Professional Documents

Culture Documents

Modeling and Analysis of Slip Power Recovery Controlled Induction Motor Drive

Uploaded by

satti849Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Modeling and Analysis of Slip Power Recovery Controlled Induction Motor Drive

Uploaded by

satti849Copyright:

Available Formats

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol.

1 Issue 5, July - 2012

Modeling and Analysis of Slip Power Recovery Controlled Induction Motor Drive

Pragnesh Patel

PG Scholar Electrical Engg. Department Govt. College of Engg. Amravati Amravati, India

A. S. Sindekar

Head of Electrical Engg. Department Govt. College of Engg. Amravati Amravati, India

Abstract- A control system based on PI_PI controller is used to improve the dynamic performance of slip power recovery motors, in which one PI controller is used as auto speed regulator (ASR) and second is used as auto current regulator (ACR). This controller tracks the need of speed and limit the stator current. The parameter values of PI controller are adjusted relaying on mathematical model value such as electromagnetic time constant and magnification factor. The simulation results of this control strategy for motor drive show that this system has high anti-disturbance capacity, fast response, low overshoot, so the system dynamic performance is improved. Keywords-PI_PI controller; motor drive speed control; modeling and simulation.

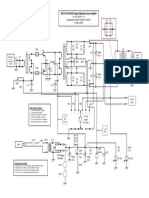

motor drive control system is shown in Figure 1, in which, one PI controller is used as auto speed regulator and second is used as auto current regulator. We will further illustrate the designs steps and the effectiveness of this control scheme via simulation experiments in MATLAB/SIMULINK. II. PROPOSED CONTROL SCHEME

I.

INTRODUCTION

The technology of slip power recovery controlled by chopper for slip ring induction motor has been widely applied in high-voltage large-capacity motor because of higher power factor, higher efficiency and lower control voltage than those without chopper. In this, both inner current loop and outer speed loop are designed with conventional proportional-integral-derivative (PID) controller to control the motor drive automatically.

Figure1. Control scheme of slip power recovery with chopper for motor drive

In this paper, a double-closed-loop control system based on PI_PI controller is presented to improve the dynamic performance of slip power recovery drives. This

This new type of double closed loop control system shown in Fig. 1 is proposed for the speed control of the nonlinear, time varying and complex motor system, in which one PI controller is used as auto speed regulator and second is used as auto current regulator. A. Principle of speed regulation From the slip power recovery circuit shown in Fig. 1, the three-phase full-wave diode bridge rectifier connects to the rotor windings via slip rings, converters a portion of slip power into DC which in turn converted into line frequency AC by a three-phase-thyristor inverter and fed back to the AC mains. The inductor L1, L2 between rectifier and inverter are placed to reduce the DC current ripple. The diode between L1 and L2 is used to keep current when IGBT is off and isolate when IGBT is on. The capacitor C is used to store the energy in the loop by keeping voltage Uc at low ripples. By using IGBT as chopper, the inverter is always fixed at the smallest inverter angle of about /6rad and the equivalent additional reverse electromotive force is obtained by changing the duty cycle of IGBT chopper. As a result, the electromagnetic torque and motor speed is changed. So the purpose of changing the motor speed can be achieved by adjusting the duty ratio of IGBT chopper. Neglecting higher order harmonics and power losses in rectifier and converter, equivalent circuit combined with converter, DC link, IGBT chopper and inverter is shown in figure 2.

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 5, July - 2012

Where

duty ratio of IGBT

Ts = sum of IGBT trigger pulse cycle and three-phase

bridge rectifier out of control time

S

Figure2. DC Equivalent Circuit

n0 n n0

slip of induction motor drive

Where, UD is the rotor rectifier voltage, UB is the active inverter DC voltage, Rd is the equivalent resistance of rotor rectifier circuit, Ld is equivalent inductance for the rotor rectifier, Rb is equivalent resistance of the inverter circuit, Lb is equivalent inductor for the inverter circuit. A. Mathematical model Mathematical model is the foundation of system analysis and correction. In engineering applications, the range of variation of capacitance voltage Uc is small. Let us assume that Uc is constant and the disturbance of Uc is approximately equal to 0. Using the average model method, the average value equivalent circuit is obtained as shown in Fig. 3.

Rd Ld

2(

Rs k2

Rr ) L1

3X D S

3X D 100

The mechanical motion equation of motor drive system is given as:

Te

TL

GD 2 dn 375 dt

(2.4)

Where Electromagnetic torque Te

CM I d

2.34 E 20

Torque coefficient

Figure3. (a) The average value equivalent circuit and (b) waveform of back voltage

3X D p

Id

CM

2 f

Then

In figure 3, considering the power switching device IGBT has lag aspect, the transfer functions of this circuit is given as follows:

ns I d s I L (s)

375 C M 1 GD 2 s

1 Tm s

(2.5)

Ui

(2.1)

(1 d )U c Ts s 1

From the above-mentioned formula, the block diagram of open-loop system is developed as shown in figure 4.

UD

2.34 E 20 S

(2.2)

Id UD UI

1 Rd Ld s 1 Rd

K Lr TLr 1

(2.3)

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 5, July - 2012

Figure4. Block diagram of open-loop motor drive system

III.

DOUBLE CLOSED LOOP CONTROL SYSTEM DESIGN

A. Design of ACR_PI in inner current loop In double closed loop design procedure, the first step is to design the controller for inner current loop and to tune the parameters. The current response is fast because the time constant of inner loop is small. According to a typical design method explain in [5], PI controller for auto current regulator (ACR) used for meeting the demand of servo performance is designed as follows. The form of PI controller can be written as

B. Design of ASR_PI in outer speed loop In double closed loop design procedure, the second step is to design the control1er for outer speed loop and to tune the parameters. This controller is designed by using Ziegler-Nichols rules for tuning PID controller. Ziegler and Nichols proposed rules for determining value of the proportional gain Kp, integral time Ti, and derivative time Td based on transient response characteristic of a given plant. There are two methods called Ziegler-Nichols tuning rules, in second method we first set Ti = and Td = 0. The proportional control action only increases Kp from 0 to a critical value Kcr at which the output exhibit sustained oscillations. Thus, the critical gain Kcr and the corresponding period Pcr are determined. Ziegler and Nichols suggested to set the values of the parameter Kp, Ti, and Td according to table 1. TABLE.1 ZIEGLER-NICHOLS TUNING RULE BASED ON CRITICAL GAIN KCR AND CRITICAL PERIOD PCR(SECOND METHOD) Type of controller P PI PID Kp 0.5Kcr 0.45Kcr 0.6Kcr Ti

1 Pcr 1.2

Td 0 0 0.125Pcr

0.5Pcr

WACR (s)

K ic ( ic s 1) ic s

K ic 1

1

ic

(3.1)

The PID controller tuned by the second method of Ziegler-Nichols rules gives

The parameters of ACR can be chosen as follow

Gc s

Kp 1

1 Ti s

Td s 1 0.5Pcr s Pcr s

2

ic

TLr

K ic

ic

0.6 K cr 1

2Ts * U C * K Lr

Then the transfer function of inner-closed-Ioop WCL_i(s) will be similar to a typical second-order system, which is given as:

s 0.075 K cr Pcr

4 Pcr s

WCL _ i s S2 2

1 2 1 2

2Ts

(3.3) Now, by using this method the ASR_PI controller for outer speed loop is designed. The form of PI controller can be written as

2Ts S 1

2Ts

1 2Ts S 2

2

WASR (s)

K is ( is s 1) is s

K is 1

1

is

2Ts S 1

(3.4)

(3.2)

www.ijert.org

International Journal of Engineering Research & Technology (IJERT) ISSN: 2278-0181 Vol. 1 Issue 5, July - 2012

IV.

SIMULATION AND EXPERIMENTAL RESULTS

150

The simulation tests have done by using PI_PI controller in double closed loop for motor drive speed regulation system. Using MATLAB/SIMULINK, the simulation model of motor drive speed control is built. Figure5 shows the model of speed control system using PI_PI controller.

100

Motor Speed n (rad/sec)

50 0 0

5 Time(second)

10

Figure7. Speed curve of dynamic response when speed change from 144 rad/sec to 100 rad/sec.

V.

CONCLUSION

Figure5. Simulation model

A slip ring induction motor of 500 kW, 2.3 kV and 50 Hz frequency is used for experiment. Parameters of this motor are given below. Pole pair = 2 Stator resistance Rs = 1.115 Rotor resistance Rr = 1.085 Inductance of stator winding Ls = 0.005974 H Inductance of rotor winding Lr = 0.005974 H Magnetizing reactance Lm = 0.2037 H That response curve of the motor speed is shown in Figure6, which shows that response having peak overshoot of 21.97 rpm and settling time of 1 second. Figure7 shows the speed curve of induction motor in which rotor speed is changed from 144 rad/sec to 100rad/sec.

150

In this paper, simulation of a double closed loop slip power recovery in induction motor, with chopper is obtained by using PI controller as both speed regulator and current regulator. The PI controller for double closed-loop is designed and the simulations are performed. The simulation results show that the PI_PI double-loop speed control system reduced the peak overshoot and obtained the rapid and smooth response against the modeling uncertainty and disturbance. So, it is an effective method to improve the robust and adaptability performance for induction motor. REFERENCES [1] E. O. Taylor, The performance and design of ac commutator motors, Wheeler publishing & Co Ltd, New Delhi, 2004. [2] Ping Jiang, Bingshu Wang and Junwei Zhang, Simulation of a new method in double closed loop for slip power recovery motor with chopper Proc. in IEEE international conference on mechatronics and automation, Aug 9-12, Changchun, China, 2009. [3] P. C. Sen, Power electronics, Tata McGraw Hill Publishing Company, New Delhi, 2007. [4] Jai P. Agrawal, Power Electronic Systems Theory and Design, Pearson Education Asia, Delhi,2004 [5] Zeguo Wei, The principle and Application of casecade speed control system with SCR, Metallurgical Industry Press, Beijing, 1985. [6] Katsuhiko Ogata, Morden control Engineering, Fifth Edition, PHI Learning Private Limited, New Delhi, 2010.

100

Motor Speed n (rad/sec)

50 0 0

5 Time(second)

10

Figure6. Speed curve of dynamic response

www.ijert.org

You might also like

- A320 - Ecam System Logic Data (Esld)Document5,089 pagesA320 - Ecam System Logic Data (Esld)Eder Luciano100% (5)

- PDK Reference ManualDocument85 pagesPDK Reference ManualIrfanAhmadNo ratings yet

- Im Cordinate Csi CNTRLDocument11 pagesIm Cordinate Csi CNTRLsandeepbabu28No ratings yet

- PID Controller For A Two Quadrant Chopper Fed DC Motor DriveDocument5 pagesPID Controller For A Two Quadrant Chopper Fed DC Motor DriveSalman HabibNo ratings yet

- Modeling and Simulation of Sensorless Control of PMSM With Luenberger Rotor Position Observer and Sui Pid ControllerDocument8 pagesModeling and Simulation of Sensorless Control of PMSM With Luenberger Rotor Position Observer and Sui Pid ControllerYassine MbzNo ratings yet

- (Journal of Electrical Engineering) A New High Speed Induction Motor Drive Based On Field Orientation and Hysteresis Current ComparisonDocument9 pages(Journal of Electrical Engineering) A New High Speed Induction Motor Drive Based On Field Orientation and Hysteresis Current ComparisonAugusto ThedoctorNo ratings yet

- DC Motor Speed Control For A Plant Based On PID Controller-354 PDFDocument6 pagesDC Motor Speed Control For A Plant Based On PID Controller-354 PDFWildanRamadhanNo ratings yet

- Analysis of Boost Converter Using PI Control AlgorithmsDocument3 pagesAnalysis of Boost Converter Using PI Control AlgorithmsTrương Văn TrọngNo ratings yet

- Speed Control of DC Motor Using Pid Controller Based On MatlabDocument8 pagesSpeed Control of DC Motor Using Pid Controller Based On MatlabAlexander DeckerNo ratings yet

- New Control Strategies of A Small Size Wind Generation System For Battery ChargingDocument6 pagesNew Control Strategies of A Small Size Wind Generation System For Battery ChargingZellagui EnergyNo ratings yet

- Intelligent Control A Class Wind Energy Conversion Systems: Chedid, F. Mrad, M. BasmaDocument8 pagesIntelligent Control A Class Wind Energy Conversion Systems: Chedid, F. Mrad, M. Basmamusaad1No ratings yet

- Sliding Mode Observer For Torque Control in Sensorless BLDC MotorDocument5 pagesSliding Mode Observer For Torque Control in Sensorless BLDC MotorIOSRjournalNo ratings yet

- Tuning of PID Controller Using Ziegler-Nichols Method For Speed Control of DC MotorDocument6 pagesTuning of PID Controller Using Ziegler-Nichols Method For Speed Control of DC Motoreubis_machado4370No ratings yet

- Archive of SID: Performance Analysis of A Cost Effective 4-Switch 3-Phase Inverter Fed IM DriveDocument6 pagesArchive of SID: Performance Analysis of A Cost Effective 4-Switch 3-Phase Inverter Fed IM DrivePranav VyasNo ratings yet

- Ijert Ijert: Speed Control of DC Motor Using Digital Control SystemDocument3 pagesIjert Ijert: Speed Control of DC Motor Using Digital Control SystemArturo ChaconNo ratings yet

- Electrical Braking of Large Wind TurbinesDocument11 pagesElectrical Braking of Large Wind Turbineslaaloo41No ratings yet

- Optimal PDFDocument6 pagesOptimal PDFjalilemadiNo ratings yet

- DSP-Based Speed Adaptive Flux Observer of Induction MotorDocument5 pagesDSP-Based Speed Adaptive Flux Observer of Induction MotorthavaselvanNo ratings yet

- Performance Analysis of A Single-Phase Ac Voltage Controller Under Induction Motor LoadDocument8 pagesPerformance Analysis of A Single-Phase Ac Voltage Controller Under Induction Motor LoadInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Simulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodDocument7 pagesSimulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodseventhsensegroupNo ratings yet

- Speed Regulation An Induction Motor Using Reference Adaptive ControlDocument5 pagesSpeed Regulation An Induction Motor Using Reference Adaptive ControlAtakan OzturKNo ratings yet

- Control System NotesDocument199 pagesControl System NotesCarson R. Dick100% (2)

- 08 July 2013Document5 pages08 July 2013IJBSTRNo ratings yet

- Jeas 0408 94Document7 pagesJeas 0408 94Jun Chee LimNo ratings yet

- Ijert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariDocument4 pagesIjert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariAvinash Babu KmNo ratings yet

- DC Link Approach To Variable-Speed, Sensorless,: Induction Motor DriveDocument5 pagesDC Link Approach To Variable-Speed, Sensorless,: Induction Motor DrivesamirmansourNo ratings yet

- Speed Control of Separately Excited D.C. Motor: Chayan Kumar, Prof. (DR.) Deoraj Kumar TantiDocument11 pagesSpeed Control of Separately Excited D.C. Motor: Chayan Kumar, Prof. (DR.) Deoraj Kumar TantiWieNo ratings yet

- A Variable-Speed, Sensorless, Induction Motor Drive Using DC Link MeasurementsDocument6 pagesA Variable-Speed, Sensorless, Induction Motor Drive Using DC Link Measurementsgowtam_raviNo ratings yet

- Disturbance Accommodating LQR Method Based Pitch Control Strategy For Wind TurbinesDocument5 pagesDisturbance Accommodating LQR Method Based Pitch Control Strategy For Wind TurbinesStefania OliveiraNo ratings yet

- Research Inventy: International Journal of Engineering and ScienceDocument8 pagesResearch Inventy: International Journal of Engineering and ScienceinventyNo ratings yet

- An Improved Efficiency of Fuzzy Sliding Mode Cont PDFDocument5 pagesAn Improved Efficiency of Fuzzy Sliding Mode Cont PDFNoureddine BounaslaNo ratings yet

- 445 AndradaDocument5 pages445 AndradaNishant GoyalNo ratings yet

- Design and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452Document4 pagesDesign and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452lajosmol100% (1)

- Paris, FranceICSTEM (2019)Document6 pagesParis, FranceICSTEM (2019)Dr. D. V. KamathNo ratings yet

- Cage RotorDocument6 pagesCage Rotordebasis250No ratings yet

- Current Limitation in The Neural Speed Control of A DC MotorDocument6 pagesCurrent Limitation in The Neural Speed Control of A DC MotorrameshhodeeeNo ratings yet

- DC Drive System For EscalatorDocument29 pagesDC Drive System For EscalatorMamta Mrjn100% (2)

- A Discussion About A Start-Up Procedure of A Doubly-Fed Induction Generator SystemDocument6 pagesA Discussion About A Start-Up Procedure of A Doubly-Fed Induction Generator Systemgirish19No ratings yet

- Pi Control System Based Speed Control of DC Motor Using MicrocontrollerDocument13 pagesPi Control System Based Speed Control of DC Motor Using MicrocontrollerAnkit BhardwajNo ratings yet

- Department University Lag-: NamicDocument7 pagesDepartment University Lag-: NamicSuhail ShahNo ratings yet

- Wheelchair Stabilizing by Controlling The Speed Control of Its DC MotorDocument5 pagesWheelchair Stabilizing by Controlling The Speed Control of Its DC Motorowais_36No ratings yet

- Model Reference Controlled Separately Excited DC Motor: Ó Springer-Verlag London Limited 2009Document9 pagesModel Reference Controlled Separately Excited DC Motor: Ó Springer-Verlag London Limited 2009Na ChNo ratings yet

- 19 Speed PDFDocument8 pages19 Speed PDFNur Muhammad DzikriNo ratings yet

- Simulation of Brushless DC Motor Speed Control in Matlab-Ijaerdv04i1290151Document7 pagesSimulation of Brushless DC Motor Speed Control in Matlab-Ijaerdv04i1290151Wairokpam DhanrajNo ratings yet

- DSP-Based Experimental Rig With The Doubly-Fed Induction Generator ForDocument12 pagesDSP-Based Experimental Rig With The Doubly-Fed Induction Generator Fordebasis250No ratings yet

- Controlling of D.C. Motor Using Fuzzy Logic Controller: Husain AhmedDocument5 pagesControlling of D.C. Motor Using Fuzzy Logic Controller: Husain AhmedCristian SsggNo ratings yet

- A Direct Torque Control Method For CSC Based PMSG Wind Energy Conversion SystemsDocument7 pagesA Direct Torque Control Method For CSC Based PMSG Wind Energy Conversion SystemsLê Xuân ThăngNo ratings yet

- A Novel Control Strategy of Power Converter Used To Direct Driven Permanent Magnet Wind Power Generation SystemDocument4 pagesA Novel Control Strategy of Power Converter Used To Direct Driven Permanent Magnet Wind Power Generation Systemjamal64722111No ratings yet

- PID Practical PDFDocument18 pagesPID Practical PDFJose Luis HurtadoNo ratings yet

- Wind Generation System For Charging BatteriesDocument6 pagesWind Generation System For Charging BatteriesAmit RanjanNo ratings yet

- Design and Fabrication of 3-Phase Ac Voltage Controller Fed Speed Control of 3-Phase Sqim L. Joseph Anil Kumar B. Krishna ChaitanyaDocument5 pagesDesign and Fabrication of 3-Phase Ac Voltage Controller Fed Speed Control of 3-Phase Sqim L. Joseph Anil Kumar B. Krishna ChaitanyaSahabat SimatupangNo ratings yet

- Speed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiaDocument5 pagesSpeed Control of BLDC Motor Using DSP: 1 4 1 JNTUH Hyderabad, India 2 JNTUH Hyderabad, IndiapravnkumarNo ratings yet

- Speed Control of Induction Motor by Using Cyclo-ConverterDocument5 pagesSpeed Control of Induction Motor by Using Cyclo-ConverterBiswajit ChangkakotyNo ratings yet

- Different Types of Speed Controllers For Brushless DC Motor - A ReviewDocument10 pagesDifferent Types of Speed Controllers For Brushless DC Motor - A ReviewGJESRNo ratings yet

- Speed Sensorless Vector Controlled Induction Motor Drive With Rotor Time Constant Identification Using Artificial Neural NetworksDocument6 pagesSpeed Sensorless Vector Controlled Induction Motor Drive With Rotor Time Constant Identification Using Artificial Neural NetworksJorge GuerreroNo ratings yet

- 1#a Comparative Study of PI Fuzzy and ANN Controllers For Chopper Fed DC Drive With Embedded Systems ApproachDocument17 pages1#a Comparative Study of PI Fuzzy and ANN Controllers For Chopper Fed DC Drive With Embedded Systems ApproachalialibabaNo ratings yet

- Artigo CJR IECON2002Document6 pagesArtigo CJR IECON2002AiflRopetNo ratings yet

- Modelling and Simulation of Doubly Fed Induction Generator Varable Speed Wind TurbineDocument6 pagesModelling and Simulation of Doubly Fed Induction Generator Varable Speed Wind TurbineSandeepKumarNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- I5 Coaching Centre EMDocument13 pagesI5 Coaching Centre EMsatti849No ratings yet

- Submit: Hall Tikcet Number 6707124 Registration Number 587441 Candidate Name Sirasu Pavani Father Name S Lingam Marks 57Document1 pageSubmit: Hall Tikcet Number 6707124 Registration Number 587441 Candidate Name Sirasu Pavani Father Name S Lingam Marks 57satti849No ratings yet

- Migration Readiness SOW GovDocument5 pagesMigration Readiness SOW Govsatti849No ratings yet

- PressedDocument98 pagesPressedsatti849No ratings yet

- The Northern Power Distribution Company of Telangana Limited (TSNPDCL)Document1 pageThe Northern Power Distribution Company of Telangana Limited (TSNPDCL)satti849No ratings yet

- Serv Let 18248864 DDocument1 pageServ Let 18248864 Dsatti849No ratings yet

- MachinesDocument98 pagesMachinessatti849No ratings yet

- Lecture1423813026 PDFDocument92 pagesLecture1423813026 PDFKarthikeyanKarunNo ratings yet

- ESE Reforms PublicityDocument11 pagesESE Reforms PublicityChirag PatelNo ratings yet

- Particle Swarm Optimization: Technique, System and ChallengesDocument9 pagesParticle Swarm Optimization: Technique, System and ChallengesMary MorseNo ratings yet

- FREE SEO Audit Analysis Report-Www - Chokowave Report 3Document7 pagesFREE SEO Audit Analysis Report-Www - Chokowave Report 3satti849No ratings yet

- EEC130A: Practice Problems For Midterm 2: Instructor: Xiaoguang "Leo" Liu (Lxgliu@ucdavis - Edu) Updated: Mar. 6 2012Document11 pagesEEC130A: Practice Problems For Midterm 2: Instructor: Xiaoguang "Leo" Liu (Lxgliu@ucdavis - Edu) Updated: Mar. 6 2012M Erizky SyaputraNo ratings yet

- Careers in Marine EngineeringDocument5 pagesCareers in Marine Engineeringsatti849No ratings yet

- Lec1 TransformerDocument17 pagesLec1 TransformerDebayan BhattacharyaNo ratings yet

- Optimal Power Ow Using Particle Swarm Optimization: M.A. AbidoDocument9 pagesOptimal Power Ow Using Particle Swarm Optimization: M.A. AbidoAbish RajanNo ratings yet

- PoEC 16 RC CircuitsDocument64 pagesPoEC 16 RC Circuitssatti849100% (1)

- A Modified Particle Swarm Optimization For Optimal Power FlowDocument7 pagesA Modified Particle Swarm Optimization For Optimal Power Flowsatti849No ratings yet

- 1 ANFIS Based Neuro-Fuzzy Controller in LFC of Wind-Micro Hydro-Diesel Hybrid Power SystemDocument8 pages1 ANFIS Based Neuro-Fuzzy Controller in LFC of Wind-Micro Hydro-Diesel Hybrid Power Systemsatti849No ratings yet

- Sgre 2013052913413818 PDFDocument11 pagesSgre 2013052913413818 PDFsatti849No ratings yet

- A Genetic Algorithm Based Approach For Improvement in Voltage Profile and Real Power Loss MinimizationDocument1 pageA Genetic Algorithm Based Approach For Improvement in Voltage Profile and Real Power Loss Minimizationsatti849No ratings yet

- Question Set No. 1: Direction (I)Document11 pagesQuestion Set No. 1: Direction (I)satti849No ratings yet

- NuclearDocument18 pagesNuclearPradeep Kumar MehtaNo ratings yet

- The Braking System VLEDocument20 pagesThe Braking System VLEsatti849No ratings yet

- l9 Linkedlist PDFDocument80 pagesl9 Linkedlist PDFSharanya SrinivasanNo ratings yet

- Newton MethodDocument11 pagesNewton Methoddeba_jyoti_das100% (2)

- 3000 Words For PronounciationDocument24 pages3000 Words For Pronounciationnjsankar1974No ratings yet

- Introduction To Matlab Application To Electrical EngineeringDocument98 pagesIntroduction To Matlab Application To Electrical EngineeringSindhu ReddyNo ratings yet

- Electric Power Distribution SystemsDocument231 pagesElectric Power Distribution SystemsŞerif DoğruNo ratings yet

- 45i4power System Stability Improvement Using Facts With Expert Systems Copyright IjaetDocument10 pages45i4power System Stability Improvement Using Facts With Expert Systems Copyright Ijaetsatti849No ratings yet

- Mock Board Examination in Electronics BDocument8 pagesMock Board Examination in Electronics BJessa Suñga100% (1)

- Lecture 6 Interconnect 2020Document58 pagesLecture 6 Interconnect 2020Noam ShemlaNo ratings yet

- HW 3 SolDocument5 pagesHW 3 SolBhagirath BhattNo ratings yet

- Asus p5gc MX Rev 2 0Document47 pagesAsus p5gc MX Rev 2 0frNo ratings yet

- Mercury Battery ReplacementDocument3 pagesMercury Battery ReplacementAntonio CompanyNo ratings yet

- XS1010 1212INSTfinalDocument6 pagesXS1010 1212INSTfinalTitus-Adelin IonNo ratings yet

- Cis Handout 2Document24 pagesCis Handout 2Trung1980ttNo ratings yet

- Objectives:: Figure: Class B Push Pull AmplifierDocument2 pagesObjectives:: Figure: Class B Push Pull AmplifierBillaTopNo ratings yet

- Embedded SystemsDocument21 pagesEmbedded Systemsmalhiavtarsingh100% (2)

- Motor Starting PDF-1Document35 pagesMotor Starting PDF-1Halimi AyoubNo ratings yet

- Teste DirectX 20110325Document13 pagesTeste DirectX 20110325Vitor PillaNo ratings yet

- Soniq Operating Manual E46Z11ADocument55 pagesSoniq Operating Manual E46Z11AAllan WilliamsNo ratings yet

- Smart Car Parking System Using IR SensorDocument5 pagesSmart Car Parking System Using IR SensorIJRASETPublicationsNo ratings yet

- Monthly Reports Purchasing (Po-Pr) 2017Document42 pagesMonthly Reports Purchasing (Po-Pr) 2017GA BINAKARYANo ratings yet

- EC 14 603 VLSI Design, April 2017Document2 pagesEC 14 603 VLSI Design, April 2017anon_742948544No ratings yet

- SSB Amp Diagram 400w IRFP460Document1 pageSSB Amp Diagram 400w IRFP460Av PlugaruNo ratings yet

- Advr 54Document5 pagesAdvr 54RonaldCarrasquelNo ratings yet

- F.Y.B.Sc Electronics Syllabus NEP 2020Document39 pagesF.Y.B.Sc Electronics Syllabus NEP 2020Dipak ValviNo ratings yet

- 936X002b 78510908V01 K-BOW Outdoor PSU 150W DatasheetDocument3 pages936X002b 78510908V01 K-BOW Outdoor PSU 150W DatasheetNataša Mihić BoskovićNo ratings yet

- Max 3600Document30 pagesMax 3600VanBelkumWNo ratings yet

- Lesson PLan Demo FinalDocument3 pagesLesson PLan Demo FinalPatricia Ann Contreras MercadoNo ratings yet

- HCU SpecificationDocument6 pagesHCU SpecificationlassasaNo ratings yet

- HC 4520 ServiceDocument187 pagesHC 4520 Service'Egemen KayaNo ratings yet

- LG cf-20d30x Chassis mc64b SM PDFDocument35 pagesLG cf-20d30x Chassis mc64b SM PDFNelu CostinNo ratings yet

- Datasheet 18Document3 pagesDatasheet 18José A.No ratings yet

- Digital SheetDocument20 pagesDigital SheetTAY CHUI SHENG100% (1)

- Bruce Array Antenna - Coaxial Whip AntennaDocument3 pagesBruce Array Antenna - Coaxial Whip AntennaRobert TurnerNo ratings yet

- Cpnversor DC - DC MAX17113Document30 pagesCpnversor DC - DC MAX17113Antonio ChavezNo ratings yet