Professional Documents

Culture Documents

Valve Seat Seal Selection Guide

Uploaded by

ecovarrubias1Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Seat Seal Selection Guide

Uploaded by

ecovarrubias1Copyright:

Available Formats

STEAM APPLICATION TECHNICAL DATA

Steam is damaging to valve parts at the moment of opening and closing, or when throttling. The high velocity of the steam erode the seat and metal parts. High speed steam may carry water droplets, dissolved gases and other suspended solids and result in more severe erosion and corrosion. In addition, steam systems will often go through a thermal cycle of start-up and shut down. This thermal cycle presents a special challenge to the sealing capability of the valves in steam service. Ball valves are well suitable for steam service if careful with the material selection and valve design. However, like all other valves, ball valves are generally rated at a lower pressure for steam service than for liquid or dry gaseous service. ValveMans Ball Valves are an excellent choice for a wide range of steam service. Graphite body seals are completely encapsulatedand contained. Stem packings are live loaded for all sizes. Live loaded stem packing will compensate for thermal cycling andwell contained body seal will prevent extrusion into crevice during thermal cycle. Our standard design valves are provided witha 1/8 hole drilled in the stem tang slot. This feature is critical for steam service since it prevents excessive pressure build-up in the cavity from trapped liquid when the valve is in the open position. Flo-Tite ball valves are supplied with stainless steel balland stem as standard. This is specially suitable for steam service since aggressive steam attacks coated carbon steel trim. ValveMans standard design valves with stainless steel trim and Super-Tek TFM seats are good for 150 psig saturated steam. When equipped with S-Tek or Super-Tek III seats, ValveMan valves are good for 250 psig saturated steam. Other seat options

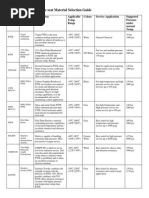

Service Pressure Pressure Steam up to 150 psi Pressure Steam up to 170 psi Pressure Steam up to 250 psi Pressure Steam up to 300 psi Pressure Steam above 300 psi Corresponding Saturated Steam Temperature Maximum 366 F Maximum 375 F Maximum 406 F Maximum 422 F Higher than 422 F Seat PTFE or Super-Tek RPTFE S-Tek or Super Tek III Peek Metal Stem Seal Body Seal TFM Graphite Graphite Graphite Graphite Graphite Graphite Graphite Graphite Graphite

ValveMan.com

Valve Soft Parts

Flanged End

Valve Seat (2)

Valve Seat & Seal Selection Guide

Choosing The Right Seat Material is the Most Challenging Decision in Ball Valve Selection

3PC Valves

Body Seal (2)

Body Seal (1) Spiral Wound 316 / Graphite

Valve Seat (2)

ValveMans standard design valves with stainless steel trim and Super-Tek TFM seats are good for 150 psig saturated steam. When equipped with S-Tek or Super-Tek III seats, ValveMan valves are good for 250 psig saturated steam. Other seat options will bring ValveMan valves to higher steam pressure rating, see chart below.

Flanged End, 2 and 3 PC Valves share the same stem packing. V-Ring Stem Seal (5)

Thrust Washer (2)

VALVE REPAIR KIT INCLUDES ALL SOFT PARTS Seats - Body Seals - Stem Packing - Thrust Washer

Steam Rating (PTFE & SuperTek) Steam Rating (RPTFE)

ValveMans ball valves are available with a variety of seat & seal options to allow use in a wide range of general as well as special services. These soft-seated ball valves are factory tested for tight shutoff and will continue to perform so for extended period. One of the most important factors affecting shutoff capability is the nature of media being handled. Service life is affected by all of the following factors. Pressure Type of Media Temperature Cycling Frequency Degree of Pressure Fluctuation Velocity of the Media Degree of Thermal Fluctuation Speed of Valve Operation All of these factors are interrelated in actual service. Maximum service life, therefore, can be gained by reducing the severity of any of these factors.

Steam Rating (S-Tek & SuperTek III)

Steam Rating (PEEK)

ValveMan.com 1-888-825-8800

Our listing of seat materials has been prepared to assist the specifying engineer & the end user in the proper seat and seal selection. This information should be used in conjunction with pressure temperature rating graph found in our catalogue for the applicable valve.

STANDARD SEAT SELECTIONS

Material DELRIN Technical Description This seat is very rigid and does not undergo cold flow. They can withstand pressures of up to 6000 psi dependent on valve size and a temperature range of -70F to 180F. Delrin also withstands nuclear radiation at doses of up to 106 rads. Do not use on oxygen service, or steam. Super-Tek, most popular seat material used by Flo-Tite. Super-Tek (TFM) offers all of the properties of reinforced TFE with greater strength, toughness, and improved thermo-mechanical properties offering lower coefficient of friction for lower torques and less permeability, reduced cold flow deformation and enhanced deformation recovery. Temperature Range -50F to 500F This material is a fluorocarbon rubber. Kel F is a registered trademark of 3M Corp. It can be used for cryogenic service at tempartures of -400F up to 500F at pressure up to 1500 psi Recommended for service with severe flashing or hydraulic shock, abrasive media or where possible trapped metal may exist. Flo-Tites metal seats are hand lapped to the ball as individually matched sets, assuring line contact between valve ball and seats, resulting in smooth operation and tight shut off class. Flo-Tite offers metal seats in different classes of Shut Off including Class IV, V and VI. Color Green Approx. Torque Adder +50%

STANDARD SEAL SELECTIONS

Material GRAPHOIL Reinforced TFE Stainless Filled TFE OffWhite 10% Less Than RPTFE Virgin TFE Technical Description Useable from -70 to 1000F on almost any mdeia. It is the standard seal on all fire rated valves This is produced by adding 15% fibrous glass to Virgin Teflon and has a greater pressure temperature rating than Teflon. They also have a better cycle life than Teflon. Combined the strength of metal with the lubricity of TFE. 50% 316 powder combined with 50% TFE. Offers the abrasion resistance of metal with higher pressure and temperature ratings than RPTFE. Temperature rating -20F to 550F / Steam rating 250 SWP Teflon is excellent at pressure below 1500 psi & at temperatures from -20F to 400F. It will not withstand temperature fluctuations in excess of 200F & are not reusable. It has excellent resistance to a wide range of chemicals. Color Green OffWhite Gray

Super-Tek (TFM)

White Opaque White OffWhite Black

Kel F (PCTFE)

+45%

This is rated to 1500 psi at temperatures from -70 to 200F. This can be used in low to medium level UHMW radiation service and in applications where fluorocarbons can not be tolerated. Abrasion resistance is Polyethylene quite good. Viton These body seals are excellent at all rated pressures with a temperature range of -20 to 400F. Viton is the best elastomer seal for higher temperature applications, but it should not be used on steam. Manufactured by spirally winding a preformed V shape SS316 metal strip and a graphite sealing filler in combination. This gasket has adequate flexibility and recovery to maintain a seal under variable and uneven loading, pressure, and temperature fluctuation, bolt stress relaxation and creep. Temperature range from 320 to +1000F.

Metal

Metallic

+50%

Spiral Wound Wire Graphite

Nylon

Special Nylon seats are offered for higher pressure and lower temperature Translucent service. They can be used in high-pressure air, oil and other gas media but White are not suited for strong oxidizing agents. Temperature rating -30F to 200F This material offers a unique combination of chemical mechanical electrical and thermal properties. The only know solvent of Peek is concentrated sulfuric acid. It will withstand temperatures up to 600F and pressures up to 4500 psi This is produced by adding 15% fibrous glass to Virgin Teflon and has a greater pressure temperature rating than Teflon. They also have a better cycle life than Teflon. 50/50 seats are combined the strength of metal with the lubricity of TFE. 50% 316 powder combined with 50% TFE. Offers the abrasion resistance of metal with higher pressure and temperature ratings than RPTFE. Temperature rating -20 to 550 / Steam rating 250 SWP. This is the most widely used seating material an dis excellent for most services. It has excellent chemical resistance throughout valve industries and a low coefficient of friction. Temperature Range -50F to 450F Brown

+35%

Peek

+50%

New seat & seal materials and sealing techniques continuously become available through our dedicated research and development programs. For seat or seal application requirements not covered in this bullein, please consult ValveMan. All products that contact plastics and elastomers comply with USP Biological Reactivity Test #87 & #88 Class VI plastics and FDA CFR21 Part 177.

Reinforced TFE

OffWhite

Standard as indicated in literature

50/50

Gray

+50%

Pressure Relieving & Equalizing Seat Design

Pressure Temperature Chart

Virgin TFE

White

Standard as indicated in literature

UHMW polyethylene is used for highly radioactive materials where TFE is not acceptable (> 104 rads ) and is rated 2 x 107 rads. These seats also meet UHMW the requirements of the tobacco industry whenever TFE is prohibited, and are Polyethylene especially well-suited for handling highly abrasive media. Temperature Range -70F to 200F, not suitable for steam Super-Tek II Super-Tek III Super-Tek II glass filled TFM-25% glass reinforced with 75% TFM, is good for temperature ranging from -320F to 572F. This material offers a wide temperature range with better cycle life than TFM. Ideal for Steam, hot gasses, thermal fluids and a variety of process chemicals. This is a Teflon base filled with glass amorphour carbon powder and graphite. It has lower thermal contraction-expansion rate than PTFE and is ideal for steam or thermal fluid applications up to 575F

Opaque White

+35%

OffWhite

+25%

Black

+50%

ValveMan.com 1-888-825-8800

Specially designed seats allow equalization of pressure in the ball cavity which reduces operating torque and increases seat life.

ValveMan.com 1-888-825-8800

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball Valvescoolguy12345No ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection Guidemurtuza5No ratings yet

- Valve Seat Selection GuideDocument4 pagesValve Seat Selection Guideim4uim4uim4uNo ratings yet

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocument4 pagesGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranNo ratings yet

- MuellerDocument24 pagesMuellerAhmad NasserNo ratings yet

- Flanges - Standard Dim For Flanges Used in InvestaDocument2 pagesFlanges - Standard Dim For Flanges Used in InvestaBharat TailorNo ratings yet

- 10 Ok Leakage Rates API 6d and Iso 14313Document0 pages10 Ok Leakage Rates API 6d and Iso 14313ZoebairNo ratings yet

- ValvesDocument24 pagesValvesaaa100% (1)

- UCM Ball ValvesDocument22 pagesUCM Ball ValvesBalakrishna BisoyiNo ratings yet

- The A To Z of Valve MaterialsDocument4 pagesThe A To Z of Valve Materialscool47guy09No ratings yet

- 6A E21 Addendum 1 PDFDocument9 pages6A E21 Addendum 1 PDFAndres FCTNo ratings yet

- Self-Study On MESC SPE 77.300 - TAT ValvesDocument34 pagesSelf-Study On MESC SPE 77.300 - TAT Valvesrosli2503No ratings yet

- FlowTek Ball Valve DesignDocument0 pagesFlowTek Ball Valve DesignGohilakrishnan ThiagarajanNo ratings yet

- File-1452328935 DBBDocument2 pagesFile-1452328935 DBBSalman100% (1)

- DBB Vs DIBDocument3 pagesDBB Vs DIBrsb72No ratings yet

- API 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsDocument2 pagesAPI 600 Overview - Steel Gate Valves - Flanged and Buttwelding Ends, Bolted BonnetsNilesh MistryNo ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- Valve Seat Material GuideDocument1 pageValve Seat Material GuidewawanNo ratings yet

- Lateral Tee 16'' Sch. 20 With Reinforcement Rev 01Document1 pageLateral Tee 16'' Sch. 20 With Reinforcement Rev 01HarryNo ratings yet

- Valve Material SelectionDocument8 pagesValve Material SelectionerovhoNo ratings yet

- Products Valves Sanitary PBM Series 9, 2 WayDocument40 pagesProducts Valves Sanitary PBM Series 9, 2 Waydingobk1No ratings yet

- Rite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Document8 pagesRite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Cristian PisitelloNo ratings yet

- Swing Check ValvesDocument5 pagesSwing Check Valveslilama45-1No ratings yet

- Valve Material TypesDocument3 pagesValve Material TypesimanadbNo ratings yet

- Ansi Valve Leakage Standards Gemco ValveDocument1 pageAnsi Valve Leakage Standards Gemco ValvenithyaNo ratings yet

- SWI Products MetalDocument21 pagesSWI Products MetalPrasanth PrasadNo ratings yet

- Floating Head Heat Exchanger MaintenanceDocument15 pagesFloating Head Heat Exchanger MaintenanceASWIN.MTNo ratings yet

- Attachment 1 API SC6 Plenary 6DDocument33 pagesAttachment 1 API SC6 Plenary 6Dderinn_cNo ratings yet

- MR 0175 Inquiries and ResponsesDocument25 pagesMR 0175 Inquiries and ResponsesPedro DutraNo ratings yet

- Mechanical Interview Rev 1Document86 pagesMechanical Interview Rev 1Syed Mohamed Gani GaniNo ratings yet

- Valve Materials Service.1 PDFDocument2 pagesValve Materials Service.1 PDFshaonaaNo ratings yet

- Steel Plug Valves 2016 1Document96 pagesSteel Plug Valves 2016 1EdinsonNo ratings yet

- Block and Bleed ValveDocument36 pagesBlock and Bleed ValveTochukwu OnuohaNo ratings yet

- F10ca004-Gb 0597Document8 pagesF10ca004-Gb 0597gabyorNo ratings yet

- HDPE Pipe PresentationDocument17 pagesHDPE Pipe PresentationSiddiqui Muhammad AshfaqueNo ratings yet

- 16 Paper169813 Apr14Document9 pages16 Paper169813 Apr14ahugandkiss77071No ratings yet

- Plug ValvesDocument14 pagesPlug Valvesashish.mathur1100% (1)

- 316 316L 317L Spec SheetDocument3 pages316 316L 317L Spec SheetLinnie McleodNo ratings yet

- 12 BonnetsDocument15 pages12 Bonnetsfaisal84in100% (1)

- Swagelok High Pressure FittingsDocument8 pagesSwagelok High Pressure FittingsSyahirul AlimNo ratings yet

- Valve Selection Guide: - ContentsDocument12 pagesValve Selection Guide: - ContentsAnonymous R23prjoKnoNo ratings yet

- Retriever Manual PDFDocument49 pagesRetriever Manual PDFJanneth Herrera FloresNo ratings yet

- Compression Packing Selection Guide: Sealing Products For IndustryDocument13 pagesCompression Packing Selection Guide: Sealing Products For IndustryAdverNo ratings yet

- Hydraulics CurriculumDocument8 pagesHydraulics CurriculumChris ChrisNo ratings yet

- MSDS 001139212Document7 pagesMSDS 001139212danny_sosa_3No ratings yet

- Nozzle Check ValvesDocument12 pagesNozzle Check Valvesjshadwan100% (1)

- KST GasketsDocument42 pagesKST Gasketsmihir_jha2No ratings yet

- Lateral Tee: What Is The Difference Between Lateral Tee and True WYEDocument2 pagesLateral Tee: What Is The Difference Between Lateral Tee and True WYEAnonymous 6ZWS6IG2J9No ratings yet

- Ball Valve KnowledgeDocument40 pagesBall Valve KnowledgeMeanRat100% (1)

- Valve and Pipeline Design Notes - Part 1Document29 pagesValve and Pipeline Design Notes - Part 1vikky123100% (1)

- Anti Blow Out StemDocument48 pagesAnti Blow Out StemimthiyazmuhammedNo ratings yet

- Seal Design For High Pressure Offshore-Morton & EvansDocument10 pagesSeal Design For High Pressure Offshore-Morton & EvansMachineryengNo ratings yet

- L&T Process Ball Valves PDFDocument16 pagesL&T Process Ball Valves PDFUnna MalaiNo ratings yet

- Valve Seat Seal Selection GuideDocument4 pagesValve Seat Seal Selection GuideDhim131267No ratings yet

- Ball Valve SeatDocument2 pagesBall Valve Seatmrkadu_61No ratings yet

- Seats and Seals Selection Guide: Share ThisDocument4 pagesSeats and Seals Selection Guide: Share ThisArjed Ali ShaikhNo ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection GuideHo Minh VietNo ratings yet

- Engineering Bulletin: Rev. 10/07 Page 1 of 4Document5 pagesEngineering Bulletin: Rev. 10/07 Page 1 of 4Iván López PavezNo ratings yet

- 180 - 18 Seat Selection GuideDocument4 pages180 - 18 Seat Selection GuidemolinachNo ratings yet

- Rules of Dynamic SimulationDocument1 pageRules of Dynamic SimulationImtihan KomahateeNo ratings yet

- Guidelines For The Protection of Pressurised Systems Exposed To Fire PDFDocument81 pagesGuidelines For The Protection of Pressurised Systems Exposed To Fire PDFhiginio.moro6182No ratings yet

- Rigorous Method For Fire Case (Process Engineer)Document5 pagesRigorous Method For Fire Case (Process Engineer)ecovarrubias1No ratings yet

- Asia Oil Product Specs PDFDocument32 pagesAsia Oil Product Specs PDFecovarrubias1No ratings yet

- B3 16M175Document2 pagesB3 16M175ecovarrubias1No ratings yet

- Especificacion DELTA PDFDocument14 pagesEspecificacion DELTA PDFecovarrubias1No ratings yet

- Gas Hydrates and Their PreventionDocument17 pagesGas Hydrates and Their Preventionecovarrubias1No ratings yet

- Wrought Iron ASTMDocument1 pageWrought Iron ASTMBords MoralesNo ratings yet

- API 610 Centrifugal Pumps For Petroleum Petrochemical and Natural Gas Industries 11th Ed 2010 APPENDIX HDocument8 pagesAPI 610 Centrifugal Pumps For Petroleum Petrochemical and Natural Gas Industries 11th Ed 2010 APPENDIX HZlatko CvetkovskiNo ratings yet

- Gmaw Guide PDFDocument54 pagesGmaw Guide PDFJorge perezNo ratings yet

- Lighting For Roadways and Bridges PDFDocument45 pagesLighting For Roadways and Bridges PDFwafikmh4No ratings yet

- E Cospace: AE Aterial SpecificationDocument5 pagesE Cospace: AE Aterial SpecificationAsraff Abdul RahmanNo ratings yet

- Furnace Atmospheres No. 1Document36 pagesFurnace Atmospheres No. 1Wilmer Quezada MurilloNo ratings yet

- SS2205 Material SpecificationDocument4 pagesSS2205 Material SpecificationCh FaiNo ratings yet

- Incoloy Alloy 825 UNS N08825 Welding Rod Manufacturer in IndiaDocument2 pagesIncoloy Alloy 825 UNS N08825 Welding Rod Manufacturer in IndiaOZAIRTRADELINKNo ratings yet

- Steel Industry Update #241Document6 pagesSteel Industry Update #241Michael LockerNo ratings yet

- Gas WeldingDocument22 pagesGas WeldingShalin Sharma50% (2)

- Seam DefectDocument4 pagesSeam DefectPatrick Dominguez100% (2)

- Interactive Knife Steel Composition ChartDocument20 pagesInteractive Knife Steel Composition ChartFlorin IonescuNo ratings yet

- 10th Metals and Non-Metals Test Paper Solved - 01 PDFDocument3 pages10th Metals and Non-Metals Test Paper Solved - 01 PDFRamachandranPerumalNo ratings yet

- Pre-Columbian Surface MetallurgyDocument8 pagesPre-Columbian Surface MetallurgyAantchuNo ratings yet

- Titanium Diboride AMCsDocument11 pagesTitanium Diboride AMCsbaskaran shanmugavelNo ratings yet

- Steeling Ships Against CorrosionDocument2 pagesSteeling Ships Against CorrosionAnonymous LY6TDeNo ratings yet

- Fisher ProdOvervueDocument88 pagesFisher ProdOvervueduongleanhNo ratings yet

- Astm A 743 PDFDocument8 pagesAstm A 743 PDFWill MottaNo ratings yet

- Mineral Identification ChartDocument4 pagesMineral Identification ChartIvica PavičićNo ratings yet

- BS En10264-1 - 2012Document14 pagesBS En10264-1 - 2012Aon HemmatadNo ratings yet

- Qcs 2010 Part 28.02 Irrigation System SpecificationsDocument38 pagesQcs 2010 Part 28.02 Irrigation System SpecificationsRotsapNayrb100% (1)

- TBT 412Document7 pagesTBT 412Mugesh RanjanendranNo ratings yet

- Inconel 601Document6 pagesInconel 601heanjiametalsNo ratings yet

- Xtek Crane BrochureDocument8 pagesXtek Crane BrochureBeniamine SarmientoNo ratings yet

- Catalog For TransformersDocument20 pagesCatalog For TransformersParthibanMKrishnanNo ratings yet

- Amps Vs Rod Size Vs Metal ThicknessDocument1 pageAmps Vs Rod Size Vs Metal ThicknessahmedNo ratings yet

- Lecture 6 - Pitting CorrosionDocument14 pagesLecture 6 - Pitting Corrosionprakush01975225403No ratings yet

- U-2 Sheet Metal OperationsDocument72 pagesU-2 Sheet Metal Operationsapi-271354682No ratings yet

- Cast Steel Abrasives: Standard Specification ForDocument6 pagesCast Steel Abrasives: Standard Specification ForCharlie ChongNo ratings yet

- Technical Specification - Klippon Roofing System V2-FinalDocument1 pageTechnical Specification - Klippon Roofing System V2-FinalRAMANNo ratings yet