Professional Documents

Culture Documents

LV Insulator

Uploaded by

praveenniteenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LV Insulator

Uploaded by

praveenniteenCopyright:

Available Formats

TITLE: SPECIFICATION FOR LOW VOLTAGE INSULATORS (Shackle Insulators, L.

V)

Doc. No. Issue No. Revision No. Date of Issue Page 1 of 4

FOREWORD

This Specification has lays down requirements for low voltage insulators. It has been approved for use by KPLC/REA in purchasing the insulators. It shall be the responsibility of the manufacturer to ensure adequacy of design and good engineering practice in the manufacture of the Insulators for KPLC/REA. The manufacturer shall submit information which confirms satisfactory service experience with products which fall within the scope of this specification

1 SCOPE

This specification is for insulators for use on Low Voltage overhead lines and service lines operating at voltages up to and including 433 Volts and frequency of 50Hz

2 REFERENCES

The following documents were referred to during the preparation of this specification, and may be further consulted. In case of conflict, however, the provision of this specification shall take precedence. Unless otherwise specified, the latest revision, edition and amendments shall apply. (a) ES1 43-93: (b) BS 137: Line Insulators Insulators of ceramic material or glass for overhead lines with a nominal voltage greater than 1000V. A.C Insulator and Conductor Fittings for Overhead Power Lines.

(c) BS 3288:

3 TERMS AND DEFINITIONS

For the purpose of this specification, the definitions in the reference standards shall apply.

4 REQUIREMENTS

4.1 SERVICE CONDITIONS

The Insulators shall be suitable for continuous operation outdoors in tropical areas at altitudes of up to 2200m above sea level, Humidity of up to 90%, average ambient Specifications of Low Voltage Insulators

TITLE: SPECIFICATION FOR LOW VOLTAGE INSULATORS (Shackle Insulators, L.V)

Doc. No. Issue No. Revision No. Date of Issue Page 2 of 4

temperature of + 30oC with a minimum of 1oC and a maximum of + 40oC, Heavy saline conditions along the coast and tropical sunshine conditions.

4.2 MATERIAL AND CONSTRUCTION

4.2.1 The insulating material shall be porcelain. The porcelain shall be sound, free from flaws and blemishes, smoothly glazed and of uniform brown colour when finished. 4.2.2 The insulator shall be free from stresses due to expansion and contraction in any part which may lead to deterioration. 4.2.3 The hole in the insulator shall be smoothly radiused to present an even bearing surface to the steel bolt. 4.2.4 The insulator shall be of reel type

4.3 GENERAL CHARACTERISTICS

The dimensional, mechanical and electrical characteristics of the insulator shall be as follows:Length of insulator Outer diameter of insulator Diameter of through hole Conductor groove diameter Minimum failing load Minimum wet flashover voltage Minimum dry flashover voltage 65mm 76mm 17.5mm 9.5mm 15kN 9kV 17kV

5 TESTS AND INSPECTION

5.1 The finished insulator shall be tested in accordance with the requirements of this specification and the relevant requirements of BS 137-1. It shall be the responsibility of the manufacturer to perform or to have performed all the tests specified. The tests shall include the following:

5.1.1 Verification of Dimensions The dimension of the sample insulator shall be those stated in clause 4.3 with a tolerance of 5%. 5.1.2 Mechanical Failing Load

Specifications of Low Voltage Insulators

TITLE: SPECIFICATION FOR LOW VOLTAGE INSULATORS (Shackle Insulators, L.V)

Doc. No. Issue No. Revision No. Date of Issue Page 3 of 4

The insulator shall be mounted on an M16 bolt of adequate length in a rigidly held bracket. A flexible wire rope of not less than 12mm diameter shall be looped round the conductor groove, and shall be pulled at right angles to the bolt of the insulator bracket and in line with the bracket. The load shall be increased up to 15 kN at a steady rate and held at this load for a period of not less than 10 seconds. This test shall not cause fracture of the insulator.

5.1.3 Porosity Test

The insulator shall be tested in accordance with BS 137, Part 1 Clause 30 5.1.4 Certified true copies of previous test reports by relevant National Testing/Standards Authority of the country of manufacture (or ISO/IEC 17025 accredited laboratory) shall be submitted with the offer for evaluation (all in English Language). 5.1.5 Complete test reports for the insulator to be supplied shall be submitted to KPLC/REA for approval before shipment/delivery of the goods. KPLC/REA shall be invited (by the supplier) to witness tests at the factory before shipment

6 MARKING AND LABELLING

6.1 The following information shall be clearly and indelibly marked on the insulator i. ii. iii. iv. v. 6.2 Manufacturers Name or Trade mark Manufacturers type Designation Batch or Serial Number Specified Electrical Characteristics Specified Mechanical Load

Instructions for storage, handling and installation shall be included in each package, all in English Language.

THIS SPACE LEFT BLANK

Specifications of Low Voltage Insulators

TITLE: SPECIFICATION FOR LOW VOLTAGE INSULATORS (Shackle Insulators, L.V)

Doc. No. Issue No. Revision No. Date of Issue Page 4 of 4

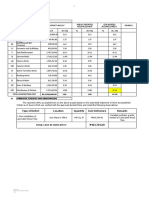

APPENDIX A:

Statement of Compliance (to be filled by the Supplier for all clauses and submitted for tender evaluation) Manufacturers catalogue, drawing, technical data or tests certificate Reference Page to support the offer.

Clause Number

Bidders offer

NB: - This schedule does not in any way substitute for detailed information required elsewhere in the specification.

Manufacturers Declaration: I on behalf of declare that the above specifications matrix conforms to a typical tender item type . as clearly marked in the attached technical brochures & drawings, and being offered for this tender. Signature Date Stamp

Specifications of Low Voltage Insulators

You might also like

- SPEC 11&33kV Composite Insulator PIN AUG 08Document7 pagesSPEC 11&33kV Composite Insulator PIN AUG 08jagadeesh_kumar_20No ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Disc InsulatorsDocument6 pagesDisc Insulatorsdaniel_sa2011No ratings yet

- Tech Specification of 33 KV 800amp Isolators With Without EB 17.06.19Document46 pagesTech Specification of 33 KV 800amp Isolators With Without EB 17.06.19SE O&M Circle Wardha WardhaNo ratings yet

- DEWA Instrumentation Cable SpecsDocument12 pagesDEWA Instrumentation Cable SpecsFlavioNo ratings yet

- Transformer - Technical Specification 10 To 1600KVADocument48 pagesTransformer - Technical Specification 10 To 1600KVAsepta ibnuNo ratings yet

- Tech - Spec. 1.1KV Grade Control Cable-2008Document4 pagesTech - Spec. 1.1KV Grade Control Cable-2008Pratik SarkarNo ratings yet

- Ddugjy 3 Phase DTsDocument32 pagesDdugjy 3 Phase DTspraveenkumarNo ratings yet

- 3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPDocument24 pages3 9031-11KV-Composite Polymer - Disc-Insulator Specifications GTPAnonymous 4kYNmixNo ratings yet

- Technical Specification For Outdoor Type Distribution Transformer 3 PHASE 500 KVA, 11 kV/433 VDocument32 pagesTechnical Specification For Outdoor Type Distribution Transformer 3 PHASE 500 KVA, 11 kV/433 Vhamida douidaNo ratings yet

- MGM Transformers Type Dry Guide SpecDocument4 pagesMGM Transformers Type Dry Guide Specmiguel.peralta.etmNo ratings yet

- 33 KV Potential TransformerDocument14 pages33 KV Potential TransformerTamal DuttaNo ratings yet

- Cable SpecificationDocument16 pagesCable SpecificationEngineering ServiceNo ratings yet

- Disc IsulatorDocument11 pagesDisc IsulatorganeshNo ratings yet

- Final Technical Specification For COMPRESSION CONNECTORS For Substation Equipment andDocument5 pagesFinal Technical Specification For COMPRESSION CONNECTORS For Substation Equipment andKiranNo ratings yet

- P 8-96 Disc Porcelain InsulatorsDocument14 pagesP 8-96 Disc Porcelain InsulatorsSyed Oon Haider ZaidiNo ratings yet

- Technical Specification For 1.1 KV Grade Single Core 400 Sq. MM LT Un-Armoured Xlpe Cable 1 .0. ScopeDocument8 pagesTechnical Specification For 1.1 KV Grade Single Core 400 Sq. MM LT Un-Armoured Xlpe Cable 1 .0. ScopePrakash RoutNo ratings yet

- EIL 6-51-0051 Rev. 6Document10 pagesEIL 6-51-0051 Rev. 6Manish Sharma100% (1)

- EP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..Document14 pagesEP-MS-P4-S3-075 - 11kV Heat Shrinkable Cable Terminations - KM Material..dimaomarNo ratings yet

- 11 TMSS 03 R0Document0 pages11 TMSS 03 R0renjithas2005No ratings yet

- 0.6 - 1 KV CV (XLPE-PVC) Rev.07Document20 pages0.6 - 1 KV CV (XLPE-PVC) Rev.07khamsone pengmanivongNo ratings yet

- Document No PCPL-0532-4-407-04-09 Cables Section - 4 PAGE: 1 of 2 ScopeDocument2 pagesDocument No PCPL-0532-4-407-04-09 Cables Section - 4 PAGE: 1 of 2 ScopetceterexNo ratings yet

- 11kV GIS Specification PDFDocument44 pages11kV GIS Specification PDFRiyazNo ratings yet

- Technical Specifications and GTP For 11KV XLPE Cable SP 574Document13 pagesTechnical Specifications and GTP For 11KV XLPE Cable SP 574hafizrahimmitNo ratings yet

- 1986-0040-EL-SPE03-0001 RA Specification For Bulk MaterialsDocument16 pages1986-0040-EL-SPE03-0001 RA Specification For Bulk MaterialsjmohammadrezaNo ratings yet

- Tech SpecificationsDocument47 pagesTech Specificationssureshn829No ratings yet

- Section 5 Solid Core Post Type InsulatorsDocument5 pagesSection 5 Solid Core Post Type Insulatorsthumula.rameshNo ratings yet

- 5110 0102 Epr1000cuDocument11 pages5110 0102 Epr1000cudevkavu1980No ratings yet

- 04 Electrical SpecificationDocument49 pages04 Electrical SpecificationVishal NarkhedeNo ratings yet

- Specification of 11kv SF6 Insulated Ring Main UnitsDocument8 pagesSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANNo ratings yet

- Detail Technical SpecificationDocument39 pagesDetail Technical Specificationshivmishra229No ratings yet

- Spec For High MastDocument61 pagesSpec For High MastVenkatRaghavendarNo ratings yet

- Section-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPEDocument5 pagesSection-6 Chapter-1 Part-I Technical Specification For 66 KV (Cross Linked Polyethylene Insulated Power Cable: 1.1 SCOPESandeep SharmaNo ratings yet

- Mahadiscom Dry TypeDocument22 pagesMahadiscom Dry TypeSANJAY BHATTACHARYANo ratings yet

- 11kv Disc Insulator GTP and SpecificationDocument10 pages11kv Disc Insulator GTP and SpecificationSatyaNo ratings yet

- Technical Specifications For Aerial BunchedDocument5 pagesTechnical Specifications For Aerial BunchedNazriNo ratings yet

- 11 TMSS 01 R0Document0 pages11 TMSS 01 R0renjithas2005No ratings yet

- Wave Trap Tech SpecsDocument13 pagesWave Trap Tech SpecsPrashant gaur100% (1)

- CSC 126R 1Document31 pagesCSC 126R 1design1No ratings yet

- Engineering Specification For MV SwitchgearDocument21 pagesEngineering Specification For MV SwitchgearSundaresan SabanayagamNo ratings yet

- 1.1Kv Grade Power and Control Cables: SectionDocument9 pages1.1Kv Grade Power and Control Cables: SectionevjbalaNo ratings yet

- 16461-Dry Type TransformerDocument8 pages16461-Dry Type TransformeruddinnadeemNo ratings yet

- Spec LV MV CABLESDocument5 pagesSpec LV MV CABLESFor AppsNo ratings yet

- Transformers SpecDocument13 pagesTransformers SpecAkshay PanttNo ratings yet

- 45 CBL 12-05-2020Document16 pages45 CBL 12-05-2020Deelip ZopeNo ratings yet

- FEWA LV Cable SpecsDocument46 pagesFEWA LV Cable Specsjtwani100% (2)

- Medium Voltage Cable SpecDocument3 pagesMedium Voltage Cable SpecOanh NguyenNo ratings yet

- Aisladores ABB - GSADocument16 pagesAisladores ABB - GSALeonel BermudezNo ratings yet

- A M 16 Electrical Installation July 09Document61 pagesA M 16 Electrical Installation July 09suneethmohanNo ratings yet

- D7) 33 C&R Panel For Infra PlanDocument54 pagesD7) 33 C&R Panel For Infra PlanPunit AswalNo ratings yet

- Msedcl Ts LT CablesDocument41 pagesMsedcl Ts LT CablesAshish bhattNo ratings yet

- Cable Low Voltage Specification PDFDocument12 pagesCable Low Voltage Specification PDFAndreas OktoraNo ratings yet

- 0.6 - 1 KV MICA-XLPE-LSHF CAT A MC Rev.02Document19 pages0.6 - 1 KV MICA-XLPE-LSHF CAT A MC Rev.02Supakanit LimsowanNo ratings yet

- Specification FOR Non-Hazardous Area Lighting Fixtures & Junction BoxesDocument5 pagesSpecification FOR Non-Hazardous Area Lighting Fixtures & Junction BoxesrukmagoudNo ratings yet

- Npcil TSDocument10 pagesNpcil TSBhavesh KeraliaNo ratings yet

- Conductors and Cables 16120 - Page 1 of 8: S0557-SPC-EL-01 REV 3Document8 pagesConductors and Cables 16120 - Page 1 of 8: S0557-SPC-EL-01 REV 3Ni ReNo ratings yet

- 151-5C - 600 - 1000cable-154Document4 pages151-5C - 600 - 1000cable-154高欣东No ratings yet

- Technical Data Book of NGRDocument54 pagesTechnical Data Book of NGRAlind Dubey0% (1)

- 11 TMSS 10 R0Document0 pages11 TMSS 10 R0renjithas2005No ratings yet

- Con 2018069Document81 pagesCon 2018069praveenniteenNo ratings yet

- LED RetrofitDocument2 pagesLED RetrofitpraveenniteenNo ratings yet

- The Prisma Medical Solution: Electrical Panels For Operating TheatresDocument12 pagesThe Prisma Medical Solution: Electrical Panels For Operating TheatrespraveenniteenNo ratings yet

- Handling of Absolute Photometry Data in EULUMDAT FilesDocument2 pagesHandling of Absolute Photometry Data in EULUMDAT Filesmoezzat13No ratings yet

- Test Before You TouchDocument2 pagesTest Before You TouchpraveenniteenNo ratings yet

- FSXN1 FSXNHDocument32 pagesFSXN1 FSXNHpraveenniteen0% (1)

- 05 High Voltage CablesDocument27 pages05 High Voltage Cablesdaegerte100% (5)

- Course Overview (Compatibility Mode)Document1 pageCourse Overview (Compatibility Mode)praveenniteenNo ratings yet

- 62656Document3 pages62656praveenniteenNo ratings yet

- Cable Sizing CalculationDocument1 pageCable Sizing CalculationhafizheryNo ratings yet

- Application of The RVSS To Replace Wye-Delta Motor StartingDocument2 pagesApplication of The RVSS To Replace Wye-Delta Motor StartingpraveenniteenNo ratings yet

- Grid PV EconomicsDocument9 pagesGrid PV EconomicsMarius AbduramanNo ratings yet

- Cable Sizing ImportantDocument6 pagesCable Sizing ImportantSreekanth RaveendranNo ratings yet

- Cable Sizing CalculationDocument1 pageCable Sizing CalculationhafizheryNo ratings yet

- Leader XlpeDocument62 pagesLeader Xlpepraveenniteen100% (1)

- Cable Correction FactorsDocument4 pagesCable Correction FactorspraveenniteenNo ratings yet

- Cable Correction FactorsDocument4 pagesCable Correction FactorspraveenniteenNo ratings yet

- IdiomsDocument11 pagesIdiomspraveenniteenNo ratings yet

- Leader XlpeDocument62 pagesLeader Xlpepraveenniteen100% (1)

- Gen Sizing Guide-SiemensDocument16 pagesGen Sizing Guide-Siemensdinesh_kp7647No ratings yet

- PC350 Prysmian Tech Cable Guide 2010 WebDocument136 pagesPC350 Prysmian Tech Cable Guide 2010 WebPeter Atkinson100% (1)

- 05 High Voltage CablesDocument27 pages05 High Voltage Cablesdaegerte100% (5)

- Katalog EngDocument8 pagesKatalog EngpraveenniteenNo ratings yet

- 1212-02-15kV Delta Delta Padmount TransformerDocument11 pages1212-02-15kV Delta Delta Padmount TransformerpraveenniteenNo ratings yet

- Cable Calculations Domestic)Document19 pagesCable Calculations Domestic)basak_pampaNo ratings yet

- 03 System Design LowDocument8 pages03 System Design LowpraveenniteenNo ratings yet

- Principles of Grounding DesignDocument16 pagesPrinciples of Grounding DesignvanpatoNo ratings yet

- Company Profile-WootzDocument113 pagesCompany Profile-Wootzaseem krishnaNo ratings yet

- Ann 5A Civil ScopeDocument49 pagesAnn 5A Civil ScopeahmadNo ratings yet

- Sheet Piles and DewateringDocument2 pagesSheet Piles and DewateringbayzuraNo ratings yet

- Bushcraft Pocket Knives Fixed Tactical Camp & OutdoorDocument48 pagesBushcraft Pocket Knives Fixed Tactical Camp & OutdoorOgnjen MočevičNo ratings yet

- SRWF Hvac CatalogueDocument12 pagesSRWF Hvac CataloguejengandxbNo ratings yet

- Samantha Alvarez Portfolio CompressedDocument11 pagesSamantha Alvarez Portfolio CompressedSam AlvarezNo ratings yet

- Format For Inspection of Maintenance Aspects of Completed PMGSY Works by Third Tier of QMDocument4 pagesFormat For Inspection of Maintenance Aspects of Completed PMGSY Works by Third Tier of QMAtul mishraNo ratings yet

- CHAPTER 1 - Introduction To Structural TheoryDocument11 pagesCHAPTER 1 - Introduction To Structural TheoryJoshua John JulioNo ratings yet

- Irc SP 53 2010Document30 pagesIrc SP 53 2010pradeepputta92567% (3)

- Construction and Building Materials: Guo Li, Lei Dong, Zhu'an Bai, Ming Lei, Jianmin DuDocument7 pagesConstruction and Building Materials: Guo Li, Lei Dong, Zhu'an Bai, Ming Lei, Jianmin DuHaniel FcNo ratings yet

- Nabil Abbas: New Ikea StoreDocument1 pageNabil Abbas: New Ikea Storewalid MegahedNo ratings yet

- 12-Samss-008 2020Document6 pages12-Samss-008 2020asimazami69No ratings yet

- LS Metasol CB QUICK SELECTION GUIDEDocument14 pagesLS Metasol CB QUICK SELECTION GUIDEmagsino ronaldNo ratings yet

- Model LT56 Series Special Sprinklers: Model FV Escutcheon Model FP EscutcheonDocument10 pagesModel LT56 Series Special Sprinklers: Model FV Escutcheon Model FP EscutcheonOscar RhenalsNo ratings yet

- WSDOT 2015 - Pavement PolicyDocument135 pagesWSDOT 2015 - Pavement PolicyPaulo PintoNo ratings yet

- Facade Issues - GRC ScreenDocument12 pagesFacade Issues - GRC Screenmohamed rafiNo ratings yet

- Damp Proof Ultra Warranty - TerracesDocument8 pagesDamp Proof Ultra Warranty - TerracesFjdjdNo ratings yet

- Dremel TrioDocument56 pagesDremel TrioSean Mclaren100% (1)

- Chirag 123Document28 pagesChirag 123Krishna MittalNo ratings yet

- Aor Cantilever 6m SignDocument6 pagesAor Cantilever 6m SignDaljit624No ratings yet

- Project ProposalDocument10 pagesProject ProposalPrincessNo ratings yet

- Reinforced Cement Concrete Work Rate Analysis Sheet 124Document4 pagesReinforced Cement Concrete Work Rate Analysis Sheet 124BVS NAGABABUNo ratings yet

- TR2381 Rev.7Document158 pagesTR2381 Rev.7Maffone Numerouno0% (1)

- Design of Concrete Structure: SyllabusDocument72 pagesDesign of Concrete Structure: Syllabusريام الموسويNo ratings yet

- Slab Design PDFDocument33 pagesSlab Design PDF1NT14CV031 CivilNo ratings yet

- Catalog PittsburghDocument32 pagesCatalog PittsburghFarras FauzanNo ratings yet

- Geology and Civil Engineering RelationshipDocument2 pagesGeology and Civil Engineering RelationshipCHAEYOUNG-AH MARR MENo ratings yet

- Peri Up: Access Technology For Construction Sites, Industry and Public AreasDocument52 pagesPeri Up: Access Technology For Construction Sites, Industry and Public AreasjoshNo ratings yet

- Sample LD ComputationDocument2 pagesSample LD ComputationkenvysNo ratings yet

- Construction Quality Control & Odit ProposelDocument7 pagesConstruction Quality Control & Odit ProposelHamayet RaselNo ratings yet