Professional Documents

Culture Documents

Oee 2

Uploaded by

fernandothekingOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oee 2

Uploaded by

fernandothekingCopyright:

Available Formats

OVERALL EQUIPMENT EFFECTIVENESS (OEE

OEE = Availability [B/A] x Performance [D/C] x Quality [

Shift Time

A B C D E F

Planned Production Time Actual Running Time

Machine running Speed (Theoretical) In Pieces Actual Pieces Produced

Pieces Produced

Good Pieces Produced

Scrap & Rework

TOTAL EQUIPMENT EFFECTIVE PERFO

TEEP = (Scheduled Time / Calendar Time [B/A]) / OEE

A

Calendar Time Scheduled Time

TIVENESS (OEE)

JR Malphrus 05/21/07

e [D/C] x Quality [F/E]

Planned Idle Time Downtime Loss

Speed Loss

ECTIVE PERFORMANCE (TEEP)

me [B/A]) / OEE

QualityROI_JM_02/15/09

OEE

Overall Equipment Effectiveness (OEE) is comprised of three factors; Availability, Performance, and Quality. To start we ne to understand Planned Production Time or the time planned for the plant to be open and running. This could be 5x8, 5x16, 5x in the extreme 7x24 or 3 shifts per day 7 days per week. From the Planned Production Time we subtract Planned shutdown t which includes meetings, breaks, lunch, planned machine maintenance time, etc. Now we can move on to Availability.

Availability is the amount of time a machine is available to run minus unplanned downtime. Unplanned downtime is due to unscheduled events such as Time machine breakdowns, machine Availability % = Actual Run / Planned Production Timeoperator not available, power outage etc.

Actual Run time = Planned Operating Time - Unplanned Down Time Planned Production Time = Production Time Available - Planned Shutdown

Performance is the machine performance or Actual number of pieces produced during the Actual Run Time devided by the Planned Pieces. Planned Pieces is the Actual Run Time devided by the Ideal Cycle Time for 1 piece. In the calculator the Ac Pieces Produced is an input. The Planned Pieces is calculated by deviding the the Actual Run Time by the Ideal Cycle Time ( minutes) for 1 piece. Performance % = Actual Pieces Produced / Planned Pieces

Planned Pieces = Actual Run Time / Ideal Cycle Time

Quality is Good Pieces Produced on the first pass. Good Pieces due to rework are considered Defective Pieces for this calculation. Quality % = Good Pieces Produced / Actual Pieces Produced

Good Pieces Produced = Actual Pieces Produced - Defective Pieces Produced

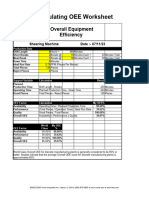

OEE Calculator

The calculator requires inputs indicated by Blue shaded cells. Grey-Green cells are calculated so DON'T change these cells.

rmance, and Quality. To start we need unning. This could be 5x8, 5x16, 5x24 or me we subtract Planned shutdown time can move on to Availability.

OEE = Availability % x Performance % x Quality %

Availability % = actual running time / planned cell production time Performance % = actual pieces produced / Ideal production rate (in pieces) Quality % = good pieces produced / Actual pieces produced

e. Unplanned downtime is due to outage etc.

e Actual Run Time devided by the for 1 piece. In the calculator the Actual Run Time by the Ideal Cycle Time (in

dered Defective Pieces for this

ated so DON'T change these cells.

Quality %

ned cell

al pieces

OEE (Overall equipment effectiveness(Eficiencia

Celdas azules requieren entradas, celdas verdes calculan resultados Cambio de informacion

Longitud de turno en Horas Minutos de almuerzo por Turno Descansos por turno Minutos de descanso Paro planeado en minutos Paros no planeados en minutos 8 30 2 15 15 30 Tiempo total de turno Descanso total Descanso + Comida + Otros 480 30 75

Informacin de Salida de produccin

Estandart Piezas actualmete producidas Piezas rechazadas por turno 120 Piezas por minuto (PpM) 48600 28000 640

Variables calculadas

Produccion planeada Tiempo de carrera real Piezas buenas producidas 405 375 27360

OEE Factor Calculations

Disponibilidad Desempeo Calidad OEE Actual Run Time/Planned Production Time (Actual Pieces/Actual Run Time)/Ideal Run Rate Good Pieces/Actual Pieces Availability x Performance x Quality 92.59% 62.22% 97.71% 56.30%

Cmo lo Hacemos?

100% 90%

80%

99.90% 97.71% 92.59%90.00% 95.00%

85.41%

70% 60% 50% 40%

30%

62.22% 56.30%

We World Class

20% 10% 0%

0% Disponibilidad Desempeo Calidad OEE

Barras Azules son es resultado de Clculos de Factor OEE barras Verdes son fijadas y muestran resultados de Clase Mundial

ss(Eficiencia General de los Equipos))

90.00% 95.00% 99.90% 85.41%

World Class

You might also like

- Evaluating The Impact of Information Technology in The Management of Nigerian Navy Logistics System and Supply ChainDocument10 pagesEvaluating The Impact of Information Technology in The Management of Nigerian Navy Logistics System and Supply ChainOlawoore Ibrahim TwiceRichNo ratings yet

- Lecture 3 - Production ConceptsDocument16 pagesLecture 3 - Production ConceptsFatimaNo ratings yet

- Tutorial 3 - SolutionDocument5 pagesTutorial 3 - SolutionAbdul Aziz Wicaksono100% (1)

- Ansi C84-1-2016 Contents and Scope PDFDocument9 pagesAnsi C84-1-2016 Contents and Scope PDFDBachai84No ratings yet

- Overall Equipment EffectivenessDocument32 pagesOverall Equipment Effectivenesshasan_waqar2004No ratings yet

- Calculating OEE Worksheet: Production DataDocument2 pagesCalculating OEE Worksheet: Production DataKhathutshelo KharivheNo ratings yet

- Electric Honeywell Non Spring Mod MN7220A2007 ManualDocument8 pagesElectric Honeywell Non Spring Mod MN7220A2007 ManualCristian Andres Astudillo MolinaNo ratings yet

- OEE CalculatorDocument11 pagesOEE CalculatorosbertodiazNo ratings yet

- Managing OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryDocument26 pagesManaging OEE To Optimize Cement Plant Performance.: A Case Study For Cement IndustryMohammad QureshiNo ratings yet

- Calculating OEE: The FormulasDocument3 pagesCalculating OEE: The FormulasMuhammad Javed IqbalNo ratings yet

- Oee 3Document2 pagesOee 3Lowell HarperNo ratings yet

- OEE Is The KeyDocument8 pagesOEE Is The Keypoonam2222No ratings yet

- Oee CalculatedDocument1 pageOee Calculatedmortezasafir62No ratings yet

- OEE PrimerDocument4 pagesOEE PrimerjaydeepsinhNo ratings yet

- Calculating OEE Worksheet: Production DataDocument2 pagesCalculating OEE Worksheet: Production DataPraveen GoswamiNo ratings yet

- Simple Calculation: Three Loss-Related FactorsDocument8 pagesSimple Calculation: Three Loss-Related FactorsTHANH THAO DO THINo ratings yet

- Overall Equipment Efficiency (OEE) : © Russel Timothy, Assoc - ProfessorDocument9 pagesOverall Equipment Efficiency (OEE) : © Russel Timothy, Assoc - ProfessornlmydvNo ratings yet

- Availability: Example OEE CalculationDocument2 pagesAvailability: Example OEE CalculationVaibhav Sharma100% (1)

- Overall Equipment EffectivenessDocument43 pagesOverall Equipment EffectivenessKailas Sree Chandran100% (4)

- World Class OEEDocument22 pagesWorld Class OEESinggihNo ratings yet

- Simple Oee SpreadsheetDocument2 pagesSimple Oee SpreadsheetadeNo ratings yet

- CFM ROss SolutionsDocument5 pagesCFM ROss SolutionsHai HaNo ratings yet

- Metric 2.1.2 TEEPDocument8 pagesMetric 2.1.2 TEEPAbdelaziz RagabNo ratings yet

- Calculate OeeDocument24 pagesCalculate OeeAyman AliNo ratings yet

- Calculating Oee WorksheetDocument2 pagesCalculating Oee WorksheetAdriano Tiago EinsfeldNo ratings yet

- OEE Calculation NorozionsDocument8 pagesOEE Calculation NorozionsNewhame DagneNo ratings yet

- What Is Oee?: Intro To LeanDocument3 pagesWhat Is Oee?: Intro To LeanNelson VianaNo ratings yet

- Oee - TPM: AvailabilityDocument4 pagesOee - TPM: Availabilityp ganeshNo ratings yet

- Computer: Manufacturing SystemsDocument39 pagesComputer: Manufacturing SystemsJeganNo ratings yet

- The Basics of OEEDocument30 pagesThe Basics of OEEguillermina_galleg_2No ratings yet

- Overall Equipment EffectivenessDocument12 pagesOverall Equipment EffectivenessAbdul RashidNo ratings yet

- Overall Equipment Effectiveness: Balakumar VDocument10 pagesOverall Equipment Effectiveness: Balakumar VBalakumar VNo ratings yet

- OEE What Is OEE?Document4 pagesOEE What Is OEE?Mamun IENo ratings yet

- CHAPTER 7 - Work MeasurementDocument29 pagesCHAPTER 7 - Work MeasurementmeeyaNo ratings yet

- Use of Oee Coefficient For Identification of Bottlenecks For Pressure Die Casting ProcessesDocument6 pagesUse of Oee Coefficient For Identification of Bottlenecks For Pressure Die Casting ProcessesIonut EduardNo ratings yet

- MaintenanceDocument21 pagesMaintenanceHarbani Wibawanto HadiNo ratings yet

- ktra hệ thống sản xuất tích hợpDocument47 pagesktra hệ thống sản xuất tích hợpVũ Quốc KhánhNo ratings yet

- Shift Length Short Breaks Meal Breaks Downtime Ideal Run Rate Total Pieces Reject Pieces Prodution DataDocument8 pagesShift Length Short Breaks Meal Breaks Downtime Ideal Run Rate Total Pieces Reject Pieces Prodution DataMustaffa FajraNo ratings yet

- OEE ComienzoDocument2 pagesOEE ComienzoSamuel ArellanoNo ratings yet

- 3.1 Work Measurement - Time Study - W4Document28 pages3.1 Work Measurement - Time Study - W4Saiful Azrie100% (1)

- How To Calculate OEE - The Real OEE Formula With Examples - Lean Execution - Intelligent MetricsDocument23 pagesHow To Calculate OEE - The Real OEE Formula With Examples - Lean Execution - Intelligent MetricsAhmad RahanNo ratings yet

- Calculate OEEDocument6 pagesCalculate OEEstanley chengNo ratings yet

- Measuring Production: Speaking A Common LanguageDocument42 pagesMeasuring Production: Speaking A Common LanguageArief TAnkziNo ratings yet

- Overall Equipment Effectiveness: Production Data Calculated DataDocument1 pageOverall Equipment Effectiveness: Production Data Calculated Datamedi38No ratings yet

- Accounting Profit Formula Excel Template-1Document52 pagesAccounting Profit Formula Excel Template-1Marwan SaidNo ratings yet

- DowntimeDocument7 pagesDowntimeJigar DesaiNo ratings yet

- Week 5 - Production SmoothingDocument34 pagesWeek 5 - Production SmoothingQuynh Chau Tran100% (1)

- 2.6 Process Planning Class 2 IEMDocument22 pages2.6 Process Planning Class 2 IEMCharan DcNo ratings yet

- OEE ExamplesDocument4 pagesOEE ExamplesSrinivas N GowdaNo ratings yet

- Productivity Improvement Through Lean Manufacturing ToolsDocument23 pagesProductivity Improvement Through Lean Manufacturing ToolsSatadeep Datta0% (1)

- OEE CalculationDocument7 pagesOEE Calculationirrosel46500% (1)

- Industrial Engineering Basics - Pharma - OEEDocument5 pagesIndustrial Engineering Basics - Pharma - OEEMelvin MarsNo ratings yet

- KPI CalcDocument12 pagesKPI Calchraj1350% (2)

- Assignments (Refer To Chapter 2 of Mikell P. Groover's Book)Document3 pagesAssignments (Refer To Chapter 2 of Mikell P. Groover's Book)Linh NguyễnNo ratings yet

- Oee Spreadsheet FabricationDocument7 pagesOee Spreadsheet FabricationVINAYNo ratings yet

- Oee Exercise Result: Please Perform This Analysis For All Key ProcessesDocument1 pageOee Exercise Result: Please Perform This Analysis For All Key ProcessesBalu RaviNo ratings yet

- Calculate OEE - Definitions, Formulas, and ExamplesDocument4 pagesCalculate OEE - Definitions, Formulas, and ExamplescleitonmoyaNo ratings yet

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- Understanding OEE in Lean Production: Toyota Production System ConceptsFrom EverandUnderstanding OEE in Lean Production: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Takt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsFrom EverandTakt Time - Understanding the Core Principle of Lean Manufacturing: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- Remote Projects Follow-up with Scrum-Excel Burn Down Chart: Scrum and Jira, #1From EverandRemote Projects Follow-up with Scrum-Excel Burn Down Chart: Scrum and Jira, #1No ratings yet

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsFrom EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsRating: 4.5 out of 5 stars4.5/5 (2)

- Ejection Device UvDocument5 pagesEjection Device UvDnyaneshwar Sham SalaveNo ratings yet

- GSM Bts 18000 OutdoorDocument36 pagesGSM Bts 18000 Outdoorsatya_33No ratings yet

- ch17 20221215171531Document12 pagesch17 20221215171531Elman BabayevNo ratings yet

- TGD JenaratörDocument3 pagesTGD JenaratörAbdulhamit Katılmış0% (1)

- Business Requirements Document Template ColombiaDocument14 pagesBusiness Requirements Document Template ColombiaKalai100% (1)

- ITIL V3 Foundation CertificateDocument7 pagesITIL V3 Foundation CertificateGLOBAL TEQNo ratings yet

- R03 I24b01 Cce XX XX SDW Ic 10323Document1 pageR03 I24b01 Cce XX XX SDW Ic 10323Sohail YounisNo ratings yet

- Joseph Shan Brilliant Dass: Proffesional SummaryDocument2 pagesJoseph Shan Brilliant Dass: Proffesional Summarymathews josephNo ratings yet

- Model: Service ManualDocument62 pagesModel: Service ManualAbdalhakeem Al turkyNo ratings yet

- 07 - CIC 2016 Detailed Design PDFDocument8 pages07 - CIC 2016 Detailed Design PDFLívia A. SouzaNo ratings yet

- Ultimate Photoshop Training: From Beginner To Pro: WORKBOOK - Section 1Document11 pagesUltimate Photoshop Training: From Beginner To Pro: WORKBOOK - Section 1Ивана Ика СтефановскаNo ratings yet

- CT QBDocument23 pagesCT QBRishikesh BhavsarNo ratings yet

- Students Guide - Steps To Upload Assignment To Microsoft TeamsDocument6 pagesStudents Guide - Steps To Upload Assignment To Microsoft TeamsDanny TengNo ratings yet

- Synthesis and Physical DesignDocument19 pagesSynthesis and Physical DesignTharun DeepNo ratings yet

- White Paper: How To Protect Video Surveillance Systems Against Lightning StrikesDocument6 pagesWhite Paper: How To Protect Video Surveillance Systems Against Lightning StrikesAashishNo ratings yet

- Biblio PDFDocument2 pagesBiblio PDFcms124dNo ratings yet

- Arcgis-10x 1 PDFDocument16 pagesArcgis-10x 1 PDFMile VasilicNo ratings yet

- Apple Macbook Air A1370 K99 - MLB 051-8379 820-2796-A Rev4.4.0 (07-22-2010) SchematicsDocument73 pagesApple Macbook Air A1370 K99 - MLB 051-8379 820-2796-A Rev4.4.0 (07-22-2010) SchematicsDiego AzevedoNo ratings yet

- SolarPassiveArchitecture2003C V SubramanianDocument6 pagesSolarPassiveArchitecture2003C V SubramanianAyushi JainNo ratings yet

- 100 TOP COMPUTER NETWORKS Multiple Choice Questions and Answers COMPUTER NETWORKS Questions and AnswersDocument21 pages100 TOP COMPUTER NETWORKS Multiple Choice Questions and Answers COMPUTER NETWORKS Questions and AnswersShital Ghodke67% (3)

- ANSYS BladeDocument2 pagesANSYS BladeMicky MouseNo ratings yet

- 3par Hp-Ux Implementation GuideDocument52 pages3par Hp-Ux Implementation GuideMuthu LNo ratings yet

- 2016 - Product Keys For Autodesk Products - Installation, Activation & Licensing - Autodesk Knowledge NetworkDocument9 pages2016 - Product Keys For Autodesk Products - Installation, Activation & Licensing - Autodesk Knowledge NetworkHerman MwakoiNo ratings yet

- Teseo SRL - Via Degli Oleandri, 1 25015 Desenzano Del Garda (BS) - Italy Tel. +39 030 9150411 - Fax +39 030 9150419 Fluid Power Distribution SystemsDocument104 pagesTeseo SRL - Via Degli Oleandri, 1 25015 Desenzano Del Garda (BS) - Italy Tel. +39 030 9150411 - Fax +39 030 9150419 Fluid Power Distribution SystemsVladimir ZaljevskiNo ratings yet

- 03 Imperative PDFDocument27 pages03 Imperative PDFwaqar asgharNo ratings yet

- Instruction Sheet 451-500 PDFDocument18 pagesInstruction Sheet 451-500 PDFJuanNo ratings yet

- Release Notes - Vissim - 2023.00-05 - ENDocument12 pagesRelease Notes - Vissim - 2023.00-05 - ENMaro gamNo ratings yet