Professional Documents

Culture Documents

Solution

Uploaded by

chompink6900Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solution

Uploaded by

chompink6900Copyright:

Available Formats

TANK, API-650/653 Analysis Licensed To: Job: yyyy Date: 06/01/12

COADE, Inc. @1994-2008 Time: 08:35:23

ID: 4369 Ver: 3.10

COADE Engineering Software, Inc. Copyright @ 1994-2008 API-650/653 TANK Design/Analysis Program Message File API-650 11th Edition, June 2007 API-653 3rd Edition, Addendum 2, Nov. 2005 Job: C:\Documents and Settings\All Users\Application Data\COADE, In Date: 6/01/12 Time: 8:52:23 Ver 3.10 Note, this file is created by the solution module, and is an "internal" file. All values shown in this file are presented in the internal units (English) of the program. This file is for data verification purposes only, this data should not be included in any formal reports. WIND DATA PER SECT 3.9.7.1 Wind Velocity in Miles/Hour: Velocity Factor, (V/120)**2: Wind Pressure, including 10% + 5 psf: Wind Profile Area in sq.ft.: Horizontal Wind Moment (ft-lb): Wind Shear Force (lb): MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Bottom Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Bottom Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature:

100.66 0.70367 26.785 590.33 0.31614E+06 15812. 1 0.90122 0.99479 22831. 28283. 0.85000 2 0.90122 0.99479 22831. 28283. 0.85000 3 0.90122 0.99479 22831. 28283. 0.85000 4 0.90122 0.99479 22831. 28283. 0.85000 5 0.90122 0.99479 22831. 28283. 0.85000 6 0.90122 0.99479 22831. 28283. 0.85000 7 0.90122 0.99479

TANK, API-650/653 Analysis Licensed To: Job: yyyy Date: 06/01/12

Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used:

COADE, Inc. @1994-2008 Time: 08:35:23

22831. 28283. 0.85000 8 0.90122 0.99479 22831. 28283. 0.85000

ID: 4369 Ver: 3.10

MATERIAL VALUES FOR COURSE: Yield Strength Reduction Factor from Table M-1: H1 Reduction Factor due to temperature: Allowable Design Stress, Top Courses (psi): Allowable Test Stress (psi): Joint Efficiency Used: Thickness evaluation based on One Foot Method. "One Foot" Shell Course Thicknesses before Sect 3.6.1.1 check and round up. Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Course, Design Test Design Test Design Test Design Test Design Test Design Test Design Test Design Test Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness Thickness (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) (in) 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 0.1769 0.0441 0.1680 0.0374 0.1591 0.0307 0.1502 0.0240 0.1413 0.0173 0.1323 0.0107 0.1234 0.0040 0.1181 0.0000

Thickness(in) for each course. # DESIGN TEST USER INPUT 1 0.23622 0.23622 0.23622 2 0.19685 0.19685 0.23622 3 0.19685 0.19685 0.23622 4 0.19685 0.19685 0.23622 5 0.19685 0.19685 0.23622 6 0.19685 0.19685 0.23622 7 0.19685 0.19685 0.23622 8 0.19685 0.19685 0.23622 API-653 THICKNESS/CORROSION RESERVES Retiring Thickness Remaining Corrosion # Design Test Design Test (in) (in) (in) (in) 1 0.00000 0.00000 0.23622 0.23622 2 0.00000 0.00000 0.23622 0.23622 3 0.00000 0.00000 0.23622 0.23622 4 0.00000 0.00000 0.23622 0.23622 5 0.00000 0.00000 0.23622 0.23622 6 0.00000 0.00000 0.23622 0.23622 7 0.00000 0.00000 0.23622 0.23622 8 0.00000 0.00000 0.23622 0.23622 Allowed Fluid Heights (ft) for each course. # DESIGN TEST REQUIRED 1 66.226 175.05 33.465 2 44.484 146.04 28.543 3 44.484 146.04 23.622 4 44.484 146.04 18.701 5 44.484 146.04 13.780 6 44.484 146.04 8.8583 7 44.484 146.04 3.9370 8 44.484 146.04 0.00000

TANK, API-650/653 Analysis Licensed To: Job: yyyy Date: 06/01/12

COADE, Inc. @1994-2008 Time: 08:35:23

ID: 4369 Ver: 3.10

Table 5.1 limits were exceeded during the computations for the Annular bottom plate thickness (in) from Table 3-1 : Annular bot. plate width (in) per API650 3.5.2 : SHELL WEIGHTS (with Nozzles) Computed weight of shell (lb): Computed corroded shell weight (lb): Insulation weight, in shell weight (lb Computed C.G. of shell (ft): Weight of shell Used (lb): C.G. of shell Used (ft): 16477. 7669.5 1430.6 19.301 16477. 19.301 0.60385 257.07 3.9430 1 8 7 6 5 4 3 2 1 37.569 4.9213 4.9213 4.9213 4.9213 4.9213 4.9213 4.9213 3.1198

0.00000 0.00000

WIND GIRDER COMPUTATIONS Top Girder, required section modulus(in^3): Distance from top to intermediate wind girder (ft): Intermediate girder section modulus (in^3): TRANSFORMED SHELL COMPUTATIONS, Girder #: Trnsfrmd shell height below last girder(ft) Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): Individual transformed course & height (ft): THIS GIRDER IS NOT NECESSARY !!! SEISMIC EVALUATION - FLUID WEIGHTS Computed operating fluid weight (lb): Computed test fluid weight (lb): Computed empty fluid weight (lb):

0.38413E+06 0.35666E+06 0.00000

TANK, API-650/653 Analysis Licensed To: Job: yyyy Date: 06/01/12

===================================== TANK - Roof Design Data Design Roof Load (psf): SELF-SUPPORTING CONE ROOF Total weight of Roof Plates (lb): Corroded weight of Roof Plates (lb): 3.10.5.1 required roof thickness (in): Design Pressure, F.4.1 P (inches of Water): P (psi) : WIND OVERTURNING STABILITY CHECK Weight for anchorage (lb): MDL (ft-lb): MF (ft-lb): MPI (ft-lb): MW (ft-lb): wa (lb/ft): Design tension load per bolt (lb): Estimated Number of anchors: Anchors needed for Section 3.11 APPENDIX F CONSIDERATIONS Uplift Pressure Force (lb): Resisting Weight (lb) : Sections F.2 through F.6 can be used. Maximum Design Pressure, F.4.2 Pmax (inches of Water): Pmax (psi) : Design Pressure, F.4.1 P (inches of Water): P (psi) : Required Roof Compression Area F.5 Compression Area (in^2) from F.5.1 : Participating Area (in^2) from 3.10.5: Participating Area (in^2) from 3.10.6: FRANGIBLE JUNCTION LIMIT (3.10.2.5.3) Maximum Area at Junction (in^2):

COADE, Inc. @1994-2008 Time: 08:35:23

ID: 4369 Ver: 3.10

34.709

1674.3 1674.3 0.22569 56.534 2.0414 10140. 74850. 0.63645E+06 12933. 0.17242E+06 1858.9 7455.1 5

1752.0 20447.

22.889 0.82654 56.534 2.0414 0.33288E-02 0.44197 0.11625 0.55772

Failure Pressure f/ Compression Ring F.6 Failure Pressure (inches of water): 89.320 Failure Pressure (psi) : 3.2254 SEISMIC EVALUATION DETAILS Sp (design level peak accel for nonASCE): Ss (MCE at period of 0.2 seconds) : S0 (MCE at period of 0.0 seconds) : S1 (MCD at period of 1.0 seconds) : SDS (design spectral accel parameter) : FA (acceleration based site coefficient): FV (velocity based site coefficient) : TS ( FvS1 / FaSs ) : TC (convective sloshing period) : Site-Specific Ground Motion Ac (convective spectral accel parameter): Ai (impulsive spectral accel parameter) : Wc (effective convective liquid weight) : Wi (effective impulsive liquid weight) : Vc (convective liquid base shear) : Vi (impulsive liquid base shear) : 0.28000 0.70000 0.28000 0.35000 0.26000 1.0000 1.0000 0.50000 2.2209 0.41669E-01 0.41669E-01 38978. 0.34718E+06 1624.1 15319.

TANK, API-650/653 Analysis Licensed To: Job: yyyy Date: 06/01/12

V (total design base shear) Xc (ring wall convective moment arm) Xi (ring wall impulsive moment arm) XCS (slab convective moment arm) XIS (slab impulsive moment arm) XR (roof CG height from shell top) XS (shell CG) WS (shell+appurtenances weight) WR (roof, framing 10% snow weight) Mrw (ringwall overturning moment) Ms (slab overturning moment) AV (vertical acceleration parameter) Ge (effective specific gravity) ta (bottom thickness under shell) wa (resisting annulus force) wrs (roof load per unit circumference) Ws (tank weight + appurtenances) wt (tank + roof weight at shell base) J (the anchorage ratio) Wab (Minimum anchorage resistance) N (number of anchor bolts required) Pab (anchor seismic design load) Sc (shell compressive stress) Sa (shell allowable stress) Seismic shell stress check passed. Hoop Stress Determination Course Number Fluid depth to bottom of course(ft) Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Course Number Fluid depth to bottom of course(ft) Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Course Number Fluid depth to bottom of course(ft) Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Course Number Fluid depth to bottom of course(ft) Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Course Number Fluid depth to bottom of course(ft) Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Course Number Fluid depth to bottom of course(ft) Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Course Number Fluid depth to bottom of course(ft) : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : : :

COADE, Inc. @1994-2008 Time: 08:35:23

15405. 29.444 15.344 29.446 17.618 39.780 19.301 18683. 1764.4 0.24465E+06 0.27699E+06 0.36400E-01 1.0613 0.35433 671.18 5.7061 18683. 408.51 1.0453 2778.3 6.0000 21477. 650.28 10002. 7 3.9370 162.71 31.456 14.299 1004.7 27540. 6 8.8583 366.10 51.648 4.1934 1776.3 27540. 5 13.780 569.49 54.191 1.2299 3187.8 27540. 4 18.701 772.88 54.191 0.36089 4236.4 27540. 3 23.622 976.27 54.191 0.10655 4407.2 27540. 2 28.543 1179.7 54.191 0.33687E-01 5286.6 27540. 1 33.465

ID: 4369 Ver: 3.10

TANK, API-650/653 Analysis Licensed To: Job: yyyy Date: 06/01/12

Nh (hydrostatic component) Ni (impulsive component) Nc (convective component) Course Hoop Stress Course allowalbe hoop stress Sloshing wave height Required Freeboard Shear sliding resistant force : : : : : : : :

COADE, Inc. @1994-2008 Time: 08:35:23

1383.1 54.191 0.18194E-01 6168.0 27540. 1.4543 1.0180 0.11961E+06

ID: 4369 Ver: 3.10

ANCHOR BOLT DETAILS PER API-650, 3.12 W1 (lbs) .................... W2 (lbs) .................... W3 (lbs) .................... Bolt uplift reset for case: Test Pressure Initial Number of Anchors: Bolt Circle Circumference: Maximum Allowed Bolt Spacing: Case Design Pressure Test Pressure Failure Pressure Wind Loading Seismic OPE Seismic Test Design Press + Wind Load Design Press + Seismic OPE Design Press + Seismic Test Anchor Bolt Initial Design Case Design Pressure Test Pressure Failure Pressure Wind Loading Seismic OPE Seismic Test Design Press + Wind Load Design Press + Seismic OPE Design Press + Seismic Test Anchor Bolt Final Design Case Design Pressure Test Pressure Failure Pressure Wind Loading Seismic OPE Seismic Test Design Press + Wind Load Design Press + Seismic OPE Design Press + Seismic Test

9875.0 10140. 21252. 10.000 46.382 10.000

Uplift, Allowable, Load/Bolt 38721. 13518. 3872.1 0.00000 18024. 0.00000 96218. 30718. 9621.8 36575. 24574. 3657.5 56145. 24574. 5614.5 0.00000 24574. 0.00000 85435. 18024. 8543.5 0.10501E+06 24574. 10501. 0.00000 24574. 0.00000 Number, 10 10 10 10 10 10 10 10 10 Number, 10 10 10 10 10 10 10 10 10 Diameter, 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 Diameter, 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 0.94488 Stress 7987.6 0.00000 19849. 7544.9 11582. 0.00000 17624. 21661. 0.00000 Stress 7987.6 0.00000 19849. 7544.9 11582. 0.00000 17624. 21661. 0.00000

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

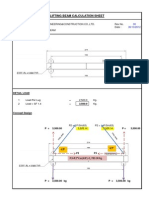

- Lifting Beam Calculation SheetDocument1 pageLifting Beam Calculation Sheetchompink6900No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Lifting Beam Cal 4Document1 pageLifting Beam Cal 4dd6077No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 1Document1 page1chompink6900No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- PCBDocument1 pagePCBchompink6900No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Cal Stru Case 1Document12 pagesCal Stru Case 1chompink6900No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 83e EnclrevDocument1 page83e Enclrevchompink6900No ratings yet

- LicenseDocument1 pageLicensechompink6900No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- BR 1887Document8 pagesBR 1887chompink6900No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Ultimate Bee Gees (CD 1)Document1 pageThe Ultimate Bee Gees (CD 1)chompink6900No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lifting Beam Calculation SheetDocument1 pageLifting Beam Calculation Sheetchompink6900No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 83e EnclrevDocument1 page83e Enclrevchompink6900No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Readme 1 STDocument1 pageReadme 1 STchompink6900No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CCK QuotationRev01Document3 pagesCCK QuotationRev01chompink6900No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Maintain TeklaStructures Form Request Improve WorkDocument1 pageMaintain TeklaStructures Form Request Improve Workchompink6900No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Drop Down ListDocument4 pagesDrop Down Listduazo2009No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- DEF File DescriptionDocument5 pagesDEF File Descriptionchompink6900No ratings yet

- KFT OfficeDocument20 pagesKFT Officechompink6900No ratings yet

- KLSDFNKLDocument1 pageKLSDFNKLShIvaleela ChoudaryNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- LiabilityDocument1 pageLiabilitychompink6900No ratings yet

- Model Basics ComponentsDocument1 pageModel Basics Componentsdd6077No ratings yet

- Maintenance RequestDocument1 pageMaintenance RequestAlex Estacio CNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cover Letter SHEETDocument1 pageCover Letter SHEETchompink6900No ratings yet

- SN 3Document1 pageSN 3chompink6900No ratings yet

- DROsDocument1 pageDROschompink6900No ratings yet

- ButtonsDocument1 pageButtonsDebbie MoleNo ratings yet

- Price Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost ItemDocument11 pagesPrice Summary Sheet: Currency (Baht) 1.direct Work Cost Offer Price Cost Itemchompink6900No ratings yet

- Cover PlateDocument1 pageCover Platechompink6900No ratings yet

- SN 3Document1 pageSN 3chompink6900No ratings yet

- Whats NewDocument2 pagesWhats Newchompink6900No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- SN 5Document1 pageSN 5chompink6900No ratings yet

- Concrete Pipe Installation Guide-CPMDocument17 pagesConcrete Pipe Installation Guide-CPMSankar CdmNo ratings yet

- Subnetting PracticeDocument5 pagesSubnetting PracticeUncleSamNo ratings yet

- RTJ Dimension ASME B16.5/B16.47Document1 pageRTJ Dimension ASME B16.5/B16.47parayilomer0% (1)

- Hdfs Default XML ParametersDocument14 pagesHdfs Default XML ParametersVinod BihalNo ratings yet

- 5SL43407RC Datasheet enDocument5 pages5SL43407RC Datasheet enDiana Martinez SifuentesNo ratings yet

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 pageChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimNo ratings yet

- Metronidazole AnalysisDocument5 pagesMetronidazole AnalysisHendri WasitoNo ratings yet

- CNA09016 SGDocument8 pagesCNA09016 SGSatyarth SampathNo ratings yet

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- AIR Modeller 75 2017-12-20 - 01Document68 pagesAIR Modeller 75 2017-12-20 - 01JoãoGilbertoAraújoPontes100% (4)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Equipment CapabilitesDocument19 pagesEquipment Capabilitesapi-1975359897% (194)

- Ball MillsDocument8 pagesBall MillsBoy Alfredo PangaribuanNo ratings yet

- Technical Report PDFDocument184 pagesTechnical Report PDFSrinivasan RajenderanNo ratings yet

- DiGas 4000 Light E 08.02Document2 pagesDiGas 4000 Light E 08.02manit1963No ratings yet

- Adobe Photoshop: The EditingDocument10 pagesAdobe Photoshop: The EditingMer Cjielo BalloonsNo ratings yet

- RT 50Document2 pagesRT 50valentin prouteauNo ratings yet

- Multi-disciplinary profile of IS/IT outsourcing researchDocument47 pagesMulti-disciplinary profile of IS/IT outsourcing researchIsabel MirandaNo ratings yet

- Textbook of Applied ElectronicsDocument8 pagesTextbook of Applied Electronicsshehnasheh99No ratings yet

- Emergency CallDocument6 pagesEmergency CallNugrohoNo ratings yet

- Acee 2018 039Document13 pagesAcee 2018 039threedlabsNo ratings yet

- The B-GON Solution: To Mist EliminationDocument20 pagesThe B-GON Solution: To Mist EliminationDimitris Sardis LNo ratings yet

- Dissolved OxygenDocument2 pagesDissolved OxygenAnonymous atBeojaNo ratings yet

- Introduction to Generators, Protection Schemes, Relays and MaintenanceDocument44 pagesIntroduction to Generators, Protection Schemes, Relays and MaintenancerahulNrana100% (1)

- Baja Parts Catalog PX250S Motorcycle VIN Prefix LUAHDocument20 pagesBaja Parts Catalog PX250S Motorcycle VIN Prefix LUAHholycostNo ratings yet

- Solution of EX2 Measurement of Liquid Electric C OnductivityDocument4 pagesSolution of EX2 Measurement of Liquid Electric C OnductivityArifiantoNo ratings yet

- Tli R3.0 PDFDocument6,465 pagesTli R3.0 PDFz_sadiq25% (4)

- JETL industrial wastewater treatment reportDocument6 pagesJETL industrial wastewater treatment reportPremKumarNo ratings yet

- Catalogo DeltaDocument2 pagesCatalogo DeltaHelena ChagasNo ratings yet

- Grove GMK 4080Document6 pagesGrove GMK 4080Deiver BarrazaNo ratings yet

- Chapter 4-EDocument42 pagesChapter 4-EMahrouz MadoNo ratings yet