the nitrogen content and the TBN of the samples were smaller. This means, that the polar end-group of FAME has an active role in the mechanism of detergent action.

80 70 60 Nozzle cleannes, % 50 40 30 20 10 0 Base gasoil PIBFSI-1 PIBFSI-2 HR-PIBSI Com. AP

Amine: Nitogen content, %: TBN, mg KOH/g DETA 2.7 60.2 TEPA 2.67 60.8 TEPA 2,6 96,6 TEPA 3.25 90.0

Figure 4 Results of the Peugeot XUD-9 test 4. Conclusions Succinic anhydride derivatives from polyisobutylene ( MnPIB 1000) and maleic anhydride in the presence of radical initiator were synthesized, which were found to be suitable for producing diesel fuel additives. It was determined that fuel additives with improved DD efficiency can be produced from reaction of intermediers and polyethylene-polyamine according to well known methods of the synthesis of PIB-succinimides. The synthesized additive blended in diesel fuel can maintain cleanness of the injector nozzles of diesel

175

engines more efficiently than traditional polyisobutene-succinimides most frequently used as commercial deposit control additives. It was realised, that with an original structure, alkyl-succinic anhydride containing biocomponent as molecular-constituent can be synthesised from fatty acid methyl ester (FAME), polyisobutene and maleic anhydride in the presence of radical initiator. The selected intermediates containing bio-component as molecular-constituent were used to acylate polyethylene polyamines according to the investigated method applied for the synthesis of polyalkylene succinimides. The products were investigated by analytical and performance tests. Based on the results it can be concluded, that the DD efficiency of traditional succinimides could be achieved, moreover, in some cases exceeded. It was confirmed that the polar end-group of FAME has an active role in the mechanism of detergent action. The synthesized fuel additives had excellent corrosion inhibiting- and lubricity improving effects. References [1] Haycock, R.F., Thatcher, R.G.F., 2004, Fuel Additives and the Environment, Technical Committee of Petroleum Additive Manufacturers in Europe Hancsk, J.: Modern engine- and jet fuels II. Diesel fuels, Textbook. Publisher's Office at University of Veszprm, Veszprm, 1999. (ISBN 963 9220 27 2), (In Hungarian) Hancsk, J., Bartha, L., Baladincz, J., Kocsis, Z., 1999, Relationships Between the Properties of PIB-Succinic Anhydrides and Their Additive Derivatives, Lubrication Science, 11(3), 297-310. J. Hancsk, F. Kovcs, M. Krr: Production of vegetable oil fatty acid methyl esters from used frying oil by combined acidic/alkali transesterification Petroleum & Coal, 46 (3), 36-44, 2004 Quesada, J., 2003, Production of alkenyl succinic anhydrides from low-erucic and low-linolenic rapeseed oil methyl esters, Eur. J. Lipid Sci. Technol., 105, 281287. 1 H NMR (400 MHz, CDCl3) 7.60 6.55 (m, 0H), 2.46 (dd, J = 23.1, 5.7, 1H), 1.96 1.21 (m, 41H), 1.80 1.21 (m, 41H), 1.96 -0.46 (m, 47H), 1.67 -2.21 (m, 46H), 2.39 -0.46 (m, 47H). 13C NMR (101 MHz, CDCl3) 180.51 160.94 (m, -8H), 128.90 (s, 1H), 128.07 (dd, J = 28.4, 17.1, 1H), 126.02 (s, 2H), 77.17 (d, J = 31.9, 18H), 76.69 (s, 7H), 76.66 76.29 (m, 2H), 59.69 (s, 2H), 59.69 58.53 (m, 32H), 58.48 57.57 (m, 3H), 39.94 38.71 (m, 2H), 38.42 37.54 (m, 36H), 33.80 30.25 (m, 98H), 30.66 30.25 (m, 2H), 30.66 30.07 (m, 2H), 29.16 27.77 (m, 1H), 26.49 (d, J = 11.7, 1H), 21.35 (s, 1H) Hancsk, J., Bublik M., Tr, M., Baladincz, J.: Synthesis of fuel additives on vegetable oil basis at laboratory scale, European Journal of Lipid Science and Technology, 2006, 108(8), 644-651 Hancsk, J., Bublik, M., Beck, ., Baladincz, J., 2008, Development of multifunctional additives based on vegetable oils for high quality diesel and biodiesel, Chemical Engineering Research & Design, 86, 793-799. 1 H NMR (400 MHz, CDCl3) 7.24 (s, 0H), 6.53 6.50 (m, 0H), 5.33 (t, J = 4.2, 1H), 5.16 5.13 (m, 0H), 4.98 4.95 (m, 0H), 4.83 4.80 (m, 0H), 4.64 4.59 (m, 0H), 3.64 (s, 2H), 3.22 3.14 (m, 0H), 2.81 2.78 (m, 0H), 2.69 2.64 (m, 0H), 2.28 (t, J = 7.5, 1H), 1.99 (d, J = 7.3, 3H), 1.37 0.90 (m, 77H), 1.37 0.46 (m, 79H), 1.83 0.46 (m, 98H), 0.86 (dd, J = 8.8, 5.0, 2H).13C NMR (101 MHz, CDCl3) 180.51 167.51 (m, -8H), 173.64 173.03 (m, 0H), 172.05 171.37 (m, 0H), 144.39 143.70 (m, 0H), 140.45 139.85 (m, 0H), 136.22 135.24 (m, -1H), 129.99 (s, 1H), 129.73 (s, 1H), 117.02 116.04 (m, 0H), 115.06 114.45 (m, -1H), 77.31 (s, 34H), 77.00 (s, 35H), 76.68 (s, 34H), 59.44 (d, J = 13.6, 24H), 58.82 (s, 2H), 58.19 (s, 2H), 51.43 (s, 2H), 38.09 (d, J = 7.1, 24H), 37.76 (s, 4H), 34.10 (s, 2H), 32.48 (d, J = 14.6, 9H), 31.89 (s, 2H), 31.43 31.01 (m, 54H), 30.76 (s, 9H), 29.36 (ddd, J = 23.4, 15.6, 6.2, 18H), 27.17 (d, J = 5.6, 3H), 24.93 (s, 2H), 22.67 (s, 2H), 14.10 (s, 2H)

[2] [3] [4] [5] [6]

[7] [8] [9]

You might also like

- Organic Chemistry Compounds 9Document30 pagesOrganic Chemistry Compounds 9silvio1980No ratings yet

- Constitutional LawDocument44 pagesConstitutional LawidownloadbooksforstuNo ratings yet

- CSA W47.1 and CSA W59 Exam questions study guideDocument5 pagesCSA W47.1 and CSA W59 Exam questions study guideAlex Alex100% (2)

- Enemies Everywhere: Terrorism, Moral Panic, and Us Civil SocietyDocument24 pagesEnemies Everywhere: Terrorism, Moral Panic, and Us Civil SocietyidownloadbooksforstuNo ratings yet

- Lecture 3: Petroleum Refining Overview: 3.1 Crude OilDocument66 pagesLecture 3: Petroleum Refining Overview: 3.1 Crude OilKumar AyushNo ratings yet

- BYCO Report Highlights Oil CompanyDocument17 pagesBYCO Report Highlights Oil CompanyAliRashidNo ratings yet

- Fabrication and Characterization of Poly Lactic Acid (PLA) - Starch Based Bioplastic CompositesDocument11 pagesFabrication and Characterization of Poly Lactic Acid (PLA) - Starch Based Bioplastic CompositesAndrea VONo ratings yet

- Fuel Oil Quality Testing with API Gravity, BSW, and ColorDocument3 pagesFuel Oil Quality Testing with API Gravity, BSW, and ColorThomas KerlNo ratings yet

- Petroleum Refining Operations: Key Issues, Advances, and OpportunitiesDocument10 pagesPetroleum Refining Operations: Key Issues, Advances, and OpportunitiesMarbel VldNo ratings yet

- Cargill - Corn To Polylactic AcidDocument6 pagesCargill - Corn To Polylactic AcidI. Murali KrishnaNo ratings yet

- Dissolvine GL Technical BrochureDocument13 pagesDissolvine GL Technical BrochurealejandroNo ratings yet

- A Review On Recent Advancement in Catalytic Materials For Biodiesel Production 2015Document23 pagesA Review On Recent Advancement in Catalytic Materials For Biodiesel Production 2015ʚïɞShymaMasȜoodʚïɞNo ratings yet

- Density and Values of Crude Oil PDFDocument9 pagesDensity and Values of Crude Oil PDFRichard Amorin0% (1)

- Industrial Biotech J ProjectDocument39 pagesIndustrial Biotech J Projectchelsea charlesNo ratings yet

- Fosroc Nitocote EPS Protective CoatingDocument4 pagesFosroc Nitocote EPS Protective CoatingmangjitNo ratings yet

- Notes On Partial Differential Equations: Department of Mathematics, University of California at DavisDocument224 pagesNotes On Partial Differential Equations: Department of Mathematics, University of California at DavisidownloadbooksforstuNo ratings yet

- SA Sugar Industry Energy ScenarioDocument6 pagesSA Sugar Industry Energy ScenarioAndy TpNo ratings yet

- Processing Technologies For Poly (Lactic Acid)Document33 pagesProcessing Technologies For Poly (Lactic Acid)Aero Fortia NaturaNo ratings yet

- Selection of Technologies For Gas Plant NaturalDocument15 pagesSelection of Technologies For Gas Plant NaturaljxlNo ratings yet

- Study of Bio-Plastics As Green & Sustainable Alternative To PlasticsDocument8 pagesStudy of Bio-Plastics As Green & Sustainable Alternative To PlasticsAndehNo ratings yet

- Methyl Alcohol Plant CostDocument3 pagesMethyl Alcohol Plant CostIntratec SolutionsNo ratings yet

- Polycarbonate Characterization: Case StudyDocument13 pagesPolycarbonate Characterization: Case StudyAmranullah Hassan ZadaNo ratings yet

- FINAL Presentation For ARA ConferenceDocument26 pagesFINAL Presentation For ARA Conferencesaleh4060No ratings yet

- World LNG 2017 IGU - Report PDFDocument100 pagesWorld LNG 2017 IGU - Report PDFRABIU M RABIUNo ratings yet

- Mahat PradeepDocument60 pagesMahat PradeependosporaNo ratings yet

- Pipeline Corrosion Control in Oil and Gas Industry: A Case Study of NNPC/PPMC System 2A PipelineDocument4 pagesPipeline Corrosion Control in Oil and Gas Industry: A Case Study of NNPC/PPMC System 2A PipelineAbdulMajidYousoffNo ratings yet

- Fpsne 100Document1 pageFpsne 100AliAliNo ratings yet

- Effect of Asphaltenes On Equilibrium andDocument13 pagesEffect of Asphaltenes On Equilibrium andMichael MedinaNo ratings yet

- 2018 Book CeramicMembranesAppliedInSeparDocument99 pages2018 Book CeramicMembranesAppliedInSeparNermeen AhmedNo ratings yet

- Engineering Dreams: A Career in Any Stream of Engineering Is Equally Fruitful and RewardingDocument4 pagesEngineering Dreams: A Career in Any Stream of Engineering Is Equally Fruitful and RewardingRamPrasadMeenaNo ratings yet

- Introdiction To Engineering PDFDocument295 pagesIntrodiction To Engineering PDFAyebareNo ratings yet

- AIMMS Tutorial BeginnersDocument46 pagesAIMMS Tutorial Beginnerstryinghard18No ratings yet

- ECJ Dossier 2020 SustainabilityDocument49 pagesECJ Dossier 2020 SustainabilityJose LopezNo ratings yet

- CFC 1criterionbrochureDocument19 pagesCFC 1criterionbrochureSuraj Amin100% (1)

- WPS SumDocument61 pagesWPS SumA. ΒρατσισταNo ratings yet

- The Petrochemical Odyssey Final v4 SmallDocument100 pagesThe Petrochemical Odyssey Final v4 SmallSaad AliNo ratings yet

- PLA-PHB-Limonene Blends for Biodegradable Food PackagingDocument16 pagesPLA-PHB-Limonene Blends for Biodegradable Food PackagingORGEX TMNo ratings yet

- JBT Foodtech H1 Food Grade GreaseDocument6 pagesJBT Foodtech H1 Food Grade Greaseandri putrantoNo ratings yet

- AWM Biomethane To Grid 05 07 11 PDFDocument80 pagesAWM Biomethane To Grid 05 07 11 PDFVido SeptaNo ratings yet

- Chevron CorporationDocument5 pagesChevron CorporationrhonamaeNo ratings yet

- Overview of Poly (Lactic Acid) (Pla) Fibre: Ozan AvincDocument11 pagesOverview of Poly (Lactic Acid) (Pla) Fibre: Ozan Avincltlongnl100% (1)

- Biogreen Solutions Limited-Bgsl: Green Product Ideas For ExportDocument64 pagesBiogreen Solutions Limited-Bgsl: Green Product Ideas For Exportncr_thazzardsNo ratings yet

- Polylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherDocument4 pagesPolylactic Acid (PLA) - A Global Market Watch, 2011 - 2016 - BroucherAxis ResearchMindNo ratings yet

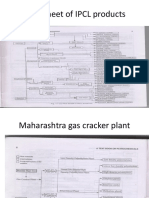

- IPCL chemicals flow sheetDocument51 pagesIPCL chemicals flow sheetDeekshith KodumuruNo ratings yet

- Introduction to production, operations management, and their objectivesDocument6 pagesIntroduction to production, operations management, and their objectivesshreekarainNo ratings yet

- Linear Programming Techniques for Optimizing Paint Product Mix in NigeriaDocument10 pagesLinear Programming Techniques for Optimizing Paint Product Mix in NigeriaHarsh SaxenaNo ratings yet

- Product Offer de CON enDocument14 pagesProduct Offer de CON enForeverNo ratings yet

- PERP Program - Isoprene/Bioisoprene: Routes Via C5 StreamsDocument3 pagesPERP Program - Isoprene/Bioisoprene: Routes Via C5 StreamsHari PurwitoNo ratings yet

- Icis Chemical Business 2013Document77 pagesIcis Chemical Business 2013mich0pNo ratings yet

- Methane conversion processDocument1 pageMethane conversion processEmir DjafarNo ratings yet

- Oil Price Trends in India and Its DeterminentsDocument16 pagesOil Price Trends in India and Its DeterminentsDeepthi Priya BejjamNo ratings yet

- Bimodal BlowMoldingBrochure PDFDocument4 pagesBimodal BlowMoldingBrochure PDFarjun rawat100% (1)

- Literature Review 2.1 BiodieselDocument18 pagesLiterature Review 2.1 BiodieselRichard ObinnaNo ratings yet

- Oil Accounting and Excise Duties at IOCL Mathura RefineryDocument127 pagesOil Accounting and Excise Duties at IOCL Mathura RefineryMohit Agarwal0% (1)

- SNGPLDocument28 pagesSNGPLKashif Naveed100% (2)

- ONGC's Welfare Policies & Industrial RelationsDocument127 pagesONGC's Welfare Policies & Industrial Relationsvpceb22enNo ratings yet

- Producing MDI in the PhilippinesDocument41 pagesProducing MDI in the PhilippinesJenny SabinoNo ratings yet

- Assignment Plastic ProductsDocument10 pagesAssignment Plastic Productsneel_nknNo ratings yet

- Roadmap2-08 Next Generation Hydrocarbon Bio RefineriesDocument181 pagesRoadmap2-08 Next Generation Hydrocarbon Bio RefineriesQuanqiu GurenNo ratings yet

- IOCL Summer Training Presentation on Barauni RefineryDocument16 pagesIOCL Summer Training Presentation on Barauni Refineryamish umar0% (1)

- ICDRDocument32 pagesICDRrohitjpatel786100% (1)

- MRPLDocument44 pagesMRPLNeha IsaacNo ratings yet

- ButadieneDocument10 pagesButadienearmanNo ratings yet

- CASE STUDY-Rockwell PetroleumDocument2 pagesCASE STUDY-Rockwell Petroleumanurag10julyNo ratings yet

- Nanoscale Dispensing of Single Ultrasmal DropletsDocument150 pagesNanoscale Dispensing of Single Ultrasmal DropletsidownloadbooksforstuNo ratings yet

- Hamiltonian Submanifolds of Regular PolytopesDocument224 pagesHamiltonian Submanifolds of Regular Polytopesidownloadbooksforstu100% (1)

- A Neural Basis For Collecting Behaviour in HumansDocument12 pagesA Neural Basis For Collecting Behaviour in HumansidownloadbooksforstuNo ratings yet

- Legal Implications of The Soviet Microwave Bombardment of The U.S. EmbassyDocument21 pagesLegal Implications of The Soviet Microwave Bombardment of The U.S. EmbassyidownloadbooksforstuNo ratings yet

- Doing Business With Darpa 2012Document10 pagesDoing Business With Darpa 2012ameraldaherNo ratings yet

- Cation Diffusion at The Polymer Coating/metal InterfaceDocument17 pagesCation Diffusion at The Polymer Coating/metal InterfaceidownloadbooksforstuNo ratings yet

- Effect of Surfactants On The Electrochemical Performance of Cation-Selective Membrane ElectrodesDocument8 pagesEffect of Surfactants On The Electrochemical Performance of Cation-Selective Membrane ElectrodesidownloadbooksforstuNo ratings yet

- An Essentially Non-Oscillatory Crank-Nicolson Procedure For Incompressible Navier-Stokes EquationsDocument7 pagesAn Essentially Non-Oscillatory Crank-Nicolson Procedure For Incompressible Navier-Stokes EquationsidownloadbooksforstuNo ratings yet

- Conjugacy of Convex BilliardsDocument23 pagesConjugacy of Convex BilliardsidownloadbooksforstuNo ratings yet

- 1208 0165v2Document7 pages1208 0165v2idownloadbooksforstuNo ratings yet

- Navy Jet Fuel SaltDocument4 pagesNavy Jet Fuel SaltidownloadbooksforstuNo ratings yet

- GEVO Hydrocarbon Fuels From Plant BiomassDocument25 pagesGEVO Hydrocarbon Fuels From Plant BiomassidownloadbooksforstuNo ratings yet

- Experiment 5: Swelling and Solute Transport Properties of HydrogelsDocument5 pagesExperiment 5: Swelling and Solute Transport Properties of HydrogelsidownloadbooksforstuNo ratings yet

- On Some Open Problems in Diophantine ApproximationDocument42 pagesOn Some Open Problems in Diophantine ApproximationidownloadbooksforstuNo ratings yet

- KAAM Theory and Lindsedt SeriesDocument38 pagesKAAM Theory and Lindsedt SeriesidownloadbooksforstuNo ratings yet

- Relationships of Mass Transfer Processes and Polymer ProcessingDocument0 pagesRelationships of Mass Transfer Processes and Polymer ProcessingidownloadbooksforstuNo ratings yet

- Navier STokes 3DDocument49 pagesNavier STokes 3DidownloadbooksforstuNo ratings yet

- Possible Controversy Over Dietary Polyphenols: Benefits Vs RisksDocument3 pagesPossible Controversy Over Dietary Polyphenols: Benefits Vs RisksidownloadbooksforstuNo ratings yet

- Envy, Personality's Riskiness and Methods For Achieving of High Economic StatusDocument4 pagesEnvy, Personality's Riskiness and Methods For Achieving of High Economic StatusidownloadbooksforstuNo ratings yet

- Vringo 2014Q1 Investor PresentationDocument20 pagesVringo 2014Q1 Investor PresentationidownloadbooksforstuNo ratings yet

- Distributed Envy Minimization For Resource AllocationDocument10 pagesDistributed Envy Minimization For Resource AllocationidownloadbooksforstuNo ratings yet

- Non Strongly Solvable Navier StokesDocument8 pagesNon Strongly Solvable Navier StokesidownloadbooksforstuNo ratings yet

- Clear and Present Danger TestDocument21 pagesClear and Present Danger TestidownloadbooksforstuNo ratings yet

- Otelbaev N-S 21 12 2013Document100 pagesOtelbaev N-S 21 12 2013idownloadbooksforstuNo ratings yet

- Transparent ArmorDocument13 pagesTransparent ArmoridownloadbooksforstuNo ratings yet

- Darpa Baa 13 32 (I2o Office Wide)Document37 pagesDarpa Baa 13 32 (I2o Office Wide)idownloadbooksforstuNo ratings yet

- Transparent ArmorDocument13 pagesTransparent ArmoridownloadbooksforstuNo ratings yet

- Technoeconomic Analysis of Alternative Pathways of Isopropanol ProductionDocument13 pagesTechnoeconomic Analysis of Alternative Pathways of Isopropanol ProductionSUTHIWAT YIMYAMNo ratings yet

- Half-Yearly Chemistry Exam Question PaperDocument9 pagesHalf-Yearly Chemistry Exam Question Paperkumar shivamNo ratings yet

- Experiment 3 KineticsDocument20 pagesExperiment 3 KineticsNItha100% (1)

- Vidya Jyothi Chem Mock TestDocument6 pagesVidya Jyothi Chem Mock TestArko SarkarNo ratings yet

- 20 C 2 Vee Foam High Expansion - C2 - PDFDocument1 page20 C 2 Vee Foam High Expansion - C2 - PDFbenonNo ratings yet

- Alkane: General Methods of Preparation: (1) by Catalytic Reduction of Alkenes and AlkynesDocument11 pagesAlkane: General Methods of Preparation: (1) by Catalytic Reduction of Alkenes and AlkynesaashishNo ratings yet

- Carbohydrate ChemistryDocument78 pagesCarbohydrate ChemistryNikhil NathNo ratings yet

- Complete Immersion Phosphating LineDocument8 pagesComplete Immersion Phosphating LineStay AwayNo ratings yet

- The Periodic Table Its Story and Its SignificanceDocument3 pagesThe Periodic Table Its Story and Its SignificanceJason Vinluan CarinanNo ratings yet

- CHEM Model QuestionDocument4 pagesCHEM Model QuestionAavash ChhetriNo ratings yet

- Aa - List-Definition-Chemistry-protected PDFDocument10 pagesAa - List-Definition-Chemistry-protected PDFFahad Hameed AhmadNo ratings yet

- Dec - 2011Document20 pagesDec - 2011Raktim DekaNo ratings yet

- Mil DTL 81706BDocument20 pagesMil DTL 81706BwcwtnuiNo ratings yet

- DegradationDocument14 pagesDegradationEmharion DinNo ratings yet

- MACDEMIDDocument55 pagesMACDEMIDSetyohdWNo ratings yet

- Plant Deodorizer-MSDS 6.8Document5 pagesPlant Deodorizer-MSDS 6.8POEM HUBNo ratings yet

- Enzymatic Desizing of Cotton FabricsDocument7 pagesEnzymatic Desizing of Cotton Fabricseshaniqbal100% (1)

- Atp InvetigationDocument6 pagesAtp InvetigationHussain IbrahimNo ratings yet

- 2011 Prep Problems With Solutions 110215Document115 pages2011 Prep Problems With Solutions 110215RSLNo ratings yet

- DSM-0279.0 Fe SpecialityDocument3 pagesDSM-0279.0 Fe SpecialityStefanoNo ratings yet

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Document8 pagesAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNo ratings yet

- Pentose Phosphate PathwayDocument2 pagesPentose Phosphate PathwayIshita SinghNo ratings yet

- 2016 Progress in Non-Isocyanate Polyurethanes Synthesized PDFDocument38 pages2016 Progress in Non-Isocyanate Polyurethanes Synthesized PDFPilar MayaNo ratings yet

- Periodic TableDocument3 pagesPeriodic Tablenada_izyanNo ratings yet

- CBSE Class-12 Chemistry Quick Revision Notes on AminesDocument8 pagesCBSE Class-12 Chemistry Quick Revision Notes on AminesAryan MeenaNo ratings yet