Professional Documents

Culture Documents

Iso Manual

Uploaded by

Sanjay MalhotraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Iso Manual

Uploaded by

Sanjay MalhotraCopyright:

Available Formats

REVISION RECORD SHEET

TITLE : PROCEDURE FOR TOOL MANAGEMENT.

REV.NO 00 DESC. OF AMENDMENT PROCEDURE RESTATED AS PER QS 9000:1995 REQUIREMENTS. DATE OF AMENDMENT 16.03.1997

PR.NO : QP-23-01 PAGE NO : 1 OF 3 ISSUE NO : 01 REV NO : A DATE : 16.06.1997 REASON FOR AMENDMENT QS 9000:1995 UPDATION

DISTRIBUTED TO :

SL.NO DESIGNATION NAME & SIGNATURE OF THE RECEIVER

PREPARED BY:

APPROVED & REVIEWED AND RELEASE CONTROLLED BY: .

QUALITY ASSURANCE PROCEDURE

TITLE : Procedure for Tool Management.

Purpose Scope : :

PR.NO : PAGE NO : ISSUE NO : REV NO : DATE :

QP-23-01. 2 OF 3 01 A 16.06.1997

To establish a procedure for tool management & to ensure proper maintenance and manufacturing methodology for all tools. For all tools developed & manufactured in tool room. Dy. Manager (Tool Room) Tool shall be developed based on the tool manufacturing request form FM-23-05 submitted by the Engg. dept. alongwith the respective tool drawings. All tool Raw materials shall be procured only through approved sources. List of approved sources shall be maintained by the purchase dept., a copy of which shall be made available with Dy. Mgr. Tool Room . On receipt of materials , the same shall be inspected by the QA Dept. as per its respective Control Plan. On acceptance of the material it is issued to Tool Room. Tools shall be developed by issuing a tool work order to the respective tool room Operators approved by Dy. Mgr. Tool Room. This tool work order FM-23-01 will have the necessary sketches drawn out (source : Tool design Drgs. provided by Engg.) , the dimensions , the tolerances to be followed, specification of the material, the cut, the depth, the feed, the speed, to be followed & cross reference to the design Drg. no. for the particular tool being developed. The general work instructions for operating machines for various operations are as described in work instruction WI-23-01 to WI-23-34 respectively. On completion of the tool work order it shall be submitted to Tool Room Inspector for Inspection. On acceptance the tool inspection report shall be endorsed by Tool Room Inspector and the report will be maintained by Dy. Mgr. Tool Room. On deviation from specifications necessary disposition action shall be taken , inspected , approval sought before incorporating it into the list of tools. The master list of all tools with identification no. shall be maintained by the Dy. Mgr. Tool Room. Tool shall be identified as per work instruction no. WI-23-28. Tool History Card FM-23-02 shall be opened with all the necessary details like tool no.,its originating Drg. no., date developed and date inspected & approved. Tool shall be stored in the tool crib at a specified location. The layout of the tool crib with the location of tools shall be displayed in the tool crib for easy retrieval. Tools shall be issued either for trial run or for regular production upon the request made by the production incharge through tool issue form FM-23-03.

Responsibility : Procedure :

+ +

QUALITY ASSURANCE PROCEDURE

PR.NO : PAGE NO : ISSUE NO : REV NO :

QP-23-01. 3 OF 3 01 A

TITLE : Procedure for Tool Management.

DATE

: 16.06.1997

The issue of the tool shall be recorded in the tool history card. Updation of the tool history card shall be done : When it is launched for production after trial for the first time. On any rectification

Tool set up shall be done by respective operators of the machine or team leaders. After completion of production, tools shall be received back to tool crib with the last off inspection report approved by QA.Based on this report if the tool report is OK it shall be directly stored in the tool crib. If not necessary modification/ rectification / repair / rework shall be carried out, submit to Tool Room Inspector for inspection and validate the same(FM-23-04). All this shall be recorded in the tool history card. Dy. Mgr. (Tool Room) shall be responsible for the same. The Inspection status on the tool shall be identified as follows : OK Tool For Rework Scrap Green Point Yellow Point Red Point

Scrap tool shall be quarantined to a defined area. Whenever there is a refurbishment of existing tool, the Engg. shall be informed and information shall be gained for any PPAP requirements and adhered ,if so. Tool history card shall be reviewed after every 6 months for tool study to establish the tool life and for continuous improvement. Based on the review, tools that are idle for a period of more than 6 months shall be checked for its physical & dimensional conditions and duly approved by Tool Room Inspector . Record shall be evident on the tool history card. Tools sent for manufacturing to any sub contractor shall be received , inspected, approved and recorded as per the system described above. Tool history card shall be updated mentioning the sub contractors name All repair or manufacturing jobs related to machineries i.e. jobs given by Maint. deptt. ,shall be given to respective operators with a work order no. FM-23-01 duly approved by Dy. Mgr. Tool Room. Inspection in such cases will be done by maint. deptt. only and acceptance of the job shall be acknowledged on the tool work order.

+

Perishable Tools : All perishable tools used for production are listed in the form no. FM-23-06 . Based on past data & experience, consumption rate and productivity rate of such tools is established. All perishable tools, will be issued from tool crib and shall be recorded on register RG-23-01 .

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Legal MaximsDocument7 pagesLegal MaximsSanjay MalhotraNo ratings yet

- Food ProcessingDocument5 pagesFood ProcessingMarycris Doria100% (2)

- Structure Dismantling JSADocument2 pagesStructure Dismantling JSAtnssbhaskar69% (13)

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Document6 pagesProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- Bank Statement LetterDocument2 pagesBank Statement LetterSanjay MalhotraNo ratings yet

- Electric Vehicle BatteryDocument15 pagesElectric Vehicle BatteryTotal Acess100% (1)

- Yoga Nidra MethodDocument13 pagesYoga Nidra MethodPrahlad Basnet100% (2)

- List Manufacturers Empanelled VendorsDocument14 pagesList Manufacturers Empanelled VendorsSanjay MalhotraNo ratings yet

- Ts CertificateDocument1 pageTs CertificateSanjay MalhotraNo ratings yet

- Measure Words Chinese AssignmentDocument7 pagesMeasure Words Chinese AssignmentSanjay MalhotraNo ratings yet

- Project 5Document1 pageProject 5Sanjay MalhotraNo ratings yet

- BiochemistryDocument1 pageBiochemistrySanjay MalhotraNo ratings yet

- Project at Glance: Project: Material Handling, Automation and Special Purpose Machines. Promoters: MRDocument2 pagesProject at Glance: Project: Material Handling, Automation and Special Purpose Machines. Promoters: MRSanjay MalhotraNo ratings yet

- Consultants List S.No. Name of The Consultants Job Title Address Office Phone Mobile No. Fax 1 Spectral Services Consultants Pvt. LTDDocument2 pagesConsultants List S.No. Name of The Consultants Job Title Address Office Phone Mobile No. Fax 1 Spectral Services Consultants Pvt. LTDSanjay MalhotraNo ratings yet

- New Technology in Solar CellDocument5 pagesNew Technology in Solar CellSanjay MalhotraNo ratings yet

- Pipeline Basics 2. 3. 4. 5. 6. Repairing FracturesDocument36 pagesPipeline Basics 2. 3. 4. 5. 6. Repairing FracturesSanjay MalhotraNo ratings yet

- LIST Engineering ArchitectDocument5 pagesLIST Engineering ArchitectSanjay MalhotraNo ratings yet

- 1) Salary and Wages (Per Month) : (Incld. Stores, Power and Maintenance)Document1 page1) Salary and Wages (Per Month) : (Incld. Stores, Power and Maintenance)Sanjay MalhotraNo ratings yet

- HamburgDocument2 pagesHamburgSanjay MalhotraNo ratings yet

- Project 8Document1 pageProject 8Sanjay MalhotraNo ratings yet

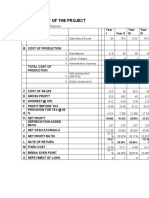

- Profitibility of The Project: (All Values in Lacs of Rupees)Document1 pageProfitibility of The Project: (All Values in Lacs of Rupees)Sanjay MalhotraNo ratings yet

- Result With Held Dean PUDocument2 pagesResult With Held Dean PUSanjay MalhotraNo ratings yet

- Promoters Profile: Mr. ABC Having - Years of Experience in Finance, AccountsDocument1 pagePromoters Profile: Mr. ABC Having - Years of Experience in Finance, AccountsSanjay MalhotraNo ratings yet

- Products To Be Manufactured: Marketing DemandDocument1 pageProducts To Be Manufactured: Marketing DemandSanjay MalhotraNo ratings yet

- Production Facilities and Machinery: ExportsDocument1 pageProduction Facilities and Machinery: ExportsSanjay MalhotraNo ratings yet

- Project 1Document1 pageProject 1Sanjay MalhotraNo ratings yet

- Bible 3Document1 pageBible 3Sanjay MalhotraNo ratings yet

- Check ListDocument14 pagesCheck ListSanjay MalhotraNo ratings yet

- Bible 2Document2 pagesBible 2Sanjay MalhotraNo ratings yet

- Mohit Marketing CVDocument3 pagesMohit Marketing CVSanjay MalhotraNo ratings yet

- Bible 1Document1 pageBible 1Sanjay MalhotraNo ratings yet

- Merit List Chinese PUDocument7 pagesMerit List Chinese PUSanjay MalhotraNo ratings yet

- Share Stock Portfolio Based On Dolly Khanna 25 OctDocument4 pagesShare Stock Portfolio Based On Dolly Khanna 25 OctSanjay MalhotraNo ratings yet

- Law and Ethics PDFDocument18 pagesLaw and Ethics PDFSanjay MalhotraNo ratings yet

- PU Chinese Fees DepositDocument1 pagePU Chinese Fees DepositSanjay MalhotraNo ratings yet

- Aripiprazole medication guideDocument3 pagesAripiprazole medication guidemissayayaya100% (1)

- We Think About Rotary Valve ReliabilityDocument8 pagesWe Think About Rotary Valve ReliabilityAhmed KhairyNo ratings yet

- FAQ: Product RegistrationDocument5 pagesFAQ: Product RegistrationCalvin WangNo ratings yet

- Sem-V Principle of Taxation Law PDFDocument3 pagesSem-V Principle of Taxation Law PDFAnantHimanshuEkkaNo ratings yet

- Acute Atelectasis Prevention & TreatmentDocument9 pagesAcute Atelectasis Prevention & TreatmentmetabolismeproteinNo ratings yet

- Supplementary Feeding ProgramDocument2 pagesSupplementary Feeding ProgramVictor Anthony CuaresmaNo ratings yet

- DepEd Region I Summative Test in Cookery 9Document2 pagesDepEd Region I Summative Test in Cookery 9Jessel Mejia OnzaNo ratings yet

- A Humanistic Approach To Medical PracticeDocument3 pagesA Humanistic Approach To Medical PracticeFilipos ConstantinNo ratings yet

- Soni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyDocument1 pageSoni Clinic & Pathology Center Chanda: Address:-Front of TVS AgencyVishalNo ratings yet

- As en 540-2002 Clinical Investigation of Medical Devices For Human SubjectsDocument8 pagesAs en 540-2002 Clinical Investigation of Medical Devices For Human SubjectsSAI Global - APACNo ratings yet

- Interest RatesDocument207 pagesInterest RatesBenjamin RogersNo ratings yet

- SIDCSDocument8 pagesSIDCSsakshi suranaNo ratings yet

- Annotated Bibliography Graphic OrganizerDocument4 pagesAnnotated Bibliography Graphic Organizerapi-348035481No ratings yet

- Paper Pet ProjectDocument27 pagesPaper Pet Projectapi-406104878No ratings yet

- Neet Structural Organisation in Animals Important QuestionsDocument18 pagesNeet Structural Organisation in Animals Important QuestionsARKA NEET BIOLOGYNo ratings yet

- Worksheet - Solubility - Water As A SolventDocument2 pagesWorksheet - Solubility - Water As A Solventben4657No ratings yet

- Sodium Chloride MSDSDocument5 pagesSodium Chloride MSDSIbaharmovic LpuNo ratings yet

- Nothing But The Truth D2Document89 pagesNothing But The Truth D2Jamie Nicholas100% (1)

- Companies Directory Alternative Fuels and Smart Transportation June 20Document82 pagesCompanies Directory Alternative Fuels and Smart Transportation June 20Mbamali Chukwunenye100% (1)

- NTFPP-Module 3 Microwave Processing of Foods - AjitKSinghDocument12 pagesNTFPP-Module 3 Microwave Processing of Foods - AjitKSinghKeshav RajputNo ratings yet

- Plant and Animal Cells Crossword Puzzle: FreebieDocument5 pagesPlant and Animal Cells Crossword Puzzle: FreebieAref DahabrahNo ratings yet

- Urinary System 1. List The Functions of The KidneysDocument6 pagesUrinary System 1. List The Functions of The KidneysheerNo ratings yet

- Computed Tomography (CT) - BodyDocument7 pagesComputed Tomography (CT) - Bodyfery oktoraNo ratings yet

- McDonlads Vs Burger KingDocument6 pagesMcDonlads Vs Burger KingSamuel Tyre Jr.No ratings yet

- Ganga Pollution CasesDocument3 pagesGanga Pollution CasesRuchita KaundalNo ratings yet