Professional Documents

Culture Documents

Inspection Procedure For Unit Transformer PDF

Uploaded by

singha98Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Procedure For Unit Transformer PDF

Uploaded by

singha98Copyright:

Available Formats

0 E

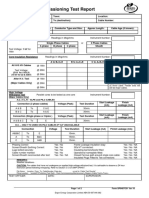

21,NOV,12 06,NOV,12

FOR CONSTRUCTION FOR REVIEW

FOR CONSTRUCTION REFLECT COMMENT

S.Y.KIM S.Y.KIM

T.W.KIM T.W.KIM

T.M.KWON T.M.KWON

14,May,12

FOR REVIEW

REFLECT COMMENT

M.S.SEO

T.W.KIM

T.M.KWON

Revised Lightning C 19 MAR 12

th

FOR REVIEW

Impulse Test acceptance criteria

M.S.SEO

T.W.KIM

T.M.KWON

B REV.

12 ,JAN,12 DATE

th

FOR REVIEW STATUS

REFLECT COMMENT DESCRIPTION

M.S.SEO PREPARED BY

T.W.KIM CHECKED BY

T.M.KWON APPROVED BY

Owner

RABIGH POWER PLANT NO.2 PROJECT UNITS # 01, 02, 03 & 04 Contract # 31021001/00

OWNERS ENGINEER

MAIN CONTRACTOR

SUB CONTRACTOR

DOCUMENT TITLE

NAME PREPARED BY CHECKED BY APPROVED BY S.Y.KIM T.W.KIM T.M.KWON

DATE

21, NOV,12 21, NOV,12 21, NOV,12

Inspection Procedure for Unit Transformer

(Reference document : HHI-ITP-11-103 page 6~13)

DOCUMENT NO.

Approval/Certification Information Doc No.: PB-10195 Rev.: v1 No. of Pages 13 Rev. No. 0

31021001/00-Z-RPP2-WE001308

DOCUMENT STATUS:

FOR INFORMATION FOR APPROVAL FOR REVIEW FOR CONSTRUCTION AS BUILT

RABIGH POWER PLANT No.2 Inspection Procedure for Unit Transformer

Doc.No Page Z-RPP2-WE-001308 2 of 13 Rev 0

Table of Content

1. Unit Transformer Test Procedure

(Ref. Hyundai Inspection and Test Procedure II Page 6 ~ Page 13)

3~ 10

2. SEC recommendation method 3. Addenda for type and routine test

11~12 13

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. 1. INSPECTION & TEST ITEMS Visual inspection(Ro) DESCRIPTION 1. Construction, painting & welding condition will be inspected visually. 2. Dimension will be measured in accordance with the approved specification. 1. The winding resistance will be measured by the DC voltage drop method with resistance measuring system. 2. This test shall be made on all windings and all tap positions. 3. Test results shall be corrected to 75 values. 4. This test shall be repeated at the end of tests. 5. DC current : Max. 100A

Doc :WE-001308

Rev.0

3/13

PASS / ACCEPTANCE CRITERIA * The inspection results shall be satisfied with approved specification and drawings.

2.

Winding resistance measurement(Ro)

3.

Ratio check(Ro)

1. The voltage ratio shall be measured by means of transformer turns ratio(TTR) test set and on single phase, phase by phase. 2. The applied voltage to HV winding will be about 120(V). 3. The test shall be made on all windings and all tap positions. 1. The phase relationship shall be checked at rated voltage tap connection. 2. Three phase 220(V) will be applied to HV winding and the voltage shall be measured between terminals. 3. Vector diagram will be drawn and confirmed. 1. The test shall be made between HV and LV1 winding, HV and LV2 winding, LV1and LV2 winding, HV winding and earth, LV1winding and earth, LV2 winding and earth with 5000(V) megger tester. 2. The test shall be made on 15Sec,1min. and 10 minutes. 3. Core to earth, clamp to earth, core+clamp to earth for one minute with 3500V megger. 1. The test shall be made each winding to ground and between the windings with Doble tester. 2. IEEE C57.12.90 table 4 method II is prefered. 3. Test voltage shall be from 2kV to 12kV in steps of 2kV.

* Ratio error shall be within 0.5% at all tappings.

4.

Phase relationship check(Ro)

* Phase relationship Dyn7yn7

5.

Insulation resistance measurement(Ro) (Including core insulation test)

* PI : Min. 1.3

6.

Insulation power factor and capacitance measurement(Ro) (Before and after dielectic tests)

* P.F : max. 0.5% at 20

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. 7 INSPECTION & TEST ITEMS Insulation power factor and capacitance measurement of capacitor bushing(Ro) DESCRIPTION 1. Capacitance C1 and tan delta of condenser bushings in voltage range of 0 to 12kV in step of 2kV shall be measured on each capacitor bushings. 2. The bushings with tan delta > 0.4% at < 30 shall be rejected. 3. Capacitance C2 and tan delta shall be measured at 0.5 & 1.0 Kv. 4. The tests on bushings shall be performed separately from transformer. C1: 10kV, C2: 0.5kV 1. The test shall be made at 70%, 90%,100%,110% & 120% of rated voltage and rated frequency.(60Hz) Tap pos. : rated tap 2. The test voltage shall be applied to a LV winding with the other winding left open circuited. 3. The loss will be measured by three wattmeter method. 4. After the completion of the dielectric test the excitation losses shall be measured at 100% rated voltage. The excitation voltage shall then be increased to 110% rated voltage and the transformer left excited for 1 hour. The voltage shall then be reduced to 100% of rated voltage and excitation losses measurements repeated. 5. Measurement of harmonics of no-load current at 100%, 110% and 120% rated voltage. 6. 1,2,3,5,7,9,11th and 13th harmonic content shall be measured using harmonic analyzer and expressed as percentage of 60Hz component. 1. The transformer shall be energized at rated voltage and frequency with no load. 2. The microphone shall be located at 1mt interval and spaced 0.3m(ONAN base) from datum level. 3. The frequency spectra of the audible sound pressure shall be measured at factory. 4. The background noise level before and after test shall be measured.

Doc :WE-001308

Rev.0

4/13

PASS / ACCEPTANCE CRITERIA

No-load loss & current measurement(Ro)

Before and after dielectric tests

* No-load loss & excitation current No-load loss Excit. Current(%) 70% 79KW 0.24% 100% 120KW 2.40% 110% 120KW 2.40% 120% * Tolerance of excitation current : +30%

(Measurement of harmonic contents)(S)

Sound level measurement(S)

* Sound Pressure level 76 dB(A) at ONAN base,0.3meter

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. 10 INSPECTION & TEST ITEMS Impedance voltage & load-loss measurement(Ro) DESCRIPTION 1. The test shall be made at rated frequency and current by short circuit method. 2. The test shall be made on the principal, highest and lowest voltage tap positions at 1.0Pu, 1.1Pu and 1.3Pu load current base on Max. rating( HV-LV1, HV-LV2). But the test of LV1-LV2 will be carried out at low capacity and the rusults will be corrected to 1.0PU and 1.3PU. The test to be performed at all other taps at 0.5Pu.( HV-LV1 & HV-LV2 ) 3. The load loss and impedance voltage will be measured on Max. rating base and corrected to the other ratings. 4. Symmetric loading(load balance) should be checked at extreme taps and principal tap base on Max. rating, and the results to be included at final test report. 5. The measured load loss and impedance voltage shall be corrected to the reference temperature of 75. 1. The test shall be made at the maximum loss tap with the rated frequency by short circuit method. 2. At first, to determine the top oil and the average oil temperature rise, the test losses shall be supplied as follow; Test losses ( Total loss ) = Load loss + No Load loss 3. After saturation, input shall be then reduced to rated current and this current is maintained for 1 hour. 4. After shut down the electric power, the temperature of winding is determined by the resistance method. Resistance measurement shall be made first on the highest temperature winding, then other windings. 5. The sequence of test shall be as follows (HV-LV1+LV2) ; a) 100% ONAN and 100% ONAN cooling without spare 110% ONAN and 100% ONAN cooling with spare cooler. b) 130% ONAN and 100% ONAN cooling without spare cooler for 4hours preceeding load of 1.0pu continues. 6. Thermograpic infra-red scanning of transformer tank walls,

Doc :WE-001308

Rev.0

5/13

PASS / ACCEPTANCE CRITERIA * % imped. and load loss at 75, principal tap Load loss % Imp.(60MVA) HV-LV1:16.0% 185KW HV-LV1, 60MVA HV-LV2:16.0% 185KW HV-LV2, 60MVA 370KW HV-(LV1+LV2), 120MVA HV-(LV1+LV2) of %imp. (120MVA, 75) : 18% Tol of %imp. : +7.5% * refer to data sheet for other %imp values.

11

Temperature rise test(T) (Before dielectric tests)

* Oil temperature rise : 40 * Winding temperature rise : 45 * Hot spot temperature rise : 48 At end of overload, The following hot spot temp. shall not be exceed. Base on Max. ambient temp. of 50. * Top oil temp. : 115 * Winding hot spot temp./metalic parts : <140 at 50 amb. * Oil exponent X=0.8 at ON cooling Winding exponent Y=1.3 at ON and OF cooling. Hotspot factor H=1.3

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. INSPECTION & TEST ITEMS DESCRIPTION bushing turrets and covers shall be performed during over-load temperature rise test. 7. Following data shall be recorded/calculated; a) bushing stud temperatures at the end of over-load heat run. b) average oil time constant c) winding time constant 1. The test will be made according to IEC:60076-3, clause 13,14 if not specified in this procedure. 2. Polarity of test voltage : Positive 3. The test shall be carried out with OLTC on SW. POS. 1, 11 and 21 with each of the three phases being tested for LI. During neutral test, tap position should be minimum volt. 4. Test sequence HV, LV1, LV2 winding : R.FW-FW-R.CW-CW-CW-FW-FW Neutral : R.FW - FW - FW - FW Where R.FW is the reduced full wave, FW is full wave, R.CW is reduced chopped wave, CW is chopped wave. 5. Standard voltage wave form(Front/Tail time) Full wave : 1.230% / 5020% Chopped wave : 2 6 Neutral : front time up to 13 6. Impulse current traces, with a sweep time of 10 to 25us shall be recorded. 7. The required crest voltage for LI shall be increased if the actual front time exceeds 2.0us or the actual time to 50% crest value is less than 40us according to correction factor table in the SEC spec. 8. Recording shall be of minimum three independent channels for LI. 9. Test voltage(LI) 1) HV winding : 250kV 2) LV1 and LV2 winding : 125kV 3) LV Neutral : 125kV

Doc :WE-001308

Rev.0

6/13

PASS / ACCEPTANCE CRITERIA

12.

Impulse tests(Ro) (Just after temp. rise test, hot condition) Lightning impulse test

* To be withstood

Dielectric test sequence lightning impulse--> neutral lightning --> separate source AC -->ACSD--> ACLD--> capacitance&tan delta

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. 13 INSPECTION & TEST ITEMS Separate-source AC voltage withstand test(Ro) DESCRIPTION 1. Test voltage at rated frequency must be adjusted using peak volt meter. 2. The single phase AC voltage shall be applied to each winding with other winding and tank solidly grounded. 3. Test frequency and duration : 60 Hz / 60sec 4. Test voltage 1) HV winding to earth : 95kV 2) LV1 winding and neutral to earth : 50kV 3) LV2 winding and neutral to earth : 50kV 1. The transformer shall be excited with high frequency power source to prevent from saturation of magnetizing flux. 2. Test frequency : 180Hz or 240Hz 3. Test duration : 60Sec 4. Test voltage : 50KV at HV (Two times of Um)

Doc :WE-001308

Rev.0

7/13

PASS / ACCEPTANCE CRITERIA * To be withstood

14

Induced overvoltage withstand test(Ro)

* To be withstood

15

Zero-sequence impedance measurement(S)

1. The test shall be made at rated frequency between the line terminals and the neutral. 2. The zero sequence impedance shall be measured on the rated and extrem tap positions. 3. Sketch showing the magnetic core and the disposition of windings shall be enclosed with the report. 4. The measuring current must not be higher than 30% of the nominal current. 1. Single phase voltage 220380V 60Hz be applied to each phase of HV or LV1 or LV2 line terminals by turn and voltage induced in the other phases are to be measured. 1. Operation test With the tap changer fully assembled on the transformer, following sequence of operations shall be performed without failure; a) with transformer un-energized, 8 complete cycles of operation at no load, 1 complete cycle of operation. b) with transformer un-energized, and with the auxiliary voltage reduced to 85% of its rated * Not to be abnormal condition

16

Magnetic balance test(Ro)

17

Test of on-load tap changer(Ro)

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. INSPECTION & TEST ITEMS DESCRIPTION value, 1 complete cycle of operation. c) with transformer energized at rated voltage and frequency at no load, 1 complete cycle of operation. d) with one winding short-circuited and, as far as practicable, rated current in the tapped winding, 10 tap-change operations across the range of two steps on each side from where a coarse or reversing changeover selector operates, or otherwise from the middle tapping. 2. Power frequency withstand test shall be carried out on auxiliary devices with 2000V AC for 1 min. 1. Completely assembled transformer shall be subjected to a pressure corresponding to twice the normal head of oil or the normal oil column + 0.5kg/cm2 whichever is higher, for 12hrs. There shall be no leak or sweating by visual. 2. The transformer tank, conservator, coolers shall be subjected to a pressure. 1. Sequence test shall be performed according to approved drawings. 2. The voltage to ground shall be 2500Vrms for equipment rated up to 250Vdc and 1500Vrms for other voltage ratings. Test voltage across open contacts shall be 1500Vrms for contacts rated for tripping and 1000V for contact not rated for tripping.(for 1 minute with all the circuits tied together) 3. Insulation resistance shall be measured with 500(V) megger tester(Include C.T). temperature indicators, fans and others shall be subjected to an operational test to assure the proper coordinated functioning. 1. Ratio and polarity test of BCT shall be carried out before installation on transformer. 2. Ratio error shall be measured between primary and secondary winding with BCT test system. 3. Polarity test shall be made by inductive kick

Doc :WE-001308

Rev.0

8/13

PASS / ACCEPTANCE CRITERIA

18

Oil leakage and pressure test(Ro) (In-process stage test before FAT)

* No leakage is allowed. * Tank permanent Deformation : 1mm

19

Control panel & Auxiliary equipment check(Ro)

* The inspection results shall be satisfied with approved specification and drawings.

20

Bushing C.T test(Ro)

Routine tests with IEC 60044-1 and test report shall be submitted. 1. Polarity test 2. Insulation resistance 3. Powerfrequency test 4. Inter-turn overvoltage test 5. current error and phase displacement 6. secondary winding resistance

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. INSPECTION & TEST ITEMS DESCRIPTION method with DC voltage source. 4. The magnetization tests of bushing C.T for protective relay shall be taken before assembly in the transformer tank and to be shown. 5. The C.T secondary winding resistance measurements shall be performed on with the bridge method. Oil samples shall be taken before and after for gas-in-oil analysis as following stages; 1) All tests 2) 1 hr 110% excitation test. 3) Temperature rise test 4) Overload test 5) After 612hrs after shut down 6) After complete tests. Certificate of vacuum test of the tank shall be submitted with final report. (Test duration : 6hrs) (Full vacuum, less than 1 torr for tank, cooler, conservator and tap changer) Before and after transformer tests, We will check dielectric strength, moisture content, particle contents(IEC 60970) in transformer oil. 1. The test shall be made at 100% and 110% of rated voltage and rated frequency under full assembly condition. 2. Vibration value shall be checked on the tank wall.

Doc :WE-001308

Rev.0

9/13

PASS / ACCEPTANCE CRITERIA

21

Dissolved gas-in-oil analysis(Ro)

22

Vacuum test(Ro) (In-process stage before final acceptance test)

* Tank permanent Deformation : 1mm

23

Mineral insulation oil test(Ro)

* Review of test reports. Break down volt.(IEC 60156) : 70kV, Water content (IEC 60814) : <10ppm * Shall not exceed 60 microns at any point of the main tank.

24

Vibration test(S)

25

SFRA test(Ro)

1. SFRA(10 ~ 2) shall be preformed on each transformer. 2. Test equipment : Doble M5100 or M5200 3. Test method : Doble recommended method or SEC Recommended method(refer to the attached SFRA test) 4. Test tap : pincipal tap and Max. voltage tap 5. Test condition : with oil and bushings 6. Open circuit tests : H1-H2, H2-H3, H3-H1, X1-X0, X2-X0, X3-X0

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

No. INSPECTION & TEST ITEMS DESCRIPTION 7. Short circuit tests X1-X2-X3 shorted together ; H1-H2, H2-H3, H3-H1 Y1-Y2-Y3 shorted together ; H1-H2, H2-H3, H3-H1, X1-X0, X2-X0, X3-X0 1.Short circuit impedance per phase basis, between each pair of winding from the HV as well as LV, LV1 & LV2 side. Measurement shall be performed for all tappings position at HV - LV1, HV - LV2, HV - LV1+LV2 conditions. 2. Test voltage : 380V5000V, 60HZ Single phase low voltage 220380V, 60Hz shall be applied to each phase of HV, LV terminal by turn and the magnetizing current is measured at max. volt. tap position. (after core demagnetizing) Tests on bushings will be carried out at bushing manufacturer. The test reports will be submitted for review. This test will be carried out after core and coil assembly but before in-tanking. The type of instruments and combination of tests, will be submitted for approval. According to SEC recommended method(refer to the attached SFRA)

Doc :WE-001308

Rev.0

10/13

PASS / ACCEPTANCE CRITERIA

26

Measurement of single phase low voltage impedance, 60Hz(Ro)

27

Measurement of single phase excitation current at low voltage 60Hz(Ro)

28

Tests on Bushing(Ro)

29

Measurement of transient voltage transfer characteristic(S)

Ro : Routine test T : Type test S : Special test

Type & special test to be carried out on one unit only of the same type. Routine test to be carried out for all units.

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

Attachment - SFRA

Doc :WE-001308

Rev.0

11/13

SEC

MVA Sweep Frequency Response Analysis test table

(Tap No. : 1/11/-, Frequency : 10Hz ~ 2MHz)

No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

Phase 1U-1N 1V-1N 1W-1N 1U-2U 1V-2V 1W-2W 1U-3U 1V-3V 1W-3W 1U-2U (1N, 2V : Ground) 1V-2V (1N, 2W : Ground) 1W-2W (1N, 2U : Ground) 1U-3U (1N, 3V : Ground) 1V-3V (1N, 3W : Ground) 1W-3W (1N, 3U : Ground) 1U-1N (2U-2V : Short) 1V-1N (2V-2W : Short) 1W-1N (2W-2U : Short) 1U-1N (3U-3V : Short) 1V-1N (3V-3W : Short) 1W-1N (3W-3U : Short) 1U-1N (2U-2V, 3U-3V : Short) 1V-1N (2V-2W, 3V-3W : Short) 1W-1N (2W-2U, 3W-3U : Short)

connection

11

11

open

Inter winding

Inductive Inter winding

Short

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

Attachment -Transient Voltage Test

Doc :WE-001308

Rev.0

12/13

MEASUREMENT OF TRANSIENT VOLTAGE TRANSFER CHARACTERIST

CH2 1U CH1 (+ Polarity)

CH5 CH6

2U

1W

1V

2W

CH4 CH7 CH3

2V

Fig. 1 The LV terminals are open

1U CH1 (+ Polarity) C

2U CH2

CH6 CH5 CH7

1W

1V

2W

2V

This test will be carried out at A, B and C phase

with same method.

CH4

CH3

Fig. 2 Each LV terminals si earthed through a CF capacitor

RABIGH POWER PLANT No.2

Inspection Procedure for Unit Transformer

addenda for type and routine test Type Test Special Test Inspection Process Temperature rise test(T) (Including over-load test) Sound level measurement(S) Measurement of transient voltage transfer characteristic.(S) - In-process test Zero-sequence impedance measurement(S) Vibration test(S) Visual inspection(Ro) Winding resistance measurement(Ro) Ratio check(Ro) Phase relationship check(Ro) Insulation resistance measurement(Ro) (Including core insulation test) Insulation power factor and capacitance measurement of transformer (Ro) Insulation power factor and capacitance measurement of capacitance bushings (Ro) No-load loss & current measurement(Ro) (Including harmonics measurement(S)) Impedance voltage and load loss measurement(Ro) Lightning impulse test(Ro) Separate-source voltage withstand test(Ro) Induced overvoltage withstand test(Ro) Magnetic balance test(Ro) Test of on-load tap changer(Ro) Oil leakage and pressure test(Ro) - In-process test Control panel & Auxiliary equipment check(Ro) Bushing C.T test(Ro) Dissolved gas-in-oil analysis(Ro) Vacuum test(Ro) - In-process test Mineral insulation oil test(Ro) SFRA test(Ro) Measurement of single phase low voltage impedance(Ro) Measurement of single phase excitation current(Ro) Tests on bushings(Ro)

Doc :WE-001308 Applicable Code IEC 60076-2(2000) IEC 551(1987) MFR Standard IEC 60076-1(2000) Clause 10.7 MFR Standard Approved drawings IEC 60076-1(2000) Clause 10.2 IEC 60076-1(2000) Clause 10.3 IEC 60076-1(2000) Clause 10.3 IEEE C57.12.90, 2006 CL 10.11 IEC 60076-1(2000) Clause 10.1.3,i) IEC 60076-1(2000) Clause 10.1.3,i) IEC 60076-1(2000) Clause 10.5 IEC 60076-1(2000) IEC 60076-3(2000) Clause 13.14 IEC 60076-3(2000) Clause 11 IEC 60076-3(2000) Clause 12 MFR Standard IEC 60076-1(2000) Clause 10.8 MFR Standard Approved drawings IEC 44-1(1996) IEC 44-1(1996) MFR Standard IEC 60296 (2003) MFR Standard MFR Standard MFR Standard IEC 137

Rev.0

13/13

Routine Test

You might also like

- Inspection Procedure For Station Transformer PDFDocument16 pagesInspection Procedure For Station Transformer PDFsingha98100% (1)

- Routine Tests For Oil Immersed TransformersDocument14 pagesRoutine Tests For Oil Immersed TransformersFreddie Asiedu LarbiNo ratings yet

- T C Procedure For TransformerDocument11 pagesT C Procedure For TransformerĐặng Xuân ViệtNo ratings yet

- MV Cable Hi-Pot Test ShetDocument1 pageMV Cable Hi-Pot Test ShetAhmad Dagamseh100% (1)

- COMMNG-ELEC-043 HT Motor PrecommissioningDocument6 pagesCOMMNG-ELEC-043 HT Motor PrecommissioningsantoshkumarNo ratings yet

- Check List For Testing: Equipment Needed To Be TestedDocument2 pagesCheck List For Testing: Equipment Needed To Be TestedKarthik EvilordNo ratings yet

- PM Check List - CB & BusbarDocument7 pagesPM Check List - CB & BusbarRizky VidiyanaNo ratings yet

- Dry Type Transformer Test Report: Page 1 of 2Document2 pagesDry Type Transformer Test Report: Page 1 of 2erwin5sambas5aryanaNo ratings yet

- CT Test ReportDocument2 pagesCT Test Reportdilipjoshi2000rytoiyNo ratings yet

- Capacitor TestDocument2 pagesCapacitor TestdineshNo ratings yet

- Test Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Document3 pagesTest Report For Motor Protection Relay-Sel 710: DATE: 21.06.2018Jayam kondanNo ratings yet

- 01 - 4 Test Report For Power Transformer 1Document7 pages01 - 4 Test Report For Power Transformer 1PUSHPARAJ MAURYANo ratings yet

- Earth Switch Contact Resistance TestDocument1 pageEarth Switch Contact Resistance TestGajendran SriramNo ratings yet

- TP-20 For Protective RelaysDocument20 pagesTP-20 For Protective RelayssathiyaseelanNo ratings yet

- PT TestingDocument7 pagesPT TestingNaveedNo ratings yet

- Test Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureDocument5 pagesTest Performed By: SWCC Witness: SWCC Engineer: Date of Test Name: Jabirali. P Rashed A.Murshed 26-DEC-2020 SignatureAnonymous dH3DIEtzNo ratings yet

- Itp For Commissioning Procedure For LV Switchgear SystemDocument4 pagesItp For Commissioning Procedure For LV Switchgear SystemSulimanNo ratings yet

- Global Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelDocument10 pagesGlobal Power Test Sdn. Bhd. Site Acceptance Test Report: Testing of 415V LV Switchgear PanelTHULASI RAMNo ratings yet

- 1 - Hi Pot Test Procedure For SwitchyardDocument6 pages1 - Hi Pot Test Procedure For Switchyardbayu dewanto100% (1)

- HV Pressure Tests - 3Document4 pagesHV Pressure Tests - 3ssNo ratings yet

- Erection Procedure For 415 V LCC, LDBS, LPS, SPDocument40 pagesErection Procedure For 415 V LCC, LDBS, LPS, SPAnmohieyNo ratings yet

- CT Secondary InjectionDocument2 pagesCT Secondary InjectionHumayun AhsanNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDocument6 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDinesh PitchaivelNo ratings yet

- 220V DCDocument15 pages220V DCsekhar_ntpcNo ratings yet

- Commissioning Procedure of CURRENT TRANSFORMER - ENDIRADocument13 pagesCommissioning Procedure of CURRENT TRANSFORMER - ENDIRAYoga SamNo ratings yet

- Current Transformer Test Report: 1S1-1S2 2S1-2S2 1S1-1S2 2S1-2S2Document2 pagesCurrent Transformer Test Report: 1S1-1S2 2S1-2S2 1S1-1S2 2S1-2S2erwin5sambas5aryanaNo ratings yet

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDocument9 pagesCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNo ratings yet

- Bet VT Test ReportDocument2 pagesBet VT Test ReportSathi Reddy ThondapuNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (1)

- Bus-1 VTDocument2 pagesBus-1 VTGajendran SriramNo ratings yet

- Inspection and Test Plan For Power Transformer PDFDocument6 pagesInspection and Test Plan For Power Transformer PDFSiva Kumar100% (1)

- Interview Questions-1Document12 pagesInterview Questions-1aryasaurabh54No ratings yet

- 415v Air Circuit Breaker-14Document2 pages415v Air Circuit Breaker-14Subhransu MohapatraNo ratings yet

- QA/QC Checklist - Installation of MDB Panel BoardsDocument6 pagesQA/QC Checklist - Installation of MDB Panel Boardsehtesham100% (1)

- Switch Gears 134-149Document16 pagesSwitch Gears 134-149Vijaya KumarNo ratings yet

- 50mva TRAFO#1 BAY#106Document19 pages50mva TRAFO#1 BAY#106Balaji DevathaNo ratings yet

- Ref615 - Oc Ef Relay TestDocument8 pagesRef615 - Oc Ef Relay TestMeghavahinaNo ratings yet

- Test Report For Protection Relay and Current Transformer: Schneider Vamp 50Document2 pagesTest Report For Protection Relay and Current Transformer: Schneider Vamp 50RamaNo ratings yet

- Itp TransformerDocument2 pagesItp TransformerDwi Mulyanti DwimulyantishopNo ratings yet

- 11KV SWGR HipotDocument2 pages11KV SWGR HipotSathi Reddy Thondapu100% (1)

- CVT Site Test Report: Capacitive Voltage TransformerDocument7 pagesCVT Site Test Report: Capacitive Voltage TransformerkamarajkanNo ratings yet

- 86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionDocument2 pages86 Lockout Auxiliary Relay Site Test Report: Mechanical Checks & Visual InspectionJaikaran DanNo ratings yet

- PART II 02 500 MVA 400 220 33 KV R 0 Mar 12 PDFDocument96 pagesPART II 02 500 MVA 400 220 33 KV R 0 Mar 12 PDFGuru Mishra100% (1)

- Motor Electric Test RecordDocument1 pageMotor Electric Test RecordArka HatiNo ratings yet

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser Mahamid100% (1)

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- SP0407C01 HV Cable Commissioning Test ReportDocument2 pagesSP0407C01 HV Cable Commissioning Test Reportkajale.shrikantNo ratings yet

- Test Forms For SSDocument105 pagesTest Forms For SSRakesh Kumar75% (4)

- LV Dielectric TestingDocument2 pagesLV Dielectric TestingwaseemsamsodienNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestDocument24 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Power Transformer TestabderrahmaneNo ratings yet

- Uss 105Document12 pagesUss 105Soumya BhowmickNo ratings yet

- NGCP-CND DS Field Test ReportDocument4 pagesNGCP-CND DS Field Test Reportedciel100% (2)

- Sop HT SWGR MeggeringDocument3 pagesSop HT SWGR MeggeringLincoln DsouzaNo ratings yet

- Etara Test Report R1Document15 pagesEtara Test Report R1Kholis JaimonNo ratings yet

- Site Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyDocument3 pagesSite Acceptance Test Report For 11Kv Cable: Project Equipment Client Date Contractor Location Testing CompanyGajendran SriramNo ratings yet

- Ohl TestDocument5 pagesOhl TestAnonymous ExWAN2xjFJNo ratings yet

- Method Statement For Testing & Commissioning of Central Battery SystemDocument6 pagesMethod Statement For Testing & Commissioning of Central Battery SystemBabuNo ratings yet

- Relays Makes Test ProcedureDocument25 pagesRelays Makes Test ProcedureRa HulNo ratings yet

- Transformer TestingDocument33 pagesTransformer Testing322399mk7086No ratings yet

- Transformer TestingDocument33 pagesTransformer TestingUsman Saeed0% (1)

- Integrated Voice Evacuation System VM-3000 Series: Operating InstructionsDocument144 pagesIntegrated Voice Evacuation System VM-3000 Series: Operating InstructionsAbraham GamaNo ratings yet

- Hyundai d467mnDocument2 pagesHyundai d467mnManuNo ratings yet

- Performance Analysis of CMOS Flip-FlopsDocument3 pagesPerformance Analysis of CMOS Flip-FlopsEditor IJRITCCNo ratings yet

- Artemis MK V PDFDocument2 pagesArtemis MK V PDFdeepsea74No ratings yet

- Manual PSW 2600Document18 pagesManual PSW 2600Jc C. GomezNo ratings yet

- (Catalog) Brochure PDFDocument13 pages(Catalog) Brochure PDFrehanNo ratings yet

- Modicon M340 Automation Platform BMXAMI0410Document2 pagesModicon M340 Automation Platform BMXAMI0410RavichandraRajeshNo ratings yet

- Esm Android Smart Phone 53693009 LG L 04c SMDocument310 pagesEsm Android Smart Phone 53693009 LG L 04c SMSpun_GNo ratings yet

- Principles of Power Systems Protection Part 1Document31 pagesPrinciples of Power Systems Protection Part 1mahmoodadeel100% (4)

- MODBUS DatasheetDocument8 pagesMODBUS DatasheetridNo ratings yet

- Stm32l0 低功耗模式、复位与时钟模块, 低功耗uart和低功耗定时器Document69 pagesStm32l0 低功耗模式、复位与时钟模块, 低功耗uart和低功耗定时器MarkoStankovicNo ratings yet

- Surfacemountdevices C 1Document5 pagesSurfacemountdevices C 1Deepa DevarajNo ratings yet

- MC AssignmentDocument7 pagesMC AssignmentAshu1803No ratings yet

- 3BSE059754R0001 - en AC 800M 5.1 Ethernet IP DeviceNet Linking Device LD 800DNDocument24 pages3BSE059754R0001 - en AC 800M 5.1 Ethernet IP DeviceNet Linking Device LD 800DNSaada LamNo ratings yet

- Datasheet RXTX SplitterDocument2 pagesDatasheet RXTX SplitterOsman ÇarhoğluNo ratings yet

- Digitization PrinciplesDocument12 pagesDigitization PrinciplesDhruv GuptaNo ratings yet

- Programming: Hardware & SoftwareDocument18 pagesProgramming: Hardware & SoftwaresantoshNo ratings yet

- Uc 51 DocuDocument61 pagesUc 51 DocuMohamed LazouriNo ratings yet

- Experiment 3 Exclusive - or and Exclusive - Nor Gates: Holy Angel University College of Engineering and ArchitectureDocument12 pagesExperiment 3 Exclusive - or and Exclusive - Nor Gates: Holy Angel University College of Engineering and ArchitectureIan Mark Cayanan GomezNo ratings yet

- VduDocument1 pageVduZain BazNo ratings yet

- Electronics Devices and Circuits - IIDocument2 pagesElectronics Devices and Circuits - IIManan ModiNo ratings yet

- EC312 PS13 Gain Filters NoiseDocument3 pagesEC312 PS13 Gain Filters NoiseJanica Rheanne JapsayNo ratings yet

- (Vol - Ii) Microwave Filters, Impedance-Matching Networks, and Coupling StructuresDocument572 pages(Vol - Ii) Microwave Filters, Impedance-Matching Networks, and Coupling Structuressuchit91No ratings yet

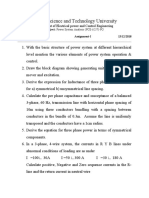

- Adama Science and Technology University: Department of Electrical Power and Control EngineeringDocument2 pagesAdama Science and Technology University: Department of Electrical Power and Control EngineeringOkezaki TemoyoNo ratings yet

- Magelis Scu Hmis65Document4 pagesMagelis Scu Hmis65josepitbulNo ratings yet

- Bose 901 Series L - LL Service ManualDocument15 pagesBose 901 Series L - LL Service Manualren_theoriginalpunksNo ratings yet

- Making A Transistor RadioDocument29 pagesMaking A Transistor Radiofoobargrok100% (1)

- ABB, AC31 Programmable Controllers IO-ModulesDocument20 pagesABB, AC31 Programmable Controllers IO-ModulesElias100% (1)

- I/O Buffer Megafunction (ALTIOBUF) User GuideDocument54 pagesI/O Buffer Megafunction (ALTIOBUF) User GuideSergeyNo ratings yet