Professional Documents

Culture Documents

Foamed Concrete

Uploaded by

basanth_712982Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Foamed Concrete

Uploaded by

basanth_712982Copyright:

Available Formats

Sustainability

As one of the UKs largest suppliers of building material solutions, CEMEX UK is committed to sustainable development across the business. The principle operations of our business are raw materials extraction, processing, distribution and re-cycling of building materials. CEMEX embraces the challenges of sustainable development, in striving to be socially, economically and environmentally responsible in everything we do to safeguard the needs of future generations. From a commercial perspective, a sustainable approach will allow CEMEX to continue as a preferred supplier to the industry, to drive further efficiencies and to ensure availability of long-term resources. To deliver this promise CEMEX track the following indicators: 1. Reducing emissions 2. Improving efficiency of production and logistics 3. Developing innovative new products and services 4. Engaging employees 5. Increasing transparent dialogue with stakeholders 6. Measuring and controlling impacts 7. Contributing to sustainable communities

FAQ

Q Which mixes are suitable for trench reinstatement? A Normally supplied as HAC (Highly Air-entrained Concrete) or HAM (Highly Air-entrained Mortar). Both comply with Roads & Streetworks Act 1991 for C2 or C4 reinstatement material. It may be surfaced at 24 hours. Q Which mixes are suitable for filling voids? A HAM with a flowing consistency is normally used for filling redundant fuel tanks, pipes, sewers, etc. Q What is the typical density of foamed concrete? A Depending on the aggregates used, typical densities are: HAC & HAM: 1,600 - 2,000 kgs/m3 Pre-formed foam: 1,000 - 1,500 kgs/m3 Q What special precautions need to be taken when using foamed concrete? A Foamed concrete is a fluid material and may cause flotation of pipes and tanks. To avoid, pour slowly around pipes/tanks, allow concrete to lose workability. Maximum placing thickness using pre-formed foam is one metre (no restriction on HAC/HAM). For reasons of safety, excavations filled with foamed concrete must be guarded whilst the concrete is still fluid. Q Which mix is suitable for a temporary reinstatement? A Mortar is more easily removed than concrete, therefore wherever possible C2 HAM should -be specified.

Material Datasheet

FOAMED CONCRETE

Readymix foamed concrete is a highly workable, low density material incorporating up to 50% entrained air. It is generally self levelling, self compacting and may be pumped. Risk of plastic shrinkage or settlement cracking is significantly lower than that of normal concrete.

Foamed concrete is ideal for filling voids such as disused fuel tanks, sewer systems, pipelines and culverts particularly where access is difficult. It is a recognised medium for the reinstatement of road trenches. Good thermal insulation properties make foamed concrete also suitable for sub-screeds and filling under floor voids. Readymix foamed concrete has an entrained air content typically of between 10-50%, dependant upon production method and preformed foam or admixture dosage. Dry densities are typically between 800 to 2000 kg/m2. The material typically remains fluid for 2/3 hours after mixing with the foam (dependant upon ambient conditions).

CEMEX Readymix provide a range of foamed concretes.

Readymix Tankfill

Has a lower water content than the traditional 20:1 sand/cement slurry which makes it more cohesive to eliminate settlement. The more cohesive property allows a controlled discharge into tanks with a restricted entry point. Air and gases in the tank are gradually displaced by the Readmix Tankfill. Being a cellular fill, Readymix Tankfill is less prone to penetration from external contaminants. Readymix Tankfill meets the building regulation codes for fire resistance.

Readymix Voidfill

A low density flowable fill material to provide a single, engineered solution. The material has guaranteed performance in terms of density, strength, or both. Therefore the density and the strength of the construction layer can be controlled over a greater depth in a one-hit solution compared to traditional fill materials.

Applications

Unwanted voids: Pipelines Service Ducts and Shafts Disused structures: Culverts Redundant Sewers Cellars and Basements Higher Structural stabilisation: Bridge Abutments Tunnel Stabilisation Embankments Insulating Fill: Low density insulating sub-screed Insulating fill to house over-sites

Applications

Filling of disused petrol and oil tanks Filling of effluent and water tanks

Readymix Roadfill

An efficient and cost-effective reinstatement material that complies with the Roads and Streets Works Act 1991. Readmix Roadfill is available as FCR Classes C2 and C4. There is no settlement with Readymix Roadfill so therefore it can be fully resurfaced in one operation. There is also no need for compaction equipment.

Applications

Unwanted voids: Reinstatement of temporary opening in streets and highways Protection of buried services

For further information please contact Customer Services on: Tel: Fax: 01788 542111 (out of hours) 01932 568833 01788 540166

CEMEX UK Materials Ltd CEMEX House, Evreux Way, Rugby, Warwickshire CV21 2DT Tel: 0808 145 1900 Fax: 01788 514 742

www.cemex.co.uk

Features and Benefits

Plastic state advantages Foamed concrete is a versatile and practical material which can be tailored to a variety of project needs and operational conditions: Feature Produced at the plant or on site. Immediate placement on delivery. No storage needed. Good workability retention. Adjustable to meet specific performance requirements. Controlled density and strength. No need for soil analysis. No requirement for moisture content checks between layers. Compatible with nearly all building products and materials. Less prone to penetration from external contaminants. Benefits

Added value

Foamed concrete: Cost compares favourably with other fill materials Reduced manpower Negligible risk of call-back for subsidence

Specification types

READYMIX foamed concrete can be supplied with or without coarse aggregate depending on the type and application. The stable bubble structure can be introduced into the mix in three ways: By adding specially formulated airentrained admixtures into the concrete during the mixing process. This generally produces an entrained air content of between 10% and 25%. The resultant material is referred to as High Air-entrained Concrete (HAC) or High Air-entrained Mortar (HAM) By adding foam generating admixtures to a mortar base mix after mixing or at site. This will produce higher levels of entrained air than air-entraining admixture and consequently a lower density. By blending a pre-formed foam into a mortar base mix after mixing or at site.

Wide range of possible mixes.

Stable chemical structure.

A cellular fill.

Working improvements The free-flowing but cohesive properties of foamed concrete provide many working benefits: Feature Easy to place and finish. Benefits Single process installation, simply pour and level. Reduced labour and supervision costs. Specialist plant (e.g. compactors, vibrators) not needed. Controlled rates of placement to ensure suitability for any loading characteristics. Foamed mortars can be pumped significant distances can be placed by conventional concrete pump. Ideal for inaccessible trenches where compaction would be difficult or impossible. Allows controlled discharge into narrow openings. Fully fills void space, including undercut pockets. Entirely surrounds and protect pipelines. Minimises traffic disruption due to road closure. No need for compaction equipment. No need to stockpile granular-fill material. Helps increase workforce productivity and cost-effectiveness. No revisit due to long term settlement. Prevents bleeding or segregation. Allows controlled discharge through narrow entry points. Does not settle after placing.

Pumpable.

Self compacting and self-levelling.

Single operation trench reinstatement.

Health and Safety

CEMEX has a global policy for health and safety that provides a framework, and a UK policy that expands on the corporate policy, which is aligned to UK standards. CEMEX has a target of zero injuries and does not accept unsafe working practices. Accident prevention, safeguarding employee health and environmental protection are an integral part of our company policy. Health and safety is part of everyday concern and should be reflected at all times in employee behaviours. CEMEX has extended this commitment to safety beyond the organisation and is involved with a number of public initiatives to improve safety and awareness. CEMEX ensures that products are safe to transport, store, handle, use and dispose of. However, some products may carry risks to peoples health and safety if the appropriate precautions are not taken. To prevent such risks, CEMEX has a range of product safety sheets, which outline any main hazards and precautions that should be taken when handling these products. These are available on request or can be downloaded from the website. Contact with wet concrete may cause irritation, dermatitis or severe alkali burns. There is serious risk of damage to the eyes. Wear suitable waterproof protective clothing, gloves and eye / face protection. In case of contact with eyes, rinse immediately with plenty of clean water and seek medical advice. After contact with skin, wash immediately with plenty of clean water. Keep out of reach of children and animals. Contains chromium (VI), may cause allergic reaction.

Good cohesion.

Final concrete performance Plastic state qualities translate into significant final performance benefits: Feature High entrained air content. Benefits Resistant to freeze/thaw damage. Good thermal and acoustic insulation. Stable foam structure reduces settlement. Reduces bleeding and segregation. Low strength allows removal for subsequent access to services. Range of densities and strengths available for each foamed concrete type.

www.cemex.co.uk/productsafety

Good cohesion.

WARNING

WET CEMENTITIOUS PRODUCTS such as concrete, mortar and screed MAY CAUSE SERIOUS BURNS in contact with eyes or skin. You MUST wear the appropriate protective clothing at all times.

Controlled density and strength.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Conferenceobject 93516Document10 pagesConferenceobject 93516Ar Aayush GoelNo ratings yet

- Industrial Tourism When The Industry Becomes A Chance For TourismDocument9 pagesIndustrial Tourism When The Industry Becomes A Chance For TourismAr Aayush GoelNo ratings yet

- Industrial & Business Park Design GuidelinesDocument22 pagesIndustrial & Business Park Design GuidelinesAr Aayush GoelNo ratings yet

- Hvac Systems ComponentsDocument28 pagesHvac Systems ComponentsArvind RNo ratings yet

- An Introduction To 00 Hubb RichDocument596 pagesAn Introduction To 00 Hubb RichSerban CalinNo ratings yet

- Guided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilDocument30 pagesGuided By:-Presented By: - Prof. P.M. Nemade Amit Maurya (B.E.) CivilAr Aayush GoelNo ratings yet

- WHI Brochure 2022 - Classic Resort CollectionDocument23 pagesWHI Brochure 2022 - Classic Resort CollectionAr Aayush GoelNo ratings yet

- Decoding Finn Juhl's Egyptian Chair - Workshop - BriefDocument5 pagesDecoding Finn Juhl's Egyptian Chair - Workshop - BriefAr Aayush GoelNo ratings yet

- 169 172, Tesma407, IJEASTDocument4 pages169 172, Tesma407, IJEASTAr Aayush GoelNo ratings yet

- Japan International Cooperation Agency: NewsletterDocument16 pagesJapan International Cooperation Agency: NewsletterAr Aayush GoelNo ratings yet

- To Download and Install Kaltura CaptureDocument4 pagesTo Download and Install Kaltura CaptureAr Aayush GoelNo ratings yet

- Light Industrial Area Design GuidelinesDocument12 pagesLight Industrial Area Design GuidelinesAr Aayush GoelNo ratings yet

- General ReqDocument19 pagesGeneral ReqVincent VivekNo ratings yet

- History of Architecture - Gate Architecture - Study MaterialDocument12 pagesHistory of Architecture - Gate Architecture - Study MaterialAr Aayush GoelNo ratings yet

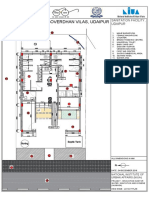

- Public Toilets at Goverdhan Vilas, UdaipurDocument1 pagePublic Toilets at Goverdhan Vilas, UdaipurAr Aayush GoelNo ratings yet

- Lec 1Document33 pagesLec 1Ar Aayush GoelNo ratings yet

- Quantitative Aptitude Tricks - PDF Download: ImplificationDocument12 pagesQuantitative Aptitude Tricks - PDF Download: ImplificationSwapnarani JadavNo ratings yet

- UPSC CPWD Architecture 2016Document38 pagesUPSC CPWD Architecture 2016Sweety KumariNo ratings yet

- Reasoning Tricks PDFDocument53 pagesReasoning Tricks PDFrupaliNo ratings yet

- Puzzles WorkbookDocument31 pagesPuzzles WorkbookAr Aayush GoelNo ratings yet

- URR Ved MittalDocument6 pagesURR Ved MittalAr Aayush GoelNo ratings yet

- Town Planning in India - Ancient Age - Med PDFDocument22 pagesTown Planning in India - Ancient Age - Med PDFAr Aayush GoelNo ratings yet

- Town Planning and Development LawsDocument24 pagesTown Planning and Development LawsDevika Hemalatha DeviNo ratings yet

- 12-A Review of Urban (Lalit Batra)Document8 pages12-A Review of Urban (Lalit Batra)Ar Aayush GoelNo ratings yet

- URR - Ved Mittal PDFDocument41 pagesURR - Ved Mittal PDFAr Aayush GoelNo ratings yet

- Hindu Temple Architecture HistoryDocument100 pagesHindu Temple Architecture HistoryHarshi Garg60% (5)

- 12-A Review of Urban (Lalit Batra) PDFDocument51 pages12-A Review of Urban (Lalit Batra) PDFKevin HansenNo ratings yet

- Housing Projects in SCP - 60 CitiesDocument3 pagesHousing Projects in SCP - 60 CitiesAr Aayush GoelNo ratings yet

- Buildings: DefinitionsDocument31 pagesBuildings: DefinitionsAr Aayush GoelNo ratings yet

- Notification 201921122018Document5 pagesNotification 201921122018Ar Aayush GoelNo ratings yet