Professional Documents

Culture Documents

Integrated Mechanical DesignJAN - 11

Uploaded by

SasiKumar PetchiappanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Integrated Mechanical DesignJAN - 11

Uploaded by

SasiKumar PetchiappanCopyright:

Available Formats

Reg. No.

Question Paper Code :

M.E./M.Tech. DEGREE EXAMINATION, JANUARY 2011. First Semester CAD/CAM

218202 INTEGRATED MECHANICAL DESIGN (Regulation 2010) Time : Three hours Use of Design Data Book is permitted.

1. 2. 3. 4. 5. 6.

Define factor of safety applied to brittle and ductile material. Differentiate between (a) stationary axle (b) revolving axle with suitable example. Which of the theories of failure is more conservative? State Distortion energy theory and hence write the equation for Von-Misses stress. What strength of the material and why is to be considered while designing the spur gear parameter of module? Define the following with respect to the gears. Normal module; Force along the line of action.

43

21

8. 9. 10.

7.

What is the reason for choosing specifically 14.5 or 20 pressure angle involute gear? What is the importance of ray/speed diagram? What is the condition for a block brake to be self-energizing?

Differentiate between Leading shoe and Trailing shoe in case of internal expanding shoe brake.

43 2

Answer ALL questions.

Any required design data can be suitably assumed.

PART A (10 2 = 20 marks)

43 21

20022

Maximum : 100 marks

PART B (16 + 16 + 48 = 80 marks) 11. (a)

Fig. 11 (a) is a schematic drawing of a countershaft that supports two V-belt pulleys. The loose belt tension on the pulley at A is 15 percent of

the tension on the tight side. For convenience each pair of belt pulls is assumed to be parallel. An analysis of this problem gave shaft forces at B and D of FB = 253j 253k N and FD = 320k N . Resultant bending moments at B and D turned Out to be MB = 58.7 N-m and MD = 29.3 N-m, but these were not in the same plane. Assuming shaft stiffness is the bending deflection that is not to exceed 0.2 mm at each pulley.

primary design factor; find a shaft diameter using cold-drawn steel and a

(b)

A six speed gear box is to be designed for a lathe. Power input is 2 kW and speed ranges from 110 to 700 rpm. Design should include the following. (i) (16)

43

21

(ii)

(iii) Kinematic arrangement.

43 2

Fig. 11 (a) Or Spur gear design 2

Preliminary and final ray diagram/speed diagram

1

All Dimensions are in mm

43 21

(16)

20022

12.

(a)

A four-wheeled automobile car has a total mass of 1000 kg. The moment of inertia of each wheel about a transverse axis through its centre of gravity is 0.5 kg-m2. The rolling radius of the wheel is 0.35 m. The rotating and reciprocating parts of the engine and transmission system are equivalent to a moment of inertia of 2.5 kg-m2, which rotates at 5 times the road-wheel speed. The car is travelling at a speed of 100 kmph on a plane road. When the brakes are applied, the car decelerates at 0.5g. There are brakes on all four wheels. Calculate : (i) (ii)

the energy absorbed by each brake and the torque capacity of each brake. Or

(b)

(i) (ii)

43 2

the actuating force P and Fig. 12 (b) 3

An internal-expanding brake with four identical shoes is shown Fig. 12 (b). Each hinge pin supports a pair of shoes. The actuating mechanism is designed in such a way that it produces same force P on each of the four shoes. The face width of the friction lining is 50 mm and the maximum intensity of pressure is limited to 1 MPa. The co-efficient of friction is 0.3. Calculate :

the torque-absorbing capacity of the brake.

43

21

Note : All dimensions are in mm

43 21

(16) (16)

20022

13.

(a)

Design and draw a hand operated screw press for 2 ton capacity to the following details. (i) Frame (made of cast iron). (16) (ii) Screw rod (select suitable carbon steel material). (12) (iii) Bush (bronze). (7) (iv) Pressure plate (high grade cast iron). (6) (v) Foundation bolts (select suitable carbon steel material). (7) Selection of screw frame is I section.

Safe working stresses shall be based on standards. Unsupported length of a screw is 600 mm. Or (b)

21

43

43 2

Tiller Crane Unit Fig. 13 (b) 4

The drive arrangement for a tiller crane is shown in Fig. l3 (b). The crane is to be used in open wells for removing the rock and other debris from the well after the blasting operation. The lifting is provided by a 7 kW two speed electrical motor running at 720 rpm. The power is transmitted to the rope drum through a belt drive and a two stage spur gear reduction unit. The speed reduction in the belt drive is 2, while the overall speed reduction in the spur gear reducer is 16. (i) Design all the gears in the reduction unit. (25) (ii) Design the intermediate shaft of the reducer. (10) (iii) Design the belt drive. (5) (iv) Select the suitable end bearings for the intermediate shafts. (8)

43 21

20022

You might also like

- ME6503 DME Question PapersDocument27 pagesME6503 DME Question PapersSaravanan KumarNo ratings yet

- Assignment Shaft DesignDocument4 pagesAssignment Shaft DesignHasham Mehmood100% (1)

- 181505-181902-MD - IiDocument2 pages181505-181902-MD - IiSiddharth PanchalNo ratings yet

- 0326 Me 2303 Design of Machine ElementsDocument3 pages0326 Me 2303 Design of Machine ElementsSaravanan MathiNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument6 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Dme Model Key 2019Document25 pagesDme Model Key 2019Siva RamanNo ratings yet

- Question Paper - Design of Machine Elements 2 Oct-19-October - 2019Document2 pagesQuestion Paper - Design of Machine Elements 2 Oct-19-October - 2019ChanduNo ratings yet

- Dme 2 QP CombinedDocument9 pagesDme 2 QP CombinedPrasinNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Mech 325 Tutorials (Questions Only)Document54 pagesMech 325 Tutorials (Questions Only)Shahriar Norouzi ZadehNo ratings yet

- MD-II Question PapersDocument7 pagesMD-II Question PapersDinesh PatilNo ratings yet

- Theory of Machines & Machine DesignDocument3 pagesTheory of Machines & Machine DesignAvilash JainNo ratings yet

- Lab Integrated DesignDocument2 pagesLab Integrated DesignSpidyNo ratings yet

- Final Exam MCT3214 Nov09Document6 pagesFinal Exam MCT3214 Nov09Deerah Aziz100% (1)

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Final ReportDocument24 pagesFinal Reportvarshasdm1987No ratings yet

- Previous Exam QuestionsDocument8 pagesPrevious Exam QuestionssallyreffatNo ratings yet

- 8th Sem - Assignment - MD II (2962108)Document5 pages8th Sem - Assignment - MD II (2962108)rishabhk28995No ratings yet

- Me 2303 - Design of Machine Elements December 2010Document3 pagesMe 2303 - Design of Machine Elements December 2010Ilaya Perumal K0% (1)

- Assignment 1 (Unit 1 and 2)Document5 pagesAssignment 1 (Unit 1 and 2)Atharva ChoudhariNo ratings yet

- No of Pages: 4 Course Code: 12M502: Fig.1 Fig 2Document4 pagesNo of Pages: 4 Course Code: 12M502: Fig.1 Fig 2CRAZY PIANO PLAYERNo ratings yet

- Integrated Mechanical Design Jan - 10Document4 pagesIntegrated Mechanical Design Jan - 10SasiKumar PetchiappanNo ratings yet

- MD-II Question BankDocument2 pagesMD-II Question BankmaheshNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument6 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- New Friction Mechanical TransmissionDocument5 pagesNew Friction Mechanical TransmissionInternational Journal of Engineering Inventions (IJEI)No ratings yet

- BMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsDocument2 pagesBMS College of Engineering, Bangalore-560019: January 2015 Semester End Make Up ExaminationsAbhyudaya SinghNo ratings yet

- DMM Ii (2015)Document35 pagesDMM Ii (2015)gorijalaNo ratings yet

- DTS Model PaperDocument3 pagesDTS Model PaperrajkumardotcomNo ratings yet

- T.E MechanicalDocument62 pagesT.E MechanicalhaptooorNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument10 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Machine Design II t2 2015 NopassDocument2 pagesMachine Design II t2 2015 NopassAshish VajirNo ratings yet

- Rotary Polishing Tool 2Document14 pagesRotary Polishing Tool 2bcairns12No ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Fall 2012 Test2 SolnDocument6 pagesFall 2012 Test2 SolnepsilonnaughtNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument8 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Tutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentDocument12 pagesTutorial: Government Enginerring College, Valsad Mechanical Engineering DepartmentSURYA S96No ratings yet

- Stress and Design Analysis of Triple Reduction Gearbox CasingDocument6 pagesStress and Design Analysis of Triple Reduction Gearbox CasingIJIRSTNo ratings yet

- Be Winter 2022Document3 pagesBe Winter 2022Karan SheladiyaNo ratings yet

- Common Subject Code: Shivaji University, KolhapurDocument10 pagesCommon Subject Code: Shivaji University, Kolhapursatyamchgl2010No ratings yet

- DME Model QuesDocument3 pagesDME Model QuesSiva RamanNo ratings yet

- NUiCONE-2015 Design and Analysis of 100 T Capacity Bottom Pulley Hook Block For Double Girder EOT CraneDocument5 pagesNUiCONE-2015 Design and Analysis of 100 T Capacity Bottom Pulley Hook Block For Double Girder EOT CraneGogyNo ratings yet

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsFrom EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsNo ratings yet

- Faculty of EngineeringDocument2 pagesFaculty of EngineeringSamNihalNo ratings yet

- Makalah GTWDocument8 pagesMakalah GTWfaisalNo ratings yet

- Machine Design - LDocument2 pagesMachine Design - LNilesh Mistry (Nilesh Sharma)No ratings yet

- Mech-Vi-Design of Machine Elements II (10me62) - Question PaperDocument11 pagesMech-Vi-Design of Machine Elements II (10me62) - Question PaperAnonymous utfuIcnNo ratings yet

- Machine Design II Question PaperDocument8 pagesMachine Design II Question PaperProf. Avinash MahaleNo ratings yet

- Assignment No 2 TEMEV 15 08 23 HGPDocument2 pagesAssignment No 2 TEMEV 15 08 23 HGPharshitgupta000000No ratings yet

- 2020-11-10SupplementaryME402ME402-E - Ktu QbankDocument2 pages2020-11-10SupplementaryME402ME402-E - Ktu QbankbilalfocusNo ratings yet

- ME2352 Design of Transmission Question BankDocument4 pagesME2352 Design of Transmission Question BankKarthik SubramaniNo ratings yet

- 07a6ec05 Designofmachinemembers IIDocument11 pages07a6ec05 Designofmachinemembers IIzahid_polyNo ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- 2019 May ME402-A - Ktu QbankDocument3 pages2019 May ME402-A - Ktu Qbankbilalfocus0% (1)

- Supp Nov 2009Document10 pagesSupp Nov 2009prk74No ratings yet

- Mechanics Ii Time Allowed: 2 HoursDocument9 pagesMechanics Ii Time Allowed: 2 HourssubipuruNo ratings yet

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Slot Information Report - 07!15!2015!19!28-07Document2 pagesSlot Information Report - 07!15!2015!19!28-07SasiKumar PetchiappanNo ratings yet

- Steps For PF Amount Transfer (New) ..............Document5 pagesSteps For PF Amount Transfer (New) ..............SasiKumar PetchiappanNo ratings yet

- Work Permit (Ra Puram) - 28-Nov - 2013Document1 pageWork Permit (Ra Puram) - 28-Nov - 2013SasiKumar PetchiappanNo ratings yet

- User Manual 5 PDFDocument518 pagesUser Manual 5 PDFSasiKumar PetchiappanNo ratings yet

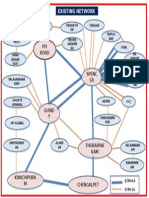

- Existing NetworkDocument1 pageExisting NetworkSasiKumar PetchiappanNo ratings yet

- Grade 3 MathsDocument3 pagesGrade 3 MathsSasiKumar PetchiappanNo ratings yet

- A R Collage of Engineering and TechnologyDocument1 pageA R Collage of Engineering and TechnologySasiKumar PetchiappanNo ratings yet

- Chapter-4: 4.1 Matrix MaterialsDocument17 pagesChapter-4: 4.1 Matrix MaterialsSasiKumar PetchiappanNo ratings yet

- Slot Information Report - 07!15!2015!19!28-07Document2 pagesSlot Information Report - 07!15!2015!19!28-07SasiKumar PetchiappanNo ratings yet

- Institution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)Document34 pagesInstitution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)SasiKumar PetchiappanNo ratings yet

- Front Pagels and BonofideDocument2 pagesFront Pagels and BonofideSasiKumar PetchiappanNo ratings yet

- Iat-2 EgDocument1 pageIat-2 EgSasiKumar PetchiappanNo ratings yet

- Chapter-5: 5.1 Fabrication Techniques of Composite MaterialsDocument6 pagesChapter-5: 5.1 Fabrication Techniques of Composite MaterialsSasiKumar PetchiappanNo ratings yet

- Content Materials1Document40 pagesContent Materials1SasiKumar PetchiappanNo ratings yet

- Ieee Electronics 2013 - 2014Document49 pagesIeee Electronics 2013 - 2014SasiKumar PetchiappanNo ratings yet

- Theory of Machines12Document1 pageTheory of Machines12SasiKumar PetchiappanNo ratings yet

- SalmanDocument2 pagesSalmanSasiKumar PetchiappanNo ratings yet

- Electrical Based Titles 2009-2010Document2 pagesElectrical Based Titles 2009-2010Siva SankarNo ratings yet

- Design Fundamentals, Methods and Material Selection 9Document1 pageDesign Fundamentals, Methods and Material Selection 9SasiKumar PetchiappanNo ratings yet

- Quality ConceptDocument2 pagesQuality ConceptSasiKumar PetchiappanNo ratings yet

- 405 M.E. Computer Science and EngineeringDocument68 pages405 M.E. Computer Science and EngineeringThanuambikaNo ratings yet

- Food and OilDocument11 pagesFood and OilSasiKumar PetchiappanNo ratings yet

- Centre For Research Anna University:: Chennai 600025 Enrolment Form/ Registration Renewal FormDocument1 pageCentre For Research Anna University:: Chennai 600025 Enrolment Form/ Registration Renewal FormruthshaNo ratings yet

- Question Bank: Ee 1403 - Design of Electrical ApparatusDocument11 pagesQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshNo ratings yet

- 2K Factor PDFDocument6 pages2K Factor PDFvmgobinathNo ratings yet

- Time Table For EngDocument1 pageTime Table For EngSasiKumar PetchiappanNo ratings yet

- Muhammad NijasDocument2 pagesMuhammad NijasSasiKumar PetchiappanNo ratings yet

- Rainwater Harvesting Basic ComponentsDocument3 pagesRainwater Harvesting Basic ComponentsSasiKumar PetchiappanNo ratings yet

- Write The Procedure To Compile and Install Linux Kernel From SourceDocument1 pageWrite The Procedure To Compile and Install Linux Kernel From SourceSasiKumar PetchiappanNo ratings yet

- Line Chart 3Document2 pagesLine Chart 3SasiKumar PetchiappanNo ratings yet