Professional Documents

Culture Documents

Entrainment Calculation PDF

Uploaded by

nirmal_subudhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Entrainment Calculation PDF

Uploaded by

nirmal_subudhiCopyright:

Available Formats

RESTRICTED COMMERCIAL

HEAT TRANSFER AND FLUID FLOW SERVICE

HTFS HANDBOOK

TM9: CORRELATION FOR KETTLE REBOILERS ENTRAINMENT IN

1.

INTRODUCTION

The information in this handbook sheet is taken from the HTRI report BK1/2 by Nakajima et al. (1970) which is available to HTFS members. The method presented here is one of two methods described in the HTRI report and was chosen because it is possible to give some indication of the possible error. An introduction to kettle reboilers is given in sheet BE3. The performance of kettle reboilers can be limited by entrainment of liquid drops from the boiling liquid. These droplets can increase the pressure drop in the vapour return pipe to the distillation column, and also decrease the efficiency of the distillation by carrying back liquid rich in heavy components into the distillation column. If the reboiler is feeding a compressor, then a separator will be needed (see Sheet TE1). Entrainment, E, is defined as the mass of liquid leaving the reboiler per unit mass of vapour leaving the reboiler. Section 2 gives some guidance on what values of E can be tolerated and Section 3 presents the method of calculating the shell diameter necessary to reduce E to the desired value. 2. SPECIFICATION OF THE ENTRAINMENT

4 gn (l g ) (3) v max = 1.77 E 2 g where gn is the acceleration due to gravity (9.81 2 m/s ) 1 1 3

is the surface tension (N/m)

3

3 l is the liquid density (kg/m )

and

g is the vapour density (kg/m )

Written in this form, the constant (1.77) is nondimensional. (2) Calculate vgV, a vertical vapour velocity from

v gV =

& M g g L L c

(4)

& is the total vapour production rate (kg/s) where M g

and L is the length of the tube bundle (m) Lc is a chord length (shown in Figure 1). Lc is given by Figure 2 if Ds/Db < 2, and by Lc = Ds (5)

if Ds/Db > 2. Ds and Db are the shell and tube bundle diameters.

The entrainment fraction E for normal kettle reboilers is limited by two factors as stated in Section 1. (i) If the fractional permissible increase in pressure drop in the vapour outlet pipe above the single phase value is I, then from homogeneous flow theory (approximately) E=I (ii) (1)

If the fractional permissible decrease in the efficiency of the bottom tray of the distillation column is D, then

1 L V 1 E= 1 D e

(2)

where e is the bottom tray fractional efficiency when E = 0 and L/V is the reflux ratio (mass of liquid/mass of vapour). 3. (1) CORRELATION Calculate the maximum velocity, vmax from permissible vapour

Figure 1: Location of Chord, Lc

(3) Calculate vgH, a horizontal vapour velocity from & M g (6) v gH = g S g N where Sg is a vapour cross flow area (see Figure 1) which can be found from Figure 3. and N is equal to twice the number of vapour

TM9 (Amended November 1983)

You might also like

- ChemEngReliefPaper2005 PDFDocument34 pagesChemEngReliefPaper2005 PDFNoirchevalNo ratings yet

- A Case Study On Design of Ammonia Conden PDFDocument3 pagesA Case Study On Design of Ammonia Conden PDFhardeep SinghNo ratings yet

- Selection of Reboiler Type Design ProceduresDocument0 pagesSelection of Reboiler Type Design ProcedurestpchoNo ratings yet

- How To Use Vertical Thermosyphon Reboiler CalculatorDocument2 pagesHow To Use Vertical Thermosyphon Reboiler CalculatorMahesh KumarNo ratings yet

- Aspen Fired Heater Models in HYSYS SimulationsDocument13 pagesAspen Fired Heater Models in HYSYS SimulationsWendellReeceFrankNo ratings yet

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Document36 pagesProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaNo ratings yet

- Controlling Heat ExchangersDocument11 pagesControlling Heat ExchangersgermanaponteNo ratings yet

- Thermosyphon Reboiler HydraulicsDocument2 pagesThermosyphon Reboiler HydraulicsMichael HaiseNo ratings yet

- Vacuum Distillation in Petroleum RefineryDocument3 pagesVacuum Distillation in Petroleum RefineryAdelmo FilhoNo ratings yet

- 2 Phase Seperator PDFDocument66 pages2 Phase Seperator PDFKanthan DevanNo ratings yet

- DesignII Lecture 02 ReboilerDesignDocument19 pagesDesignII Lecture 02 ReboilerDesignRam L Rao100% (1)

- Kettle ReboilersDocument4 pagesKettle ReboilersMuhammad Usman100% (1)

- PRO II Column Algorithms SelectionDocument6 pagesPRO II Column Algorithms SelectionWade ColemanNo ratings yet

- GoyalDocument3 pagesGoyalVan LeNo ratings yet

- Specifying Shell and Tube Heat ExchangersDocument10 pagesSpecifying Shell and Tube Heat ExchangersMicheal BrooksNo ratings yet

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument3 pagesCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberNo ratings yet

- Design Practices-ReboilerDocument7 pagesDesign Practices-Reboileragarwalashwin32100% (1)

- KG Tower Loadings V1.1Document13 pagesKG Tower Loadings V1.1Lee Koon PengNo ratings yet

- Article PSV Specific HeatDocument6 pagesArticle PSV Specific Heatprq123No ratings yet

- Vertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyDocument9 pagesVertical Thermosyphon Re Boilers. Maximum Heat Flux and Separation EfficiencyPuskar GuptaNo ratings yet

- Thermosiphon ReboilersDocument3 pagesThermosiphon ReboilersMuhammadNo ratings yet

- Flow Instabilities in A Horizontal Thermosyphon Reboiler LoopDocument22 pagesFlow Instabilities in A Horizontal Thermosyphon Reboiler Loopwylie01No ratings yet

- NGL Fractionation Train Hysys Sim ReportDocument6 pagesNGL Fractionation Train Hysys Sim ReportOsas Uwoghiren100% (1)

- HTRI 20case 20study 20shellsideDocument2 pagesHTRI 20case 20study 20shellsideHarish KaushikNo ratings yet

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Reboiler Case StudyDocument6 pagesReboiler Case StudyamlhrdsNo ratings yet

- Steam Condensate Drainage OptionsDocument6 pagesSteam Condensate Drainage Optionssatishchemeng100% (2)

- Condenser - Valuable Book PDFDocument6 pagesCondenser - Valuable Book PDFRajesh OwaiyarNo ratings yet

- Determining heat transfer coefficients in a falling film evaporatorDocument7 pagesDetermining heat transfer coefficients in a falling film evaporatorSeyit AvcuNo ratings yet

- Ejector technology for efficient and cost effective flare gas recoveryDocument10 pagesEjector technology for efficient and cost effective flare gas recoverySdadNo ratings yet

- Introduction To Reboiler DesignDocument3 pagesIntroduction To Reboiler Design1940LaSalleNo ratings yet

- Thermal Intgration ReboilerDocument3 pagesThermal Intgration ReboilerChem.EnggNo ratings yet

- Extractor Flowsheet Definition: - Objective - Create A Graphical FlowsheetDocument20 pagesExtractor Flowsheet Definition: - Objective - Create A Graphical Flowsheetyoly10No ratings yet

- Select Best Model Two-Phase Relief Sizing: The ForDocument9 pagesSelect Best Model Two-Phase Relief Sizing: The ForjowarNo ratings yet

- Column-Base and Arrangements: ReboilerDocument27 pagesColumn-Base and Arrangements: ReboilerPacyfik Kameron100% (1)

- EjectorsDocument5 pagesEjectorsJaykumarNo ratings yet

- Allowable Vapor Control ValveDocument9 pagesAllowable Vapor Control Valvejohn VilladaNo ratings yet

- Rupture Disc-PSV CombinationDocument3 pagesRupture Disc-PSV CombinationManikandan SubramanianNo ratings yet

- CHE Facts 1211Document1 pageCHE Facts 1211kumar_chemicalNo ratings yet

- HTRIDocument1 pageHTRIDhanny MiharjaNo ratings yet

- 2nd Part of CalculationDocument26 pages2nd Part of CalculationLohith NatarajNo ratings yet

- Advanced Heat Exchanger Design TechniquesDocument9 pagesAdvanced Heat Exchanger Design Techniquesjdgh1986No ratings yet

- Nptel ReboilerDocument8 pagesNptel ReboilerGurubasavaraju T MNo ratings yet

- CBE 417 FlashDrumSizing Wankat PDFDocument7 pagesCBE 417 FlashDrumSizing Wankat PDFAbdul RehmanNo ratings yet

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- Design of Valve TrayDocument4 pagesDesign of Valve TrayVirendra BhagatNo ratings yet

- Thermocompressor PerformanceDocument8 pagesThermocompressor PerformanceLaboratorio PapelesRegionalesNo ratings yet

- MC Kee - Thermosiphon Reboileres A ReviewDocument7 pagesMC Kee - Thermosiphon Reboileres A Reviewbltzkrig100% (1)

- REBOILER CALCULATION GUIDEDocument12 pagesREBOILER CALCULATION GUIDESabba CabbaNo ratings yet

- Gas Blow-By From A Production Separator To Tank PDFDocument7 pagesGas Blow-By From A Production Separator To Tank PDFebby1100% (1)

- HTFS Presentation 2 Heat ExchangerDocument57 pagesHTFS Presentation 2 Heat ExchangerSuphi YükselNo ratings yet

- Kettle ReboilersDocument6 pagesKettle ReboilersHow Jie WeiNo ratings yet

- King Abdulaziz University Mechanical Engineering Heat Exchanger DesignDocument65 pagesKing Abdulaziz University Mechanical Engineering Heat Exchanger DesignMuhammad HaidiNo ratings yet

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocument10 pagesEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNo ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationFrom EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- ADocument5 pagesAnirmal_subudhiNo ratings yet

- 3888 6839 1 PBDocument8 pages3888 6839 1 PBnirmal_subudhiNo ratings yet

- Class 6-10Document1 pageClass 6-10nirmal_subudhiNo ratings yet

- ENPE 505 Lecture 6: Gas Water System DehydrationDocument1 pageENPE 505 Lecture 6: Gas Water System Dehydrationnirmal_subudhiNo ratings yet

- LaricinaDocument15 pagesLaricinanirmal_subudhiNo ratings yet

- VBA Tutorial for Process View UsersDocument1 pageVBA Tutorial for Process View Usersnirmal_subudhiNo ratings yet

- Compressor Dynamics 3Document1 pageCompressor Dynamics 3nirmal_subudhiNo ratings yet

- Compressor Dynamics 5Document1 pageCompressor Dynamics 5nirmal_subudhiNo ratings yet

- Compressor Dynamics 4Document1 pageCompressor Dynamics 4nirmal_subudhiNo ratings yet

- NoteDocument1 pageNotenirmal_subudhiNo ratings yet

- Compressor Dynamics 1Document1 pageCompressor Dynamics 1nirmal_subudhiNo ratings yet

- Need For Bypass During Positive Displacement PumpDocument2 pagesNeed For Bypass During Positive Displacement Pumpnirmal_subudhiNo ratings yet

- Compressor Dynamics 2Document1 pageCompressor Dynamics 2nirmal_subudhiNo ratings yet

- Pviewtutme IntroDocument6 pagesPviewtutme Intronirmal_subudhiNo ratings yet

- Hydrocarbon Processing: Deep Water FLNGDocument1 pageHydrocarbon Processing: Deep Water FLNGnirmal_subudhiNo ratings yet

- Dispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology MalaysiaDocument44 pagesDispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology Malaysianirmal_subudhi100% (1)

- HeneicosaneDocument3 pagesHeneicosanenirmal_subudhiNo ratings yet

- Basic Prog For FlowmeterDocument1 pageBasic Prog For Flowmeternirmal_subudhiNo ratings yet

- Msds DodecaneDocument6 pagesMsds Dodecanenirmal_subudhiNo ratings yet

- M MercaptanDocument7 pagesM Mercaptannirmal_subudhiNo ratings yet

- Msds Benzena PDFDocument6 pagesMsds Benzena PDFIrianto Rizaldi FaturrahmanNo ratings yet

- SilicaDocument4 pagesSilicaTgk HM Kinglie Nya'OenoeNo ratings yet

- E MercaptanDocument8 pagesE Mercaptannirmal_subudhiNo ratings yet

- Msds HeptadecaneDocument5 pagesMsds Heptadecanenirmal_subudhiNo ratings yet

- MSDS N EicosaneDocument3 pagesMSDS N Eicosanenirmal_subudhiNo ratings yet

- Msds HexadecaneDocument5 pagesMsds Hexadecanenirmal_subudhiNo ratings yet

- Msds UndecaneDocument5 pagesMsds Undecanenirmal_subudhiNo ratings yet

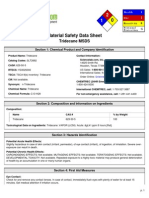

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: 1. Chemical Product and Company Identificationnirmal_subudhiNo ratings yet

- Msds TridecaneDocument5 pagesMsds Tridecanenirmal_subudhiNo ratings yet

- Msds TolueneDocument6 pagesMsds Toluenenirmal_subudhi100% (1)

- 11th Physics Ch-9 - Mechanical Properties of Fluids (SQP) 2023-24Document11 pages11th Physics Ch-9 - Mechanical Properties of Fluids (SQP) 2023-24Mahalaksshmi .DNo ratings yet

- Fluid Statics and DynamicsDocument34 pagesFluid Statics and DynamicsBiprodeep14No ratings yet

- SulzerDocument3 pagesSulzerVladimir AleksandrovNo ratings yet

- Technical Literature: Droplet SeparationDocument33 pagesTechnical Literature: Droplet SeparationrattanaceesayNo ratings yet

- Fluids Jee-Main-Oline 2021 Without AnswersDocument2 pagesFluids Jee-Main-Oline 2021 Without AnswersHarsh SinghNo ratings yet

- Gep Primary Water Resource Aug12 NSWDocument50 pagesGep Primary Water Resource Aug12 NSWNitin AroraNo ratings yet

- The Physics of Water Drops and Lift-OffDocument3 pagesThe Physics of Water Drops and Lift-OffBobapatatasNo ratings yet

- AA V1 I3 Predicting Liquid AtomizationDocument1 pageAA V1 I3 Predicting Liquid AtomizationKaushik Ram SNo ratings yet

- BS en 00546-4-2006Document16 pagesBS en 00546-4-2006Karina CastroNo ratings yet

- Characterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSDocument183 pagesCharacterization and Prediction of Water Droplet Size in Oil Water Flow - J Yao - MSGianmarco Corticelli100% (1)

- API 521 Flare Knockout Drum SizingDocument35 pagesAPI 521 Flare Knockout Drum Sizingnghiemta1892% (13)

- KOSO DSH General Catalog - Ver08Document20 pagesKOSO DSH General Catalog - Ver08निखिल बायवारNo ratings yet

- A Molecular Dynamics Simulation of Droplet EvaporationDocument10 pagesA Molecular Dynamics Simulation of Droplet EvaporationSayan DasNo ratings yet

- Solved Examples: Example 1Document10 pagesSolved Examples: Example 1Emejoi TemblacoNo ratings yet

- Wa0003.Document54 pagesWa0003.subhrojyoti balaNo ratings yet

- Berkland, JCR 2001Document16 pagesBerkland, JCR 2001Dan PackNo ratings yet

- Gas Liquid Separation TechnologyDocument24 pagesGas Liquid Separation TechnologyAlan ChewNo ratings yet

- ASTM D 889 99 Volatile Oil in Rosin PDFDocument3 pagesASTM D 889 99 Volatile Oil in Rosin PDFAmir HamzahNo ratings yet

- Selectie CTADocument5 pagesSelectie CTAValeriu CerneaNo ratings yet

- Foaming in Fractionation ColumnsDocument7 pagesFoaming in Fractionation ColumnsmehdiNo ratings yet

- Fluid Properties Viscosity and Surface Tension ProblemsDocument4 pagesFluid Properties Viscosity and Surface Tension ProblemsBrijesh KumarNo ratings yet

- Design and Fabrication of Solar Powered Air PurifierDocument7 pagesDesign and Fabrication of Solar Powered Air PurifierKala JattNo ratings yet

- CFD Simulation of Dust Particle Removal Efficiency of A Venturi Scrubber in CFXDocument9 pagesCFD Simulation of Dust Particle Removal Efficiency of A Venturi Scrubber in CFXCristian MartínezNo ratings yet

- Coalesce RDocument4 pagesCoalesce Rrieza_fNo ratings yet

- Artigo SoldagemDocument8 pagesArtigo SoldagemRômuloScapiniNo ratings yet

- Properties of Fluids PROBLEMSDocument12 pagesProperties of Fluids PROBLEMSJohn FerreNo ratings yet

- Two Phase Useful Information 2Document27 pagesTwo Phase Useful Information 2sara25dec689288No ratings yet

- Velocity Coefficients For Free Jets From Sharp-Edged OrificesDocument5 pagesVelocity Coefficients For Free Jets From Sharp-Edged OrificesMarco Batista XandóNo ratings yet

- Agriculture Range Training Presentation PDFDocument94 pagesAgriculture Range Training Presentation PDFManisha rana100% (2)

- Gejala Kilat: 1. General KarakteristikDocument4 pagesGejala Kilat: 1. General KarakteristikKhaddavi KhalifNo ratings yet