Professional Documents

Culture Documents

Design

Uploaded by

Shubhangi SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design

Uploaded by

Shubhangi SinghCopyright:

Available Formats

3/5/2010

Design Process

Effective design can provide a competitive edge

Design Process (cont.)

Product design

Service design

matches product or service characteristics with customer requirements ensures that customer requirements are met in the simplest and least costly manner reduces time required to design a new product or service minimizes revisions necessary to make a design workable

5-1

defines appearance of product sets standards for performance specifies which materials are to be used determines dimensions and tolerances

specifies what physical items, sensual benefits, and psychological benefits customer is to receive from service defines environment in which service will take place

5-2

Design Process (cont.)

Idea generation

Product or service concept

Idea Generation Sources

Companys own R&D department Customer complaints or suggestions Marketing research Suppliers Salespersons in the field Factory workers New technological developments Competitors

Feasibility study

Performance specifications

Suppliers R&D Marketing

Customers Competitors

Form design

Revising and testing prototypes

Functional design New product or service launch

Final design & process plans Design specifications

Production design

Manufacturing or delivery specifications

Pilot run and final tests

5-3

5-4

Idea Generation Sources (cont.)

Perceptual Maps

Visual comparison of customer perceptions

Feasibility Study

Market analysis Economic analysis Technical/strategic analysis

Benchmarking

Comparing product/service against best-in-class

Reverse engineering

Dismantling competitors product to improve your own product

5-5 . 5-6

3/5/2010

Rapid Prototyping

Build a prototype

Form and Functional Design

Form Design

form design functional design production design

how product will look? reliability maintainability usability

Functional Design

Test prototype Revise design Retest

5-7

5-8

Usability

Ease of use of a product or service

Production Design

Simplification

ease of learning ease of use ease of remembering how to use frequency and severity of errors user satisfaction with experience

reducing number of parts, assemblies, or options in a product using commonly available and interchangeable parts combining standardized building blocks, or modules, to create unique finished products

5-10

Standardization

Modularity

5-9

Final Design and Process Plans

Final design

Design Team

Process plans

detailed drawings and specifications for new product or service

workable instructions

necessary equipment and tooling component sourcing recommendations job descriptions and procedures computer programs for automated machines

5-11

5-12

3/5/2010

Concurrent Design

A new approach to design that involves simultaneous design of products and processes by design teams Improves quality of early design decisions Involves suppliers Incorporates production process Scheduling and management can be complex as tasks are done in parallel

Design for Manufacture and Assembly (DFMA)

Design for manufacture

Design for assembly

a set of procedures for:

design a product for easy and economical production

reducing number of parts in an assembly evaluating methods of assembly determining an assembly sequence

5-13

5-14

DFM Guidelines

Minimize number of parts and subassemblies Avoid tools, separate fasteners, and adjustments Use standard parts when possible and repeatable, well-understood processes Design parts for many uses, and modules that can be combined in different ways Design for ease of assembly, minimal handling, and proper presentation Allow for efficient and adequate testing and replacement of parts

5-15

Technology in the Design Process

Computer Aided Design (CAD)

assists in creation, modification, and analysis of a design includes

computer-aided engineering (CAE)

tests and analyzes designs on computer screen

computer-aided manufacturing (CAM)

ultimate design-to-manufacture connection

5-16

Improving Quality of Design

Review designs to prevent failures and ensure value Design for environment Measure design quality Use quality function deployment Design for robustness

Design Review

Failure mode and effects analysis (FMEA)

a systematic method of analyzing product failures a visual method for analyzing interrelationships among failures helps eliminate unnecessary features and functions

Fault tree analysis (FTA)

Value analysis (VA)

5-17

5-18

3/5/2010

FMEA for Potato Chips

Failure Mode

Stale

Cause of Failure

low moisture content expired shelf life poor packaging too thin too brittle rough handling rough use poor packaging outdated receipt process not in control uneven distribution of salt

Effect of Failure

tastes bad wont crunch thrown out lost sales cant dip poor display injures mouth chocking perceived as old lost sales eat less drink more health hazard lost sales

Corrective Action

add moisture cure longer better package seal shorter shelf life change recipe change process change packaging

Fault tree analysis (FTA)

Broken

Too Salty

experiment with recipe experiment with process introduce low salt version

5-19

5-20

Design for Environment

Design for environment

Design for Robustness

Robust product

designing a product from material that can be recycled design from recycled material design for ease of repair minimize packaging minimize material and energy used during manufacture, consumption and disposal holds companies responsible for their product even after its useful life

designed to withstand variations in environmental and operating conditions yields a product or service designed to withstand variations design parameters such as material used, dimensions, and form of processing users control (length of use, maintenance, settings

Robust design

Controllable factors

Extended producer responsibility

Uncontrollable factors

Copyright 2006 John Wiley & Sons, Inc.

5-21

5-22

Tolerance and Consistency

Tolerance

Special Considerations in Service Design

Services are intangible Service output is variable Service have higher customer contact Services are perishable Service inseparable from delivery Services tend to be decentralized and dispersed Services are consumed more often than products Services can be easily emulated

allowable ranges of variation in the dimension of a part consistent errors are easier to correct than random errors parts within tolerances may yield assemblies that are not within limits consumers prefer product characteristics near their ideal values

5-23

Consistency

5-24

3/5/2010

Service Design Process (cont.)

Service concept

purpose of a service; it defines target market and customer experience mixture of physical items, sensual benefits, and psychological benefits performance specifications design specifications delivery specifications

5-25

Service package

Service specifications

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- BM 2 Operations Management and TQM NewDocument9 pagesBM 2 Operations Management and TQM NewEly GragasinNo ratings yet

- HVAKR Cheat SheetDocument2 pagesHVAKR Cheat SheetandreNo ratings yet

- Tutorial Week 10 (Group 2)Document4 pagesTutorial Week 10 (Group 2)Nuranis QhaleedaNo ratings yet

- Week 10 Tutorial QuestionsDocument3 pagesWeek 10 Tutorial QuestionsIsha ChandNo ratings yet

- Remotivation Therapy (Sammm)Document4 pagesRemotivation Therapy (Sammm)Sam Venezuelȧ100% (3)

- Cisco Catalyst 4500 Information SheetDocument3 pagesCisco Catalyst 4500 Information SheetEva CastilloNo ratings yet

- Pe Unit Plan TemplateDocument3 pagesPe Unit Plan Templateapi-239320998No ratings yet

- E-Learning For Universiti Teknologi Mara Malaysia (Uitm) : Campus Wide Implementation and AccomplishmentsDocument10 pagesE-Learning For Universiti Teknologi Mara Malaysia (Uitm) : Campus Wide Implementation and AccomplishmentsWan SyahlanNo ratings yet

- Youth Protection WaiverDocument1 pageYouth Protection WaiverKatie McCarthyNo ratings yet

- Kullu Tamam Merged - Cropped - TextDocument345 pagesKullu Tamam Merged - Cropped - TextEuro-trading GroupNo ratings yet

- Product PolyolDocument1 pageProduct PolyolAgung SiswahyuNo ratings yet

- Marciniak Barbara The PleiadiansDocument89 pagesMarciniak Barbara The Pleiadiansaman100% (3)

- Approach SlabDocument2 pagesApproach SlabMahmood Mufti100% (1)

- MCT Grade 5 LANGUAGE ARTS 2017 (1)Document16 pagesMCT Grade 5 LANGUAGE ARTS 2017 (1)Boppy VevoNo ratings yet

- Neurohealth Properties of Hericium Erinaceus MycelDocument11 pagesNeurohealth Properties of Hericium Erinaceus Myceldokan42No ratings yet

- Understanding The Internet of Things Definition, Potentials, and Societal Role of A FasDocument19 pagesUnderstanding The Internet of Things Definition, Potentials, and Societal Role of A FasSteven GarcíaNo ratings yet

- Role of Women in Urban and Rural AreasDocument3 pagesRole of Women in Urban and Rural AreasUmair AltafNo ratings yet

- HTJ22 StarsDocument6 pagesHTJ22 StarsCruzKevin20No ratings yet

- Introduction To Social WorkDocument3 pagesIntroduction To Social WorkSheherbano TariqNo ratings yet

- Vendor Document Cover SheetDocument11 pagesVendor Document Cover SheetSagar SawantNo ratings yet

- Ethnography Discussion QuestionsDocument2 pagesEthnography Discussion Questionsapi-235718856100% (1)

- Lecture 9Document26 pagesLecture 9Tesfaye ejetaNo ratings yet

- Nidhi Mittal ReportDocument123 pagesNidhi Mittal Reportarjun_gupta0037No ratings yet

- F Series Flexible Elastic Resin InstructionDocument5 pagesF Series Flexible Elastic Resin InstructionChristian EnglandNo ratings yet

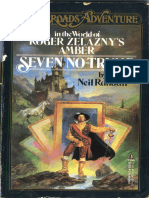

- Crossroads #10 - Roger Zelazny's Amber - Seven No-TrumpDocument254 pagesCrossroads #10 - Roger Zelazny's Amber - Seven No-TrumplerainlawlietNo ratings yet

- D457778-0460 Te Connectivity LTD Product Details: Part Number: Firstbom Part: Category: Manufacturer: ApplicationsDocument3 pagesD457778-0460 Te Connectivity LTD Product Details: Part Number: Firstbom Part: Category: Manufacturer: Applicationsfarhood ranjbarkhanghahNo ratings yet

- Mse 110l Fall 15 - Lab 4Document25 pagesMse 110l Fall 15 - Lab 4Billy JonesNo ratings yet

- Equipment Mark Type Matricule N de Serie Cont, Tec 3Rd Prty Cert ComentaireDocument1 pageEquipment Mark Type Matricule N de Serie Cont, Tec 3Rd Prty Cert ComentaireGTP HSE SECURITYNo ratings yet

- Guide To Integrate IBM System Storage With SAP HANA TDI V2.9Document18 pagesGuide To Integrate IBM System Storage With SAP HANA TDI V2.9Redbulls ThailandNo ratings yet

- Kuis ITSMDocument31 pagesKuis ITSMHariyanto HalimNo ratings yet