Professional Documents

Culture Documents

Sec26 Engineering

Uploaded by

Jay SuguitanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sec26 Engineering

Uploaded by

Jay SuguitanCopyright:

Available Formats

ENGINEERING DATA

ENGINEERING DATA

ENGINEERING DATA FOR SWIMMING POOLS AND SPAS

587

ENGINEERING DATA

ESTIMATING TOTAL GALLONS IN A POOL OR SPA

ENGINEERING DATA

Average Depth 3.5 ft. 24 ft. Dia. Width

Length

Depth (deep)

Depth (shallow)

Radius2 x 3.14 x A.D. x 7.5 = Gallons 12 x 12 x 3.14 x 3.5 x 7.5 = 11,869 Gals. Dia. x Dia. x Av Dp x 5.9 = Gallons 24 x 24 x 3.5 x 5.9 = 11,894 Gals. Gal.cu.ft. Rectangle: Oval: Kidney: 7.5 6.7 7.0

Formula A: Length X Width X Average Depth X Gal.cu.ft. = Gallons Example: Pool Length Pool Width Shallow Depth Deep Depth Total Depth = = = = = 40 ft. 20 ft. 3 ft. +8 ft. 11 ft.

Using formula A: 40 X 20 = 800 sq. ft., 800 X 5.5 = 4,400 cubic ft., 4,400 X 7.5 = 33,000 gallons

588

The area in square feet for pools and spas can be determined by using one or more of the above formulas.

ENGINEERING DATA

ENGINEERING DATA

UNITS OF MEASURE

UNITS OF LENGTH

FOOT .0833 1.0 3.0 3.281

UNIT INCH FOOT YARD METER

INCH 1.0 12.0 36.0 39.37

YARD .0278 .333 1.0 1.094

METER .0254 .305 .9144 1.0

UNITS OF AREA

UNIT SQUARE INCH SQUARE FOOT SQUARE YARD SQUARE METER SQUARE INCH 1.0 144.0 1,296.0 1,550.0 SQUARE FOOT .00694 1.0 9.0 10.76 SQUARE YARD .000772 .1111 1.0 1.196 SQUARE METER .000645 .0929 .836 1.0

UNITS OF VOLUME

UNIT U.S. GALLON IMPERIAL GALLON CUBIC FEET POUNDS OF WATER CUBIC METERS U.S. GALLON 1.0 1.2 7.481 .12 264.2 IMPERIAL GALLON .833 1.0 6.232 .09996 220.0 CUBIC FEET .1337 .1605 1.0 .0160 35.31 POUNDS OF WATER 8.33 10.0 62.37 1.0 2,204.0 CUBIC METERS .003785 .004546 .0283 .00045 1.0

UNITS OF FLOW

UNIT U.S. G.P.M. IMPERIAL G.P.M. CUBIC FT. PER SECOND CUBIC FT. PER HOUR LITERS PER SECOND U.S. G.P.M. 1.0 1.2 448.8 .1247 15.85 IMPERIAL G.P.M. .833 1.0 374.0 .104 13.21 CUBIC FEET/ SECOND .00223 .00268 1.0 .00028 .0353 CUBIC FEET/HOUR 8.02 9.63 3.600 1.0 127.13 LITERS/ SECOND .0631 .0757 28.32 .0078 1.0

589

ENGINEERING DATA

ENGINEERING DATA

UNITS OF MEASURE

UNITS OF PRESSURE

UNIT INCHES OF WATER FEET OF WATER POUNDS PER SQUARE INCH INCHES OF MERCURY

INCHES OF WATER 1.0 12.0 27.72 13.596

FEET OF WATER .0833 1.0 2.31 1.133

POUNDS PER SQUARE INCH .0361 .433 1.0 .4906

INCHES OF MERCURY .0736 .883 2.04 1.0

PRESSURE AND EQUIVALENT FEET HEAD OF WATER

Lbs. per Sq. In. 1 2 3 4 5 6 7 8 9 10 15 Feet Head 2.31 4.62 6.93 9.24 11.54 13.85 16.16 18.47 20.78 23.09 34.63 Lbs. per Sq. In. 20 25 30 40 50 60 70 80 90 100 110 Feet Head 46.18 57.72 69.27 92.36 115.38 138.46 161.53 184.62 207.69 230.77 253.85 Lbs. per Sq. In. 120 125 130 140 150 160 170 180 190 200 Feet Head 276.42 288.46 300.00 323.08 346.15 369.23 392.31 415.38 438.46 461.54

H= Lbs. per Sq. In. 225 250 275 300 325 350 375 400 500 1000

pressure (psi) x 144 62.4 Feet Head 519.23 576.92 634.62 692.31 750.00 807.69 865.38 923.08 1153.85 2307.69

590

ENGINEERING DATA

ENGINEERING DATA

UNITS OF MEASURE

EQUIVALENT VALUES OF PRESSURE 1 in. of Mercury (hg) = 1.13 ft. of water

Inches of Mercury 1 2 3 4 5 6 7 8 9 10 Feet of Water 1.13 2.26 3.39 4.52 5.65 6.78 7.91 9.04 10.17 11.30 Pounds per Sq. In. 0.49 0.98 1.47 1.95 2.44 2.93 3.42 3.91 4.40 4.89 Inches of Mercury 11 12 13 14 15 16 17 18 19 20 Feet of Water 12.45 13.57 14.70 15.82 16.96 18.09 19.22 20.35 26.47 22.60 Pounds per Sq. In. 5.39 5.87 6.37 6.86 7.35 7.84 8.33 8.82 9.31 9.80 Inches of Mercury 21 22 23 24 25 26 27 28 29 29.929 Feet of Water 23.78 24.88 26.00 27.15 28.26 29.40 30.52 31.65 32.80 33.947 Pounds per Sq. In. 10.3 10.8 11.28 11.75 12.25 12.73 13.23 13.73 14.22 14.6969

WEIGHT 1 U.S. GALLON OF WATER = 8.33 LBS. 1 CUBIC FOOT OF WATER = 62.35 LBS. 1 KILOGRAM (LITRE) = 2.2 LBS. 1 IMPERIAL GALLON = 10.0 LBS.

CURRENT CAPACITY (AMPS) OF WIRE * Three wires in cable, ambient temp. 86F

WIRE SIZE 14 12 10 8 6 4 3 2 1 0 AMPERES COPPER 20 25 30 40 55 70 85 95 110 125 ALUMINIUM 20 25 30 40 55 65 75 85 100 EFFICIENCY MOTOR EFFICIENCY PUMP EFFICIENCY OVERALL PLANT EFFICIENCY (OPE) EFFICIENCY POWER OUTPUT POWER INPUT HP OUTPUT K.W. INPUT G.P.M x TOTAL HEAD (F.T.) 3960 x BHP G.P.M x TOTAL HEAD (F.T.) 5310 x K.W. INPUT

Amperage = Watts =

Watts Volts Volts x Amperage Water Horsepower

* Wire size is minimum for amperes listed.

WHP =

(output HP of pump) = g.p.m x total head 3960

HP input (to motor) = Total Head = Discharge Head =

KW input x 1.341 Discharge head + Pumping water level (ft) Discharge Pressure (PSI) x 2.31 ft. of head

591

ENGINEERING DATA

ENGINEERING DATA

HEATER SIZING INFORMATION

Pool heaters can be sized by the volume method for maintenance heating or for spot heating. For many days during the swimming season, the sun maintains a desirable pool temperature of 7880F. and the pool requires no supplemental heating. However, during cooler periods a pool will usually lose 24F. per day. To get the water to the desired temperature, you could choose a smaller heater and run it during the daily filter cycle of 46 hours every day. This would be sufficient to overcome a slight temperature drop between filter cycles, but it would mean leaving the heater on every day. If you dont use the pool daily, its more economical to spot heat the pool, say for the weekend. In this case, you could choose a larger heater which will heat the pool faster, and then can be turned off between uses. With either, maintenance heating or spot heating, you need to determine the size of heater to select and the time it will require to heat the pool.

MASTERTEMP AND MAX-E -THERM MODEL REQUIRED TO HEAT POOL IN 24 HOURS

MASTERTEMP AND MAX-E -THERM MODEL REQUIRED TO HEAT THE SPA 30F IN A GIVEN TIME PERIOD

* For Commercial Heaters 500,000 BTU/hr and over please contact factory for sizing.

TIME IN HOURS POOL & SPA TIME IN MINUTES SPA

Vol. in Gal. x 8.34 lb./gal. x temprise Heater BTUH input x efficiency of heater Vol. in Gal. x 8.34 lb./gal. x temprise x 60 min Heater BTUH input x efficiency of heater

592

ENGINEERING DATA HEATER GAS SUPPLY AND PIPE SIZING INFORMATION

When installing any Pentair Pool Products or Sta-Rite pool or spa heater, it is very important to have the proper amount of gas supplied to all Pentair or Sta-Rite Heaters for pools. Below, for your information, is a table which will assist you in selecting the correct size of piping for the installation. When installing any gas appliance, it is very important to have the proper size gas meter and home pressure regulator installed. Once you have selected the correct size heater for the pool or spa, contact the local utility which supplies the gas and request a field review of the installation and have them install the proper size meter and proper size pressure regulator.

ENGINEERING DATA

LOW PRESSURE, SINGLE STAGE PIPE SIZING FOR GAS LINE CONNECTIONS

4 Natural gas at 1000 BTU per Cubic Foot Propane Gas at 2500 BTU per Cubic Foot MODEL 100 & 75 150 200 250 300 350 400 525 750 900 Gas Pressure 1/2 in. NAT 20 ft. 10 ft. PRO 50 ft. 40 ft. 20 ft. 10 ft. Model 3/4 in. NAT 50 ft. 50 ft. 30 ft. 20 ft. 10 ft. 10 ft. PRO 150 ft. 150 ft. 80 ft. 50 ft. 30 ft. 20 ft. 10 ft. 5 ft. Natural 1 in. NAT 150 ft. 150 ft. 125 ft. 70 ft. 50 ft. 30 ft. 20 ft. 15 ft. PRO 600 ft. 600 ft. 250 ft. 150 ft. 100 ft. 70 ft. 60 ft. 35 ft. 20 ft. 15 ft. 1-1/4 in. NAT 450 ft. 250 ft. 200 ft. 125 ft. 100 ft. 65 ft. 35 ft. 20 ft. PRO 600 ft. 500 ft. 350 ft. 250 ft. 150 ft. 150 ft. 80 ft. 45 ft. 1-1/2 in. NAT 600 ft. 400 ft. 250 ft. 200 ft. 130 ft. 75 ft. 45 ft. PRO 600 ft. 500 ft. 450 ft. 360 ft. 180 ft. 100 ft. 500 ft. 400 ft. 390 ft. 260 ft. 150 ft. 2 in. NAT PRO 700 ft. 600 ft. 360 ft. Natural 2-1/2 in. NAT 400 ft. PRO -

Propane

Inches W. C.

10 10 10 10 6 6 4 6 4 4 2 4 14 14 N/A N/A 12 12 N/A N/A 11 11 N/A N/A

Gas Pressure

Propane

Inches W. C.

Gas Pressure Requirements Pentair Water Heaters CH Maximum Inlet STD TSI LN CH Minimum Inlet STD TSI LN CH Manifold STD TSI LN

Gas Pressure Requirements for MiniMax 75 & 100 Pentair Water Heaters Normal Altitudes (02500 ft. above Sea Level) Maximum Inlet Minimum Inlet Normal Manifold Maximum Inlet Minimum Inlet Normal Manifold 10 5 4 10 5 3 14 12 11 14 12 7

High Altitudes (25007000 ft. above Sea Level)

Gas Pressure

Model

Natural

Propane

Note: All readings must be taken while heater is operating. Any adjustments or readings made while heater is off will give incorrect readings and should not be used for evaluation of heater operation. All Values are +/- 0.2 inch W. C.

Inches W. C.

Gas Pressure Requirements for MasterTemp and Max-E-Therm Pentair Water Heaters Maximum Inlet Minimum Inlet Manifold MT MT MT 14 4 -0.2 0.1 14 4 -0.2 0.1

593

ENGINEERING DATA

HEATER GAS SUPPLY AND PIPE SIZING INFORMATION

RESIDENTIAL PROPANE GAS 2 STAGE REGULATION In many Propane gas line installations, the gas supplier and or installer will utilize a two stage regulation process whereby, at the supply tank, they will install the first stage gas regulator, which would be at a higher pressure, usually 10 psi. This higher pressure allows for much longer distance and in a much smaller pipe size. Then, within a short distance from the pool heater, generally around 24 inches, a second regulator, which is the second stage, would be installed and set at the required inlet pressure of the heater.

SEE GAS PRESSURE REQUIREMENT CHART.

ENGINEERING DATA

Stage One High Pressure Gas Pipe Sizing 10 PSI @ 2500 BTU Per CU. FT. MAXIMUM EQUIVALENT PIPE LENGTH Model 75 through 400 0 to 50 Feet 1/2 in. 50 to 100 Feet 1/2 in. 100 to 150 Feet 1/2 in.

Stage Two Low Pressure Gas Pipe Sizing Stage 2 set at 14 in. W.C. MAXIMUM EQUIVALENT PIPE LENGTH Model 75 through 400 0 to 10 Feet 3/4 in. 10 to 20 Feet 3/4 in.

RESIDENTIAL NATURAL GAS 2 STAGE REGULATION In many Natural gas line installations, the gas supplier and or installer will utilize a two stage regulation process whereby, at the streets main gas supply, they will install the first stage gas regulator, which would be at a higher pressure. This higher pressure is usually set at 2 psi or 5 psi and can be run for long distances and in a much smaller pipe size. Then, within a short distance from the pool heater, generally around 24 inches, they will install a second regulator, which is the second stage. This second stage regulator would be set at the minimum operating pressure for the heater. For Natural Gas Pentair Pool Heaters the minimum is 7 inches W.C.

Stage One High Pressure Gas Pipe Sizing 2 PSI @ 1000 BTU Per CU. FT. MAXIMUM EQUIVALENT PIPE LENGTH Model 75 through 400 0 to 20 Feet 3/4 in. 20 to 90 Feet 1 in. 90 to 200 Feet 1-1/4 in.

Stage Two Low Pressure Gas Pipe Sizing Stage 2 set at 7 in. W.C. MAXIMUM EQUIVALENT PIPE LENGTH Model 75 through 300 350 & 400 0 to 5 Feet 3/4 in. 1 in. 0 to 15 Feet 1 in. 1 in.

Stage One High Pressure Gas Pipe Sizing 5 PSI @ 1000 BTU Per CU. FT. MAXIMUM EQUIVALENT PIPE LENGTH Model 75 through 400 0 to 50 Feet 3/4 in. 50 to 100 Feet 3/4 in. 100 to 200 Feet 3/4 in.

Stage Two Low Pressure Gas Pipe Sizing Stage 2 set at 7 in. W.C. MAXIMUM EQUIVALENT PIPE LENGTH Model 75 through 300 350 & 400 0 to 5 Feet 3/4 in. 1 in. 0 to 15 Feet 1 in. 1 in.

594

ENGINEERING DATA

ENGINEERING DATA

BLOWER SIZING

HORSEPOWER

Divide This Kwatts Watts Torque (ft. lbs.) X RPM Torque (ft. lbs.) X RPS GPM x TDH (ft.) GPH X TDH (psi)

To Get This Horsepower Horsepower Horsepower Horsepower Horsepower required to pump water at a given rate to a given Height, assuming 100% eff. AKA Water Horsepower Brake HP

By This 0.746 746 33000 550 3960 103000 Pump eff.

Water HP

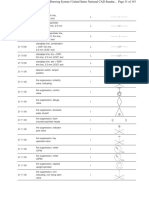

AIR BLOWER SIZING GUIDE

BLOWER MOTOR SIZE 1 HP 1-1/2 HP 2 HP 1 HP 1-1/2 HP 2 HP VOLTS 120V 120V 120V 240V 240V 240V AMPS 6.6 7.4 9.3 3.9 4.3 5.0 MAXIMUM INCHES OF WATER DEPTH 35 in. 45 in. 55 in. 30 in. 40 in. 50 in. JETS ONLY RECOMMENDED NUMBER OF JETS 510 915 1217 49 813 1217

BLOWER SIZING FORMULA Measure total depth of water in spa (not total spa depth) Add - 1 in. water for each 10 ft. of 2 in. air pipe Add 1/2 in. water for each 90 deg. 2 in. elbow Compare your total with maximum inches of water column and select that size or the next size higher blower than your total, in your selected voltage. The number of holes in the air channel (both floor and seat) should be approximately 1.6 sq. in. total plus or minus .5 1/8 in. hole = .0123 sq. in. 5/32 in. hole = .0192 sq. in. 3/16 in. hole = .0276 sq. in. 1/4 in. hole = .0491 sq. in.

595

ENGINEERING DATA

FRICTION/FLOW CHART FOR SCHEDULE 40 RIGID PVC PIPE *

3/4 in. pipe U.S. Gal.per min. Velocity feet per second Loss in feet 1 in. pipe Velocity feet per second Loss in feet 1-1/4 in. pipe Velocity feet per second Loss in feet 1-1/2 in. pipe Velocity feet per second Loss in feet 2 in. pipe Velocity feet per second Loss in feet 2-1/2 in. pipe Velocity feet per second Loss in feet 3 in. pipe Velocity feet per second Loss in feet 4 in. pipe Velocity feet per second Loss in feet 5 in. pipe Velocity feet per second Loss in feet 6 in. pipe Velocity feet per second Loss in feet U.S. Gal.per min.

ENGINEERING DATA, FRICTION FLOW

1 2 3 4 5 6 8 10 15 20 25 30 35 40 45 50 60 70 80 90 100 125 150 175 200 225 250 275 300 325 350 375 400 425 450 475 500 550 600 650 700 750 1000

.71 1.43 2.14 2.85 3.56 4.28 5.70 7.13 10.69

.40 1.44 3.05 5.19 7.85 11.01 18.75 28.34 60.06

.40 .80 1.20 1.60 2.00 2.41 3.21 4.01 6.01 8.02 10.02 12.03

.10 .35 .75 1.28 1.94 2.71 4.62 6.99 14.81 25.24 38.16 53.48

0.26 .51 .77 1.03 1.28 1.54 2.05 2.57 3.85 5.13 6.41 7.70 8.98 10.26 11.54 12.83

0.03 .12 .25 .43 .65 .92 1.56 2.36 5.00 8.52 12.88 18.06 24.03 30.77 38.27 46.51 .36 .53 .71 .89 1.07 1.43 1.78 2.67 3.56 4.45 5.34 6.24 7.13 8.02 8.91 10.69 .05 .10 .18 .27 .38 .64 .97 2.06 3.51 5.31 7.44 9.89 12.67 15.76 19.16 26.85 .50 .60 .80 1.00 1.50 2.00 2.51 3.01 3.51 4.01 4.51 5.01 6.01 7.01 8.02 9.02 10.02 .07 .09 .16 .24 .51 .87 1.31 1.83 2.44 3.13 3.89 4.72 6.62 8.81 11.28 14.03 17.06 .32 .38 .51 .64 .96 1.28 1.60 1.92 2.24 2.57 2.89 3.21 3.85 4.49 5.13 5.77 6.41 8.02 9.62 .02 .03 .05 .08 .17 .29 .44 .62 .82 1.06 1.31 1.60 2.24 2.98 3.81 4.74 5.76 8.71 12.20 .22 .27 .36 .45 .67 .89 1.11 1.34 1.56 1.78 2.00 2.23 2.67 3.12 3.56 4.01 4.45 5.57 6.68 7.79 8.91 10.02 11.13 .01 .01 .02 .03 .07 .12 .18 .26 .34 .43 .54 .66 .92 1.23 1.57 1.95 2.37 3.59 5.03 6.69 8.56 10.65 12.95 .50 .63 .75 .88 1.00 1.13 1.25 1.50 1.75 2.00 2.25 2.51 3.13 3.76 4.38 5.01 5.64 6.26 6.89 7.52 8.14 8.77 9.39 10.02 .03 .04 .06 .08 .11 .13 .16 .23 .30 .39 .48 .59 .88 1.24 1.65 2.11 2.63 3.19 3.81 4.48 5.19 5.95 6.77 7.63 .48 .56 .64 .72 .80 .96 1.12 1.28 1.44 1.60 2.00 2.41 2.81 3.21 3.61 4.01 4.41 4.81 5.21 5.61 6.01 6.41 6.81 7.22 7.62 8.02 8.82 9.62 .02 .03 .04 .05 .05 .08 .10 .13 .16 .20 .30 .42 .56 .71 .89 1.08 1.29 1.51 1.75 2.01 2.28 2.57 2.88 3.20 3.54 3.89 4.64 5.46 .56 .67 .78 .89 1.00 1.11 1.39 1.67 1.95 2.23 2.51 2.78 3.06 3.34 3.62 3.90 4.18 4.45 4.73 5.01 5.29 5.57 6.12 6.68 7.24 7.79 8.35 11.13 .02 .03 .04 .05 .07 0.08 .12 .17 .23 .29 .37 .44 .53 .62 .72 .83 .94 1.06 1.19 1.32 1.46 1.60 1.91 2.25 2.61 2.99 3.40 5.79

1 2 3 4 5 6 8 10 15 20 25 30 35 40 45 50 60 70 80 90 100 125 150 175 200 225 250 275 300 325 350 375 400 425 450 475 500 550 600 650 700 750 1000

596

* Friction loss of water in feet per 100 feet length of pipe. Based on Williams & Hazen formula using constant 150. * Recommended operating flow velocities indicated by boxed areas.

You might also like

- Features and ComponentsDocument11 pagesFeatures and ComponentsJay SuguitanNo ratings yet

- SymbolDocument25 pagesSymbolJay SuguitanNo ratings yet

- AMCA - Certified ProductsDocument13 pagesAMCA - Certified ProductsJay SuguitanNo ratings yet

- Ashrae 36 PDFDocument66 pagesAshrae 36 PDFJay SuguitanNo ratings yet

- Air Changes Per HoursDocument1 pageAir Changes Per Hoursmpwasa100% (3)

- Adm Apn005 enDocument8 pagesAdm Apn005 enNeal JohnsonNo ratings yet

- 5 Room Requirements FormDocument1 page5 Room Requirements FormJay SuguitanNo ratings yet

- Commercial Electric Water Heater: Instruction ManualDocument20 pagesCommercial Electric Water Heater: Instruction ManualJay SuguitanNo ratings yet

- Reason For InvitationDocument2 pagesReason For InvitationKevin Nave RiveraNo ratings yet

- Circuit - Low Suction Superheat - Low Saturated Suction TempDocument3 pagesCircuit - Low Suction Superheat - Low Saturated Suction TempJay SuguitanNo ratings yet

- (H) 8x6x10F - 8100 SERIES: FP 2.1 A-C Fire Pump SystemsDocument1 page(H) 8x6x10F - 8100 SERIES: FP 2.1 A-C Fire Pump SystemsJay SuguitanNo ratings yet

- Pipe Conversion PDFDocument1 pagePipe Conversion PDFJay SuguitanNo ratings yet

- Circuit - Low Suction Superheat - Low Saturated Suction TempDocument3 pagesCircuit - Low Suction Superheat - Low Saturated Suction TempJay SuguitanNo ratings yet

- 5 Room Requirements FormDocument1 page5 Room Requirements FormJay SuguitanNo ratings yet

- (H) 8x6x10F - 8100 SERIES: FP 2.1 A-C Fire Pump SystemsDocument1 page(H) 8x6x10F - 8100 SERIES: FP 2.1 A-C Fire Pump SystemsJay SuguitanNo ratings yet

- Duct Conversion PDFDocument1 pageDuct Conversion PDFJay SuguitanNo ratings yet

- 1.8 Using Documentation Resources in Hap: Getting StartedDocument9 pages1.8 Using Documentation Resources in Hap: Getting StartedJay SuguitanNo ratings yet

- LegendDocument17 pagesLegendJay SuguitanNo ratings yet

- Max Piping Oper PressDocument8 pagesMax Piping Oper PressSandi ApriandiNo ratings yet

- EWHDocument4 pagesEWHJay SuguitanNo ratings yet

- Duct ConversionDocument1 pageDuct ConversionJay SuguitanNo ratings yet

- Pipe ConversionDocument1 pagePipe ConversionJay SuguitanNo ratings yet

- Max Piping Oper PressDocument8 pagesMax Piping Oper PressSandi ApriandiNo ratings yet

- Commercial Vertical Round Electric BruteDocument4 pagesCommercial Vertical Round Electric BruteJay SuguitanNo ratings yet

- Seamless Pipes and Tubes For The Chemical Industry: (Stainless Steel and Ni-Based Alloys)Document16 pagesSeamless Pipes and Tubes For The Chemical Industry: (Stainless Steel and Ni-Based Alloys)Jay SuguitanNo ratings yet

- CI-245 - Micro-Lok® HP BrochureDocument12 pagesCI-245 - Micro-Lok® HP BrochureJay SuguitanNo ratings yet

- FMDS0732 Factory Mutual Data Sheet 7-32Document50 pagesFMDS0732 Factory Mutual Data Sheet 7-32Jay Suguitan100% (1)

- Technology of Balancing - Chapter5Document3 pagesTechnology of Balancing - Chapter5Jay SuguitanNo ratings yet

- Korea Seal Tech Gasket GuideDocument42 pagesKorea Seal Tech Gasket Guidemihir_jha2No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MATH2070 Computer Project: Organise Porject FoldDocument4 pagesMATH2070 Computer Project: Organise Porject FoldAbdul Muqsait KenyeNo ratings yet

- Excavator Loading To Truck TrailerDocument12 pagesExcavator Loading To Truck TrailerThy RonNo ratings yet

- ASME Y14.6-2001 (R2007), Screw Thread RepresentationDocument27 pagesASME Y14.6-2001 (R2007), Screw Thread RepresentationDerekNo ratings yet

- Tata Chemicals Yearly Reports 2019 20Document340 pagesTata Chemicals Yearly Reports 2019 20AkchikaNo ratings yet

- Craft's Folder StructureDocument2 pagesCraft's Folder StructureWowNo ratings yet

- Econ Old Test 2Document7 pagesEcon Old Test 2Homer ViningNo ratings yet

- Database Chapter 11 MCQs and True/FalseDocument2 pagesDatabase Chapter 11 MCQs and True/FalseGauravNo ratings yet

- Globalisation - Theories of Digital CommunicationDocument12 pagesGlobalisation - Theories of Digital CommunicationDiya Patel-10SNo ratings yet

- 1990-1994 Electrical Wiring - DiagramsDocument13 pages1990-1994 Electrical Wiring - Diagramsal exNo ratings yet

- Usa Easa 145Document31 pagesUsa Easa 145Surya VenkatNo ratings yet

- Understanding CTS Log MessagesDocument63 pagesUnderstanding CTS Log MessagesStudentNo ratings yet

- CompactLogix 5480 Controller Sales GuideDocument2 pagesCompactLogix 5480 Controller Sales GuideMora ArthaNo ratings yet

- Resume Ajeet KumarDocument2 pagesResume Ajeet KumarEr Suraj KumarNo ratings yet

- Chapter 2a Non Structured DataRozianiwatiDocument43 pagesChapter 2a Non Structured DataRozianiwatiNur AnisaNo ratings yet

- Instrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1ZDocument24 pagesInstrumentos de Medición y Herramientas de Precisión Starrett DIAl TEST INDICATOR 196 A1Zmicmarley2012No ratings yet

- RAP Submission Form, OBIDocument3 pagesRAP Submission Form, OBIAhmed MustafaNo ratings yet

- RTL8316C GR RealtekDocument93 pagesRTL8316C GR RealtekMaugrys CastilloNo ratings yet

- Bank Statement AnalysisDocument26 pagesBank Statement AnalysisAishwarya ManoharNo ratings yet

- 04 Dasmarinas Vs Reyes GR No 108229Document2 pages04 Dasmarinas Vs Reyes GR No 108229Victoria Melissa Cortejos PulidoNo ratings yet

- Jurisdiction On Criminal Cases and PrinciplesDocument6 pagesJurisdiction On Criminal Cases and PrinciplesJeffrey Garcia IlaganNo ratings yet

- Eritrea and Ethiopia Beyond The Impasse PDFDocument12 pagesEritrea and Ethiopia Beyond The Impasse PDFThe Ethiopian AffairNo ratings yet

- 7458-PM Putting The Pieces TogetherDocument11 pages7458-PM Putting The Pieces Togethermello06No ratings yet

- 2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoDocument12 pages2CG ELTT2 KS TitanMagazine Anazelle-Shan PromoJohn SmithNo ratings yet

- High Altitude Compensator Manual 10-2011Document4 pagesHigh Altitude Compensator Manual 10-2011Adem NuriyeNo ratings yet

- Diana's Innermost House: MagazineDocument42 pagesDiana's Innermost House: MagazinealexgoagaNo ratings yet

- Conplast SP430 0407Document4 pagesConplast SP430 0407Harz IndNo ratings yet

- NAC Case Study AnalysisDocument25 pagesNAC Case Study AnalysisSushma chhetriNo ratings yet

- L-1 Linear Algebra Howard Anton Lectures Slides For StudentDocument19 pagesL-1 Linear Algebra Howard Anton Lectures Slides For StudentHasnain AbbasiNo ratings yet

- Account STMT XX0226 19122023Document13 pagesAccount STMT XX0226 19122023rdineshyNo ratings yet

- CCT AsqDocument12 pagesCCT Asqlcando100% (1)