Professional Documents

Culture Documents

Copper Thickness FAQ

Uploaded by

hlgc63Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copper Thickness FAQ

Uploaded by

hlgc63Copyright:

Available Formats

7/17/13

Printed Circuit Boards - Buy Custom PCB Prototypes and Production Circuit Boards Online with our Instant PCB Quote | PCB Universe

Toll Free: 888-775-PC BU ( 7228) | E-mail Us PC B U n iv er s e Call today for a fast PCB quote VA NC O U VER, WA SHINGTO N U SA Local: 360-256-7222 E-Fax: 503-296-2925

HOME

PCB QUOTE

RIGID PCBS

FLEX CIRCUITS

FAQ

OUR ADVANTAGE

ABOUT

CONTACT

MY ACCOUNT

FREE QUOTE

Coppe r Thickne ss FAQ

The most common unit of measure for the copper thickness on a printed circuit board is ounces (oz). But how thick is that? Its the resulting thickness when 1 oz of copper is pressed flat and spread evenly over a one square foot area. This equals 1.37 mils (1.37 thousandths of an inch). Of course not everyone thinks in mils so please refer to the chart below to convert into your favorite unit of measure.

ARTICLES Array Design Tips Controlled Dielectric or Controlled Impedance? Copper Thickness F AQ Countersink vs. Counterbore Via Tenting, Plugging, and F illing

1 o z C o pper Th ic kn es s C o n v er s io n 1 1.37 0.00137 0.0347 34.79 oz mils (thousandths of an inch) inch mm m (micron/micro meter)

*To determine the thickness of 4 oz, simply multiply 1 oz thickness x 4. 1.37 mil x 4 = 5.48 mils = 4 oz

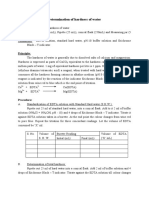

Most PCBs are constructed with 1 oz copper thickness. At PCB Universe, if we are not given specific specs, we will assume 1 oz when quoting and building your design. If you have determined that your design requires more current than 1 oz can carry, youll need to consider increasing the copper weight or increasing the width of your traces. Of course the thicker the copper the higher the cost, but there are certainly times where this is necessary. The cost increase is not only due to the raw material costs but processing thicker copper weights takes more time and is a little trickier to do. Keep the following chart in mind when designing your board. The more space you can allow between copper features the better. Etching the spaces (air gap) between traces is more difficult than etching a trace of the same width as your space.

Cu Weight

Gen er al Gu idelin e fo r Min Spac in g by C o pper Weig h t *Tighter spacing is possible but it will require an engineering review. These numbers are Min Recommended Space given as guidelines to assist you when setting between Copper Features your design rules. Allowing as much space as possible between copper elements will 1 oz 3.5 mil (0.089 mm) yield a more robust final product and will be cheaper to manufacture in the long term. 2 oz 3 oz 4 oz 8 mil 10 mil 14 mil (0.203 mm) (0.254 mm) (0.355 mm)

Why do I need to allow for more space between copper features when ordering thicker copper? Glad you asked! Bare Laminate

www.pcbuniverse.com/articles.php?a=4

1/3

7/17/13

Printed Circuit Boards - Buy Custom PCB Prototypes and Production Circuit Boards Online with our Instant PCB Quote | PCB Universe

Printed circuit board material is purchased from the laminate supplier pre-clad with copper on both sides. The laminate looks like a solid sheet of copper. This preclad material comes in various laminate and copper thicknesses so PCBs can be constructed with different thicknesses and finished copper weights. If your target finished copper thickness is 1 oz, well start with a oz sheet of material. This is oz on each side.

Imaging Since the production panels are completely covered with copper, the excess copper needs to be removed to reveal your design. To do this, a 1:1 size image of your design is photo plotted onto a film. The copper clad panel is coated with an etch-resistant material and your image is then transferred onto the etch resist.

Etching Next, the panel is submerged in a chemical bath where only the protected areas of the panel will have copper

www.pcbuniverse.com/articles.php?a=4

2/3

7/17/13

Printed Circuit Boards - Buy Custom PCB Prototypes and Production Circuit Boards Online with our Instant PCB Quote | PCB Universe

remaining. This is where the spacing between your copper features are critical. Since etching is a subtractive process, meaning excess material is removed, there is no way to prevent the chemical solution from removing the sides of the traces as it etches down toward the bare laminate.

As soon as the chemicals begin etching down toward the laminate, they also begin etching laterally underneath the resist. Since the copper closest to the resist will be exposed longest, these areas will have the most lateral etching resulting in a trapezoidal shape to copper features. As you can imagine, the thicker the copper, the more time it will take for the solution to etch all the way down to the bare laminate to define your pattern. One of the many things that is done during the tooling and setup of your order is the size of your copper features are slightly increased to compensate for lateral etching. This compensation will reduce the spacing between features. This, combined with the longer required time spent in the etchant, is why more space is needed between elements on thicker copper boards. If elements are too close together, it wont be possible to etch down to the laminate before the copper features are reduced too significantly or are etched

completely away.

Home | PCB Articles | Printed Circuit Boards | How To Order | FAQ | Glossary | Testimonials | BLOG | Privacy | Contact Us

Copyr ight 2013 PCB Univer se. All r ights r eser ved.

www.pcbuniverse.com/articles.php?a=4

3/3

You might also like

- What Functions Does The Copper Layer in PCB OfferDocument4 pagesWhat Functions Does The Copper Layer in PCB OfferjackNo ratings yet

- What Is 0.5 Oz PCBDocument4 pagesWhat Is 0.5 Oz PCBjackNo ratings yet

- Introduction To Metal EtchingDocument2 pagesIntroduction To Metal EtchingfoobiedotNo ratings yet

- How Thick Is The Copper On A 1 Oz Copper PCB in MMDocument13 pagesHow Thick Is The Copper On A 1 Oz Copper PCB in MMjackNo ratings yet

- How Thick Should A PCB BeDocument12 pagesHow Thick Should A PCB BejackNo ratings yet

- How To Choose Flex PCB Thickness For Your Electronic DeviceDocument12 pagesHow To Choose Flex PCB Thickness For Your Electronic DevicejackNo ratings yet

- How Thick Is The 5oz PCBDocument5 pagesHow Thick Is The 5oz PCBjackNo ratings yet

- Top Things To Know About PCB Board Thickness ToleranceDocument5 pagesTop Things To Know About PCB Board Thickness TolerancejackNo ratings yet

- How To Design Thickness For PCBsDocument14 pagesHow To Design Thickness For PCBsjackNo ratings yet

- MultiSIM - PCB Layout PDFDocument29 pagesMultiSIM - PCB Layout PDFRomeu Corradi JúniorNo ratings yet

- What Is PCB Slot and Cutouts PCBDocument8 pagesWhat Is PCB Slot and Cutouts PCBjackNo ratings yet

- What Is A Copper Trace PCB and Why Is It ImportantDocument7 pagesWhat Is A Copper Trace PCB and Why Is It ImportantjackNo ratings yet

- Why 9oz PCB Is Best For YouDocument5 pagesWhy 9oz PCB Is Best For YoujackNo ratings yet

- PCB ProcessDocument10 pagesPCB ProcessChetan AwasthiNo ratings yet

- How To Make A Bendable PCB More FlexibleDocument4 pagesHow To Make A Bendable PCB More FlexiblejackNo ratings yet

- 2oz Copper PCB Thickness and Its Design GuidelinesDocument14 pages2oz Copper PCB Thickness and Its Design GuidelinesjackNo ratings yet

- Why You Should Use 6oz PCB For Your DevicesDocument4 pagesWhy You Should Use 6oz PCB For Your DevicesjackNo ratings yet

- The Manufacturing Process of Stencil ElectronicsDocument5 pagesThe Manufacturing Process of Stencil ElectronicsjackNo ratings yet

- The Importance of PCB Inner Layer ClearanceDocument5 pagesThe Importance of PCB Inner Layer ClearancejackNo ratings yet

- What Is The Difference Between Flex Board Design and Rigid-Flex DesignDocument22 pagesWhat Is The Difference Between Flex Board Design and Rigid-Flex DesignjackNo ratings yet

- PCB Design WorkshopDocument18 pagesPCB Design WorkshopPrasun SinhaNo ratings yet

- Heavy Copper PCB Manufacturing and Design GuidelinesDocument15 pagesHeavy Copper PCB Manufacturing and Design GuidelinesjackNo ratings yet

- Sheet Metal Design Guidelines - Design For ManufacturingDocument13 pagesSheet Metal Design Guidelines - Design For ManufacturingShashank Maheshwari100% (1)

- PCB ManufacturingDocument7 pagesPCB ManufacturingAbhishek SharmaNo ratings yet

- Trade 1 PDFDocument8 pagesTrade 1 PDFRajveer Singh SachdevNo ratings yet

- WET PCB Fabrication ProcessDocument14 pagesWET PCB Fabrication Processwebip33713100% (1)

- How 12 Oz Copper PCB Increases Efficiency in Electronic DevicesDocument6 pagesHow 12 Oz Copper PCB Increases Efficiency in Electronic DevicesjackNo ratings yet

- PCB Design WorkshopDocument18 pagesPCB Design WorkshopPrasun SinhaNo ratings yet

- Annular Ring Via A Comprehensive OverviewDocument10 pagesAnnular Ring Via A Comprehensive OverviewjackNo ratings yet

- Enclosure Design Basics: © Protocase Inc. All Rights Reserved Document Edition - 1.2 Last Updated: March, 2007Document12 pagesEnclosure Design Basics: © Protocase Inc. All Rights Reserved Document Edition - 1.2 Last Updated: March, 200796chaitanya96No ratings yet

- Steps For PCB DesignDocument6 pagesSteps For PCB DesignAnkit AgrawalNo ratings yet

- Copper Foil WeightxDocument4 pagesCopper Foil Weightxjav_ra993986No ratings yet

- How Is Thick 0.093 Inches An In-Depth LookDocument9 pagesHow Is Thick 0.093 Inches An In-Depth LookjackNo ratings yet

- Types and Applications of A Special PCBDocument6 pagesTypes and Applications of A Special PCBjackNo ratings yet

- The Impact of Bent PCB - How To Prevent ItDocument5 pagesThe Impact of Bent PCB - How To Prevent ItjackNo ratings yet

- Printed Circuit Board: Presented by Ruby Kumari B.SC (MATHS), B.E (ECE)Document75 pagesPrinted Circuit Board: Presented by Ruby Kumari B.SC (MATHS), B.E (ECE)Ruby Pathak100% (2)

- What Is The Significance of ENIG Plating ThicknessDocument4 pagesWhat Is The Significance of ENIG Plating ThicknessjackNo ratings yet

- How Thick Is 3 Oz Copper in PCBDocument13 pagesHow Thick Is 3 Oz Copper in PCBjackNo ratings yet

- Mechanical Engineering Manufacturing-Process Machine-Drawing Notes PDFDocument10 pagesMechanical Engineering Manufacturing-Process Machine-Drawing Notes PDFahmed titoNo ratings yet

- Sheet Metal BasicsDocument16 pagesSheet Metal BasicsvittlevishnuNo ratings yet

- Laser Cut SMT StencilsDocument4 pagesLaser Cut SMT StencilsAvadhutNo ratings yet

- Comparing Tinning Flux Vs Regular Flux What's The DifferenceDocument13 pagesComparing Tinning Flux Vs Regular Flux What's The DifferencejackNo ratings yet

- Make your own non-inductive graphite resistors from pencil leadsDocument12 pagesMake your own non-inductive graphite resistors from pencil leadsedalzurcNo ratings yet

- PCB Basics: Available Online atDocument17 pagesPCB Basics: Available Online atDineshNo ratings yet

- Explaining Via-Filling Plating in PCB Manufacturing ProcessDocument8 pagesExplaining Via-Filling Plating in PCB Manufacturing ProcessjackNo ratings yet

- 10 129Document15 pages10 129Vasanth PrasadNo ratings yet

- Sheet Metal Design1Document57 pagesSheet Metal Design1Mohamed ZeinNo ratings yet

- PCB Raw MaterialsDocument17 pagesPCB Raw MaterialsjackNo ratings yet

- PCB Basics: A Guide to Printed Circuit Board Components and TerminologyDocument10 pagesPCB Basics: A Guide to Printed Circuit Board Components and TerminologyTeenaNo ratings yet

- Stencil TechnologyDocument15 pagesStencil TechnologyVinceDeSilvaNo ratings yet

- Radial ApplianceDocument9 pagesRadial ApplianceCyrrexNo ratings yet

- All About Printed Circuit Board (PCB)Document8 pagesAll About Printed Circuit Board (PCB)Aspire_TechnologyNo ratings yet

- PDC Bits CourseDocument76 pagesPDC Bits CourseRobert Koch100% (1)

- PDC BitsDocument75 pagesPDC Bitsamin peyvand100% (1)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Mission Style Lamps and Shades: Eighteen Projects You Can Make at HomeFrom EverandMission Style Lamps and Shades: Eighteen Projects You Can Make at HomeNo ratings yet

- Design For Manufacturing Course - by DFRDocument257 pagesDesign For Manufacturing Course - by DFRhlgc63100% (2)

- Resistance Welding Electrodes - Do's and Don'TsDocument2 pagesResistance Welding Electrodes - Do's and Don'Tshlgc63No ratings yet

- Setting Up Package On Package Assembly Process r0Document1 pageSetting Up Package On Package Assembly Process r0hlgc63No ratings yet

- Design Checklist For Microcircuits 2203Document7 pagesDesign Checklist For Microcircuits 2203hlgc63No ratings yet

- Miyachi Fundamentals Resistance WeldingDocument8 pagesMiyachi Fundamentals Resistance Weldinghlgc63No ratings yet

- Stencil Aperture Shape DefinitionDocument3 pagesStencil Aperture Shape Definitionhlgc63No ratings yet

- Miyachi Fundamentals Resistance WeldingDocument8 pagesMiyachi Fundamentals Resistance Weldinghlgc63No ratings yet

- 2003 12 Tin WhiskersDocument5 pages2003 12 Tin Whiskershlgc63No ratings yet

- Screen Printing Small DieDocument6 pagesScreen Printing Small Diehlgc63No ratings yet

- PCB Book v5.0.4 e Demo WDocument56 pagesPCB Book v5.0.4 e Demo Whlgc63100% (1)

- Sweet 15 Traditions - EhowDocument6 pagesSweet 15 Traditions - Ehowhlgc63No ratings yet

- VirtualDJ 7 - User GuideDocument65 pagesVirtualDJ 7 - User GuideBastian Schweinsteiguer KolvemorNo ratings yet

- Automate Processes EdgeDocument10 pagesAutomate Processes Edgehlgc63No ratings yet

- Iondesign ChklistDocument1 pageIondesign Chklisthlgc63No ratings yet

- Wphs Chemistry Unit 5 Packet Stoichiometry: Bergmann-SamsDocument56 pagesWphs Chemistry Unit 5 Packet Stoichiometry: Bergmann-SamsShin SasakiNo ratings yet

- Waste Water TreatmentDocument10 pagesWaste Water TreatmentOms LdnsNo ratings yet

- Polymer Practice ProblemsDocument11 pagesPolymer Practice ProblemspolypolyyNo ratings yet

- 10 1002@cptc 201900068Document9 pages10 1002@cptc 201900068Alvaro Putra PrasetyaNo ratings yet

- Aromatic Compounds: NamingDocument13 pagesAromatic Compounds: NamingTanzimNo ratings yet

- 10 - SOT Question Paper End Sem 2012Document2 pages10 - SOT Question Paper End Sem 2012Harsh ThakurNo ratings yet

- O2 Concentrator Design for COPD PatientsDocument16 pagesO2 Concentrator Design for COPD PatientsSai ShivaNo ratings yet

- POGIL: Dynamic Equilibrium: Name - Regents Chemistry Unit 7: Part C: EquilibriumDocument5 pagesPOGIL: Dynamic Equilibrium: Name - Regents Chemistry Unit 7: Part C: EquilibriumsydNo ratings yet

- Oxidizer Classification Research Project: Tests and CriteriaDocument94 pagesOxidizer Classification Research Project: Tests and Criteriakdsessions100% (1)

- AMP MicroprojectDocument13 pagesAMP Microprojectprasad patil33% (3)

- Properties of Matter QuizDocument55 pagesProperties of Matter QuizLemuel Glenn BautistaNo ratings yet

- IIT Guwahati Green Chemistry ExamDocument3 pagesIIT Guwahati Green Chemistry ExamKotla NishanthNo ratings yet

- Ce 6021 RRS QBDocument32 pagesCe 6021 RRS QBdhivya100% (1)

- Benzalkonium ChlorideDocument1 pageBenzalkonium ChlorideVaibhav SankheNo ratings yet

- Titanium: A Strong yet Lightweight MetalDocument16 pagesTitanium: A Strong yet Lightweight Metalrifaldy100% (1)

- Factors Affecting Enzyme ActivityDocument32 pagesFactors Affecting Enzyme ActivityHus Arif100% (1)

- Mech Control of Corrosion On Underwater PilesDocument14 pagesMech Control of Corrosion On Underwater Pilesraghavendra ragguNo ratings yet

- Determination of Hardness of WaterDocument2 pagesDetermination of Hardness of WaterNitinSrivastavaNo ratings yet

- Electric Arc Welding or Smaw: Fernando O. Paras JRDocument17 pagesElectric Arc Welding or Smaw: Fernando O. Paras JRMirasol Nilo GumbaNo ratings yet

- Analytical Chemistry Lab: Gravimetric Estimation of Nickel (IIDocument11 pagesAnalytical Chemistry Lab: Gravimetric Estimation of Nickel (IIConnieNo ratings yet

- Chemistry Edexcel RevisionDocument3 pagesChemistry Edexcel RevisionchogoNo ratings yet

- MP Board Class 12 Chemistry Previous Year Paper 2018Document4 pagesMP Board Class 12 Chemistry Previous Year Paper 2018Varun PatidarNo ratings yet

- C146-94a (2014) Standard Test Methods For Chemical Analysis of Glass SandDocument12 pagesC146-94a (2014) Standard Test Methods For Chemical Analysis of Glass SandAhmed AlzubaidiNo ratings yet

- Weathering: Joshua Benedict H. RigorDocument23 pagesWeathering: Joshua Benedict H. RigorShairuz Caesar Briones DugayNo ratings yet

- Lipase-Catalyzed Processforbiodieselproduction:enzyme Immobilization, ProcesssimulationandoptimizationDocument16 pagesLipase-Catalyzed Processforbiodieselproduction:enzyme Immobilization, ProcesssimulationandoptimizationMichelli SantarelliNo ratings yet

- Classification Tests For Carbonyl and Hydroxyl GroupsDocument10 pagesClassification Tests For Carbonyl and Hydroxyl GroupsJennifer HerediaNo ratings yet

- Oxidation and ReductionDocument19 pagesOxidation and ReductionLaaria ChrisNo ratings yet

- Catalog Produk PT Dipa Puspa LabsainsDocument1,798 pagesCatalog Produk PT Dipa Puspa LabsainsMuh SyahrulNo ratings yet

- PropranololDocument6 pagesPropranololDaniel LawsonNo ratings yet

- Ball ValveDocument16 pagesBall ValveAdhie WaelacxhNo ratings yet